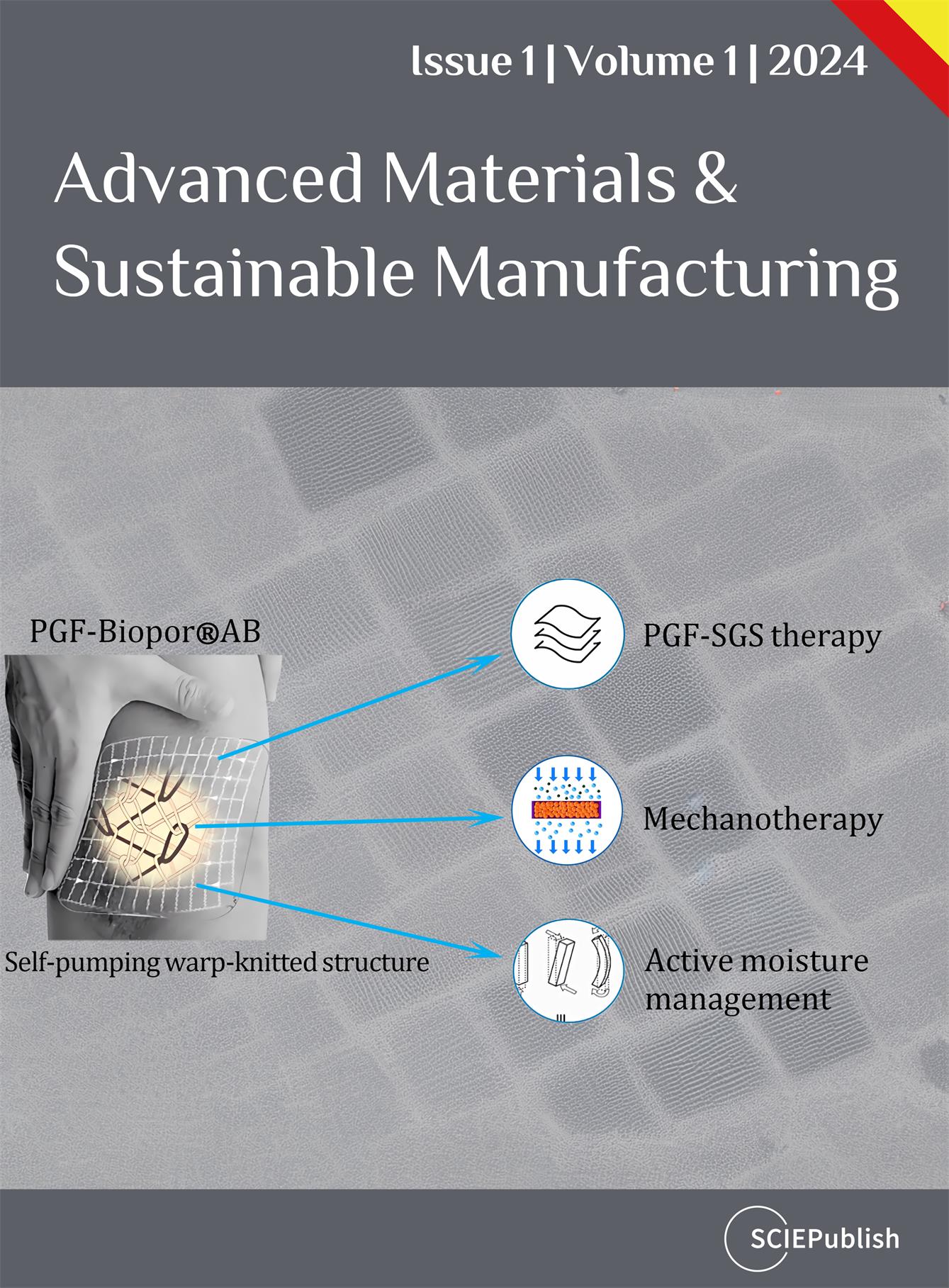

Advanced Materials & Sustainable Manufacturing

Open Access

Open Access

ISSN: 3006-2829 (Online)

3006-2810 (Print)

An Official Journal of Hubei Digital Textile Equipment Key Laboratory

Advanced Materials & Sustainable Manufacturing is an international, cross-disciplinary, scholarly, peer-reviewed journal dedicated to development of sustainable, everything connected and AI-based manufacturing systems in the frame of Industry 4.0 and 5.0. It is published quarterly online by SCIE Publishing Ltd. View full Aims&Scope