Found 14 results

Review

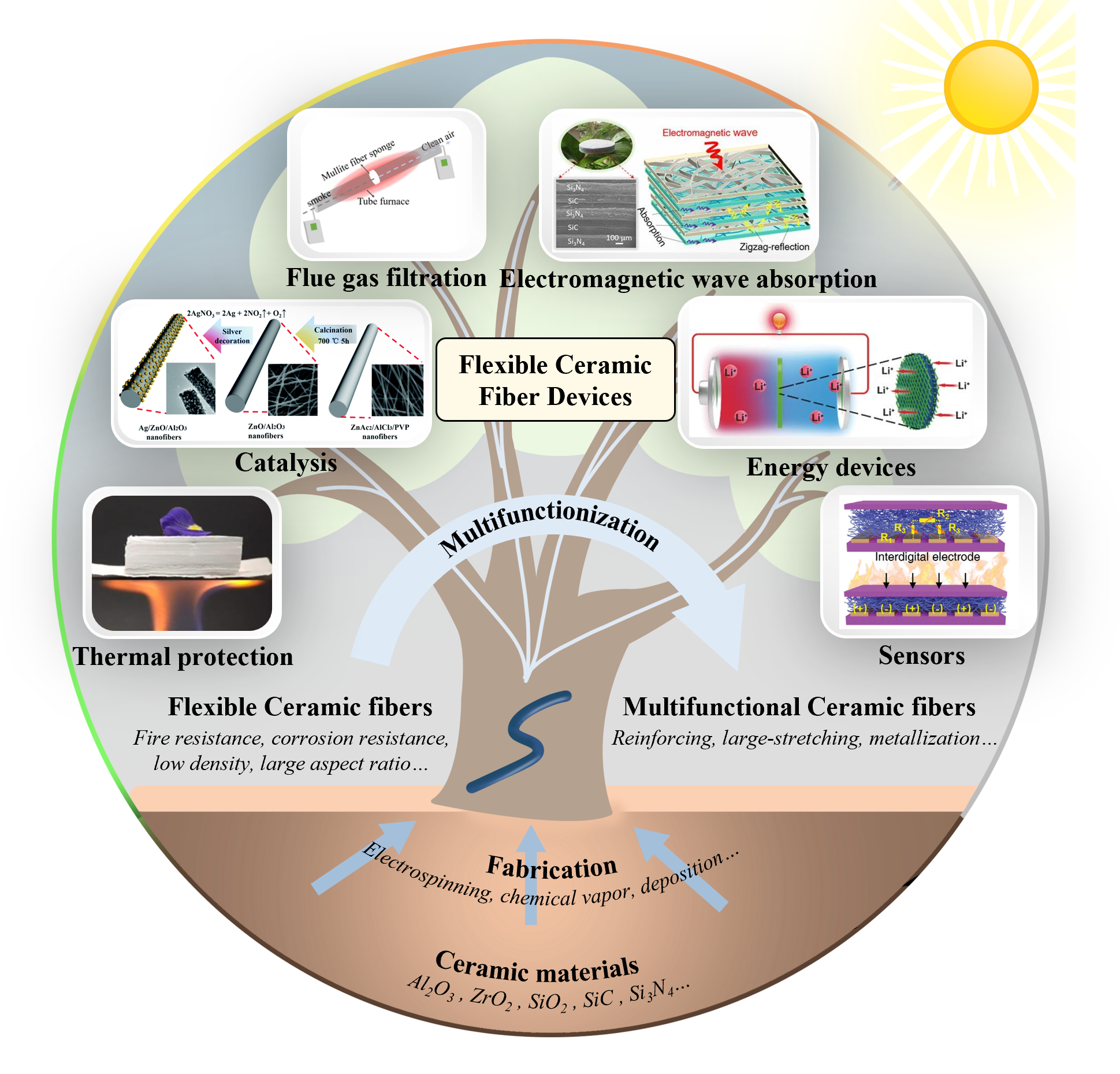

14 April 2025Advancements in Flexible Ceramic Fibers for High-Temperature Applications: A Comprehensive Review

Flexible ceramic fibers (FCFs) have emerged as a highly promising material for high-temperature applications, effectively combining the excellent thermal stability of ceramic materials with the robust mechanical properties of flexible fibers. This review provides a comprehensive overview of recent advances in multifunctional FCF devices, focusing on innovative methods across material selection, structural design, and fabrication techniques to enhance their functional properties. These improvements, i.e., mechanical strength, thermal conductivity, and oxidation resistance, make FCFs particularly suitable for a wide range of applications, including energy storage, sensing, and high-temperature filtration. Notably, advancements in fabrication techniques have enabled the creation of novel FCF devices for thermal insulation and high-temperature sensing, such as stretchable ceramic membranes and printable ceramic fiber papers. The review concludes by discussing the future potential of FCFs, especially in multifunctional applications in high-temperature environments, where they can serve as essential components of advanced technologies. This work highlights the versatility and potential of FCFs as a transformative material for next-generation high-temperature applications.

Review

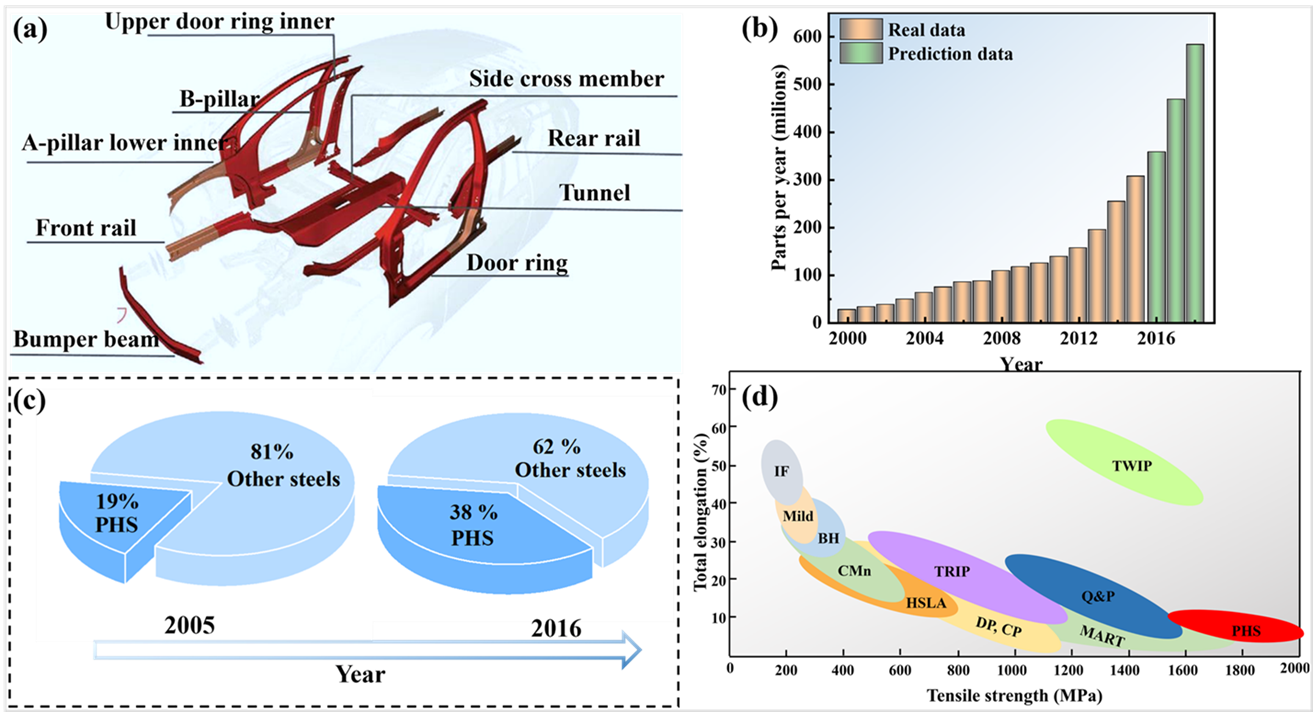

06 March 2025A Comprehensive Review towards Oxidation Resistant Press-Hardened Steels

As an important lightweight material, press-hardened steels (PHS) are now widely used in the car body-in-white. However, severe oxidation of conventional Mn–B bare sheets not only damages production molds, but also prevents subsequent welding and painting, leading to a significant increase in production costs. The aim of this review is to systematically summarize the current solutions to overcome the problem of high-temperature oxidation of conventional Mn–B PHS and to highlight future directions for improvement. The review begins with a brief background on PHS, followed by a detailed description of measures to improve the oxidation resistance of conventional Mn–B PHS and the development of novel PHS with superior oxidation resistance. The oxidation resistance solutions for conventional Mn–B PHS mainly include the use of coatings and pre-deposited films. In contrast, the oxidation resistant PHS mainly includes the use of the oxidation resistant elements Cr, Si, Al or rare earth elements to improve the steel’s own high-temperature oxidation resistance.

Article

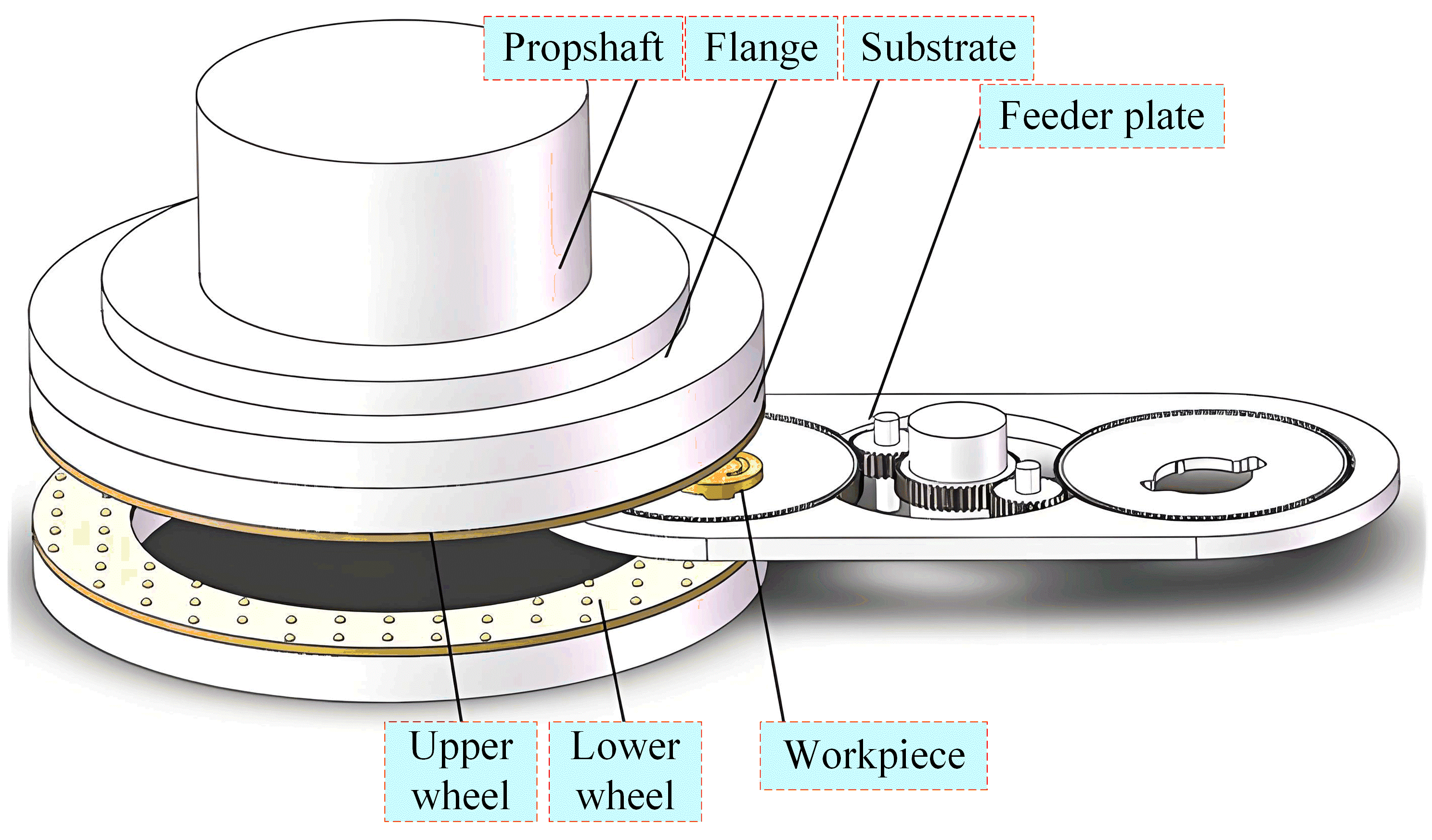

25 February 2025Thermal Characterization Study of Double End Face Grinding Powder Metallurgy Stainless Steel 316L

Double end face grinding machining is a highly efficient surface grinding technique. And grinding temperature is an important factor affecting the surface quality of workpieces. However, it is difficult to monitor the surface temperature of the workpiece in real time because of the covered contact between the grinding wheel and the upper and lower surfaces of the workpiece during the machining process. This paper aims to conduct a mechanistic analysis and experimental investigation of the machining process to address this challenge. Initially, the paper conducts an analysis of the kinematic mechanism, modal analysis, and the grinding force mechanism specific to the double end face grinding process. Afterwards, the mechanisms leading to the generation of grinding heat and the associated heat transfer mechanisms are explored in depth. The paper then proceeds to solve the instantaneous temperature field during double end face grinding by the finite element method (FEM). Furthermore, the micro and macro profile heights of the machined workpiece surfaces are measured and analyzed. The results show that the machined workpiece surface shows a high center and low edge. This is due to the fact that the temperature at the edge of the workpiece is higher than the center during machining, resulting in more material removal. Through these investigations, the study is able to determine the optimal process parameters for the machining process. This in turn improves machining efficiency and product conformity. And these findings not only guide practical production processes but also provide a foundation for future theoretical research in this area.

Review

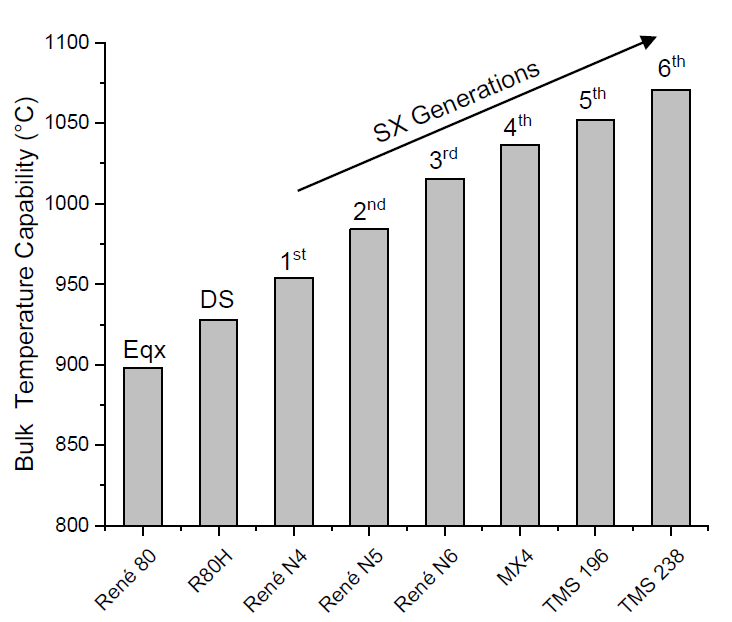

25 February 2025Innovations in IN939: From Cast Alloy to Additive Manufacturing

Nickel-based superalloys are the most reliable material choice for the hot sections of turbines. These superalloys are mainly employed in aircraft engines, particularly in the combustor and turbine sections. In this scenario, the growing need for materials that can endure high temperatures while retaining their strength has driven the development of IN939. Although IN939 holds these significant important properties and applications, it has received less attention in recent literature than other superalloys. This review aims to comprehensively analyze the main research on IN939 over the past 50 years. From 1970 to 1980, research primarily focused on the development of IN939 through casting methods. Between 1980 and 1990, the emphasis shifted to studying its oxidation resistance and microstructural stability during service. The period from 1990 to 2000 focused on repairing components after long service time at high temperatures. In recent decades, advances in additive manufacturing techniques have led to growing interest in developing IN939 using methods like laser powder bed fusion (LPBF). Research in the area has demonstrated that the LPBF technique offers a promising approach to manufacturing high-performance IN939 components.

Review

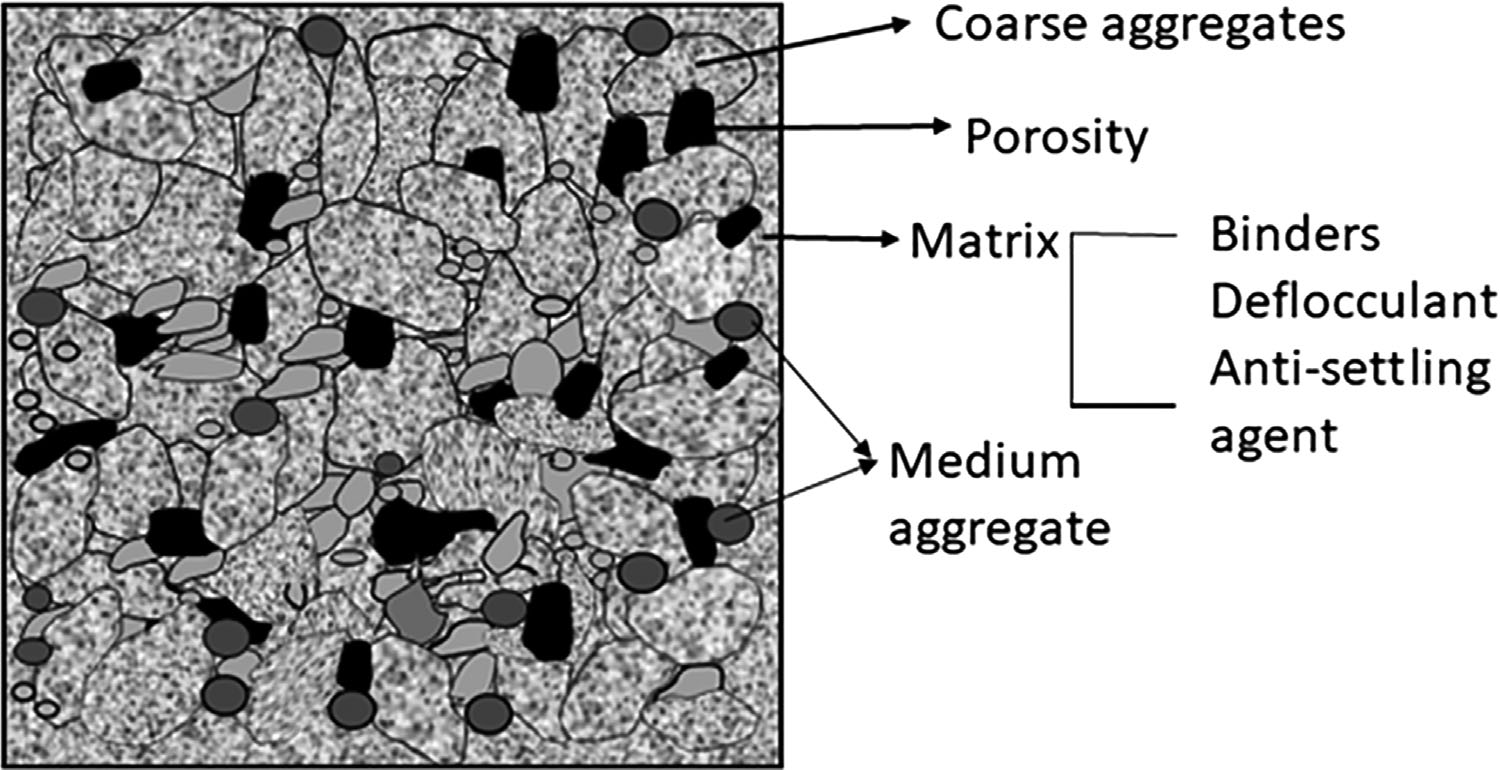

21 February 2025Cement-Free Binders in Alumina-Magnesia Refractory Castables—A Review

To solve the problem of the accelerated deterioration of calcium aluminate (CAC)-bonded alumina-magnesia refractory castables during the secondary refining process, the development of cement-free binders has emerged as one significant research field of castables. The hydration behavior, curing mechanism, and properties of the most recent research on cement-free binders are compared in this paper. The problems and the modification of each binder of recent research are summarized. High-temperature performance of the castables bonded by traditional hydraulic cement-free binders (ρ-Al2O3 and activated MgO) is outstanding, explosive spalling resistance of the castables bonded by sol binders (silica sol, alumina sol) is good, and the properties of the castables bonded by novel organic hydratable binder (hydratable magnesium citrate) combine the advantages of these two binders above, but the mid-temperature mechanical strength is low. Furthermore, alumina-magnesia castables bonded by organic-composited inorganic cement-free binders are expected to be a future domain.

Review

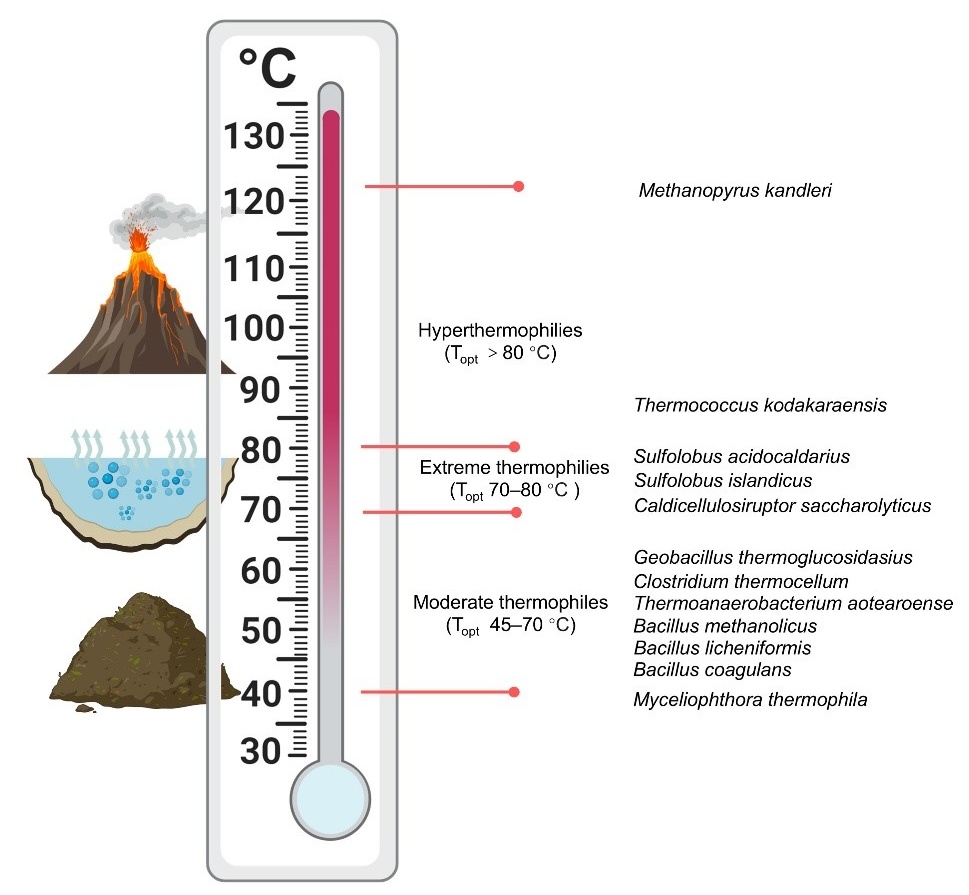

13 February 2025High-Temperature Catalytic Platform Powered by Thermophilic Microorganisms and Thermozymes

Thermophilic microorganisms, capable of thriving under high temperatures, are emerging as key platforms for next-generation industrial biotechnology (NGIB), driving innovations in lignin biorefining, bioplastics synthesis, biodiesel production, and environmental remediation. Enzymes derived from thermophilic microorganisms, thermozymes, exhibit remarkable stability and efficiency under extreme conditions, making them highly suitable for diverse industrial applications. This review highlights recent advances in leveraging thermophilic microorganisms and thermozymes for high-temperature catalysis, focusing on their economic and environmental benefits. It also emphasizes progress in high-throughput screening and artificial intelligence (AI), which have revolutionized the bioprospecting, engineering, and application potential of thermozymes. Challenges and potential solutions for industrial implementation of high-temperature catalytic platforms are also discussed, highlighting their transformative impact on sustainable biotechnology.

Review

09 January 2025Recent Advancements in Alumina-Based High-Temperature Insulating Materials: Properties, Applications, and Future Perspectives

As a high-temperature thermal insulation material with excellent mechanical properties, alumina (Al2O3)-based materials hold significant potential for applications in aerospace, advanced manufacturing, automobiles, industrial furnaces, and other fields. However, the inherent brittleness of alumina poses a limitation to its wider application. Therefore, there is a pressing need to develop alumina-based materials that offer high toughness while retaining superior mechanical properties. This paper begins by exploring the structure of alumina, highlighting its thermal conductivity, insulation, and mechanical properties in high-temperature environments. It then reviews the classification and synthesis methods of alumina-based materials, along with the latest advances in design strategies. Notably, the rational design of alumina composition, structure, and morphology is emphasized as crucial for optimizing material performance, thereby supporting the industrial development and application of these materials in high-tech sectors. Finally, the paper discusses the challenges and evolution of alumina-based materials in real-world industrial applications and suggests potential directions for future development.

Article

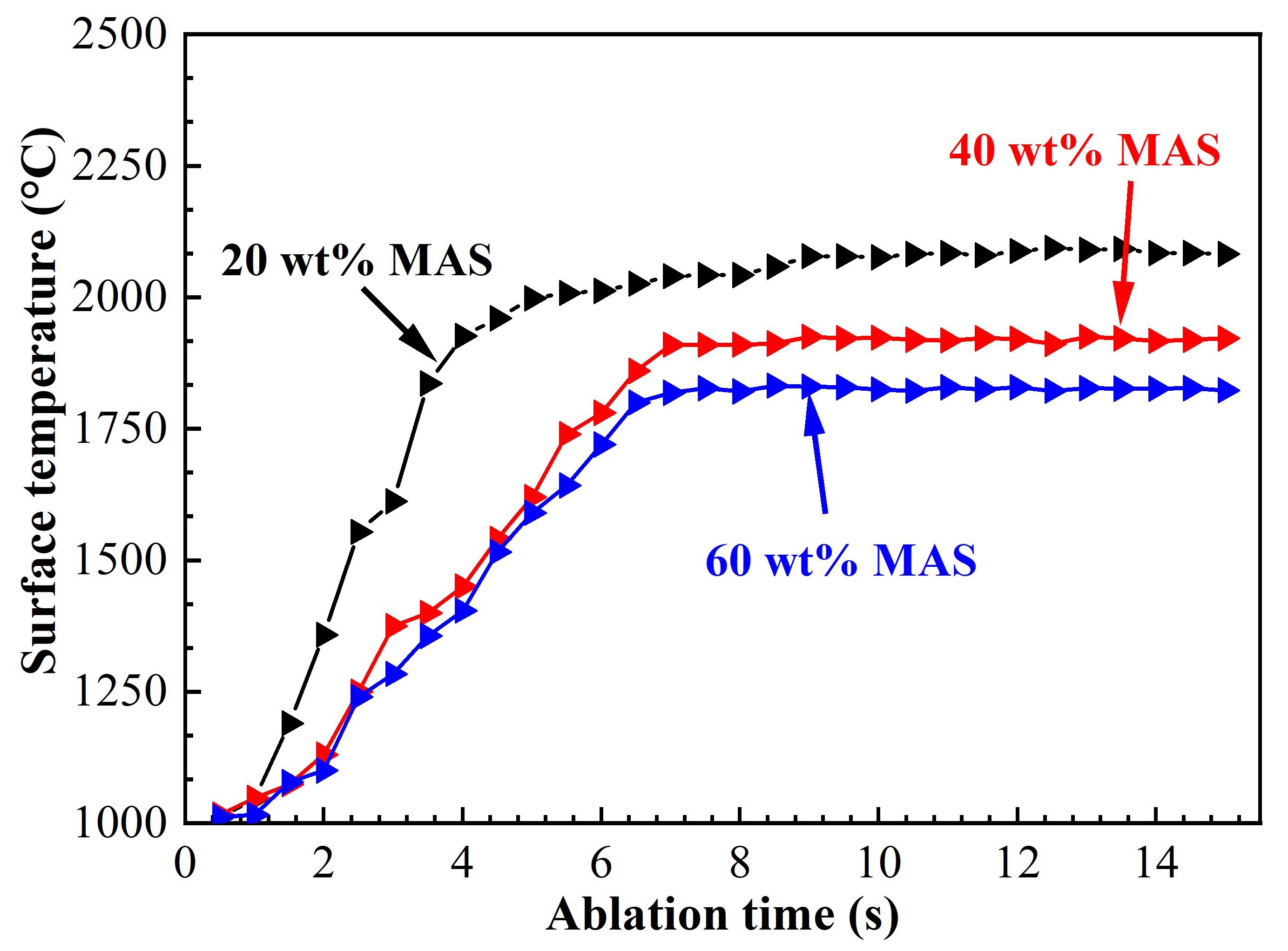

27 December 2024Effect of Magnesium Aluminum Silicate Addition on the Ablation Resistance of BN Matrix Ceramics

Ablation resistance is a critical factor in evaluating the performance of BN-based ceramic composites under extreme service conditions. This study investigates the ablation behavior and underlying mechanisms of BN-MAS wave-transparent ceramic composites with varying magnesium aluminum silicate (MAS) content through oxyacetylene torch tests. The results reveal that increasing the MAS content reduces the mass ablation rate from 0.0298 g/s to 0.0176 g/s and the linear ablation rate from 0.149 mm/s to 0.112 mm/s. The incorporation of MAS into h-BN ceramics significantly lowers the surface ablation temperature, primarily due to the evaporation of B2O3 (g) and MAS ceramics. Cross-sectional analysis of the ablated composites indicates the presence of micro- and macro-spallation in the ablation center. The primary ablation products are magnesium-aluminum borosilicate glass and mullite. Key ablation mechanisms include the oxidation of h-BN under flame exposure, the erosion of viscous oxidation products, and the physical degradation of the matrix caused by the high-velocity gas flow.

Article

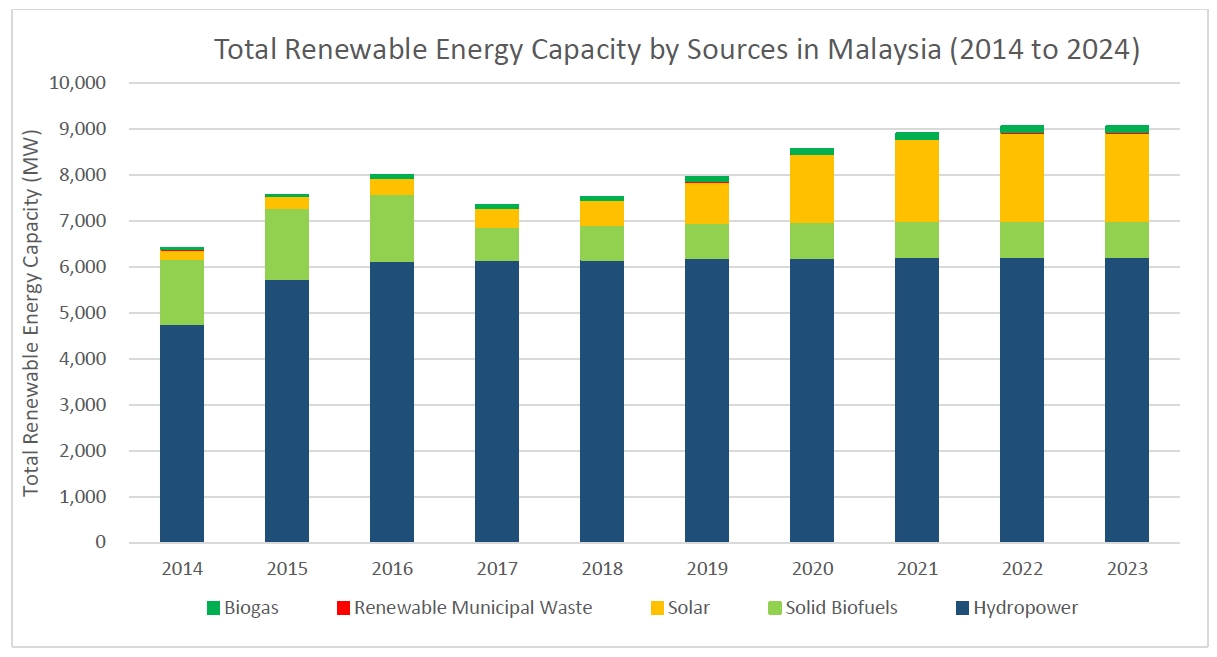

28 November 2024Correlations of System Degradation, Losses and Significant Parameters for 49 MW Large Scale Solar Plant with Real Site Data Validations

A smooth transition towards a clean and sustainable environment will heavily rely on the continuous increase of renewable energy (RE) integration. Malaysian authorities have set targets to increase the RE capacity to 31% by the end of 2025 and achieve 40% by 2035, specifically through the power generation plan. Solar PV systems have been widely used, from industries to residential homes, because Malaysia receives a high irradiation potential of up to 5000 Wh/year. The increase in the potential of solar PV usage has allowed solar companies to provide this system regardless of its complexity and system size. However, a drop in efficiency due to system parameters within the photovoltaic (PV) system is evident over time. This study aims to analyze the relationship between solar PV system parameters and their energy performance, particularly in a tropical climate region, for a large-scale solar (LSS) plant. This project was undertaken with two objectives: First, it is to develop an optimum solar PV system by adhering to and implementing GCPV standards in Malaysia. Stage 1 will primarily focus on managing and manipulating various PV system parameters to ensure the optimum energy yield received from the plant. The system parameters analyzed are tilt angle, module technology and its effect on different temperatures, the effect of the optimizer, sizing and thermal loss. Stage 2 will then incorporate the industry data of the LSS plant by creating a Pearson’s Correlation model on how energy yield is correlated against real time system parameter values obtained. An optimum tilt angle of 10°, monocrystalline module and inclusion of optimizer increases the overall energy production from 88,986 MWh/year to 89,782 MWh/year and performance ratio (PR) from 78.9% to 79.8%. The outcome of this study demonstrates the significant parameters of the PV system to maximize the energy output to the grid. This will further support the government’s plan to reduce GHG emissions by 45% through the use of renewable energy, with the aim of producing up to 2.5 GW from LSS systems by 2030.

Article

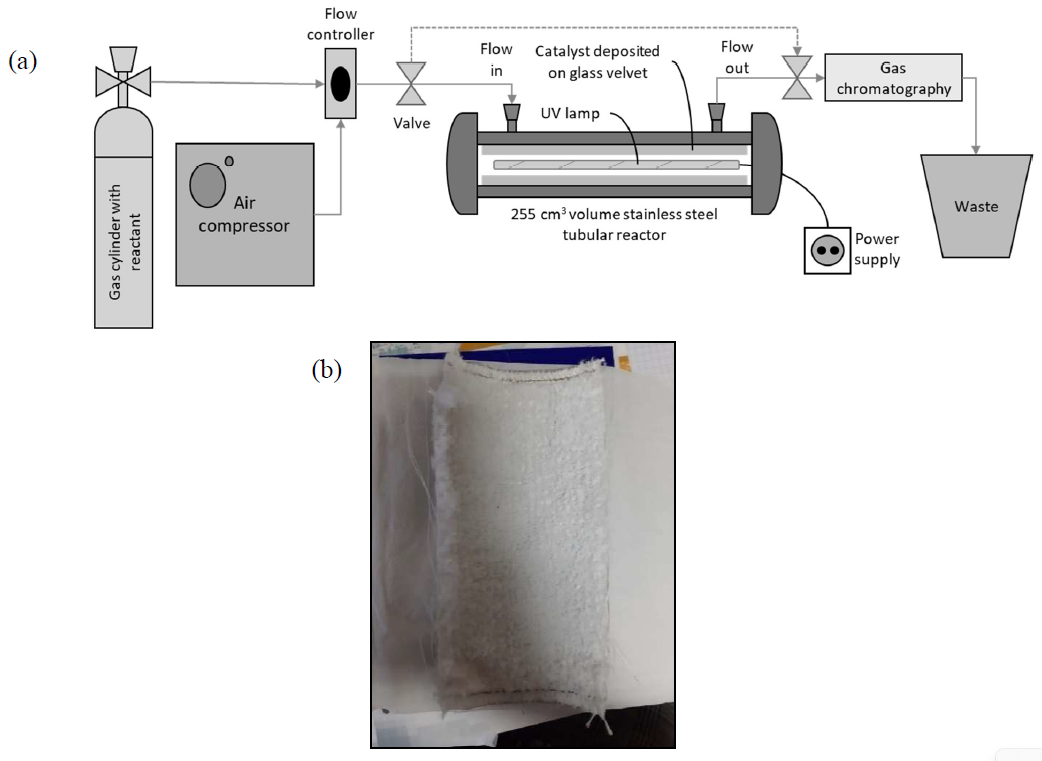

28 August 2024Photocatalytic and Photothermal Catalytic Oxidation of Ethene and Ethanol Using TiO2-Based Catalysts under UV-C and UV-A Irradiation

Photocatalytic (PCO) and photothermocatalytic oxidation (PTCO) of ethene (C2H4) and ethanol (EtOH) are investigated using TiO2 and 1%Pt/TiO2 coating on velvet glass support in the presence of UV-A and UV-C irradiation. Both VOC are efficiently mineralised under UV-A irradiation and PCO, but the presence of Pt has a minor impact on their transformation. Instead, there is only a slight increase in the disappearance of EtOH and the formation of acetaldehyde, which are already observed in the dark. Surprisingly, when a higher photon flux is emitted with a UV-C lamp, photocatalytic disappearance and mineralisation of EtOH are less effective than under UV-A irradiation in the presence or absence of Pt. Similar behaviour is also observed on C2H4 PCO in the presence of 1%Pt/TiO2 but not on its PCO mineralisation with TiO2, which is improved by a factor equivalent to the number of photons emitted. Under PTCO, by increasing the temperature from 40 °C to 120 °C, only a benefit impact is observed on C2H4 and EtOH disappearance but an important decrease of mineralization of C2H4 was observed in presence of TiO2 and UV-C The behaviour of these two VOCs under different irradiations and temperatures will be discussed according to the catalytic process.