Found 52 results

Open Access

Article

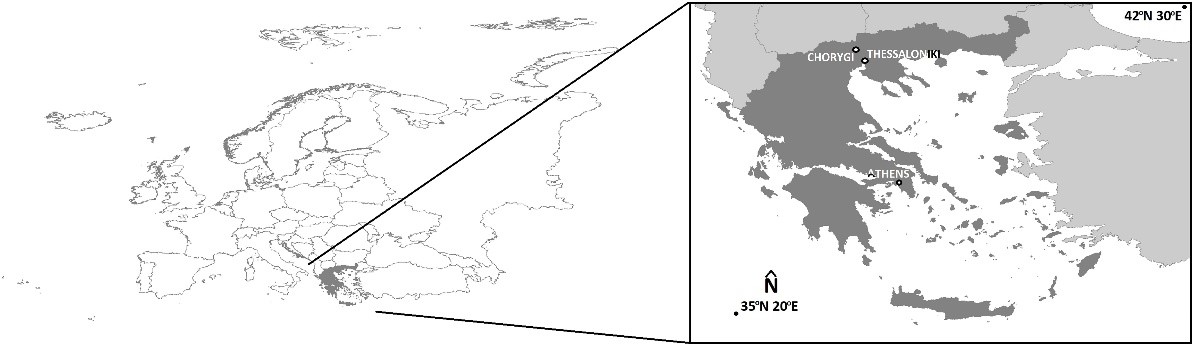

20 January 2025Visible Monuments above and below Ground Level, a Time-Honored Site from the Late Bronze Age to Modern Times

Due to the complex geometry of the monuments, it is often necessary to adapt the image collection process for their mapping. For the optimal mapping of the stronghold of Lazaritsa Chorygi (Greece) and its slopes, vertical, inclined, and horizontal images from different heights were collected using an Unmanned Aircraft System. Thus, for a monument of special archaeological/historical interest and natural beauty, a large set of high-spatial resolution data and final products (digital surface model and orthophotomosaic with spatial resolution 5.6 cm and 2.8 cm, respectively) is available. In addition, in the wider area of the fortified site, military structures (fire trenches, communication trenches, shelters, front and support trenches, and strong points) of the Great War length of 9 km were identified and mapped, which were identified in the 2003 or 2004 Google Earth Pro images, but worryingly are almost absent from the contemporary Google Earth Pro images.

Open Access

Article

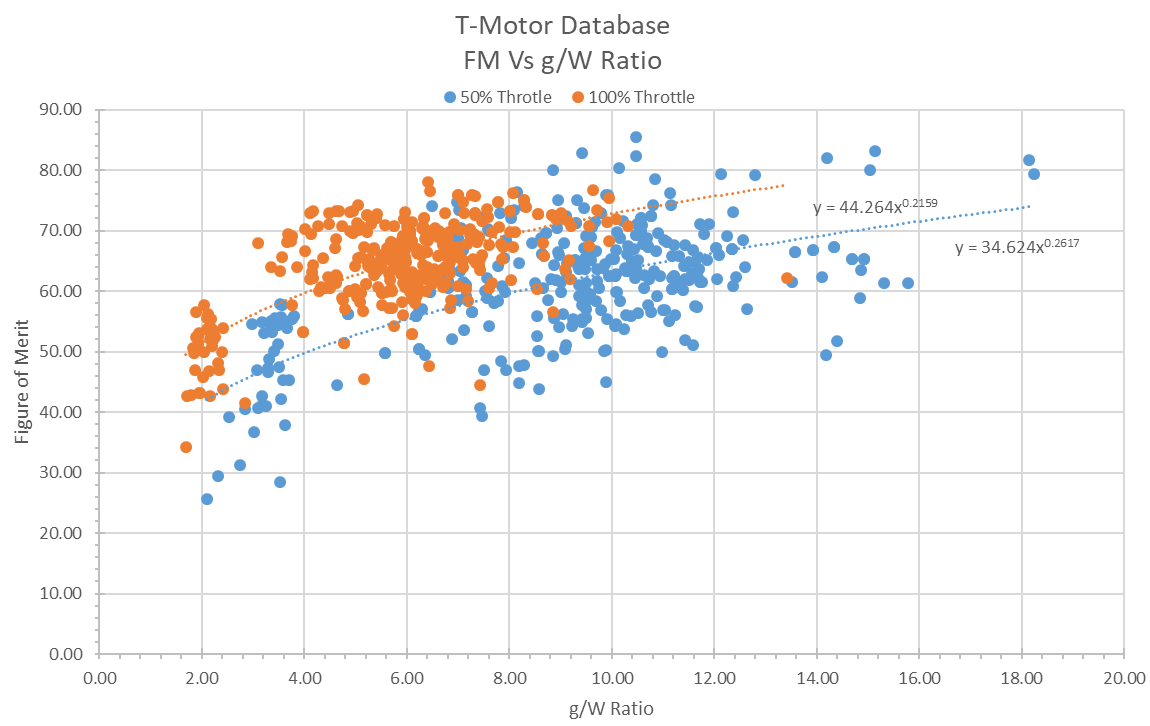

10 January 2025Investigation of the Performance Characteristics of Unequal Co-Axial Rotors

The behaviour of co-axial rotors is well understood, and they are especially practical for large UAVs due to their increased thrust without changing the vehicle footprint. However, for co-axial systems with varying propeller diameters between the two disks, research is more limited. The goal of this paper was to determine an optimal configuration for several different unequal co-axial setups using numerous different propeller combinations and separation ratios. Propellers with diameters of 26 and 29 inches are tested at separation ratios of 0.05 to 0.35. Thrust and power were collected using an off-the-shelf FS15-TYTO thrust stand, with the upstream and downstream propellers running at equal throttles. From this, performance was assessed through efficiency, thrust, and power consumption, and comparisons were made to an ideal combination without losses. The results show that for unequal combinations, the user should place the smaller propeller upstream for greater efficiency, but for maximum thrust capacity, two equal propellers are preferred. When compared to two independent rotors of the same size, a 26″ upstream rotor and a 29″ downstream rotor minimised thrust loss to 16%, compared to 23% for the opposite arrangement. It was also found that the optimal separation ratio is always approximately 0.2.

Open Access

Article

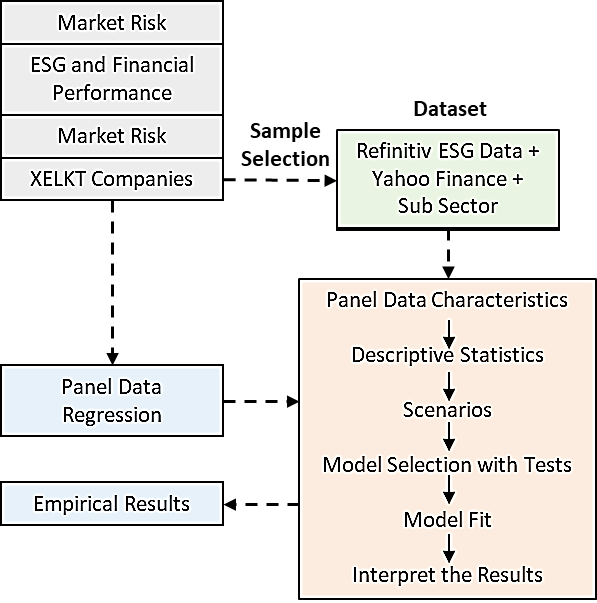

09 January 2025Sustainability Practices and Financial Performance: Evidence from BIST Electricity Index

Amidst the backdrop of heightened market risks associated with transitioning to a lower-carbon economy, this study pioneers an examination of the correlation between sustainability and financial performance within Turkish energy market generator and retailer companies. In this study, the sustainability performance, exposure to market risks and effects on the financial performance of sub-sectors of companies listed in the BIST Electricity index were analyzed using panel data regression. The findings reveal a nuanced relationship between sustainability factors and financial performance, underscoring the imperative for electricity sector companies to prioritize sustainability initiatives not only for ethical reasons but also as a strategic imperative for long-term financial success and stakeholder value creation. Finally, the possibility of impending regulatory changes underscores the importance of early adoption of sustainability practices to mitigate potential financial liabilities and navigate future market risks effectively.

Open Access

Review

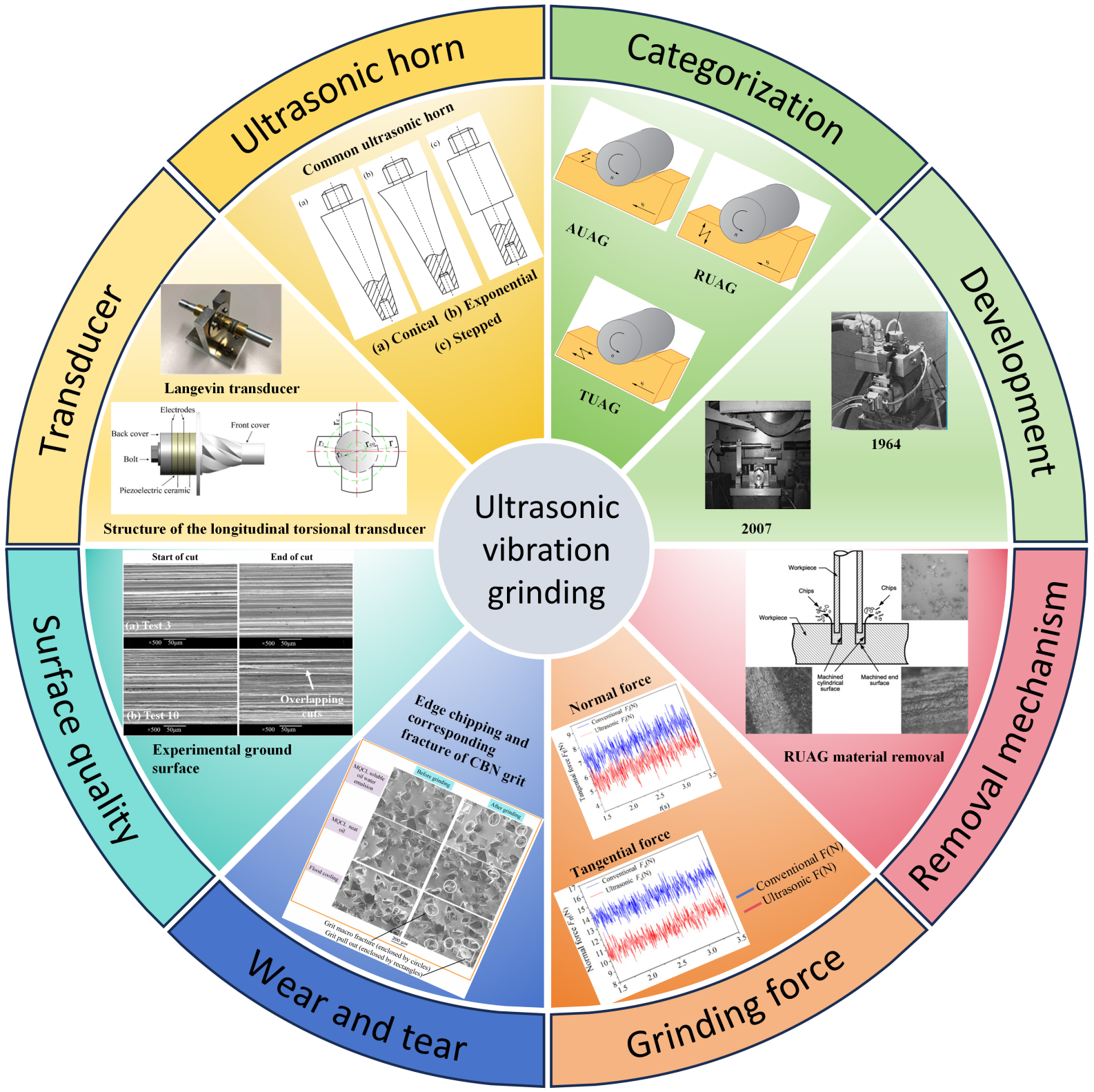

08 January 2025A Review of Ultrasonic Vibration-Assisted Grinding for Advanced Materials

Ultrasonic vibration-assisted grinding (UVAG), which superimposes high-frequency, micro-amplitude ultrasonic vibration onto conventional grinding (CG), offers several advantages, including a high material removal rate, low grinding force, low surface roughness, and minimal damage. It also addresses issues such as abrasive tool clogging, thereby enhancing machining efficiency, reducing tool wear, and improving the surface quality of the workpiece. In recent years, the rapid development of advanced materials and improvements in UVAG systems have accelerated the progress of UVAG technology. However, UVAG still faces several challenges in practical applications. For example, the design and optimization of the ultrasonic vibration system to achieve high-precision, large-amplitude, and high-efficiency grinding remain key issues. Additionally, further theoretical and experimental studies are needed to better understand the material removal mechanism, the dynamics of grinding force, abrasive tool wear, and their effects on surface quality. This paper outlines the advantages of UVAG in machining advanced materials, reviews recent progress in UVAG research, and analyzes the current state of ultrasonic vibration systems and ultrasonic grinding characteristics. Finally, it summarizes the limitations of current research and suggests directions for future studies. As an emerging machining technology, UVAG faces challenges in many areas. In-depth exploration of the theoretical and experimental aspects of high-precision, large-amplitude, and high-efficiency ultrasonic vibration systems and UVAG is essential for advancing the development of this technology.

Open Access

Article

24 December 2024Hydrodynamic Performance of a Hybrid Floating Power Dock Combining Multi-Cantilever Type Buoys

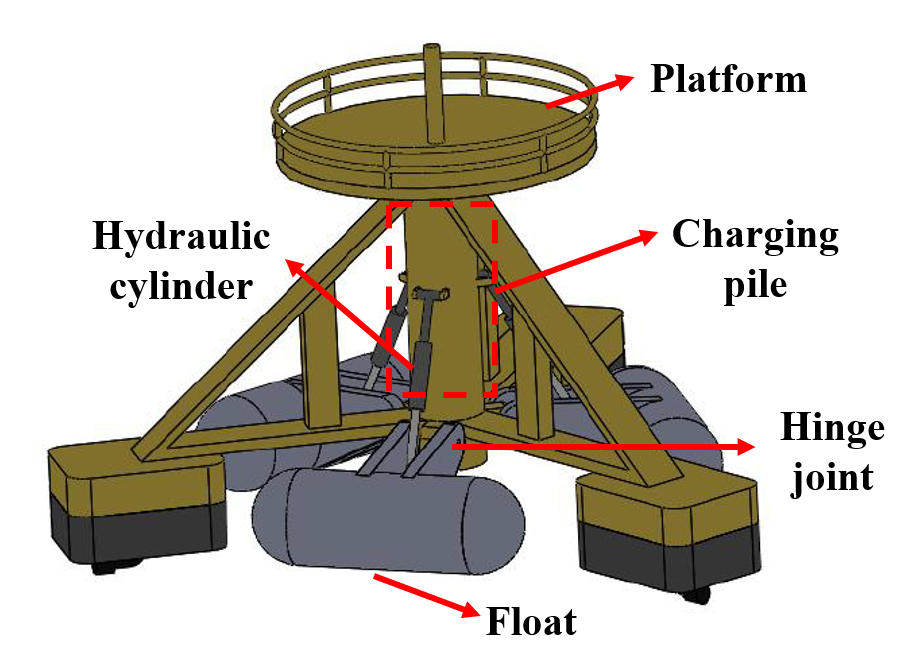

This paper proposes a novel three-dimensional oscillating pendulum wave energy converter (WEC) that integrates an oscillating float dock station. The device captures wave energy by utilizing both the pitch and roll motions of its primary float and the pendular motion of a buoy. A time-domain analysis method is used to numerically evaluate the hydrodynamic behavior and energy conversion efficiency of the WEC. In ANSYS AQWA, a multi-cantilever WEC model is employed to address the fluid-solid coupling, calculating the device’s motion response and capturing the width ratio under various environmental conditions. Additionally, by modifying key geometric parameters including float radius, length, and cantilever angle, the study examines the rotation at the articulation point and the capture width ratio variation for different device configurations. Results indicate that the device achieves a maximum capture width ratio at a float radius of approximately 120 mm under T = 1.4 s, and a 130 mm for wave periods of 1.5 s and 1.6 s. The highest average capture width ratio is reached at a power take-off (PTO) damping coefficient of 400 N·s/m. The study further investigates the effect of cantilever angle and float length, aiding in the optimization of these geometric parameters.

Open Access

Article

28 November 2024Correlations of System Degradation, Losses and Significant Parameters for 49 MW Large Scale Solar Plant with Real Site Data Validations

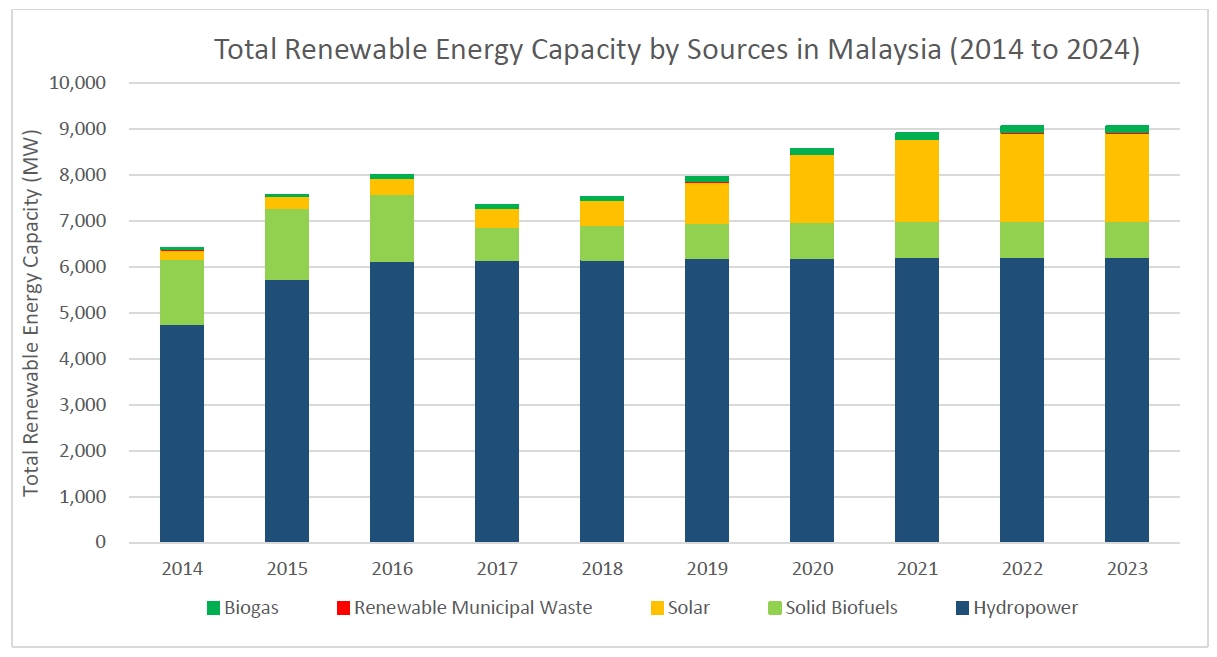

A smooth transition towards a clean and sustainable environment will heavily rely on the continuous increase of renewable energy (RE) integration. Malaysian authorities have set targets to increase the RE capacity to 31% by the end of 2025 and achieve 40% by 2035, specifically through the power generation plan. Solar PV systems have been widely used, from industries to residential homes, because Malaysia receives a high irradiation potential of up to 5000 Wh/year. The increase in the potential of solar PV usage has allowed solar companies to provide this system regardless of its complexity and system size. However, a drop in efficiency due to system parameters within the photovoltaic (PV) system is evident over time. This study aims to analyze the relationship between solar PV system parameters and their energy performance, particularly in a tropical climate region, for a large-scale solar (LSS) plant. This project was undertaken with two objectives: First, it is to develop an optimum solar PV system by adhering to and implementing GCPV standards in Malaysia. Stage 1 will primarily focus on managing and manipulating various PV system parameters to ensure the optimum energy yield received from the plant. The system parameters analyzed are tilt angle, module technology and its effect on different temperatures, the effect of the optimizer, sizing and thermal loss. Stage 2 will then incorporate the industry data of the LSS plant by creating a Pearson’s Correlation model on how energy yield is correlated against real time system parameter values obtained. An optimum tilt angle of 10°, monocrystalline module and inclusion of optimizer increases the overall energy production from 88,986 MWh/year to 89,782 MWh/year and performance ratio (PR) from 78.9% to 79.8%. The outcome of this study demonstrates the significant parameters of the PV system to maximize the energy output to the grid. This will further support the government’s plan to reduce GHG emissions by 45% through the use of renewable energy, with the aim of producing up to 2.5 GW from LSS systems by 2030.

Open Access

Article

26 November 2024Identification of Cutting Workpiece Surface Defects Based on an Improved Single Shot Multibox Detector

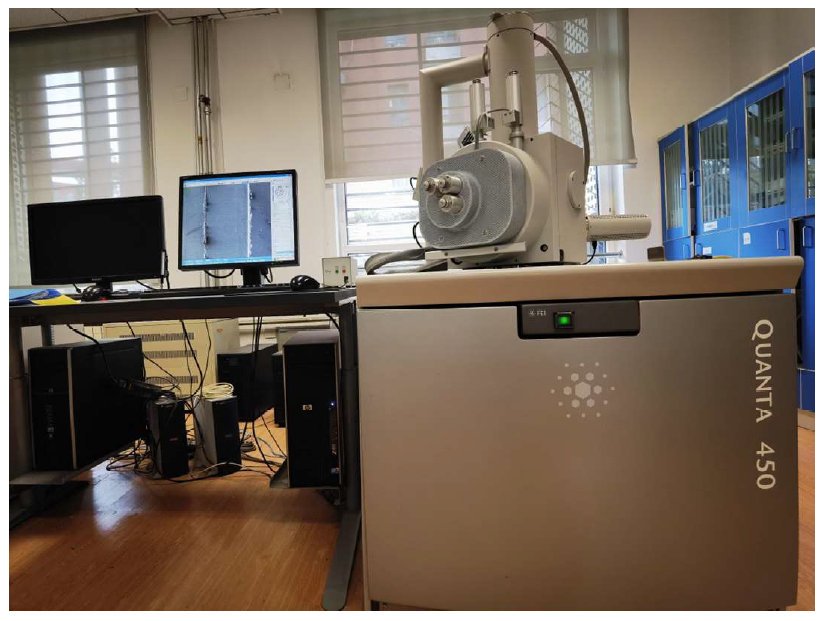

In the mechanical cutting process, the surface defects of the workpiece are an important indicator of cutting quality and also reflect the condition of both the machine tool and the cutting tool. Effective detection of defects on the surface of the workpiece plays an important role in adjusting the processing conditions promptly, reducing losses, improving the utilization rate of the workpiece, and maintaining the normal operation of the equipment. To address the challenge of detecting surface defects on workpieces, an inspection method based on an improved Single Shot Multibox Detector (SSD) model is proposed. The method simplifies the detection model and reduces the computation by proposing a DH-MobileNet network instead of a VGG16 network in the SSD structure. The inverse residual structure is also used for position prediction, and null convolution is used instead of a down-sampling operation to avoid information loss. A scanning electron microscope was used to obtain the surface image of the workpiece. A dataset of workpiece surface defects was constructed and expanded, then used to train and test the model for detecting three common types of high-frequency defects: peel-off, chip adhesion, and scratches. The effect was compared with YOLO, Faster R-CNN, and the original SSD model. The detection results show that the method can detect the defects on the surface of the workpiece more accurately and quickly, which provides a new idea for defect detection in real industrial scenarios.

Open Access

Article

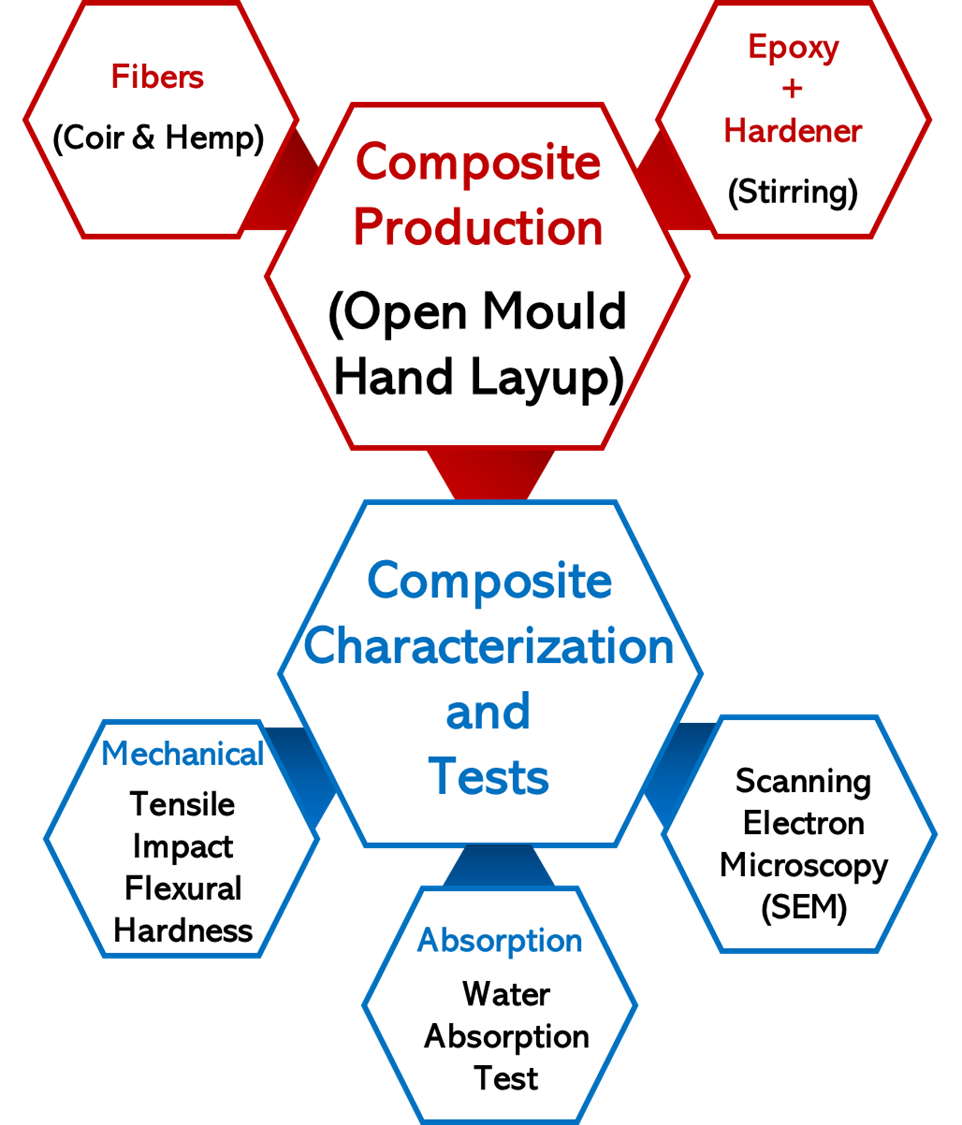

01 November 2024Alkaline Modified Coir and Unmodified Hemp Fiber Reinforced Epoxy Based Composite for Automotive Application

The growing demand for sustainable materials in the automotive industry has prompted research into natural fiber-reinforced composites. To reduce carbon footprints and enhance product sustainability, the sectors increasingly focus on renewable and biodegradable materials. Composites made from natural fibers, such as coir and hemp, offer a promising solution for creating lightweight, high-performance components with a reduced environmental impact.In this study, an experimental investigation was conducted to examine the impact of single and hybrid and treated and untreated fibers, on the properties of epoxy-based composites. Untreated hemp fiber with treated Coir fiber was used for the research. The composites were fabricated through the open mould hand lay-up technique. Samples were prepared by randomly dispersing the fibers in the epoxy matrix before pouring them into the respective moulds prepared according to ASTM standards. Tensile, impact, and hardness tests were conducted on the cured samples to determine their mechanical properties, while a scanning electron microscope was used to evaluate the fractured surface. Water absorption tendencies were also determined. The results showed that the sample denoted as 5CF wt.% had the best property combination with tensile strength (32.4 MPa), tensile modulus (11.9 GPa), flexural strength (167.0 MPa), and impact strength (46.8 kJ/mm2). It was discovered that hemp fiber-based composites were not enhanced properly due to lack of fiber surface modifications. Though optimum results were obtained from treated coir fiber-based single/distinct composite, untreated hemp fiber was discovered to aid some flexural modulus and hardness properties in the hybrid composite based on the best results obtained in its distinct-based composite. Therefore, untreated hemp fiber can be used in hybrid form with treated coir fiber where one of the fibers is scarce or when fiber surface medication is difficult to achieve. Thus, the results showed that 5CH-based composites are the most suitable composition for automotive components development where high-mechanical properties are essential.

Open Access

Article

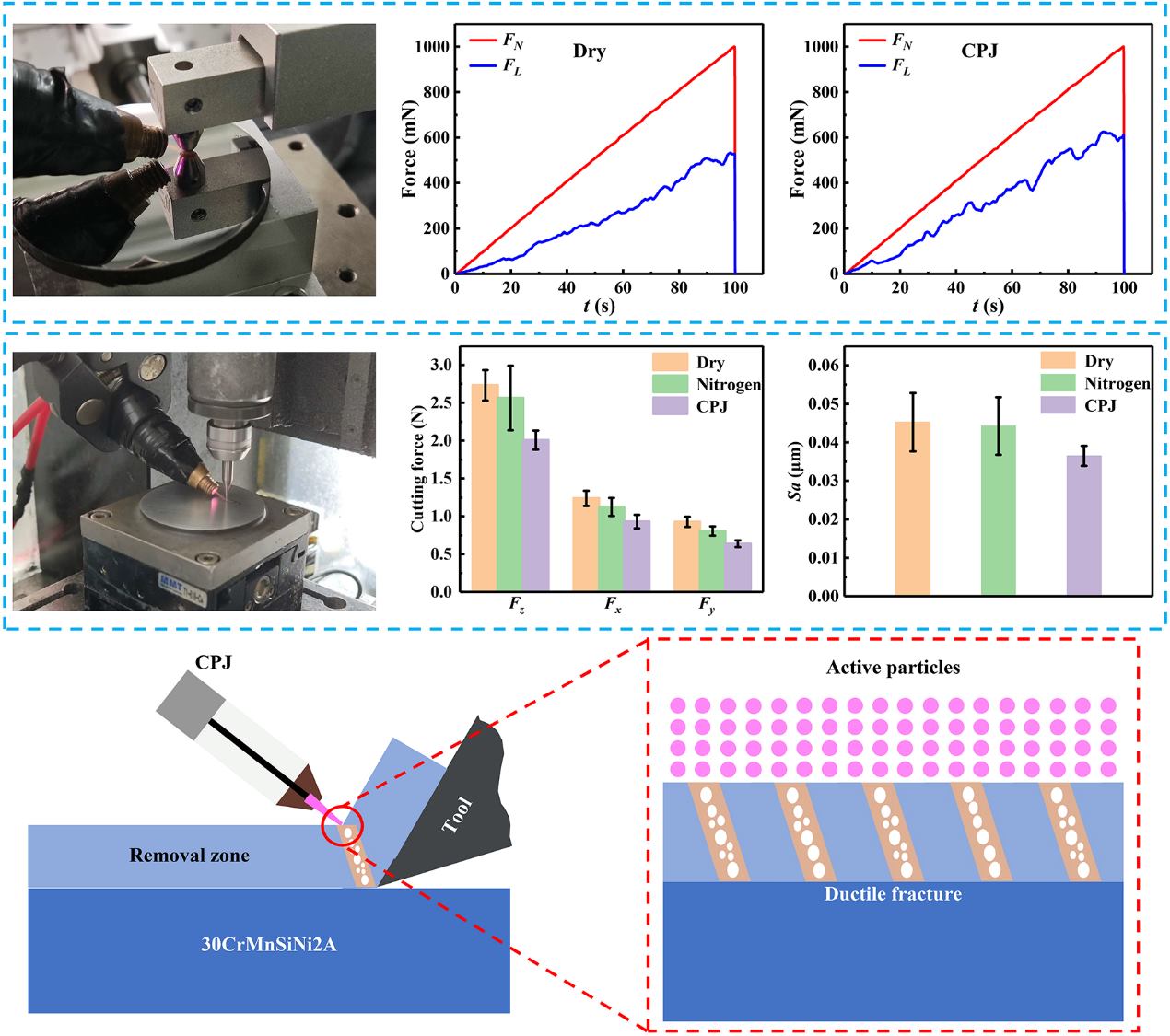

29 October 2024Experimental Study on Cold Plasma Jet (CPJ) Assisted Micro-Milling of 30CrMnSiNi2A

As a typical high-performance alloy, the excellent mechanical properties and stringent processing requirements of 30CrMnSiNi2A high-strength steel pose great challenges to high-quality and efficient processing. Currently, researchers have proposed methods such as improving cutting tool performance, minimal quantity lubrication (MQL), and applying external energy field to assist processing. However, due to the unregulated material properties, the further improvement of surface quality is limited, and there are problems of phase change and thermal damage in laser processing. Cold plasma jet (CPJ) is rich in active particles and has a low macroscopic temperature. It can effectively regulate material properties without causing serious surface damage. Therefore, a new 30CrMnSiNi2A machining approach adopting CPJ is proposed to improve the cutting process. The mechanism of its action on material properties and cutting process is revealed based on single-grain diamond scratching tests and micro-milling tests. The results show that CPJ can promote material fracture and improve material removal efficiency. The material removal efficiency R at 400 mN is increased from 0.433 before treatment to 0.895. Under the optimal processing parameters (feed speed Vf = 800 μm/s, spindle speed n = 40,000 rpm, and milling depth ap = 5 μm), compared with dry micro-milling, the cutting forces Fz, Fx and Fy in CPJ-assisted micro-milling are reduced by 26.5%, 24.8% and 31.3%, respectively. The surface roughness Sa is reduced by 19.3%, and the phenomena of plastic flow and burr are suppressed. The CPJ-assisted machining process proposed in this paper can regulate the material properties to improve the cutting process without causing serious damage to the material, providing a new approach for achieving high-quality and efficient processing of 30CrMnSiNi2A.

Open Access

Article

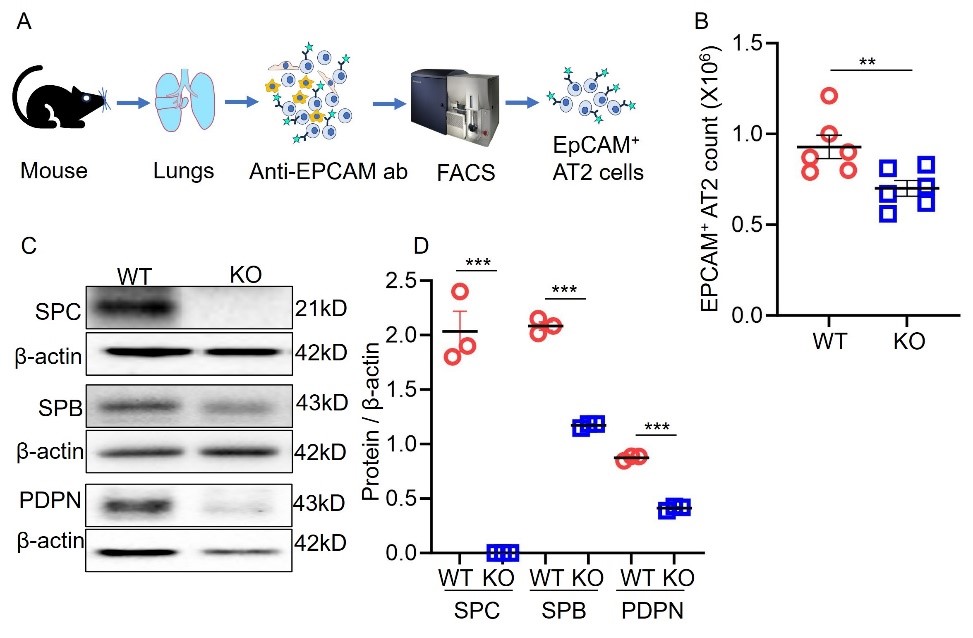

11 October 2024Surfactant Protein-C Regulates Alveolar Type 2 Epithelial Cell Lineages via the CD74 Receptor

Deficiency of surfactant protein-C (SPC) increases susceptibility to lung infections and injury, and suppressed expression of SPC has been associated with the severity of acute respiratory distress syndrome (ARDS). Alveolar type 2 epithelial cells (AT2) are critical for maintenance and repair of the lung. However, the role of the SPC in the regulation of AT2 cell lineage and the underlying mechanisms are not completely understood. This study aimed to investigate the mechanisms by which SPC regulates AT2 lineages. Sftpc−/− mice were used to model the SPC deficiency in ARDS patients. We utilized three-dimensional (3D) organoids to compare AT2 lineage characteristics between wild type (WT) and Sftpc−/− mice by analyzing AT2 proliferation, alveolar type 1 cells (AT1) differentiation and CD74 expression, using colony-formation assay, immunofluorescence, flow cytometry, and immunoblots. The results showed that Sftpc−/− mice demonstrated a reduced AT2 cell population. Influenza A virus subtype H1N1 (H1N1) infected Sftpc−/− mice demonstrated reduced AT2 proliferation and AT1 differentiation. Western blot indicated elevated levels of CD74 protein in AT2 cells of Sftpc−/− mice. Colony-forming efficiency was significantly attenuated in AT2 cells isolated from Sftpc−/− mice compared to the WT controls. Podoplanin (PDPN, a marker of AT1 cells) expression and transient cell count significantly increased in Sftpc−/− organoids. Moreover, siRNA-mediated gene silencing of CD74 in AT2 cells significantly increased AT2 proliferation and AT1 differentiation in Sftpc−/− organoids. This study suggests that SPC regulates AT2 lineage in vitro and in vivo. The SPC might influence AT2 lineage during the lung epithelium repair by activating signaling mechanism involving CD74 receptor.