1. Introduction

Microorganisms are natural reservoirs for a wide variety of metabolites, many of which are important compounds such as amino acids, vitamins, alcohols, organic acids, and antibiotics, with broad applications in our daily lives. Metabolic engineering enables the design and rational modification of natural microorganisms, empowering them with the capability to efficiently biosynthesize these naturally occurring molecules. Furthermore, the development of synthetic biology makes it possible to reconstitute and fine-tune non-native biosynthesis pathways in a heterologous microbial chassis or even construct artificial pathways for the production of non-natural molecules.

While most of the microbial-derived small-molecule products that have reached the commercial stage are natural metabolites synthesized through their native metabolic pathways, such as ethanol, lactic acid, succinic acid, citric acid, amino acids and antibiotics, some pioneering companies have attempted and succeeded in the industrial scale microbial production of non-native and non-natural molecules such as 1,3-propanediol (1,3-PDO), 1,4-butanediol (BDO) and isobutanol. 1,3-PDO is a platform chemical with primary applications in the synthesis of polyesters, polyethers, and polyurethanes [

1,

2]. It is naturally produced only from glycerol by certain microbial species including

Klebsiella,

Citrobacter,

Enterobacter, and

Clostridium, while

Escherichia coli lacks the 1,3-PDO biosynthesis pathway [

3]. Moreover, no naturally occurring microorganisms have been reported to produce 1,3-PDO from glucose. In 2000, scientists from DuPont and Genencor introduced an artificial pathway into

E. coli to convert glucose to glycerol and then incorporated a foreign 1,3-PDO biosynthesis pathway [

1]. Following extensive optimizations in the production strain and process, economically viable bioprocesses were successfully developed in 2006, using starch sugar as the raw material [

4]. This milestone marked a starting point for microbial production of non-natural commodity chemicals through engineered artificial pathways. Following this success, Genomatica and Gevo commercialized the biomanufacturing of 1,4-BDO and isobutanol, respectively, through non-natural biosynthesis pathways [

5,

6]. Other well-known examples with the potential for commercialization include 1,2-propanediol, 1-butanol, 2,3-butanediol, 1,2,4-butanetriol, cadaverine, etc. [

7,

8,

9,

10,

11].

It's evident that the majority of these non-natural chemicals were primarily confined to three- and four-carbon (C3 and C4) molecules. This limitation arises from the fact that the abundant C2-C5 metabolites such as acetyl-CoA, pyruvate, PEP, oxaloacetate, succinyl-CoA, and α-ketoglutarate within the host cells can readily serve as biosynthetic precursors to the C3 and C4 molecules. In contrast, biosynthesis of certain C5 and C6 chemicals encounters challenges due to the lack of suitable native precursors.

In recent years, significant efforts have been made to develop microbial synthesis approaches for their production, because C5 and C6 chemicals have broad applications, especially in the production of polymers, such as nylon 5, nylon 5,6, nylon 6, nylon 6,6 and poly-caprolactone (PCL). The global polymer market was valued at $17.1 billion in 2022 and is expected to grow 3.5% annually from 2023–2030 [

12]. Currently, almost all the C5 and C6 chemicals are manufactured through chemical synthesis processes using petroleum-derived feedstocks such as benzene, cyclohexanol, and cyclohexanone. The chemical processes involve multiple toxic reactants, intermediates, and catalysts, and result in significant emissions of greenhouse gases such as nitrogen oxides. For instance, the chemical synthesis of caprolactam, a precursor for nylon 6, relies on the hydrogenation of benzene to cyclohexane, and then subsequent oxidation. This manufacturing route results in the emission of nitrous oxide, carbon dioxide, and sulfur dioxide, in addition to various non-methane volatile organic compounds. Nitrous oxide emissions alone are 10–15 million metric tons of CO

2-equivalent [

13]. Particularly, the limited availability of C5 feedstock from petroleum makes chemical synthesis complicated and expensive.

To alleviate the dependence on fossil fuels and pave the way to a greener future, scientists and engineers have made substantial efforts to explore the bio-based production of these chemicals, utilizing renewable starting materials such as glucose, glycerol, xylose, lignin, and syngas. Glucose, sourced from plant-based origins such as potato, wheat, and maize starch [

14,

15], and glycerol, a byproduct of biodiesel synthesis, offer readily available and eco-friendly carbon sources [

16]. Using these carbon sources, microbial cell factories have been engineered to produce a variety of C5 and C6 chemicals. Due to the frequent involvement of decarboxylation reactions resulting in the loss of one carbon, biosynthesis of C5 and C6 molecules typically requires C6 and C7 precursors. For example, lysine, a C6 amino acid, and its decarboxylation products are often employed as the precursor to many non-natural C5 chemicals. Given the lack of native C7 precursors in microbial cells, biosynthesis of C6 molecules is even more challenging. To address this limitation, efforts have been made by engineering novel, non-natural biosynthesis pathways involving chain extension (+1) reactions, condensation reactions, and ring-fission reactions of aromatic compound catechol to create the six-carbon backbone. Recently, Genomatica and Aquafil announced the pre-commercial production for nylon-6 derived from plant sugars [

17]. Additionally, Toray is currently upscaling its production of plant-based adipic acid (AA) in preparation for commercialization [

18]. As the development of bio-based chemicals matures, these innovations are anticipated to account for an increased percentage of chemicals produced worldwide.

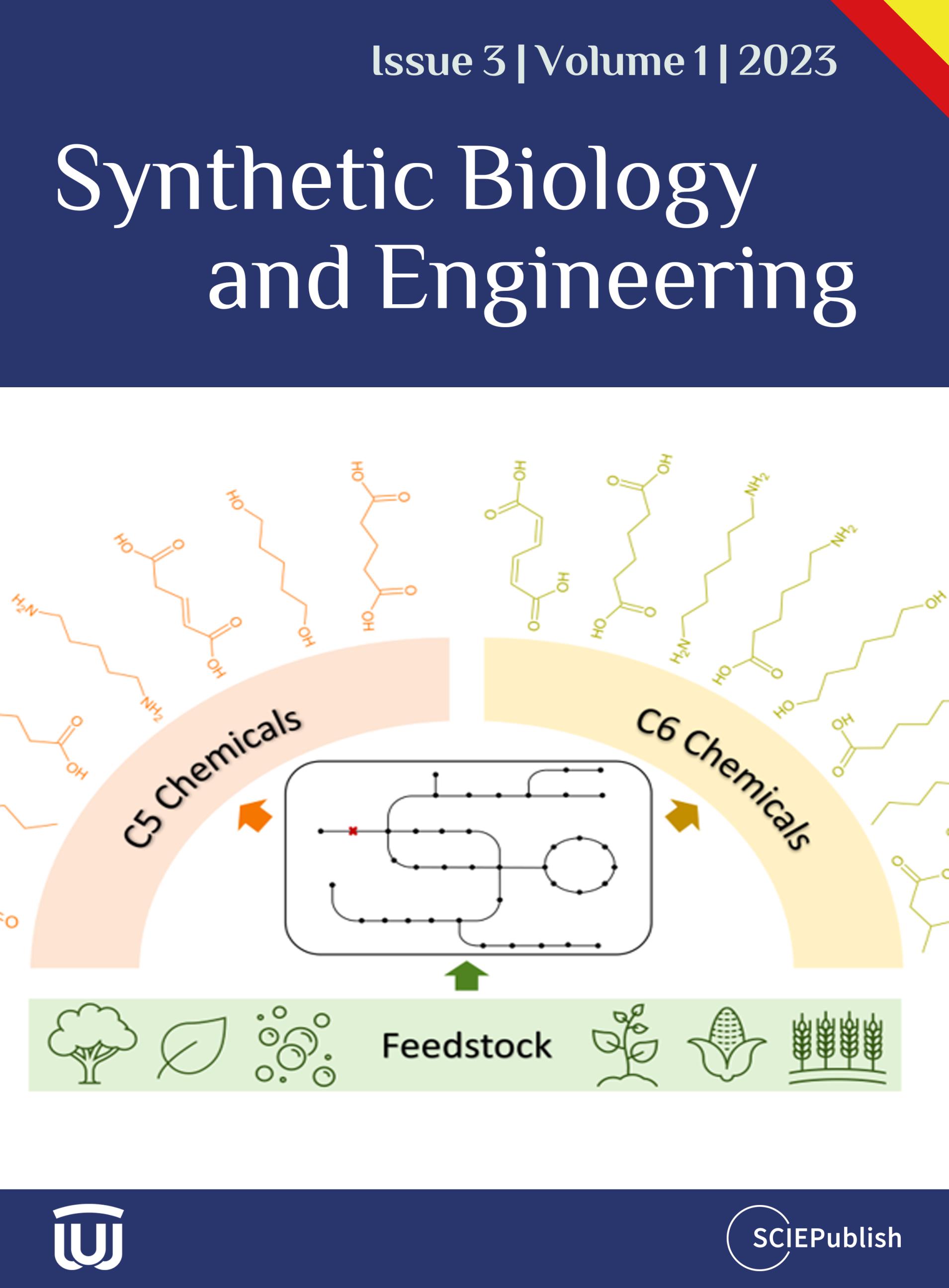

In this review, we focus on the progress in the microbial production of the non-natural C5 chemicals () including 1-pentanol, 1,5-pentanediol (1,5-PDO), cadaverine, δ -valerolactam, glutaric acid (GA), glutaconic acid, and 5-hydroxyvaleric acid (5-HV), as well as the non-natural C6 chemicals () including

cis,

cis-muconic acid (MA), AA, 1,6-hexamethylenediamine (HMDA), 6-aminocaproic acid (ACA), β-methyl-δ-valerolactone (MVL), 1-hexanol, ε-caprolactone (CL), 6-hydroxyhexanoic acid (HHA), and 1,6-hexanediol (1,6-HDO) with an emphasis on strategies employing renewable carbon sources.

. Best-performing metabolic engineering strategies for the microbial production C5 chemicals with diverse chassis and substrates.

. Best performing metabolic engineering strategies for the microbial production C6 chemicals with diverse chassis and substrates.

2. C5 Chemicals

2.1. 1-Pentanol

1-Pentanol is a straight-chain C5 alcohol commonly used as a coating solvent or in fragrances, while it also has potential as a fuel alternative [

19]. It is considered a semi-natural alcohol, as only trace amounts are generated in yeast fermentations. Recent studies have reported the microbial production of 1-pentanol in

E. coli through extending the 2-ketobutyrate (2-KB) pathway [

58]. This pathway utilizes the chain elongation cycle mediated by the broad-substrate LeuABCD in the leucine biosynthesis and can be employed to produce C5-C7 alcohols that lack a natural biosynthetic pathway, such as 3-methyl-1-butanol and 3-methyl-1-pentanol [

58]. However, the wild-type LeuABCD was unable to act on 2-KB for 1-pentanol production. To address this limitation, Zhang et al. introduced a leucine-feedback insensitive mutation into LeuA (G462D). Along with the action of 2-ketoisovalerate decarboxylase (KIVD) from

Lactococcus lactis and alcohol dehydrogenase (ADH6) from

Saccharomyces cerevisiae, they achieved the biosynthesis of 494 mg/L of 1-pentanol. Subsequent protein engineering of KIVD led to the identification of a more efficient mutant V461A/M538A, resulting in an increase in 1-pentanol to 750 mg/L [

59].

Building on this foundation, Chen et al. attempted to further enhance the 1-pentanol production by specifically focusing on the effects of the residue V461 on KIVD activity. A saturated mutagenesis study of this residue revealed that the V461G mutant exhibited the highest activity and selectivity towards the 2-ketocaproate, the precursor of 1-pentanol. This improvement may be attributed to the extra space created within the binding pocket, allowing for a looser docking of the substrate. Notably, this particular mutant also showed a reduced catalytic efficiency for 2-KB and 2-ketovalerate, which decreased the production of the shorter-chain alcohols, 1-propanol, and 1-butanol, while increasing the production of 1-pentanol. Additional improvement was achieved by synergistically overexpressing the

E. coli native threonine pathway alongside the

CimA gene from

Methanococcus jannaschii, whose catalytic activity was enhanced through directed evolution to bolster the citramalate pathway, ultimately resulting in an increased supply of 2-KB. Moreover, the elevated supply of acetyl-CoA, the iterative addition unit, by acetate feeding further directed the 2-ketoacid flux into the elongation cycle, thus enhancing the 1-pentanol productivity. As a result of these combined efforts, a final titer of 4.3 g/L was achieved [

19].

2.2. 1,5-Pentanediol (1,5-PDO)

1,5-PDO is a commodity chemical widely recognized for its industrial application as a plasticizer and its role in the production of polyester and other diol compounds [

60]. Despite its high industrial value, the production and market size of 1,5-PDO has been constrained due to its complex manufacturing process and lack of readily available C5 feedstock in petroleum. 1,5-PDO is a non-natural chemical that lacks a natural biosynthesis pathway which is a great challenge for its microbial production [

60]. However, metabolic engineering and synthetic biology allow the construction of non-natural pathways in microorganisms for their production ().

. An overall schematic of the biosynthetic pathways that extend off of the TCA cycle for the production of C5 chemicals. Solid arrows signify direct steps. Dashed arrows represent multiple steps. The red pathway corresponds to the reference [

60]. The green pathway coincides with the reference [

20]. Light olive pathway correlates to reference [

61]. The fuchsia pathway is shown in reference [

21,

22,

23,

24,

25,

62–75]. The orange pathway can be found in reference [

26,

76]. The grey pathway is highlighted in the reference [

30,

77,

78,

79,

80,

81,

82,

83,

84,

85,

86]. Blue pathway belongs to reference [

27,

28,

87]. The purple pathway corresponds to the reference [

88]. The pink pathway correlates with the reference [

31]. Brown pathway signifies the reaction in reference [

32,

33]. Black arrows represent steps utilized by multiple pathways. LDC, lysine decarboxylase; ABAT, 4-aminobutyrate transaminase; ALR, aldehyde reductase; CAR, carboxylic acid reductase; 5-AVA, 5-aminovaleric acid; 5-HV, 5-hydroxyvaleric acid; 5-HV-CoA, 5-hydroxyvaleric acid CoA; 1,5-PDO, 1,5-pentanediol.

As of now, the microbial production of 1,5-PDO via metabolic engineering has only been studied in

E. coli as the host microorganism. For example, Cen et al. created a lysine-overproducing

E. coli strain by expressing

lysC,

dapA, and

ddh, which are all genes that encode for rate-limiting enzymes in the biosynthesis pathway. Building upon the lysine-producing chassis, the

davB and

davA genes from

Pseudomonas putida were introduced to allow for an efficient conversion from lysine to 5-AVA as well as an alcohol dehydrogenase encoded by

yqhD. Furthermore, the performance of 4-aminobutyrate transaminases (ABAT) encoded by gabT genes from different organisms including

E. coli,

P. putida, and

Pseudomonas stutzeri were evaluated, among which GabT from

E. coli produced the highest amount of 5-hydroxyvalerate (5-HV). During the conversion from 5-AVA to 5-HV, a high accumulation of GA was observed. Therefore, Cen et al. included the use of two types of transporters, which are encoded by

cgl0841 from

C. glutamicum and

gabP from

E. coli into the plasmid construction to reduce the byproduct accumulation. As this article used the 5-HV-CoA-based pathway, Cen et al. screened different CoA-transferases from different sources, with the

abfT gene from

Clostridium aminobutyricum producing the highest titer. Ultimately, the final strain showed a considerable amount of 5-HV and lysine accumulation and a low yield of the final product, 1,5-PDO, of less than 1 g/L. This result suggests there is a huge metabolic imbalance present between all three modules, which could be due to the lack of NADPH available for the entire pathway [

60].

The same group of researchers continued to optimize this reaction and found a new pathway using cadaverine, which was found to be more energy efficient. As a result, in addition to the

gabT gene and alcohol dehydrogenase used to synthesize 5-HV, this study required the involvement of a putrescine transaminase (

patA), 4-aminobutyraldehyde dehydrogenase (

patD), and an endogenous lysine decarboxylase. In

E. coli, there are two lysine decarboxylases, encoded by

cadA and

ldcC, while the former was chosen for its greater stability.

CadA and

patAD were co-expressed along with

gabT and

yqhD or

yahK as the alcohol dehydrogenase. Unlike the previous study, where

yqhD was used in the final strain, this study saw

yahK producing a higher titer of 1,5-PDO. Cen et al. also made an adjustment in this study by using the CAR-based pathway from 5-HV to 1,5-PDO, therefore, different CAR enzymes were screened to test its efficiency for the production of 5-hydroxypentanal. Ultimately, the CAR from

M. marinum produced the highest 1,5-PDO titer. Another addition is the knock-out of the

gdhA and

gabD genes, which are involved in a separate GA synthesis pathway, in an attempt to reduce its accumulation. The strain consisting of these changes resulted in an overall titer of 9.25 g/L of 1,5-PDO, which is significantly higher than the previous study but is still considered low on the industry scale. Furthermore, a high accumulation of byproducts still remained as well, therefore, this engineered pathway needs to be further optimized and tested [

20].

In a separate study conducted by Wang et al., they explored the charged amino acid catabolic pathway to synthesize various diols, including 1,3-PDO, 1,4-BDO, and 1,5-PDO. However, for the purpose of this discussion, the focus will be primarily on the last compound. Starting with glucose as the carbon source to produce lysine, Wang et al. applied a similar strategy as discussed in prior studies. They inserted a synthetic AMV pathway by introducing

davAB from

P. putida,

gabT, and

yqhD from native

E. coli. Additionally, they employed a CAR-based pathway for the conversion of ω-hydroxy acids (ω-HA) to diols. This pathway specifically consisted of the CAR enzyme from

M. marinum and phosphopantetheine transferase (

sfp) from

B. subtilis. The study revealed that the titer of 1,5-PDO increased exponentially only when lysine was exogenously supplied to the cell culture, highlighting the bottleneck limitation imposed by lysine supply on the pathway. To address this issue, Wang et al. co-expressed

lysC and

dapA, to enhance the lysine degradation pathway. However, even after deleting the

iclR gene in an effort to maintain the precursor supply of oxaloacetate, the highest titer reached only 0.97 g/L [

61].

2.3. Cadaverine

Cadaverine, or 1,5-diaminopentane is a straight-chain diamine that has shown to have many commercial applications, notably in bio-based materials, and is seen in chelating agents [

89]. Cadaverine is naturally formed by bacterial decarboxylation of lysine that occurs during putrefaction of animal tissues. There is a growing interest in enhancing cadaverine production using microbial engineering methods with a focus on renewable carbon sources () [

11].

2.3.1. Cadaverine Production in

E. coli

In

E. coli, the majority of studies focused on the bioconversion of lysine to cadaverine instead of a direct fermentative approach from glucose in order to avoid limitations of precursor availability and cell growth [

89]. There are two main lysine decarboxylases (LDC) that can achieve this conversion: CadA and LdcC, both of which originate from

E. coli. When compared, CadA has a higher catalytic activity than LdcC, thus the former is more frequently used to produce cadaverine. Hong et al. worked to improve the enzymatic stability and activity of the CadA by inserting a combination of mutations: F14C, K44C, L7M, and N8G. This mutated strain produced an overall titer of 157 g/L of cadaverine [

62]. Another study by Kou et al. focused on enhancing the thermal and pH stability of CadA by overexpressing a T88S mutant to achieve an increase in titer to 198 g/L [

63]. Xi et al. also attempted to accomplish this by introducing additional mutations, K477R, E445Q, and F102V, along with T88S. However, this combinatorial mutagenesis approach led to a slight decrease in concentration of 160.7 g/L compared to the previous study [

64]. Gao et al. discovered a combination of different mutations, V12C and D41C, using rational engineering on the CadA. In addition to optimizing the pH conditions during fermentation, this strain achieved the highest cadaverine titer at 418 g/L [

21].

Additionally, Ma et al. co-expressed the CadA gene with CadB, a lysine and cadaverine antiporter fused with a signal sequence PelB, leading to a production titer of 221 g/L [

65]. Huang et al. further built upon this system by deleting the genes responsible for the accumulation of byproducts, including

speE,

speG,

ygjC, and

puuA. However, this knockout strain only produced 32.1 g/L of cadaverine [

66]. An additional effort was made by Moon et al. on modification of the ATP regeneration system within the pathway. They overexpressed

cadA, along with a polyphosphate kinase (

ppk), and pyridoxal kinase (

pdxY), to assist in the conversion of lysine. They further optimized the cell system by introducing hexadecyltrimethylammonium bromide (CTAB) to increase the permeability of the cell membrane. The implementation of both these strategies resulted in the production of 1 M of cadaverine, with a 100% conversion rate from lysine [

67]. Xue et al. achieved a titer of 83.2 g/L by utilizing a similar strategy of co-expressing

cadA with only

pdxY [

68]. In another study, Wang et al. introduced lysine decarboxylase (LDC) from

Hafnia alvei with the mutation, E583G into

E. coli. This heterologous expression saw a decent concentration of 63.9 g/L [

69].

Noh et al. conducted an experiment involving the engineering of a synthetic sRNA scaffold. Using the cadaverine biosynthesis pathway to test their approach, they identified and used 67 genes to construct the strongest scaffold. To determine the effect of the modifications on carbon metabolism, this strategy utilized direct fermentation from glucose. As a result, 13.7 g/L of cadaverine was produced following fed-batch fermentation [

70]. As for the study performed by Wei et al., their experiment focused on altering the fermentation process by using a CO

2 reconversion approach to control pH levels, which reduced cellular damage and led to a titer of 208.2 g/L [

71].

Instead of using glucose as a carbon source, Kwak et al. utilized galactose as the carbon source to produce cadaverine in

E. coli. To metabolize galactose, Kwak et al. engineered the Leloir pathway by overexpressing the genes involved,

galE,

galT,

galK,

galM,

galP, and

pgm. Additionally, they modified the carbon flux to increase the supply of lysine by inserting

asd,

dapA fbr,

dapB,

ddh,

lysA, and

lysC fbr into the chromosome. Disruption of the cadaverine degradation pathway was also attempted by knocking out

speE,

speG,

ygjG, and

puuPA, resulting in a titer of 8.80 g/L [

22].

2.3.2. Cadaverine Production in

C. glutamicum

Corynebacterium glutamicum has shown tremendous success in constructing engineered microbial cells in the past, making it an excellent candidate as the host organism for cadaverine production. Kind et al. utilized a previously engineered

C. glutamicum strain, LYS-12, that hyper-produces lysine as a precursor. In this strain, Kind et al. opted to introduce the constitutive gene,

ldcC from

E. coli, as the lysine decarboxylase, along with a major facilitator permease,

Cg2893, to enhance cellular transport. They additionally deleted the lysine exporter gene,

lysE, to maintain the precursor supply, and removed

NCgl1469, a gene involved in the production of by-product

N-acetyl-diaminopentane. This modified strain resulted in a titer of 88 g/L following fed-batch fermentation using glucose as the starting substrate [

72].

Similarly, the direct fermentation approach was utilized by Li et al., who employed a heterologous co-expression system involving

cadB from

E. coli and the LDC gene from

Hafnia alvei, producing 2.75 g/L of cadaverine [

73]. In another study, Kim et al. used a strong synthetic H30 promoter to express the

ldcC gene from

E. coli, where it significantly increased the activity of lysine decarboxylase. Coupled with the deletion of

lysE, this approach achieved one of the highest titers from glycose in

C. glutamicum, 103.78 g/L of cadaverine [

23].

Kobayashi et al. utilized a different approach by constructing a system with an oxygen-responsive switch that could transition the carbon flux from glycolysis to the pentose phosphate pathway (PPP). This was accomplished through the replacement of the glucose 6-phosphate isomerase (

pgi) promoter with the promoter of lactate dehydrogenase (

ldhA). Furthermore, they deleted the lactate pathway through the disruption of

ldhA, menaquinone oxidoreductase (

pqo), acetate kinase (

ack), and phosphotransacetylase (

pta). However, to improve the supply of oxaloacetate, a precursor of lysine, they introduced a mutation in isocitrate dehydrogenase to reduce its activity. They also introduced a P328S mutation into pyruvate carboxylase (

pyc) to increase its enzymatic activity. Finally, a

lysC-T311I mutant was introduced into the strain to increase lysine by eliminating the feedback inhibition. The final strain produced 0.74 g/L of cadaverine [

74].

In the studies by Buschke et al., xylose was used as the carbon source. They constructed a mutant strain by expressing

xylA and

xylB genes from

E. coli, that converts xylose into xylulose 5-phosphate to be used as a metabolic intermediate [

24]. Using this recombinant strain, Buschke et al. overexpressed

icd, along with fructose bisphosphatase (

fbp), and transketolase (

tkt), enzymes involved in the production of lysine from a carbon source. This strain consumed xylose to achieve 103 g/L of cadaverine, a high titer seen in

C. glutamicum [

25]. Mao et al. also employed xylose as their substrate, but their method centered on the introduction of Beta-xylosidase BSU17580 from

B. subtilis into the strain, facilitated by a PorH anchor protein. This enzyme played a crucial role in generating the xylose supply through the conversion of xylo-oligosaccharides. Along with the overexpression of the

xylA and LDC genes, Imao et al. achieved a yield of 11.6 mM of cadaverine [

75].

2.4. δ-Valerolactam

δ-valerolactam plays a pivotal role in the synthesis of bioplastics, which can subsequently be utilized in the manufacturing of various items and goods [

76]. This class of products has garnered increased attention due to its reliance on non-petroleum-based sources and its exceptional durability, with predictions suggesting that bioplastics production may exceed 2.43 million tons in the near future [

26]. While there are various other compounds capable of synthesizing biopolyamides, δ-valerolactam has been shown to be a potential candidate for large-scale bioplastics production. However, currently, there are limited methods for δ-valerolactam production, achieved either through plant extraction or the chemical conversion of 5-AVA. Therefore, engineered microorganisms have become a focal point, although there have only been a handful of studies reporting on this compound ().

While there have been relatively few studies on the synthesis of δ-valerolactam via metabolic engineering, Xu et al. proposed a novel pathway that included L-pipecolic acid (L-PA) as the intermediate. In this study, Xu et al. uses

E. coli as the host organism to first introduce the

DavB genes from

P. putida to convert L-PA to δ-valerolactam, which produced an initial titer of 90.3 mg/L. Further modifications involved co-expressing DavB with multiple proteins including an apoptosis-inducing protein (

rAIP) from

Scomber japonicus,

Bacillus subtilis glucose dehydrogenase (GDH),

P. putida Δ-piperideine-2-carboxylae reductase (

DpkA), and Oryza sativa lysine permease (

LysP). These changes allowed for δ-valerolactam to be produced directly from L-lysine, resulting in a final titer of 242 mg/L of δ-valerolactam [

76]. In a separate study, Cheng et al. built upon the information from this previous experiment and further optimized the pathway to co-produce δ-valerolactam and 5-AVA. While Cheng et al. also introduced the

RaiP from

S. japonicus, they also expressed a catalase gene,

katE. They supplemented the process with H

2O

2 and adjusted the pH level to the optimal value of 9.0. With these modifications, this strain obtained a significantly improved titer of 6.88 g/L [

26].

2.5. Glutaric Acid (GA)

GA, also known as 1,5-pentanedioic acid, is a dicarboxylic acid that is an important component for the production of polyester and polyamides, which are essential for the manufacturing of fabric and textiles, amongst other materials [

87]. Typically, GA is synthesized via a chemical process using potassium cyanide to catalyze the ring-opening reaction of butyrolactone or using other toxic petroleum-based materials [

30,

90]. Apparently, some of the main issues associated with this approach are the high costs as well as the environmental burdens. Therefore, there is a preference for transitioning to efficient biobased approaches over traditional chemical methods.

2.5.1. GA Production in

E. coli

E. coli is a widely used host microorganism for metabolic engineering due to its fast growth and capacity to express heterologous genes, enabling the rapid construction of efficient microbial systems for producing desired compounds. GA is a compound derived from lysine and 5-AVA, whose pathways require the introduction of heterologous enzymes from different organisms. Two separate studies conducted by Park et al. and Adkins et al. first focused on the production of 5-AVA and then the conversion of 5-AVA to GA in

E. coli (). Both studies synthesized 5-AVA from L-lysine by introducing the davAB genes from

P. putida into an

E. coli, which encodes for the δ-aminovaleramidase and lysine 2-monooxygenase, respectively. The

gabTD genes from

P. putida, which encode for 5-AVA aminotransferase and GA semialdehyde dehydrogenase, were also co-expressed to catalyze the conversion of 5-AVA to GA. Adkins et al. further deleted the

cadA and

ldcC genes, which were involved in a separate lysine degradation pathway to reduce the formation of the byproduct, cadaverine. With similar modifications, Adkins et al. and Park et al. obtained a final titer of 0.82 and 1.7 g/L, respectively [

77,

78].

In a study conducted by Li et al., their approach closely resembled the biosynthesis of 1,5-PDO via the cadaverine pathway, as previously explored by Cen et al [

59]. In this approach,

E. coli native genes

cadA,

patAD, and

gabTD were incorporated to facilitate the synthesis of GA. Furthermore, to reduce the accumulation of cadaverine, Li et al. overexpressed PotE, a bi-directional cadaverine transporter. The study also focused on boosting the supply of lysine by enhancing the precursor oxaloacetate, achieved through the deletion of

iclR. These modifications resulted in minimal byproduct formation, culminating in a final GA titer of 54.5 g/L [

27]. Wang et al. also utilized the cadaverine pathway in their study, albeit with slight variations. They introduced the

patAD genes from

Klebsiella pneumoniae and

gabTD from

Pseudomonas fluorescens into their pathway. Wang et al. also discovered the

patA gene was a rate-limiting enzyme in the 5-AVA synthesis reaction, to which they improved its efficiency via a hydrophobic scanning strategy, where certain hydrophilic residues within the catalytic binding pocket were replaced with a hydrophobic residue. The introduction of a T332A/E120G

patA mutant into the strain resulted in an enhancement of 5-AVA production. The transporter gene,

gabP, was also overexpressed to reduce the accumulation of 5-AVA. This particular strain achieved an impressive titer of GA, reaching 77.62 g/L [

28].

Hong et al. improved the production of GA via the 5-AVA pathway by coupling the overexpression of the

gabTD genes with the Nox gene from

Lactobacillus sanfranciscensis that encodes for an NADPH oxidase. In doing so, it reduced the need for NAD

+ as a cofactor and allowed the overall production of GA to reach 282 mM [

79]. In another study, they inserted the

gabTD genes from

B. subtilis into

E. coli, where they obtained 191 μmol of GA after five cycles of whole-cell bioconversion [

80]. Yang et al. attempted to improve this experiment by using polyvinyl alcohol and polyethylene glycol (PVA-PEG) hydrogel to entrap and immobilize the entire system. With this addition, the production of GA from 5-AVA increased to 995.2 mM [

81]. The same group published another study focusing on the involvement of α-ketoglutaric acid, where they introduced glutamate oxidase (GOX) from

Streptomyces mobaraensis to lower the demand of α-KG by regenerating its supply, with the addition of a catalase to further enhance the system. Despite these changes, the titer of GA lowered to 468.5 mM [

82].

The whole-cell biocatalysts approach was also explored by Wang et al., who used

E. coli to build a synthetic microbial consortium. In this study, they used two engineered strains to express the

davAB and

gabTD genes separatly, as they realized that these two genes had a negative interaction when placed in a single cell strain. This approach resulted in the production of 43.8 g/L [

83].

In a separate study, Wang et al. established a new pathway by using a ketoacid chain elongation strategy in

E. coli. They extend the TCA cycle intermediate α-ketoglutarate to form α-ketoadipate (α-KA) by introducing three enzymes from

S. cerevisiae: homocitrate synthase, homoaconitase, and homoisocitrate dehydrogenase. After the formation of α-KA, they expressed a α-ketoacid decarboxylase, KivD from

L. lactis, and a semialdehyde dehydrogenase,

gabD from

P. putida, to catalyze the conversion to GA. To optimize this alternative pathway, Wang et al. used CRISPR to silence

sucAB genes from the TCA cycle, in order to increase the supply of the precursor, α-ketoglutarate. This novel pathway resulted in a GA titer of 420 mg/L [

76]. The same research group explored the GA biosynthesis using xylose as a carbon source instead of glucose. They also investigated different metabolic pathways to produce GA and found that a combination of the xylose isomerase and Weimberg pathways yielded the highest titer of 602 mg/L [

29].

Yu et al. proposed an alternative strategy to produce GA in

E. coli, by utilizing α-ketoglutarate in a reported glutaconate biosynthesis pathway. They first formed trans-glutaconyl-CoA by expressing

hgdH,

gctAB, and

hgdC from

A. fermentans, and

hgdAB from

C. symbiosum. This compound can then be converted to form GA using either trans-enoyl-CoA reductase from

E. gracilis (egTer) or

T. denticola (tdTer), along with the

E. coli thioesterase enzymes (

TesB). Using this pathway, the best strain obtained 3.8 mg/L of GA with egTer, although it accumulated a higher amount of glutaconate with 27.7 mg/L [

88].

Another study by Zhao et al. explored the production of GA in

E. coli through the

Thermobifida fusca native reverse adipate degradation pathway (RADP), with the overexpression of five enzymes: Tfu_0875, Tfu_2399, Tfu_0067, Tfu_1647, and Tfu_2576-7. Using this pathway, Zhao et al. attempted to use both acetyl-CoA and malonyl-CoA as precursors for GA. They increased the supply of malonyl-CoA by using the antibiotic, cerulenin, to inhibit a fatty acid synthesis pathway. Additionally, to increase acetyl-CoA, genes encoding for L-lactate dehydrogenase (

ldhA), acetyl-CoA acetyltransferase (

atoB), and formate C-acetyltransferase I (

pflB) were deleted to disrupt competitive pathways and reduce byproduct formation. The resulting yield of GA from this engineered

E. coli strain was approximately 4.8 g/L [

91]. Years later, another study was published extending upon this established pathway. As the previous experiment found a limitation with the supply of malonyl-CoA, Sui et al. introduced the

matB and

matC genes from

Clover rhizobia to convert malonic acid to malonyl-CoA. The addition of malonic acid into this pathway increased the overall titer to 6.3 g/L [

92].

2.5.2. GA Production in

C. glutamicum

C. glutamicum has shown to be an excellent microorganism for the synthesis of amino acids such as lysine and glutamate via fermentation [

87]. As GA biosynthesis requires the catabolism of lysine, the engineering of lysine producing

C. glutamicum was thought to be a promising approach. Rohles et al. conducted a study in

C. glutamicum using strategies similar to those of Park et al. Deletion of the

lysE gene that encodes for the lysine exporter reduced the amount of lysine excretion, resulting in the production of a total 7 g/L of GA [

84]. In a subsequent study, Rohles et al. further refined their approach by using native

gabTD genes and overexpressing a 5-AVA importer,

NCg10464, which would re-import 5-AVA back into the cell to maintain the supply for GA production. Amplifying the transport protein significantly improved the final titer of GA after fed-batch fermentation to 90 g/L, with little to no presence of any known byproduct [

85].

Kim et al. adopted a different strategy, where they used a synthetic promoter H30 to express the

davAB and

gabTD genes to enhance the enzyme activity. Additionally, Kim et al. fused the

davB gene with an N-terminal His6-tag, with the intention of improving its solubility and expression within the cell. As a result, this incorporation led to 24.5 g/L of GA to be produced [

86]. Han et al. continued to optimize the engineered

C. glutamicum strain by overexpressing or deleting 11 different genes (

icd,

ddh,

dapB,

pyc,

dapA,

ppc,

lysA,

lysI,

lysE,

lysC, and

pck) that were found to increase the supply of lysine as the precursor. Additionally, they introduced the gene

ynfM, which encodes for a GA exporter, into the strain, producing a final titer of 105.3 g/L of GA [

30].

Perez-Garcia et al. developed a new pathway that does not require oxygen to produce GA. For this, they employed the use of the transaminase-oxidoreductase pathway to form 5-AVA by heterologous expression of the

patAD and

ldcC genes from

E. coli. To reduce byproduct formation and increase the production of 5-AVA as a precursor, they deleted the transcriptional repressor (

sugR), lactose dehydrogenase (

ldh), N-acetyltransferase (

snA), and diamine exporter (

cgmA). In this study, Perez-Garcia examined the

gabTD genes from three different

Pseudomonas species to produce GA, with the gene from

P. stutzeri performing the best. Additionally, the glutamate biosynthesis pathway was eliminated by deleting the

gdh gene. The final modified

C. glutamicum strain produced 25.2 g/L of GA through fed-batch fermentation [

87].

2.6. Glutaconic Acid

Glutaconic acid is an unsaturated dicarboxylic acid that can be reduced to synthesize GA. As such, it has similar applications, being a precursor to polyamides and other biodegradable polymers [

31]. Currently, the only natural biosynthetic pathway is found in anaerobic organisms such as

Acidaminococcus fermentans and

Clostridium symbiosum, which are capable of removing the ammonia from glutamate to convert into glutaconic acid [

9]. However, since these microbes cannot produce glutaconic acid on an industrial scale, alternative microbial production methods have been developed ().

In prior studies, it has been shown that anaerobic bacteria are capable of converting glutamate to glutaconate in fermentation conditions. From this information, Djurdjevic et al. attempted to modify

E. coli to produce glutaconate by introducing enzymes from those bacteria. Specifically, they heterologously introduced six genes: 2-hydroxyglutarate dehydrogenase (

hgdH), glutaconate CoA-transferase (

gctAB), 2-hydroxyglutaryl-CoA dehydratase (

hgdC) from

A. fermentans, and 2-hydroxyglutaryl-CoA dehydratase (

hgdAB) from

C. symbiosum. When this modified strain was cultivated in an anaerobic medium to replicate the conditions of an anaerobic bacteria, it yielded a glutaconate concentration of approximately 2.7 mM [

31].

Sun et al. conducted another study in which they developed a novel pathway in

E. coli using the estradiol ring catechol degradation pathway. Through this pathway, catechol can be catabolized to ketoacid, 4-oxalocrotonate, which can then be converted to glutaconic acid. Sun et al. first started this experiment by introducing the genes directly involved in this reaction:

C23O and

DmpI from

P. putida, and

DmpC from

R. eutropha. Once 4-oxalocrotonate was reached, KivD from

L. lactis and

gabD from

P. putida are capable of converting it into glutaconic acid. To synthesize catechol, Sun et al. used salicylic acid as the precursor, which required the expression of

nahG to catalyze this bioconversion. Furthermore, the

entC and

pchB genes were also expressed in

E. coli to help produce salicylic acid from glucose. This modified strain resulted in a titer of 35.3 mg/L of glutaconic acid [

93].

2.7. 5-Hydroxyvaleric Acid

5-hydroxyvaleric acid (5-HV), also referred to as 5-hydroxypentanoic acid, is a versatile compound with a wide range of applications. It is used in the production of various materials, such polyurethanes and polyhydroxyalkanoates (PHA) [

32]. In addition, 5-HV serves as a precursor to 1,5-pentanediol. Similar to GA, the current chemical approach primarily relies on furfural derivatives, involving costly substrates and catalysts, and is a highly resource-intensive process [

33]. As of recently, the interest in PHAs have been rising due to its applicability in packaging and in the biomedical industry. Given that 5-HV is a major building block for the material, the interest in its production has risen significantly as well.

In a previous study by Rohles et al., they established an innovative pathway for synthesizing 5-AVA, a valuable precursor to 5-HV, by incorporating the

davAB and

davTD genes from

P. putida into

C. glutamicum. In this study, Sohn et al. attempts to increase the production of 5-HV by building onto this established 5-AVA pathway, while making slight modifications such as introducing an appropriate aldehyde reductase that would efficiently convert glutarate semialdehyde to 5-HV (). In the pathway found by Rohles et al., the absence of 5-HV demonstrated a clear preference in the system's metabolic flux toward GA. To address this issue, Sohn et al. deleted the

gabD gene to eliminate the GA pathway entirely. Despite this deletion, the overall titer of 5-HV did not improve, indicating that further investigation is needed to understand this metabolic flux. Additionally,

yahK gene from

E. coli was used in the final strain as the aldehyde reductase. The culmination of these modifications resulted in an overall titer of 52.1 g/L of 5-HV following fermentation, however, a significant amount of GA remained present [

32].

In contrast, instead of using an engineered

C. glutamicum strain, Chen et al. utilized

E. coli to produce 5-HV. The main pathway is very similar to Sohl et al. with the implementation of the

davAB gene, however, a key difference is the use of a native enzyme, aminobutyrate aminotransferase encoded by

gabT to convert 5-AVA to glutarate semialdehyde. Additionally, Chen et al. screened

yqhD and

yahK genes from

E. coli and

yajO gene from

P. putida for the best aldehyde reductase activity. Although it was found that the

yqhD gene performed the best, a dual vector system was employed, constructing a secondary promoter with

yajO to overexpress the enzyme activity. Chen et al. also introduced genes that encoded for a 5-aminovalerate exporter and a lysine-specific permease,

gabP and

lysP, respectively, to increase the transport rate of key intermediates into the cell. Furthermore, a hok/sok system was introduced to reduce plasmid instability. Despite these changes differing from Sohl et al., the outcome of this study yielded a lower titer of 5-HV at 35.6 g/L [

33].

3. C6 Chemicals

3.1. cis,cis-Muconic Acid

MA is a pivotal six-carbon platform chemical serving as a precursor for a diverse range of polymers used in consumer plastics such as polyurethane and terephthalate [

94,

95]. Furthermore, MA can be converted into AA, which is a building block for nylon-6,6 synthesis [

44]. However, the petroleum-derived production of AA involves carcinogenic substrates and intermediates such as benzene, cyclohexane, cyclohexanol, and cyclohexanone, which cause environmental concerns [

95]. To date, microbial production of MA has been achieved in various chassis microorganisms through several different pathways. Remarkably, this is the only approach for C6 chemical production via ring-fission oxidation of catechol ().

. Overview of metabolic pathways extended from the shikimate pathway. Solid arrows signify direct steps. Dashed arrows represent multiple steps. Red X’s portray genes that are disrupted. Pink pathway corresponds to references [

34,

35,

96,

97,

98,

99,

100,

101,

102]. Purple pathway correlates to reference [

103]. Dark blue pathway corresponds to reference [

104]. Light blue pathway correlates to reference [

105]. Olive pathway corresponds to references [

106,

107]. Dark green pathway correlates to reference [

40]. Orange pathway corresponds to reference [

43]. Black arrows represent steps utilized by multiple pathways. E4P, erythrose-4-phosphate; PEP, phosphoenolpyruvate; DAHP, 3-deoxy-D-arabino heptulosonate-7-phosphate; DHS, 3-dehydroshikimate; CHR, chorismate; PHE, phenylalanine; TYR, tyrosine; TRP, tryptophan; PCA, protocatechuate; 4-HBA, 4-hydroxybenzoic acid; ISO, isochorismate; ANT, anthranilate; 2,3-DHBA, 2,3-dihydroxybenzoic acid; SA, salicylate; CA, catechol; MA,

cis,

cis-muconic acid; AA, adipic acid; HMDA, 1,6- hexamethylenediamine; DHSD, 3-dehydroshikimate dehydratase; PCAD, protocatechuate decarboxylase; CPL, chorismate pyruvate lyase; HBAH, 4-hydroxybenzoic acid hydrolase; ICS, isochorismate synthase; IPL, isochorismate pyruvate lyase; SMO, salicylate 1-monooxygenase; DHBAD, 2,3-dihydroxybenzoic acid decarboxylase; AS, anthranilate synthase; ADO, anthranilate 1,2-dioxygenase; CDO, catechol 1,2-dioxygenase; ER, enoate reductase; CAR, carboxylic acid reductase; TA, transaminase.

3.1.1 MA Production in

E. coli

The earliest reported microbial production of MA was pioneered by Draths and Frost in

E. coli, utilizing glucose as the substrate. The pathway begins with the dehydration of DHS, an intermediate in the shikimate pathway. Subsequently, the conversion of DHS to MA is facilitated by the introduction of

aroZ (encoding DHSD) and

aroY (encoding PCAD) from

K. pneumoniae, as well as

catA (encoding CDO) from

A. calcoaceticus [

96]. Niu et al. optimized this strategy by employing feedback inhibition-insensitive

aroF and integrating

aroZ into the

E. coli chromosome while disrupting

aroE (encoding shikimate dehydrogenase) to prevent the consumption of DHS. These improvements resulted in the production of 36.8 g/L of MA under fed-batch fermentation conditions [

97]. Further enhancements involved the disruption of

ptsG (encoding phosphoenolpyruvate phosphotransferase) and

pykA (encoding pyruvate kinase 2) to increase phosphoenolpyruvate (PEP) availability and the disruption of

tyrR (a tyrosine dependent transcriptional regulator) to prevent the negative transcriptional control of

aroG and

aroF. Moreover,

aroB (encoding DHQ synthase),

aroD (encoding DHQ dehydratase),

galP (encoding D-galactose transporter),

ppsA (encoding PEP synthase),

aroG (encoding DAHP synthase),

aroF (encoding DAHP synthase), and codon-optimized

asbF (encoding DHS dehydratase) were overexpressed, leading to the production of 64.5 g/L of MA through fed-batch fermentation [

34]. In addition to the single culture process, Zhang et al. reported coculture strategies with two separate

E. coli strains, each carrying a portion, or the full MA pathway reported by Draths and Frost. A transporter protein encoded by

shiA was employed to facilitate the cross-membrane transportation of the intermediate DHS. The optimized cocultures utilized glycerol as the substrate and produced 2 g/L with a batch bioreactor [

108]. This group also devised another coculture strategy that utilized two engineered

E. coli strains, one of which utilized glucose while the other utilized xylose, resulting in the production of 4.7 g/L of MA from a mixture of glucose and xylose in a bioreactor [

109]. Fujiwara et al. employed a parallel metabolic pathway engineering approach by simultaneously expressing the Dahms pathway from

Caulobacter crescentus alongside a MA biosynthesis pathway. The primary goal of this strategy was to direct the host organism’s metabolic processes in such a way that glucose was exclusively utilized for MA synthesis, while xylose was allocated for biomass production. For this purpose,

eda,

ppsA,

ppc, and

pck disruptions were incorporated to prevent the intermediates generated through glycolysis from entering the TCA cycle which yielded 4.09 g/L of MA using minimal media [

103].

Instead of diverting DHS from the shikimate pathway to produce MA, Lin et al. utilized chorismate (CHR) as a precursor and introduced

entC (encoding ICS),

pchB (encoding IPL), codon-optimized

nahG (encoding SMO), and

catA (encoding CDO) into an engineered phenylalanine overproducing

E. coli strain QH4 with

pheA and

tyrA disrupted. To further optimize the process,

aroL (encoding shikimate kinase),

ppsA,

tktA (encoding transketolase), and feedback-inhibition resistant

aroG were overexpressed to increase the availability of CHR, leading to the production of 1453.64 mg/L of MA in shake flasks [

110]. Fujiwara et al. explored the expression of an AroC-MenF fusion protein to increase the availability of intermediates while expressing the MA biosynthetic pathway previously established by Lin et al. Fusion proteins enhance reaction efficiency by maintaining enzymes in close proximity to one another, facilitating a smoother transfer of intermediates between their respective enzymes. This strategy achieved a production 4.45 g/L of MA under pH-controlled jar fermenter conditions [

111].

Inspired by the ubiquinone pathway, Sengupta et al. devised the conversion of 4-HBA into MA by expressing

ubiC (encoding CPL),

pobA (encoding HBAH),

aroY, and

catA. To increase the availability of precursors,

ptsH,

ptsI, and

crr, which code for proteins involved in the phosphotransferase system (PTS), and

pykF (pyruvate kinase 1) were deleted from the

E. coli genome. These modifications resulted in the production of 170 mg/L of MA [

104].

Additionally, Sun et al. reported the production of 389.96 mg/L of MA by hybridizing the tryptophan biosynthesis and anthranilate degradation pathways, which was achieved by expressing

trpEG (AS), ADO from

P. aeruginosa, and CDO from

P. putida. The

trpD gene was deleted to prevent the formation of tryptophan, which would otherwise consume anthranilate [

105]. Yan and Zheng groups produced 480 mg/L and 605.18 mg/L of MA, respectively, by connecting 2,3-DHBA biosynthesis with its degradation pathway.

EntCBA, DHBAD from

K. pneumoniae, and CDO from

P. putida were expressed while

entE was knocked out to prevent the consumption of 2,3-DHBA [

106,

107].

. Schematic of biosynthesis pathways for MA and AA production that utilize lignin-derived feedstocks. Solid arrows signify direct steps. Dashed arrows represent multiple steps. Red X’s portray enzymes that are disrupted. Dark green pathway correlates to reference [

37]. Orange pathway corresponds to reference [

38]. Pink pathway correlates to reference [

112]. Dark blue pathway corresponds to references [

113,

114]. Purple pathway correlates to reference [

41]. Black arrows represent steps utilized by multiple pathways. 4-HBA, 4-hydroxybenzoic acid; PCA, protocatechuate; CA, catechol; MA,

cis,

cis-muconic acid; AA, adipic acid; CRP, catabolite repression protein; HBAH, 4-hydroxybenzoic acid hydrolase; DHBAD, 2,3-dihydroxybenzoic acid; CDO, catechol 1,2-dioxygenase; ACT, adipoyl-CoA thioesterase; MCI, muconate cycloisomerase.

3.1.2. MA Production in

S. cerevisiae

Curran et al. pioneered the production of MA in

S. cerevisiae by introducing codon optimized DHSD from

Podospora anserina, PCAD from

Enterobacter cloacae, and CDO from

Candida albicans, creating the MuA12 strain. Furthermore, this strain harbors

aro3 and

zwf1 knockouts and overexpresses

tkl1 and feedback-resistant

aro4 to increase the flux of precursors. They achieved a production of 141 mg/L of MA in a shake flask culture [

98]. Suastegui et al. further refined the MuA12 strain by incorporating

aroZ from

P. anserina,

aroY from

K. pneumoniae, HQD2 gene (CDO) from

C. albicans, and

tkl1, resulting in 559.5 mg/L of MA [

99]. Leavitt et al. employed an adaptive laboratory evolution and rational metabolic engineering strategy for MA production. An aromatic amino acid-overproducing

S. cerevisiae strain was employed due to the innate ability to synthesize greater amounts of shikimate pathway intermediates. This strain was selected through anti-metabolite selection. Its derivative strain MuA-5.01.1.02+aro1t+scPAD1 produced 2.1 g/L of MA in a fermentor [

100].

Wang et al. engineered the endogenous shikimate pathway in

S. cerevisiae to produce 20.8 g/L of MA using a biosensor-aided genome engineering approach. The MA-responsive biosensor BenM was used to identify cells with enhanced MA production capabilities due to the presence of multiple copies of AroY.B and AroY.Ciso, which encode functional subunits of PCAD from

K. pneumoniae. Restoring

URA3 prototrophy, introducing Aro1p

ΔE, Aro4p, and additional copies of PaAroZ and CaCatA were found to increase MA yields [

35].

Suastegui et al. disrupted Ric1, a transcriptional repressor of several genes in the aromatic amino acid pathway and overexpressed

RKI1 (encoding ribose-5-phosphate isomerase), which promotes the accumulation of E4P and flux redirection into the aromatic amino acid pathway. These modifications in addition to the introduction of a non-native MA biosynthesis pathway resulted in 2.7 g/L of MA [

101]. Liu et al. overexpressed an MA biosynthesis pathway alongside a xylose fermentation pathway to facilitate the production of MA using glucose and xylose as carbon sources. Specifically, the xylose isomerase gene from

Bacteroides valgutus, pentose phosphate pathway genes from

S. cerevisiae,

Aro1 with an

AroE stop codon, and feedback inhibition-resistant

Aro4opt were expressed. The addition of CA to the media increased MA titer to 1286 mg/L, surpassing the yield obtained when culturing with only glucose and xylose [

102].

3.1.3. MA Production in

C. glutamicum

The superior amino acid production capabilities of

C. glutamicum suggest its suitability for the production of MA via the aromatic amino acid pathway [

115]. Becker et al. engineered

C. glutamicum to produce MA by deleting

catB (MCI) and overexpressing

catA. Endogenous

BenABCD and

Phe facilitate the degradation of benzoate and phenol, respectively, enabling the organism to utilize lignin as a carbon source (). When cultivated in the presence of CA, the created MA-2 strain produced the highest reported titer of 85 g/L of MA in 60 h [

37]. Lee et al. introduced a previously established DHS-derived MA biosynthetic pathway in

C. glutamicum and engineered the endogenous shikimate pathway. This was achieved by disrupting

aroE, along with

cg1835 (encoding shikimate dehydrogenase),

pcaGH (encoding PCA dioxygenase alpha/beta subunits), and

catB (encoding MCI) to prevent carbon flow into the TCA cycle. Codon-optimized

aroY and

kpdBD (encoding 4-HBA decarboxylase from

K. pneumoniae) was overexpressed to convert PCA into CA, which was subsequently converted to MA, achieving a production of 54 g/L of MA from a 50 L fed-batch fermentation [

115]. Shin et al. aimed to increase the availability of PEP, which is a precursor in the shikimate pathway. Introducing a Δ

ptsI knockout prevents the PTS system from consuming PEP at the cost of limiting cell growth. To address this limitation,

iolR, which encodes a transcriptional regulator, was inactivated. Additionally,

qsuB,

aroY, and

kpdBD were overexpressed to facilitate the conversion of DHS to MA, resulting in 4.5 g/L of MA [

116].

3.1.4. MA Production by Other Microorganisms

Amycolatopsis sp. ATCC 39116 is capable of the natural production of MA on a micro-scale and favors lignin-based aromatic compounds such as CA, guaiacol, phenol, toluene,

p-coumarate, and benzoate as carbon sources over sugar. Barton et al. deleted AATC3_02010018510, which encodes a putative MCI, to promote the accumulation of MA. Using guaiacol as the feedstock, 3.1 g/L of MA was produced in a fed-batch fermentor [

38].

P. putida KT2440 exhibits native production of MA via the CA branch of the β-ketoadipate pathway (). To optimize MA production, Vardon et al. aimed to funnel both the PCA and CA branch carbon fluxes towards MA production. This was achieved by disrupting

pcaHG and

catBC, which prevents PCA and CA progression through the β-ketoadipate pathway.

aroY,

dmpKLMNOP (encoding phenol hydroxylase), and

asbF were introduced to further accumulate CA. This strategy produced 13.5 g/L of MA after 78.5 h using lignin-derived compounds as the starting materials [

112]. By expressing codon-optimized

AroY and its subunits

EcdB and

EcdD from

E. cloacae, 15.59 g/L of MA was produced in fed-batch conditions supplemented with

p-coumarate and glucose [

113]. Subsequent deletion of the CRP reduced accumulation of the precursor 4-HBA and increased MA production from

p-coumarate by 70% and doubled from ferulate [

114]. Another strategy involved the overexpression of

catA and

catA2 along with

catBC,

endA-1, and

endA-2 (both encoding endonucleases) knockouts, which achieved an MA titer of 64.2 g/L from lignin-derived catechol [

36].

3.2. Adipic Acid

AA, also known as hexanedioic acid, is a derivative of MA with a wide variety of applications in the production of nylon-6,6, polyurethanes, lubricant components, polyester polyols, and food additives [

117]. However, the conventional chemical synthesis of AA involves benzene, which yields harmful byproducts such as cyclohexane, cyclohexanol, and cyclohexanone, which are not only carcinogenic but also pose environmental contamination risks [

117]. To address these concerns, a benzene-free bio-based approach was developed that utilizes glucose as the feedstock [

96].

. Overview of biosynthetic pathways extended from the TCA cycle for the production of C6 chemicals. Solid arrows signify direct steps. Dashed arrows represent multiple steps. Red X’s portray genes that are disrupted. Light blue and orange pathways correspond to reference [

44]. Purple pathway correlates to reference [

46]. Pink pathway corresponds to reference [

39]. Light purple pathway correlates to reference [

118]. Dark green pathway corresponds to references [

47,

48,

49,

50]. Dark blue pathway correlates to reference [

59]. Black arrows represent steps utilized by multiple pathways. MVL, β-methyl-δ-valerolactone; ACA, 6-aminocaproic acid; AA, adipic acid; KivD, α-ketoisovalerate decarboxylase; ADH, alcohol/aldehyde dehydrogenase; AtoB, acetyl-CoA acetyltransferase; BktB, β-ketothiolase; HBD, 3-hydroxybutyryl-CoA dehydrogenase; CRT, crotonase; TER,

trans-enoyl-CoA reductase; KCT, β-ketoadipyl-CoA thiolase; HAD, 3-hydroxyadipyl-CoA dehydrogenase; ECH, enoyl-CoA hydratase; HCR, hexenoyl-CoA-reductase; TA, transaminase.

3.2.1. AA Production in

E. coli

Joo et al. explored the capability of ERs from a variety of microorganisms to reduce the double bond(s) in MA and 2-hexenedioic acid to produce AA in

E. coli. Notably, ER from

Bacillus coagulans (ER-BC) had an in vivo substrate conversion rate of 94.3% for MA and 99% for 2-hexenedioic acid after 24 h [

119].

Zhao et al. reconstructed the reverse adipate-degradation pathway from

T. fusca in

E. coli by overexpressing the genes Tfu_0875, Tfu_2399, Tfu_0067, Tfu_1647, Tfu_2576, and Tfu_2577 (). Initially, this yielded 0.3 g/L of AA in suboptimal broth. To remove competing pathways,

ldhA (encoding lactate dehydrogenase),

sucD (encoding succinyl-CoA synthase alpha subunit), and

atoB were deleted. After optimizations, 68.0 g/L of AA was produced using fed-batch fermentation [

39].

3.2.2. AA Production by Various Microorganisms

Raj et al. reported the production of 2.59 mg/L of AA in

S. cerevisiae utilizing glucose as the starting material. An MA biosynthesis pathway was introduced. Subsequently, ER-BC was overexpressed to complete the conversion of MA into AA. However, CDO necessitates oxygen as a substrate while ER-BC requires anaerobic conditions for functional maturation. This challenge was addressed through a three-stage fermentation process.

S. cerevisiae was initially cultivated under aerobic conditions to achieve the desired cell density. Thereafter, anaerobic conditions were created to facilitate the functional formation of ER-BC. Finally, the process reverted to aerobic conditions to complete AA production [

40].

Niu et al. designed an AA biosynthesis pathway that harnessed both endogenous and heterogenous enzymes within

P. putida KT2440. This pathway effectively converted lignin-derived aromatic compounds into either PCA or CA, which were then funneled into the β-ketoadipate pathway. The native enzymes

pcaIJ and ACT, coupled with the overexpression of

paaH,

paaF, and

ter, and the deletion of

pcaF and

paaJ facilitated the production of 2.5 g/L of AA under fermentor-controlled conditions [

41].

Since

Pseudomonas taiwanensis VLB120 possesses high tolerance to highly toxic substrates such as cyclohexane, Bretschneider et al. introduced a heterologous biosynthesis pathway to produce HHA from cyclohexane. Cytochrome P450 monooxygenase (CPMO), cyclohexanol dehydrogenase (CHD), cyclohexanone monooxygenase (CHMO), and lactonase (Lac) from

Acidovorax sp. CHX100 were expressed to produce HHA. Additionally, ADH and aldehyde dehydrogenases (AldDH) from

Acidovorax sp. CHX100 were overexpressed to complete the conversion of HHA to AA, producing 10.2 g/L of AA under fed-batch conditions [

42].

3.3. 1,6-Hexamethylenediamine (HMDA)

HMDA, also named 1,6-hexanediamine or 1,6-diaminohexane, serves as a precursor for the production of nylon-6,6 and various resins [

44,

120]. Beyond its application in nylon production, HMDA is also utilized in the textile and water treatment industries [

120]. So far, some whole-cell bioconversion approaches were reported for its production.

Wang et al. engineered a strategy in which a CAR and TA enzyme cascade is employed to produce HMDA in

E. coli, using AA as the feedstock. This work tested the use of a variety of CARs and TAs, each that utilize their respective substrates. The strain with the highest HMDA titer, DAH86, expressed CARs from

Mycobacterium smegmatis MCS 155 (MSM CAR) and

Mycobacteroides abscessus (MAB CAR), and TAs from

Silicibacter pomeroyi (SPTA) and

E. coli (PatA), resulting in the production of 53.11 mg/L of HMDA. Since CARs are NADPH-dependent enzymes,

sthA, which encodes a transhydrogenase responsible for the conversion of NADH to NADP, was disrupted to increase the availability of NADPH. This modification raised the titer to 238.5 mg/L in a shake-flask culture [

43]. A patent converted (S)-2-amino-6-oxopimelate, an intermediate of the lysine biosynthesis pathway, into HMDA in six steps [

121]. An alternative approach converted acetyl-CoA into HMDA in polyhydroxyalkanoate-accumulating bacteria by utilizing CoA-dependent elongation or analogous enzymes associated with carbon storage pathway [

122].

3.4. 6-Aminocaproic Acid (ACA)

ACA, also known as 6-aminohexanoic acid, serves as a precursor for nylon-6 and is used in the medical field as an antifibrinolytic drug [

123]. The current chemical synthesis of ACA is done by ring fission of caprolactam, a derivative of benzene [

44]. Microbial synthesis approaches were developed through carbon chain elongation cycles.

Turk et al. devised two pathways to produce ACA in

E. coli, utilizing glucose as the substrate. The first synthetic pathway was inspired by the adipyl-CoA route which involves the combination of succinyl-CoA and acetyl-CoA to produce 3-oxoadipyl-CoA which is subjected to further reduction. However, conversion rates for this strategy were found to be below 5%. The second strategy is based on the branched-chain amino acid degradation pathway which occurs in methanogenic archaea, referred to as the α-ketopimelate route. In this pathway, α-ketoacids are decarboxylated into their corresponding aldehydes.

NifV from

Azotobacter vinelandii, codon-optimized

aksD,

aksE, and

aksF from

Methanococcus aeolicus,

vfl from

Vibrio fluvialis, and

kdcA from

Lactococcus lactis were introduced. Due to the oxygen-sensitive nature of

aksE and

aksE, special considerations were made during fed-batch fermentation, ultimately resulting in the production of 160 mg/L of ACA [

44]. An alternative approach yielded 24.12 mg/L of ACA from lysine via a sequence of carbon-chain-extension cycles involving condensation, isomerization, oxidation, and decarboxylation reactions which were catalyzed by the enzymes

LeuABCD and

PadA from

E. coli MG1655,

RaiP from

Scomber japonicas, and KivD from

L. lactis [

118]. A patent reported a yield of 4783 mg/kg of ACA when expressing

vfl from

V. fluvialis,

kdcA from

L. lactis, and TA from

P. aeruginosa in

S. cerevisiae [

45]. Another patent reported a strategy that converts (S)-2-amino-6-oxopimelate, a lysine biosynthesis pathway intermediate, into ACA in four steps [

121].

Additionally, Bretschneider et al. reported a mixed species strategy that allows the ACA production from cyclohexane.

P. taiwanensis strains carrying the upstream cascade converting cyclohexane to 6-hydroxyhexanoic acid (HHA) and

E. coli strains carrying ADH and ω-TA responsible for downstream conversion of HHA into ACA, were co-cultured to circumvent complications when expressing the whole pathway in a single species, which were likely caused by improper folding of enzymes and high metabolic burden. This approach led to an 86% yield and 7.7 U g

−1 CDW of the initial formation rate of ACA [

124].

3.5. β-methyl-δ-valerolactone (MVL)

Polyurethanes (PUs) are compounds with versatile applications in adhesives, sealants, elastomers, and foams [

59]. Like most polymers, PUs are petroleum-derived and non-biodegradable material [

125]. To lessen the environmental impact, efforts have been made to develop alternatives that are biodegradable or derived from renewable materials. MVL is a C6 compound that is used to create precursors for recyclable PUs [

46]. Poly(MVL) is a rubbery polyester that can be produced by ring-opening polymerization of MVL, which is then incorporated into PUs [

126]. MVL can be produced microbially, which is more environmentally friendly than traditional chemical synthesis methods [

46].

Xiong et al. established a total biosynthesis pathway for the production MVL in

E. coli utilizing glucose as the substrate by combining the mevalonate pathway with the fungal siderophore biosynthesis pathway (). Overexpression of endogenous

atoB (encoding acetyl-CoA acetyltransferase), and

MvaS (encoding HMG-CoA synthase) and

MvaE (HMG-CoA reductase) from

Lacticaseibacillus casei lead to the accumulation of 14.6 g/L and 88 g/L of mevalonate in shake flasks and bioreactors, respectively. However, MVL biosynthesis was limited to 270 mg/L due to the less efficient downstream pathway even though the codon-optimized

sidI (acyl-CoA ligase) and

sidH (enoyl-CoA hydratase) from

A. fumigatus in addition to mutant

YqjM with C26D and I69T mutations from

B. subtilis were expressed. Additionally, a semisynthetic approach was developed to produce MVL through biosynthesizing mevalonate followed by chemical conversion of mevalonate to MVL [

46].

3.6. 1-Hexanol

1-Hexanol, a versatile chemical compound, finds broad applications in biofuels, solvents, plasticizers, pesticides, flavorings, and as a building block for chemical synthesis [

49]. 1-Hexanol has a higher cetane number and energy density than short-chain alcohols such as 1-butanol, which make it an attractive option to blend into diesel [

127]. Furthermore, 1-hexanol can be converted into 1-hexene, which can be utilized as a platform chemical for the production of jet fuel [

128]. 1-Hexanol is currently synthesized using petroleum-based routes that require harsh reaction conditions [

129]. To reduce the dependency on fossil fuels and unsustainable processes, efforts have been made to research the production of alternative and renewable fuels.

Zhang et al. reported the extension of the Ehrlich pathway, redirecting 2-keto acid intermediates from amino acid biosynthesis pathways towards alcohol synthesis, yielding 38.4 mg/L of 1-hexanol in

E. coli using glucose as the starting material.

ThrABC facilitates the production of threonine which is subsequently converted into 2-KB by

TdcB. G462D, S139G, and H97A mutations were introduced to LeuA which results in larger binding pockets and allows for chain elongation to occur by

LeuABCD. 2-KB is eventually elongated to form 2-ketoheptanoate. Subsequently, ADH VI from

S. cerevisiae and KivD from

L. lactis with V461A and F381L mutations converts 2-ketoheptanoate to 1-hexanol [

59].

Dekishima et al. expanded a CoA-dependent 1-butanol pathway that converts glucose into 1-hexanol in 9 steps in

E. coli. The 1-butanol pathway involves the expression of AtoB, BtkB, HBD, CRT, TER, and ADH from various organisms. BtkB from

Ralstonia eutropha has the ability to add 2 carbons onto the chain of acetoacetyl-CoA which provides the base for 1-hexanol production. The titer can be raised by overexpressing formate dehydrogenase from

C. boidinii, which increases the availability of NADH, a cofactor required for reducing enzymes. This method produced 47 mg/L of 1-hexanol after 48 h [

47]. Similarly, another strategy utilizes

Clostridium saccharoperbutylacetonicum due to its ability to convert sugars into acids, such as acetate. THL, HBD, CRT, and BCDH with electron-transferring flavoprotein A and B were all overexpressed to enable the elongation of acetyl-CoA, yielding 5.2 mM of 1-hexanol [

48]. Following a similar route, Lauer et al. engineered

Clostridium ljungdahlii since it can utilize gaseous substrates such as CO

2 and H

2 through the Wood-Ljungdahl pathway. The

C. kluyveri genome encodes at least 2 versions of THL, CRT, HBD, and BCHD. Both were grouped into separate operons:

thlA1,

crt1,

bcd1,

etfB1,

etfA1, and

hbd1, as well as

thlA2,

crt2,

bcd2,

etfB2,

etfA2, and

hbd2, which were subsequently integrated into the genome. Additionally,

adhE2 (encoding a bifunctional aldehyde-alcohol dehydrogenase) from

C. acetobutylicum were included to complete the biosynthesis of 1-hexanol. To address the low abundance of enzymes observed,

hbd,

thl,

crt,

bcd,

etfB,

etfA, and

hbd from

C. carboxidivorans were further integrated, producing 393 mg/L of 1-hexanol under fermentation conditions [

49].

Diender et al. explored the usage of a synthetic co-culture of

Clostridium autoethanogenum and

C. kluyveri fueled by syngas.

C. autoethanogenum can convert syngas into ethanol and acetate, which serve as main substrates while

C. kluyveri utilizes its native reverse β-oxidation metabolism for chain elongation. Together, these microbes are capable of producing 2.0 mmol/L/day of 1-hexanol [

50]. Oh et al. optimized the syngas fermentation conditions for the production of 1-hexanol using

C. carboxidivorans P7, attaining a production 2.34 g/L of hexanol [

51].

Hashem et al. reported the production of 8 mM of 1-hexanol in

Komagataella phaffii using linoleic acid as the substrate. Inspired by the synthesis of green leaf volatiles in plants, a lipoxygenase and hydroperoxide lyase from

Pleurotus sapidus and

Medicago truncatula, respectively, was expressed to produce hexanal. Subsequently, an endogenous ADH/aldo-keto reductase converts hexanal to 1-hexanol [

52].

3.7. ε-Caprolactone, 6-Hydroxyhexanoic Acid, and 1,6-Hexanediol

CL, HHA, and HDO hold applications in the production of important polymers such as polycaprolactone and nylon 66. Currently, the microbial synthesis of CL, HHA, and HDO mainly relies on the bioconversion of cyclohexane and cyclohexanol, which are nonrenewable substrates derived from petroleum [

56].

Mallin et al. devised a method to produce 600 mg/L of CL from cyclohexanol in

E. coli. A tailored PDH with a substrate loop from

Rhodobacter sphaeroides and the thermostable scaffold of PDH from

Deinococcus geothermalis converts cyclohexanol into cyclohexanone. CHMO from A. calcoaceticus subsequently produces CL from cyclohexanone. Initially, the PDH mutant suffered from poor expression rates. To remedy this, chaperones were co-expressed and found to increase the expression of PDH 4.9-fold. To increase conversion rates, the redesigned PDH and CHMO were co-immobilized on RelizymeTM HA403 to promote enzymatic stability. While immobilization offered certain advantages in terms of enzyme stability, it resulted in lower conversion rates, achieving only 34% efficiency compared to the 83% conversion rate observed when utilizing free enzymes [

53].

Srinivasamurthy et al. reported the production of HHA in

E. coli utilizing cyclohexanol as the feedstock. ADH and CHMO were overexpressed simultaneously allowing for the recycling of cofactors NADP+/NADPH. ADH catalyzes the conversion of cyclohexanol to cyclohexanone, followed by the conversion of cyclohexanone to CL by CHMO. Product inhibition of CHMO caused by the formation of CL was addressed by the use of lipase CAL-B to hydrolyze CL, leading to the production of 20 g/L of HHA under fed-batch fermentation conditions [

54]. Bretschneider et al. designed a cyclohexane-based HHA biosynthesis pathway in

P. taiwanensis. CPMO, CHD, CHMO, and Lac were overexpressed to produce 3.3 g/L of HHA in a bioreactor [

55]. Following a similar strategy, Salamanca et al. utilized

Acidovorax sp. CHX100, which inherently possesses a cyclohexane degradation pathway. To promote the accumulation of HHA, the gene encoding 6-hydroxyhexanoate dehydrogenase was deleted, resulting in the synthesis of 4.92 mM of HHA in 6 h [

56].

Zhang et al. engineered a 3-module system to synthesize 1,6-HDO in

E. coli using cyclohexane as the feedstock. Each module was expressed in a separate strain to facilitate redox self-sufficiency. Module 1 converts cyclohexane into cyclohexanol via CPMO. Module 2 utilizes ADH, Baeyer-Villiger monooxygenase, and Lac to synthesize cyclohexanone from cyclohexanol. Module 3 completes the synthesis of 1,6-HDO through the usage of CAR, aldo-keto reductase, and glucose dehydrogenase. 13 mM of 1,6-HDO was produced from 30 mM substrate concentration without the accumulation of intermediates [

57].

4. Discussion and Conclusions

C5 and C6 molecules are important and valuable chemicals for the polymer, pharmaceutical, and biofuel industries. As the demand for these compounds continues to rise, research efforts have been dedicated to developing methods for the efficient and low-cost production of these compounds. However, current chemical synthesis strategies lead to adverse environmental repercussions such as the emission of greenhouse gases and pollution, promoting expanded research into more sustainable methods.

Bio-based routes that utilize microbial production of value-added chemicals have great potential to address concerns of climate change and petroleum depletion. This is because these microorganisms can be engineered to convert renewable feedstock, such as glucose, glycerol, xylose, lignin, and syngas into desired compounds. These modifications include: (a) expanding or combining natural metabolic pathways; (b) design and construction of non-natural/artificial pathways; (c) deleting competing pathways to redirect metabolic flux; (d) modifying enzymes to improve substrate scope and/or catalytic efficiency; (e) cultivating co-cultures to reduce the metabolic burden of overexpressing multiple genes; (f) employing synthetic biology tools to optimize native and artificial pathways; (g) optimization of the fermentation process, through combinational approaches.

While the microbial production of C3 and C4 compounds benefits from the abundance of C2-C5 metabolites inherently produced in host cells, the biosynthesis of C5 and C6 chemicals poses challenges due to the lack of natural C5-C7 precursors. Creative solutions to this issue involve chain extension, condensation, and ring fission reactions catalyzed by various enzymes. Chain extension reactions are employed to elongate the carbon backbones of molecules, which expands the range of products that can be biosynthesized from shorter-chain compounds. Condensation reactions involve the combination of two separate molecules into a single molecule, which provides a viable alternative for utilizing short chain chemicals to produce longer carbon backbones. In ring fission reactions, the cyclic structures of aromatic compounds are linearized to serve as carbon-chain backbones for C5 and C6 chemicals. These strategies illustrate the versatility of metabolic engineering approaches in manipulating microbial pathways to produce C5 and C6 compounds from more readily available starting materials, overcoming the limitations imposed by the scarcity of suitable native precursors.