High-Temperature Materials

Open Access

Open Access

ISSN: 3006-9971 (Online)

3006-9963 (Print)

An Official Journal of State Key Laboratory of Advanced Refractories, Wuhan University of Science and Technology

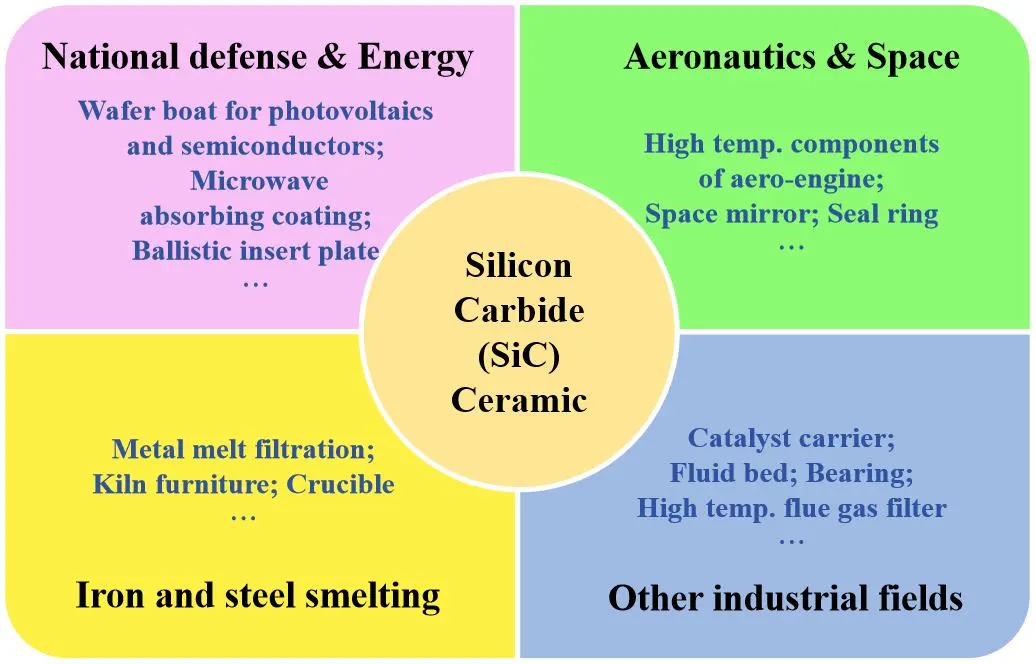

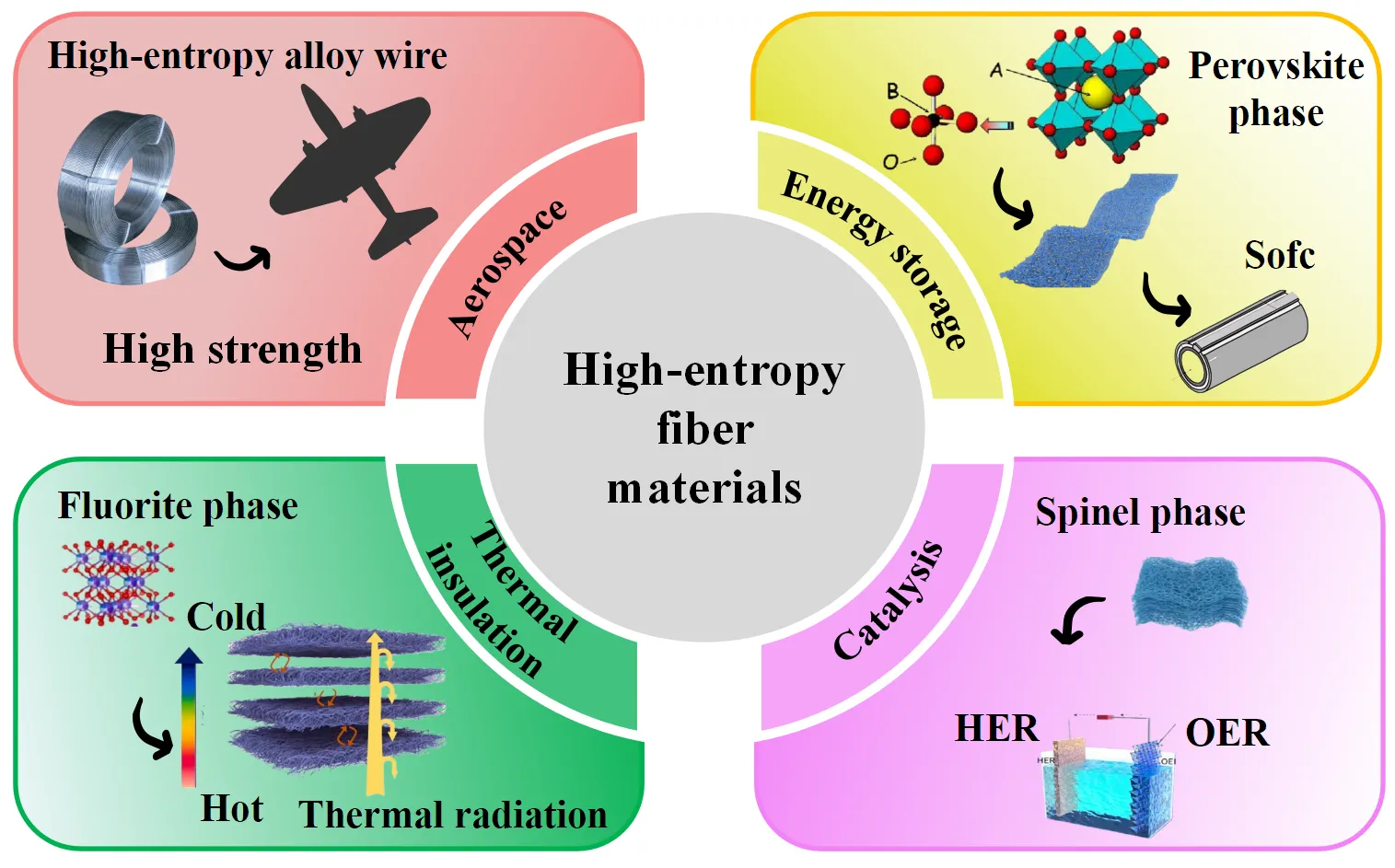

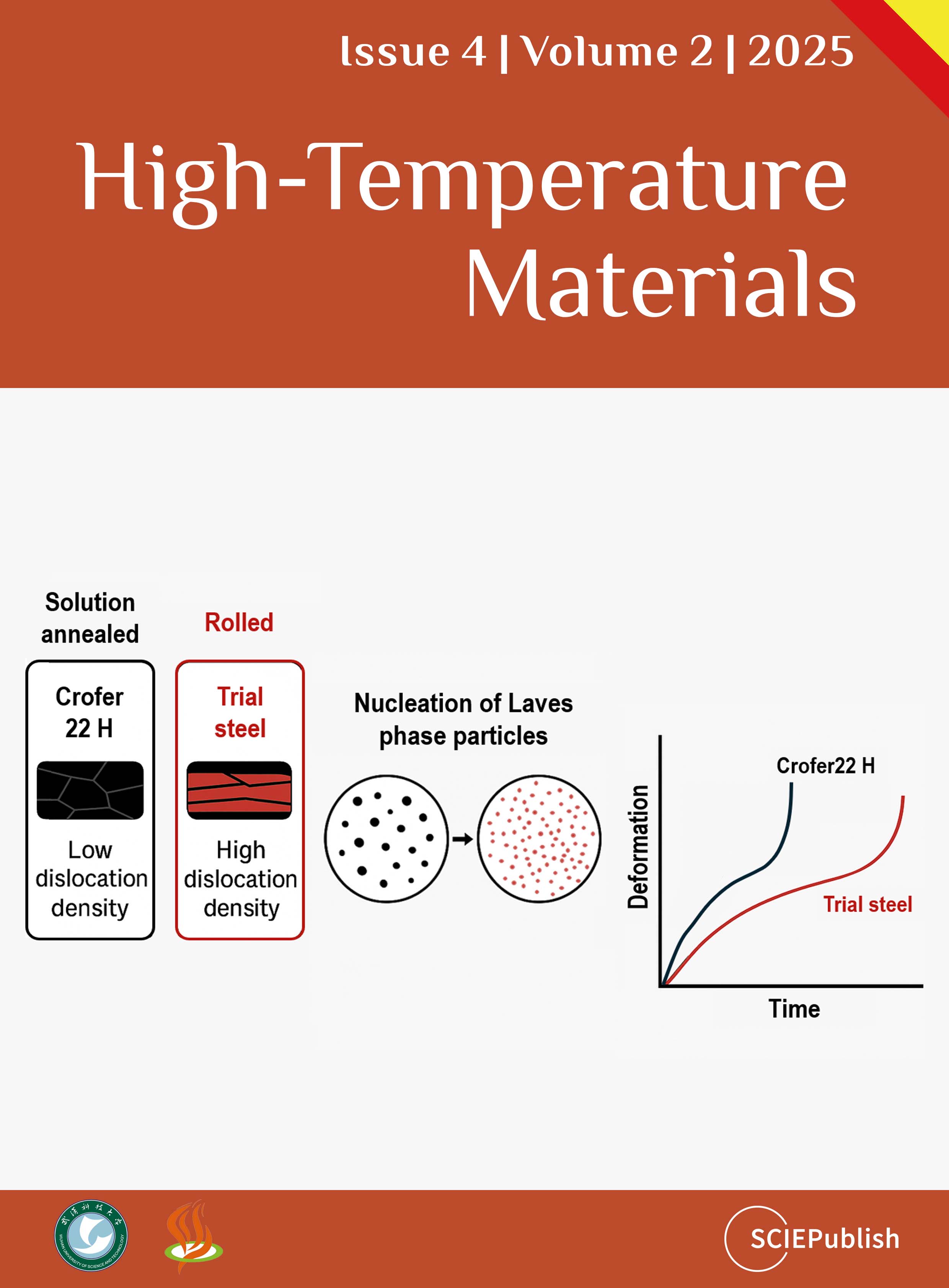

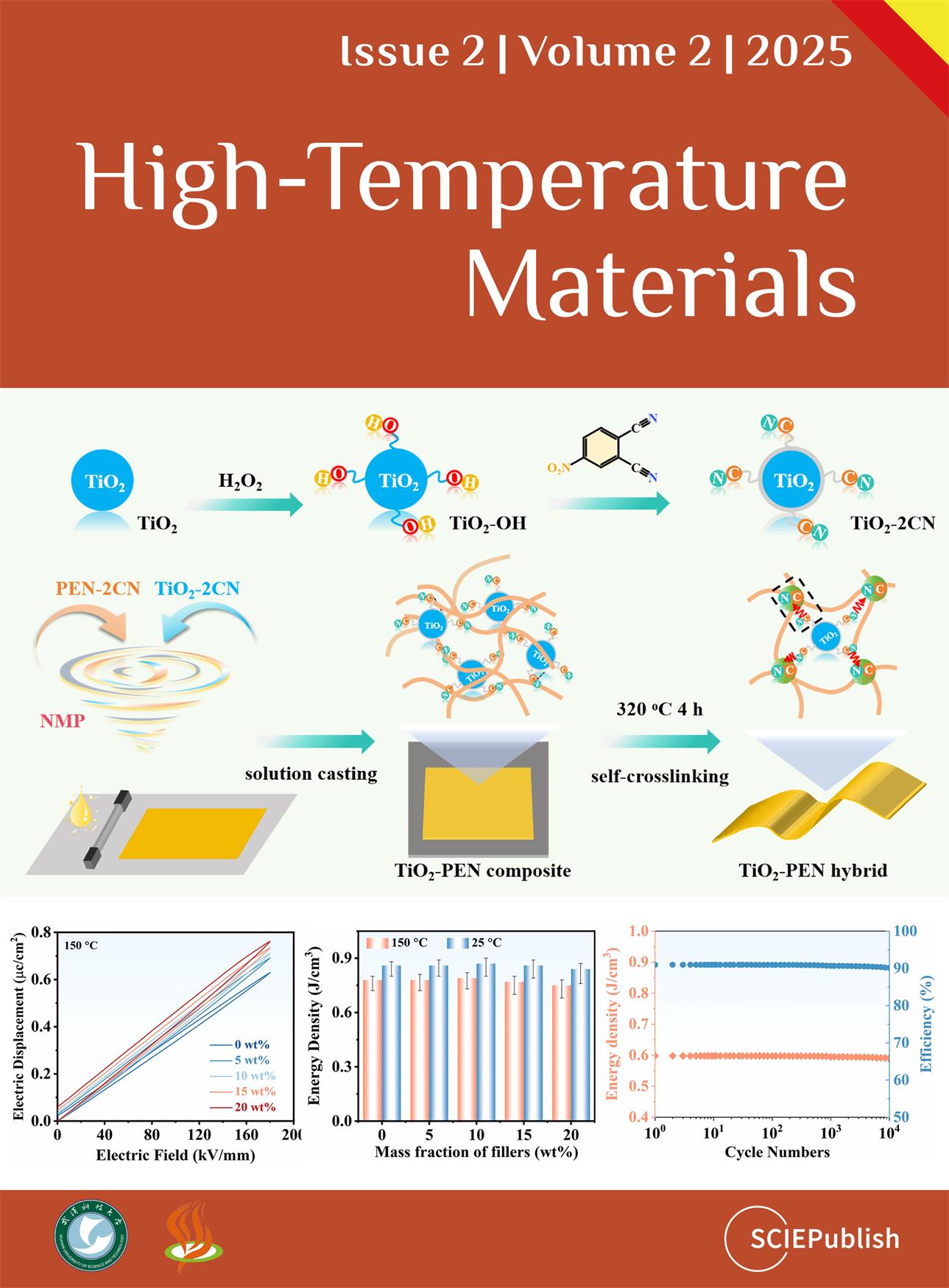

High-Temperature Materials is a peer-reviewed and open-access journal publishing original, high-quality research on all aspects of materials relating to high-temperature processing in science and technology and high-temperature applications in the energy generation, aerospace, metallurgy, chemical and other process industries. It is published quarterly online by SCIE Publishing Ltd. View full Aims&Scope