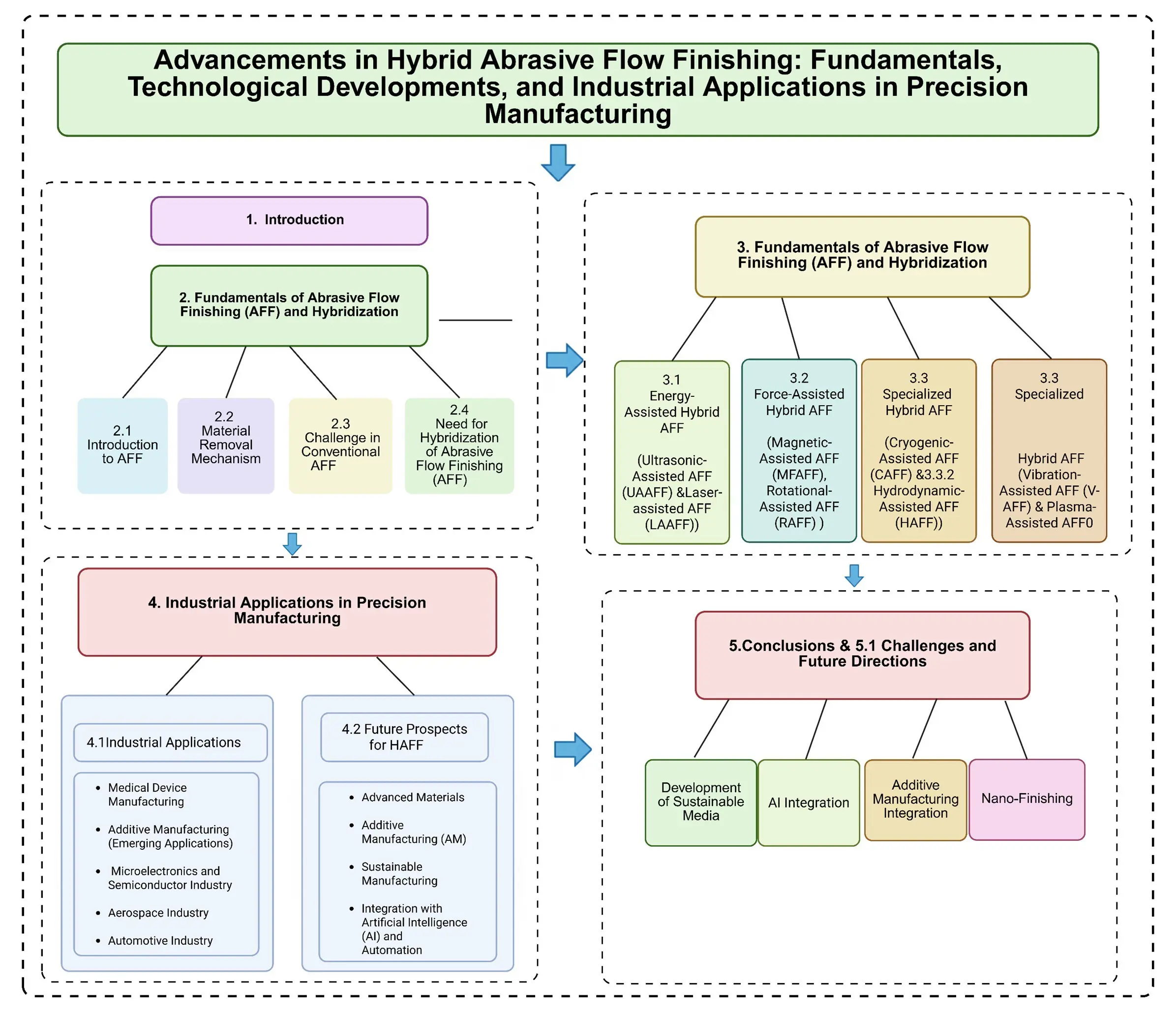

Advancements in Hybrid Abrasive Flow Finishing: Fundamentals, Technological Developments, and Industrial Applications in Precision Manufacturing

Received: 04 September 2025 Revised: 11 October 2025 Accepted: 29 October 2025 Published: 14 November 2025

© 2025 The authors. This is an open access article under the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).

1. Introduction

Precision in surface finishing forms a cornerstone of advanced production techniques, confirming that assemblies satisfy the intense operational and longevity criteria upheld in domains ranging from aviation and vehicle engineering to medical implants, semiconductor production, optical components, and renewable energy systems. These industries require not only impeccable surface finishes but also geometrical intricacies to ensure the optimal functioning of components in high-stress environments. The quest for improved methods to refine such components has led to the evolution of Abrasive Flow Finishing (AFF) and its hybrid forms, addressing long-standing challenges in material removal rates (MRR), surface consistency, and the handling of complex geometries. These fields require components with outstanding surface quality and intricate geometries to ensure superior performance, reliability, and longevity [1,2].

Outer layer properties, including texture irregularities, sliding drag, abrasion durability, and cyclic load endurance, transcend superficial visual elements to act as essential operational metrics that dictate the operational efficacy, steadfastness, and service lifespan of premium-grade engineering assemblies [3,4,5,6,7,8,9,10]. The evolution of innovative materials, including high-strength alloys, ceramic blends, and layered composites, has significantly boosted their structural resilience, yet it introduces fabrication hurdles due to their exceptional rigidity, fragility, and rapid tool degradation. These challenges emphasize the necessity for cutting-edge outer-layer refinement techniques to address the stringent requirements of today’s industrial production [11,12,13,14]. Recent advancements in sustainable machining, such as robot grinding and energy-assisted techniques, further highlight the need for innovative hybrid processes like HAFF [15,16,17]. Recent advancements, such as those in 2025, demonstrate enhanced MRR for hard alloys under hybrid conditions [18]. While traditional surface-finishing techniques are effective for simpler geometries, they face limitations with complex internal features or advanced materials. Grinding, for instance, is effective for hard materials but generates high temperatures that compromise the surface integrity. Similarly, honing and lapping are limited to flat or cylindrical surfaces, often proving inefficient for intricate geometries or challenging materials [14,19,20]. Innovations in smart manufacturing, including deep learning for demand forecasting and cutting power models for aerospace materials, support the integration of AI and predictive tools in hybrid finishing [21,22,23]. Conventional fabrication paradigms are impeded by suboptimal material removal rates (MRR), labor-intensive operational configurations, and protracted production timelines, collectively exacerbating cost escalations. To mitigate these impediments, innovative machining modalities, including Abrasive Flow Finishing (AFF), Magnetic Abrasive Finishing (MAF), and Magnetorheological Finishing (MRF), have been engineered. These state-of-the-art methodologies leverage finely granulated abrasives, whether in unbound or consolidated form, to achieve exceptional surface topographies while mitigating thermal and mechanical degradation [24,25]. Value Engineering (VE) plays a crucial role in optimizing these processes by systematically analyzing functions to reduce costs without compromising quality, as demonstrated in recent reviews [26,27,28]. For instance, VE approaches integrated with hybrid finishing can enhance innovation by identifying cost-effective energy modalities and sustainable media [29,30]. Sustainable production lines and endurance modeling for components such as heat exchangers and capacitors align with HAFF’s focus on reliability and eco-friendly practices [31,32]. Despite their efficacy, these non-conventional processes have limitations, such as limited control over abrasive interactions and extended finishing times, highlighting the need for further technological advancements in areas like catastrophic infrastructure recovery and asset management [33,34]. Despite their efficacy, these non-conventional processes have limitations, such as limited control over abrasive interactions and extended finishing times, highlighting the need for further technological advancements [35,36].

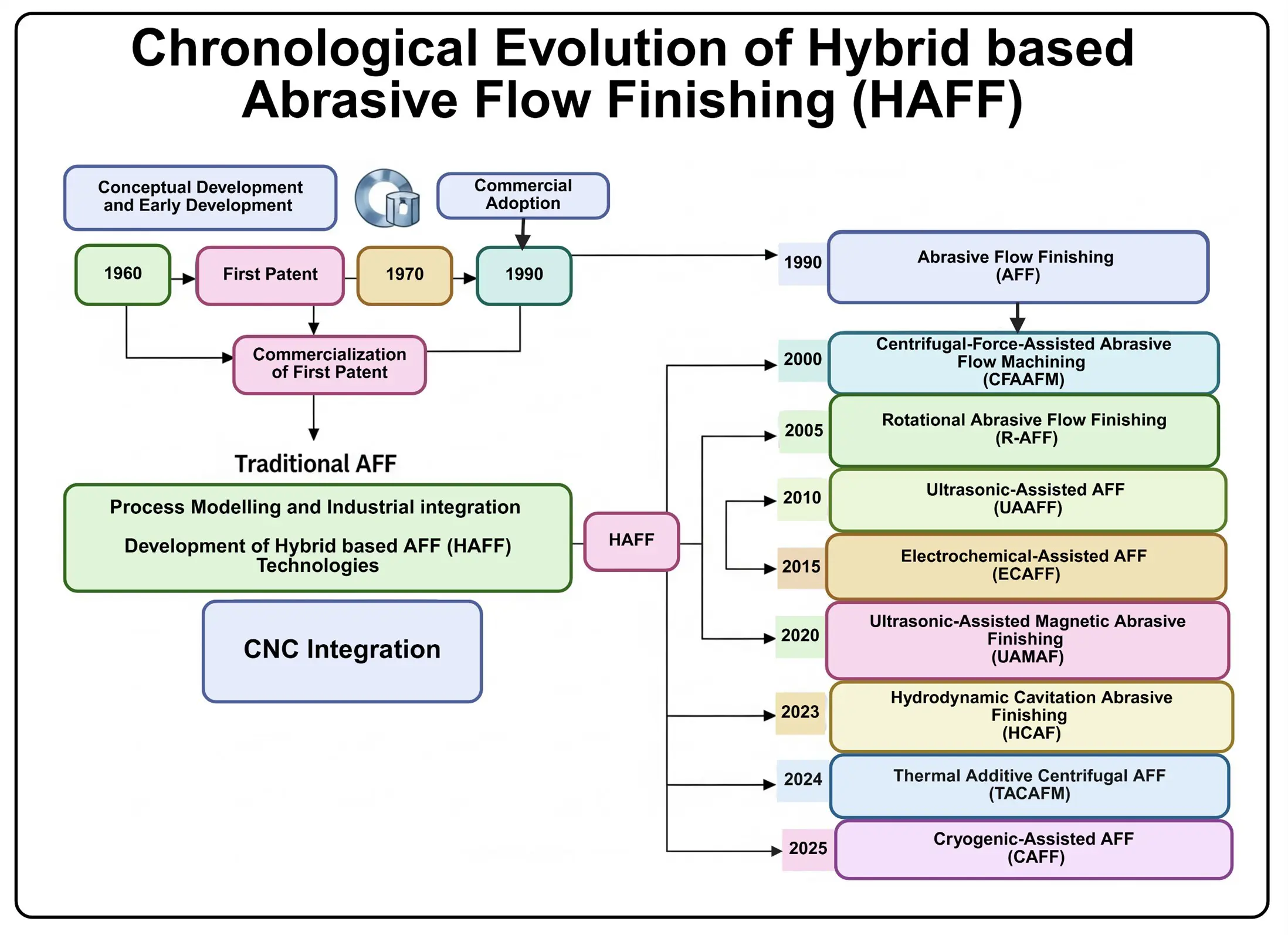

AFF has emerged as a transformative innovation, adeptly surmounting the limitations inherent to both traditional and non-standard finishing methodologies. Originating in the 1960s through the pioneering efforts of the Extrude Hone Corporation, AFF employs a viscoelastic matrix embedded with abrasive particles, which is methodically propelled across or within workpiece surfaces. This controlled displacement facilitates precise material excision, yielding superior surface quality [37,38,39,40].

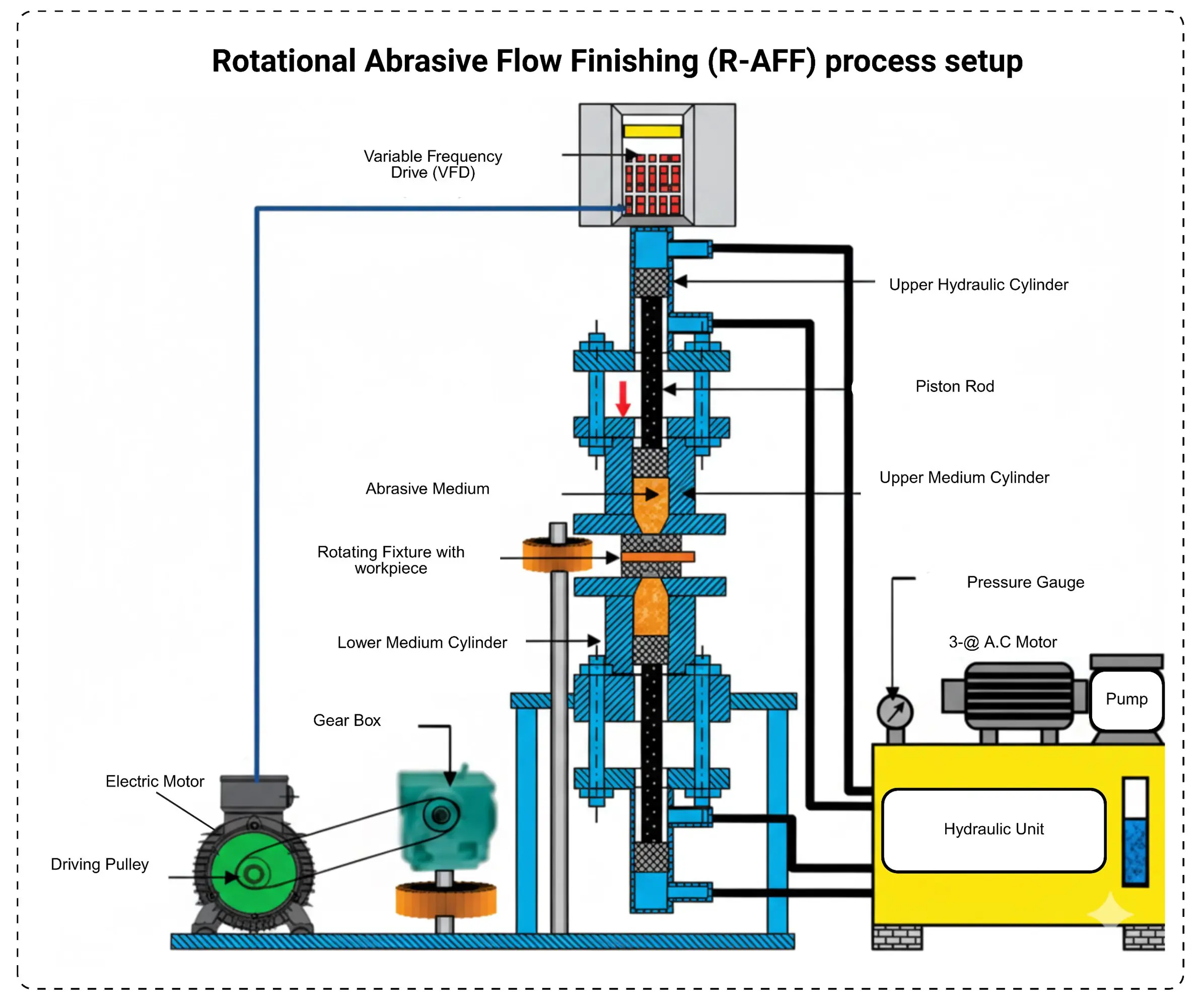

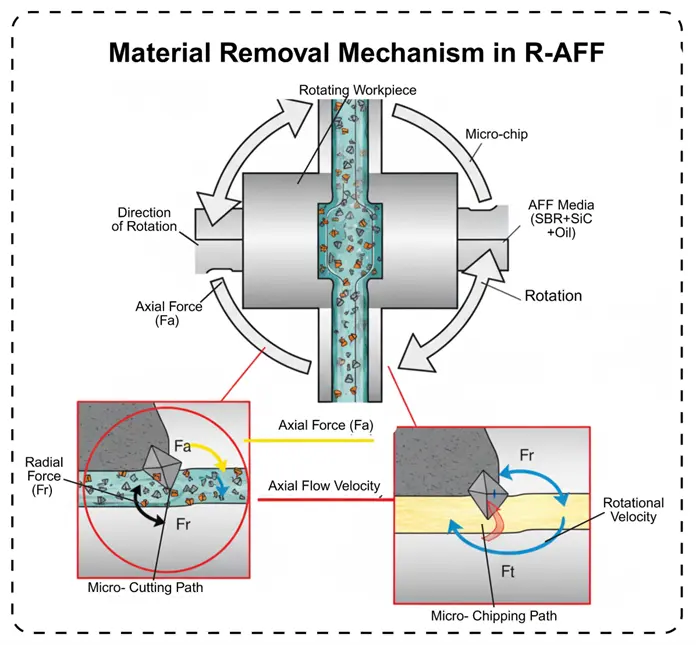

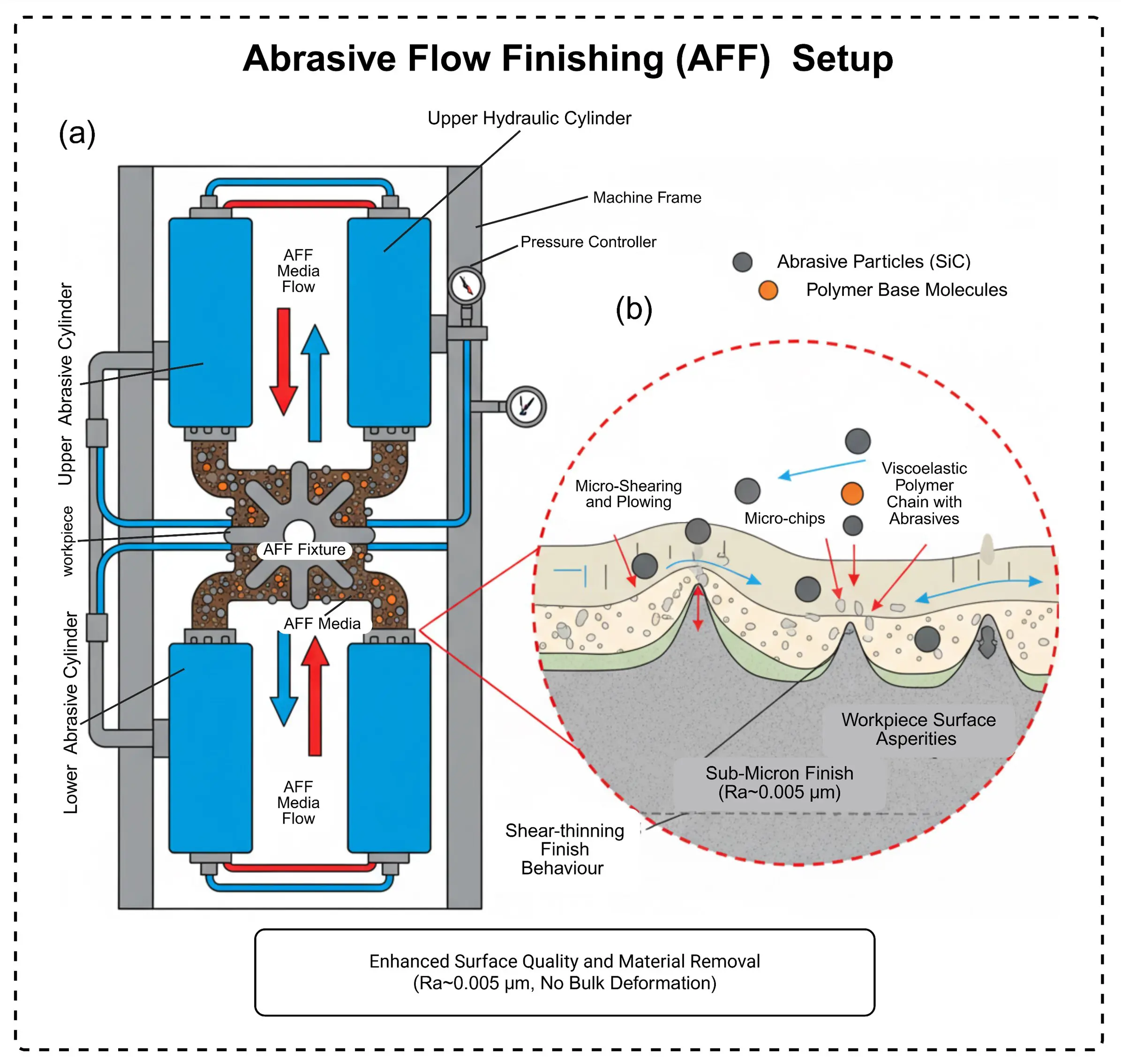

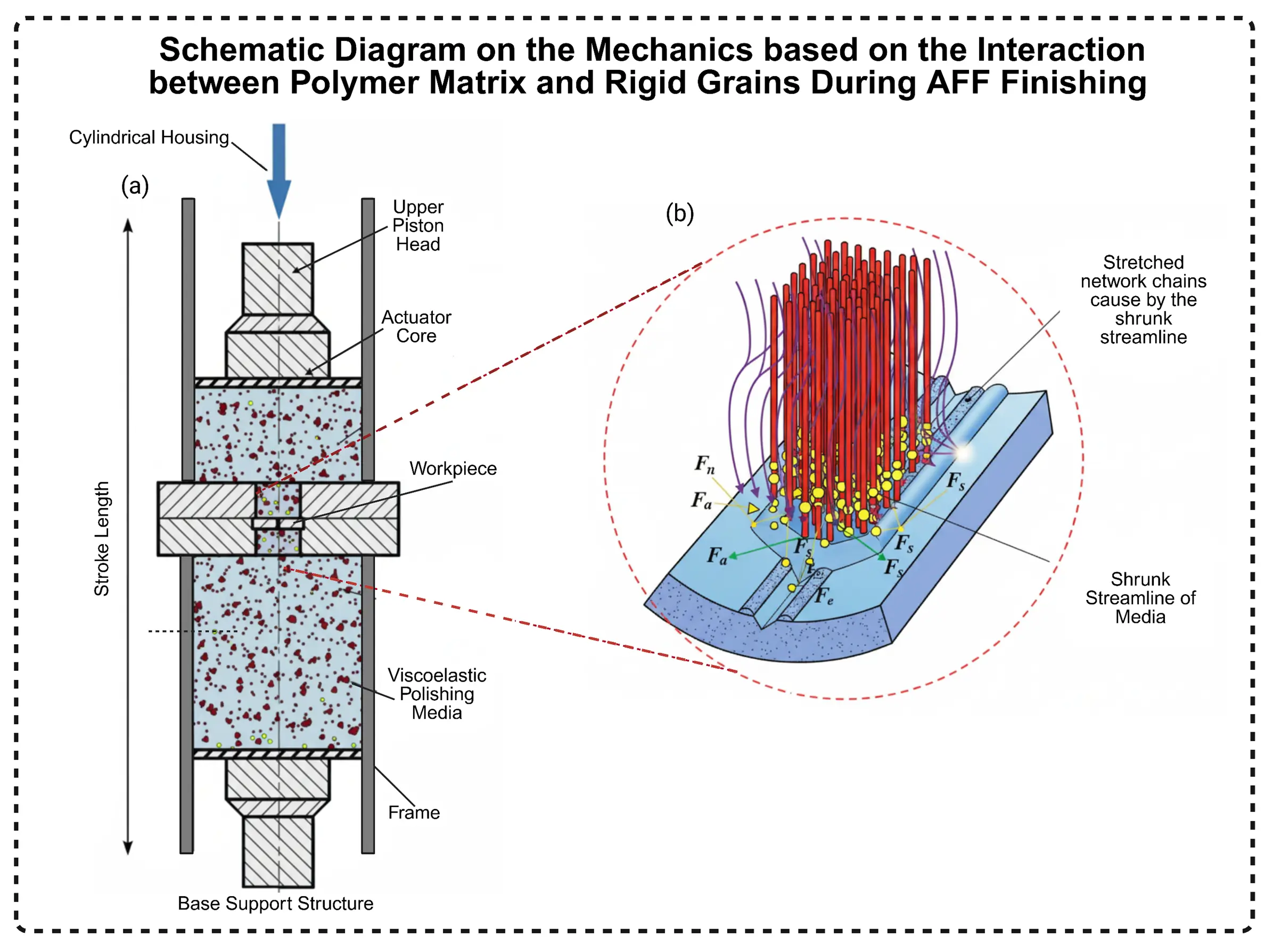

AFF is adept at overcoming the challenges posed by intricate geometries and internal passages, making it a critical process in the aerospace, automotive, and medical device manufacturing industries, among others. Its applications are diverse, including deburring fuel injectors, polishing turbine blades, and refining surgical implants. However, traditional AFF methods face limitations, such as low material removal rates, inefficient processing times, and variability in surface quality, especially when dealing with harder materials [11,41,42,43,44]. The mechanism governing material excision in the Abrasive Flow Finishing (AFF) process is depicted in Figure 1.

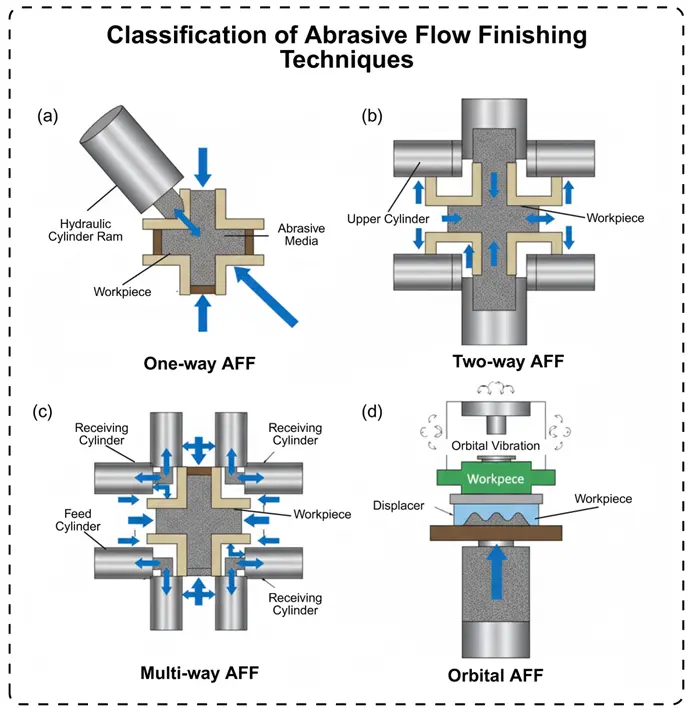

The progression of the Abrasive Flow Machining (AFM) paradigm has engendered sophisticated architectural variants tailored to mitigate targeted material excision and surface refinement exigencies. Variant (a) integrates a hydraulic actuator for exact modulation of abrasive transit. Variant (b) deploys twin-media reservoirs to facilitate reciprocal circulation, thereby augmenting surface homogeneity. Variant (c) incorporates a poly-cylindrical architecture enabling concurrent processing of labyrinthine contours. Variant (d) embeds oscillatory orbital dynamics to elevate material excision efficacy and surface fidelity [46,47,48,49]. These innovations, meticulously engineered for multifaceted sectoral implementations, are graphically illustrated in Figure 2.

Figure 2. Diagrammatic representation of (a) unidirectional AFF (One-way AFF), (b) bidirectional AFF (Two-way AFF), (c) polydirectional AFF (Multi-way AFF), and (d) gyratory AFF (Orbital AFF) configurations.

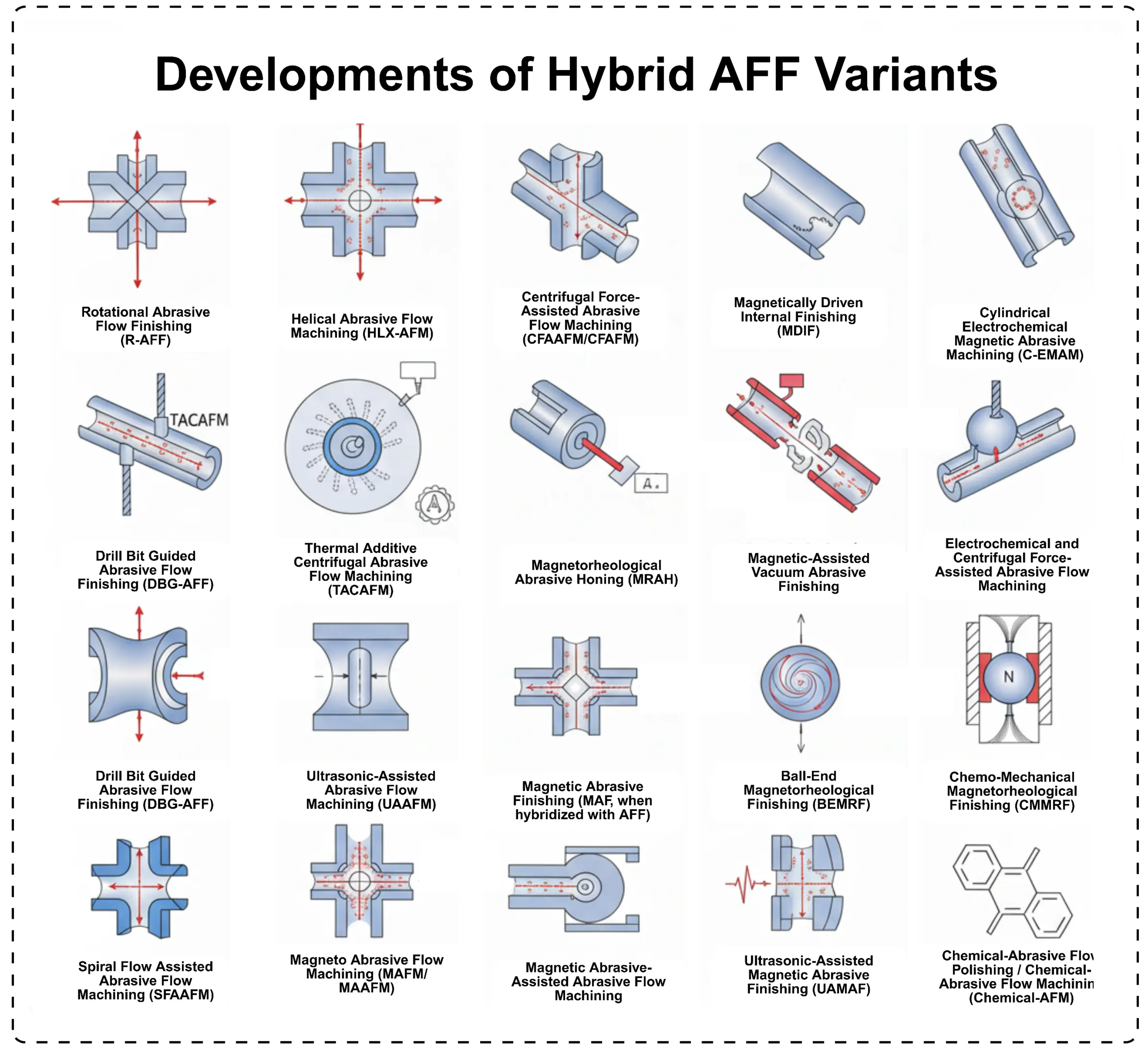

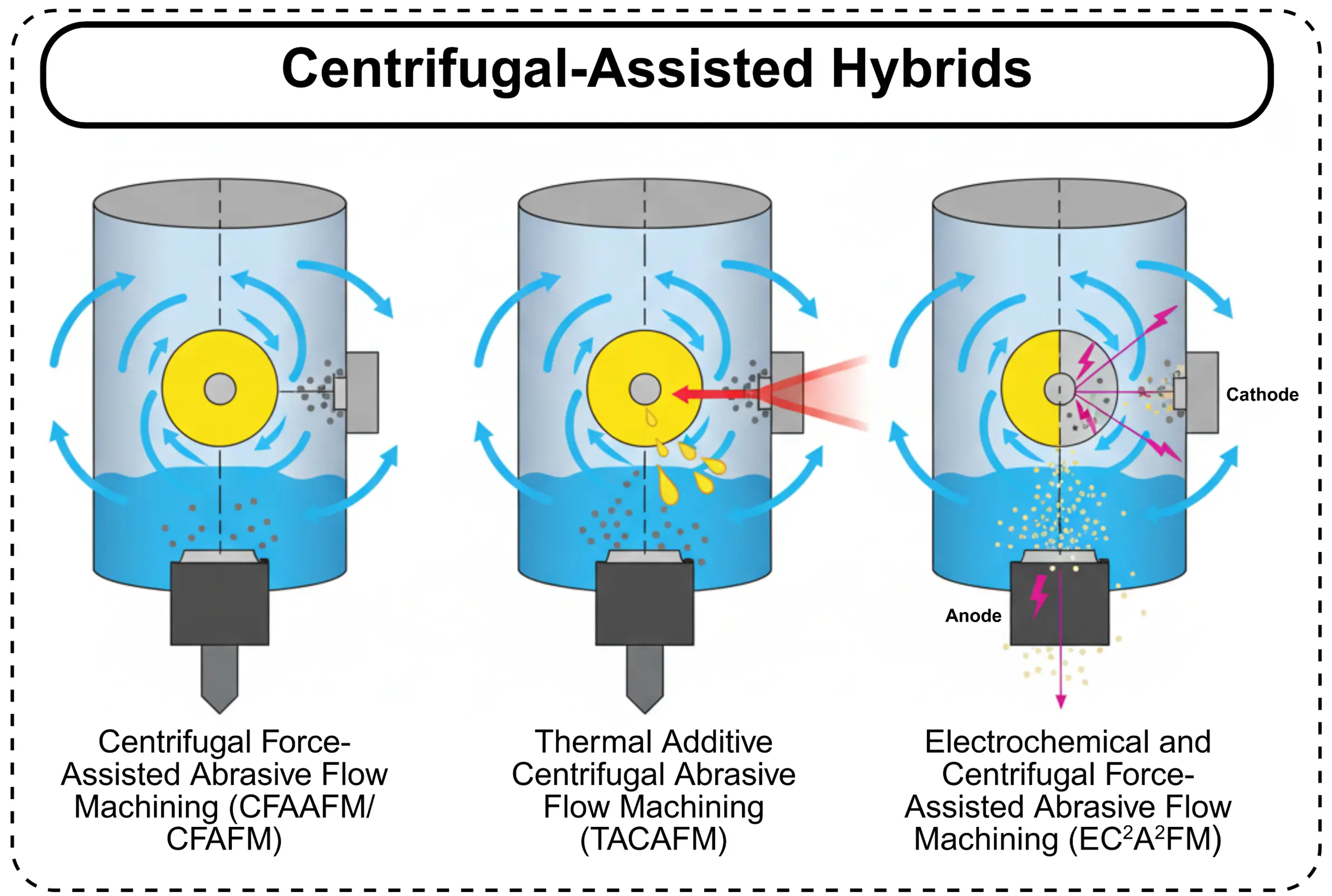

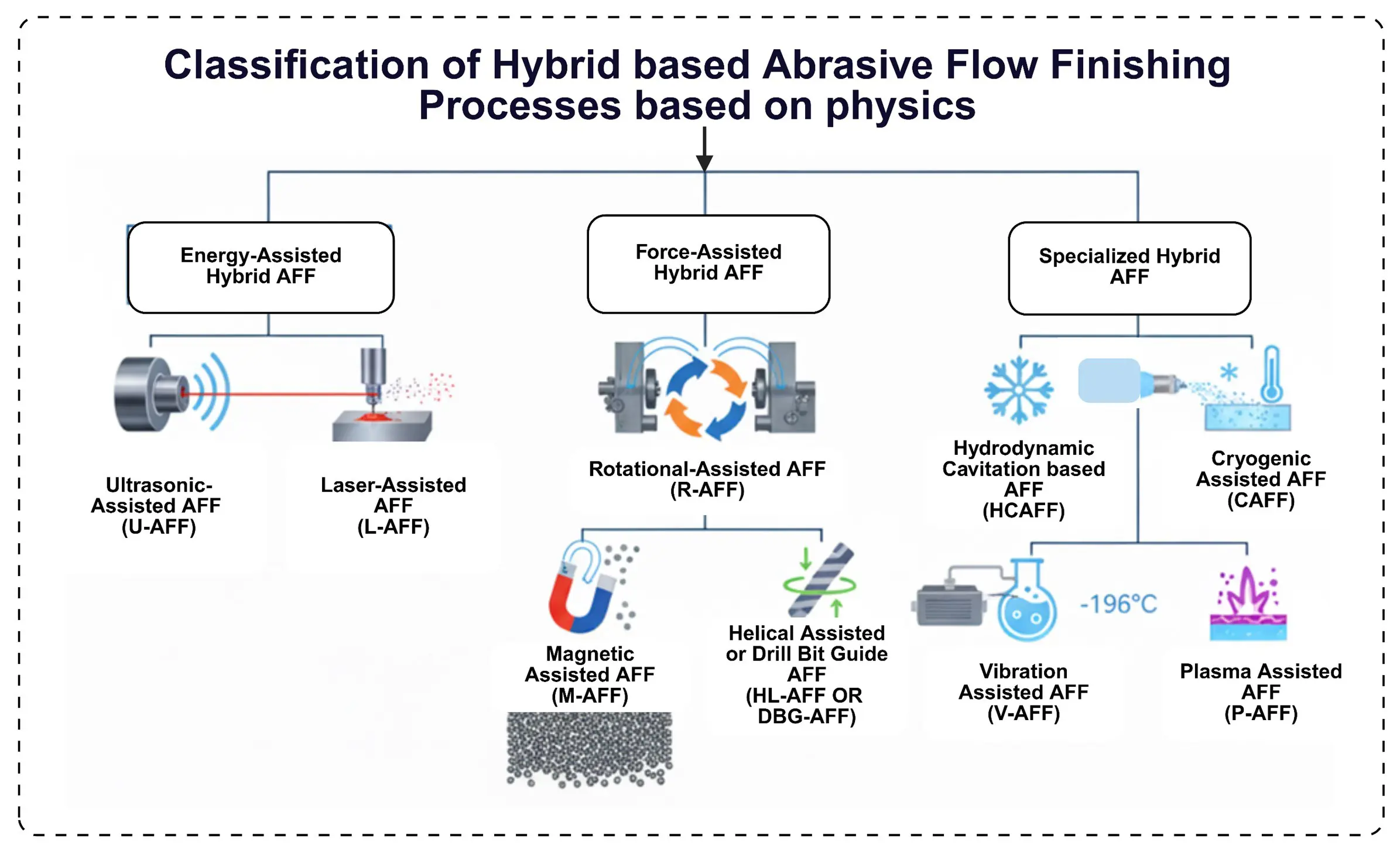

To surmount the inherent constraints of conventional AFF, fused methodologies integrating dynamic influences such as sonic oscillations, electromagnetic gradients, and rotational kinematics have been devised. These paradigms refine the interfacial dynamics between abrasive particulates and substrate interfaces, thereby augmenting process throughput, dimensional fidelity, and superficial integrity [50,51]. The manifold hybrid archetypes of the AFF apparatus are delineated in Figure 3.

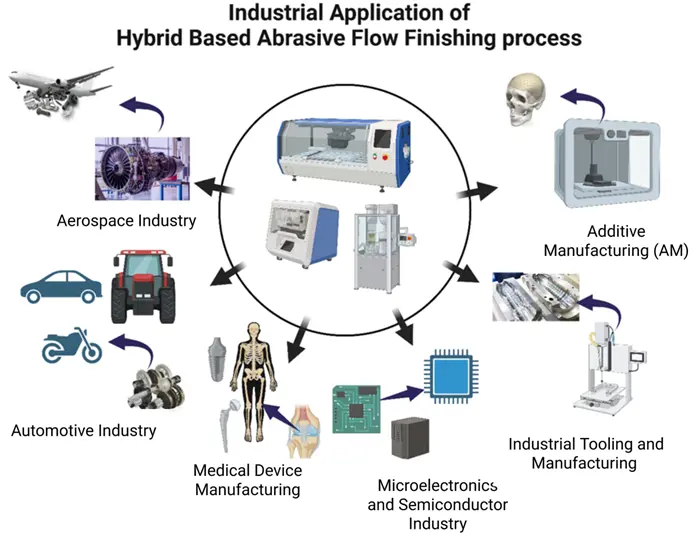

The hybrid Abrasive Flow Finishing (AFM) methodology garners pervasive utilization throughout industrial domains for attaining scrupulous surface refinement and regulated material excision. Its implementations permeate automotive assemblies, aerospace architectures, and biomedical prostheses, wherein superlative interfacial planarity and metrological fidelity are imperative. Recent advancements have demonstrated the ability of this process to integrate multiple techniques, thereby enhancing efficiency and precision. This process combines methods like Electrochemical AFM (ECAFM), Magnetic AFM (MAFM), Laser-AFM (LAAFM), Thermal-AFM (TAAFM), Ultrasonic-AFM (UAAFM), Vibrational-AFM (VAAFM), and Rotational-AFM (RAFM), each offering unique advantages in optimizing material removal, surface quality, and performance for various industrial applications [55,56,57,58,59,60,61,62]. Various hybrid-based abrasive flow finishing (AFF) processes have been presented, encompassing magnetic field, rotational, electrochemical, and thermal-assisted variants, as shown in Figure 4. The diagrammatic representations elucidate fusion tactics, underscoring the amalgamation of auxiliary modalities and kinematic tenets across disparate archetypes of the Abrasive Flow Finishing (AFF) paradigm.

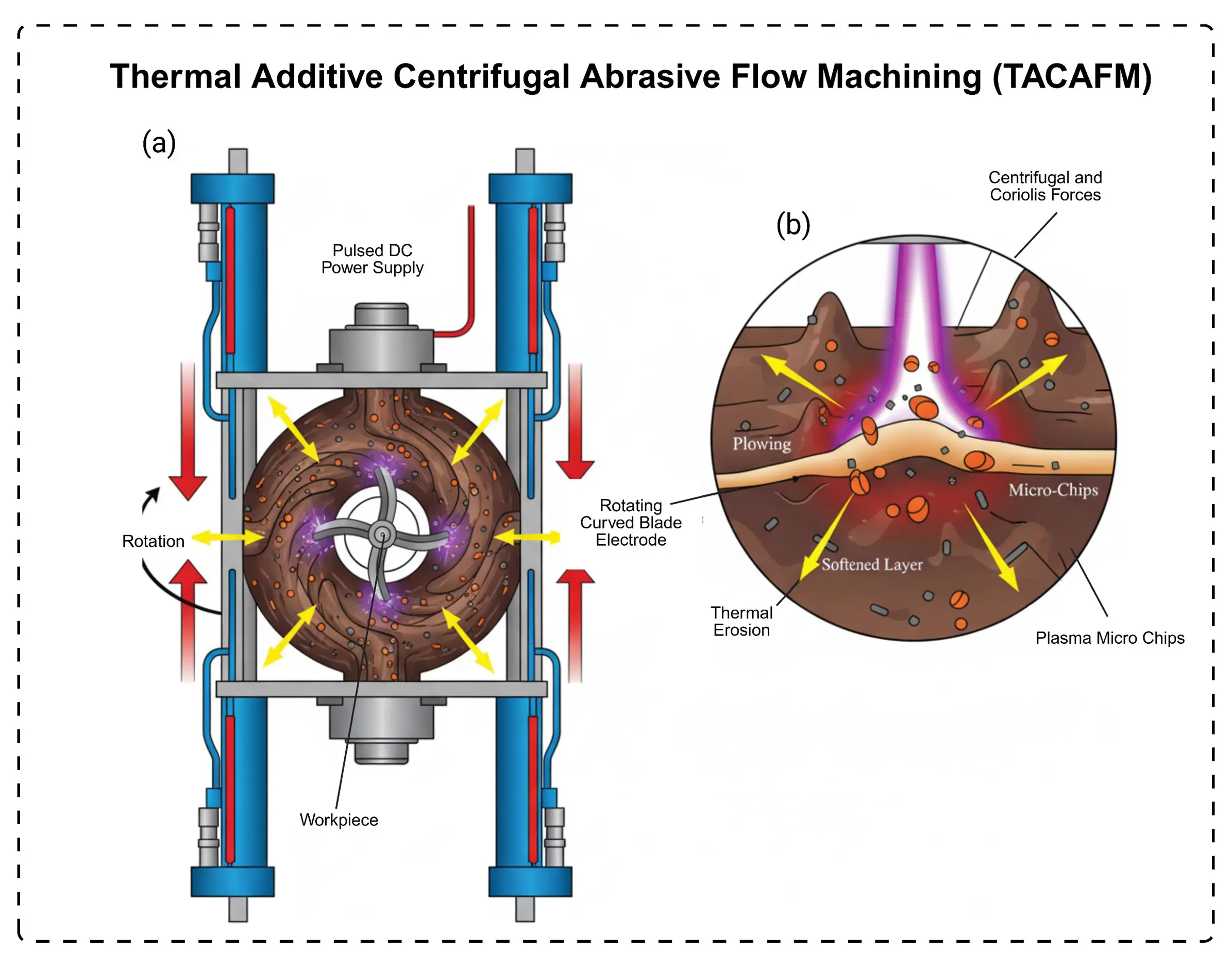

Ultrasonic-Assisted Abrasive Flow Finishing (UAAFF) harnesses sonic perturbations to augment material excision and superficial refinement, with particular efficacy for recalcitrant substrates resistant to conventional machining [66,67]. Magnetic Field-Assisted Abrasive Flow Finishing (MFAFF) exploits magnetic fields to orient abrasive particles, thereby conferring exacting surface refinement capabilities upon ferromagnetic substrates [68,69]. Rotational Abrasive Flow Finishing (RAFF) uses rotational motion to achieve uniform material removal, making it effective for cylindrical components. These advanced techniques represent a significant advance in precision finishing, revolutionizing manufacturing processes by enhancing efficiency and surface quality [70]. The UAAFF archetype incorporates ultrasonic vibrations to elicit microscale perturbations in abrasive particles. This synergistic interplay substantially elevates material removal rates and superficial topographies, with pronounced efficacy for recalcitrant substrates impervious to conventional machining [71]. In MFAFF, magnetic fields orient and regulate the trajectories of abrasive particles embedded in the finishing matrix, thereby imparting meticulous controllability and profoundly ameliorating superficial refinement. This modality exhibits exceptional prowess in machining ferromagnetic substrates and convoluted topographies [72]. In RAFF, rotational motion applied to the workpiece or abrasive medium creates dynamic abrasive flow paths, ensuring uniform material removal. This variant is effective for cylindrical components and applications requiring consistent surface finishes [73,74]. The Electrochemical-Aided Abrasive Flow Machining (ECA2FM) paradigm synergizes Electrochemical Machining (ECM) with Abrasive Flow Machining (AFM) to amplify material removal rates concomitant with the sustenance of premium surface topographies. This integrated modality augments process throughput, particularly in the refinement of labyrinthine internal architectures and fragile constituents of refractory alloys [75]. The Thermal Additive Centrifugal Abrasive Flow Machining (TAC-AFM) fused paradigm amplifies material excision and surface refinement by judiciously calibrating operational variables, including electrode morphology, amperage, and pulse duty ratio. Deployment of a spline-configured electrode under calibrated conditions evinced substantial augmentations in process throughput and interfacial topography [76]. These hybrid methodologies mark a paradigm shift in precision finishing, addressing the limitations of traditional AFF processes. By optimising abrasive interactions and integrating advanced process controls, hybrid AFF offers a robust solution that meets the stringent performance requirements of modern manufacturing [77,78,79,80]. Exploration of bio-inspired abrasives for eco-friendly finishing. Sustainable innovations in HAFF, such as energy-efficient modalities, eco-friendly media, and precision grinding techniques for hard materials, will be crucial for addressing these gaps, as seen in the production of recovered materials and mould parameter analyses [81,82,83,84,85,86,87]. Prospective trajectories encompass the propagation of total productive maintenance frameworks within intelligent manufacturing ecosystems to fortify holistic operational robustness [88].

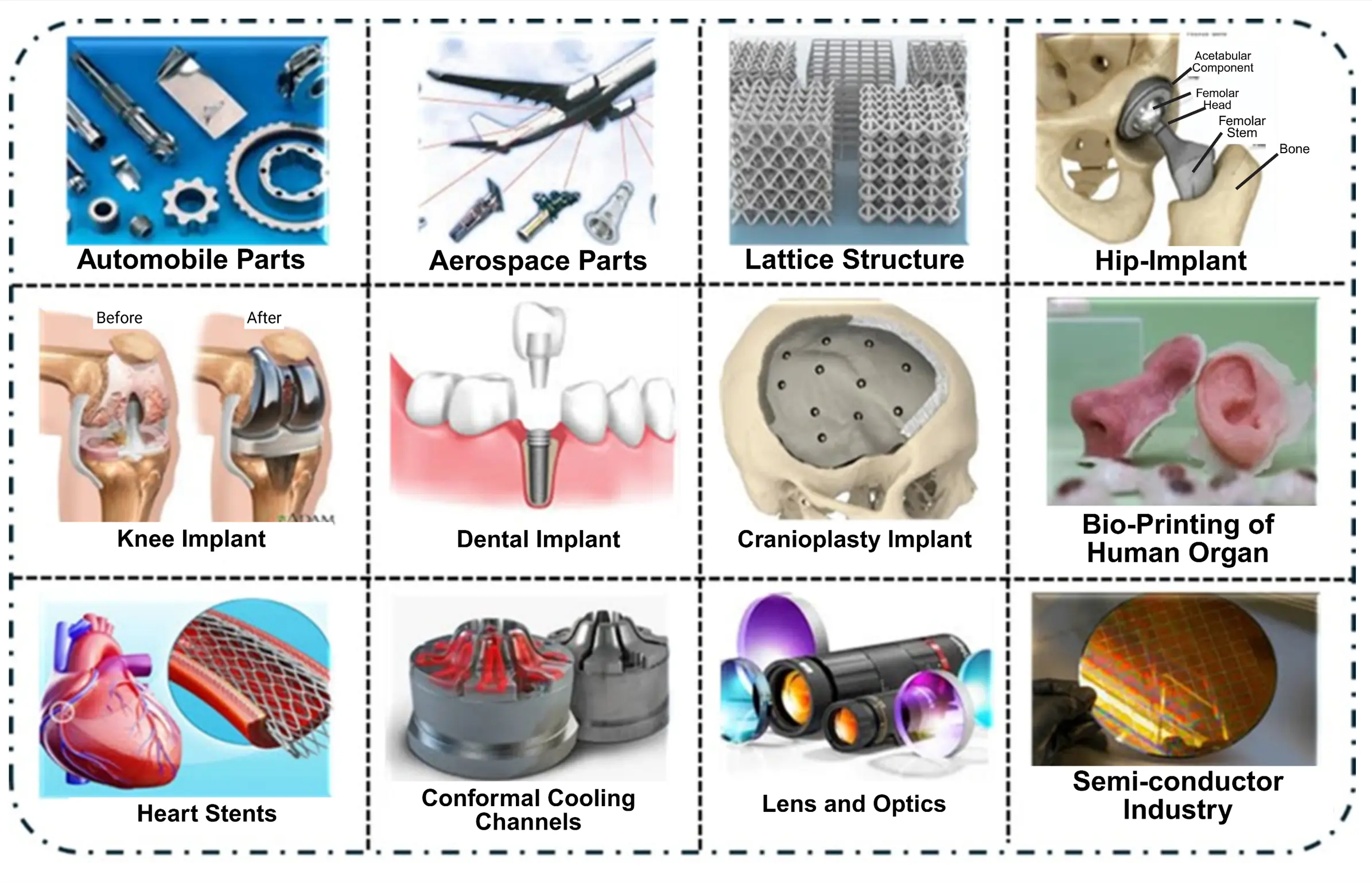

This paradigm underpins the synthesis of lattice architectures, acetabular prostheses, genicular prostheses, odontological fixtures, and calvarial prostheses, each manifesting ameliorated interfacial attributes that maximize functional efficacy and cytocompatibility. Furthermore, it is employed across advanced manufacturing sectors, including bioprinting of human organs, heart stent production, design of conformal cooling channels, lens and optics polishing, and semiconductor manufacturing [89,90,91,92]. These applications highlight the versatility and significance of AFM in achieving superior finishes and functional enhancements across diverse fields, as delineated in Figure 5.

Figure 5. Implementations of the hybrid Abrasive Flow Finishing (AFF) paradigm extend to vehicular subassemblies, aeronautical constituents, reticular scaffolds, acetabular prostheses, genicular prostheses, odontological anchors, calvarial prostheses, organotypic bioprinting scaffolds, coronary stents, isogeometric cooling conduits, refractive optics, and microelectronic fabrication [93,94,95,96].

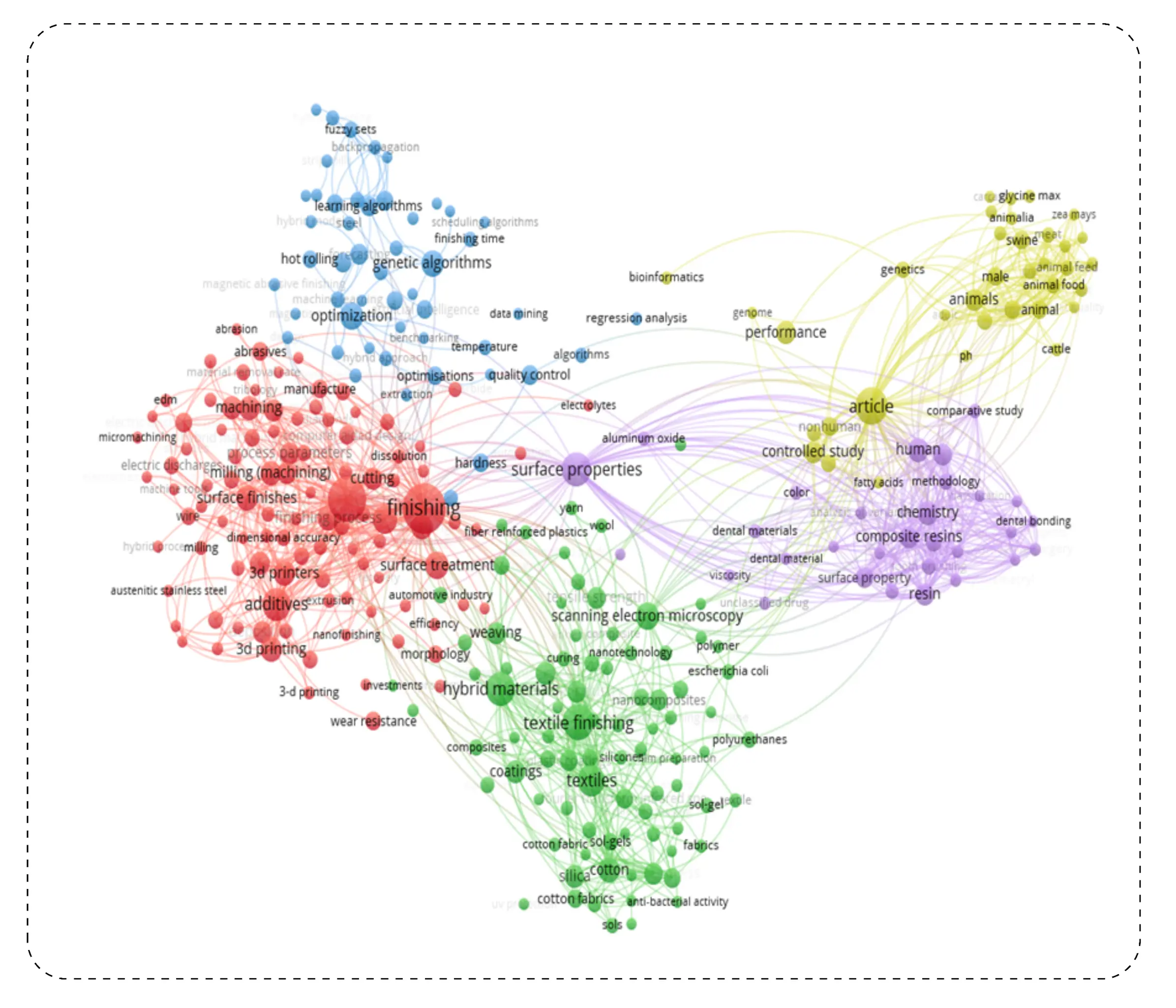

Figure 6, developed using the VOSviewer (version 1.6.20) tool, illustrates a network visualization of the research keywords pertinent to hybrid-based abrasive flow finishing processes. This visualization delineates significant research domains, including “machining”, “abrasion”, “surface finishes”, and “process parameters”, which are prominently represented within the red cluster. The blue cluster emphasizes computational methodologies such as “optimization” and “genetic algorithms”, highlighting their role in advancing hybrid abrasive flow finishing techniques. The green cluster centers on “textile finishing”, “coatings”, and “hybrid materials”, showcasing the interdisciplinary nature of the field. This visualization captures the extensive scope of hybrid abrasive flow finishing research, integrating various scientific and engineering disciplines crucial for enhancing finishing processes in industrial contexts.

Figure 6. Network visualization of research keywords for hybrid-based abrasive flow finishing processes generated using VOSviewer (version 1.6.20).

Figure 7 illustrates a comprehensive flowchart outlining the review strategy for hybrid-based abrasive flow finishing (AFF). It encompasses essential topics such as fundamentals, process development, modeling, applications, and prospective directions. The chart systematically identifies the core elements of the review, including AFF techniques, process development, modeling and simulation, parametric optimization, applications, and advanced materials used in AFF systems. This emphasizes the importance of challenges and future directions as pivotal areas for ongoing research and industrial applications.

This review furnishes an exhaustive scrutiny of emergent paradigms in hybrid Abrasive Flow Finishing (HAFF) architectures, delineating their foundational kinematics, operational variables, and sectoral deployments. It interrogates contemporary strides in computational modeling, parametric optimization, and robotic orchestration, accentuating their pivotal role in catalyzing the assimilation of AFF within high-fidelity fabrication ecosystems. This appraisal confronts salient impediments, encompassing scalability, economic viability, and instantaneous process governance, while proffering prospective investigative vectors. It aspires to function as an indispensable compendium for scholars and industrialists, augmenting perceptual acuity and the pragmatic deployment of hybrid AFF to satiate the exacting imperatives of precision-centric enterprises.

2. Foundational Mechanics of Abrasive Flow Finishing (AFF) and Hybrid Augmentations

Abrasive Flow Finishing (AFF) embodies a high-fidelity interfacial refinement methodology tailored for non-Euclidean morphologies; nonetheless, it contends with intrinsic impediments, including subdued material excision kinetics and suboptimal efficacy against recalcitrant substrates. The amalgamation of AFF with auxiliary force fields or energetic infusions has crystallized as a remedial framework, surmounting these bottlenecks while amplifying throughput, superficial topography, and metrological exactitude. Subsequent delineations interrogate the seminal ablation dynamics intrinsic to AFF, its endemic constraints, and the catalytic influence of hybridization in elevating process sophistication.

2.1. Introduction to AFF

Abrasive Flow Finishing (AFF) is an unconventional superfine refinement modality that leverages a viscoelastic slurry impregnated with abrasive grits, which is methodically propelled across or within workpiece interfaces. The distinctive rheological attributes of this matrix, governed by its viscoelastic rheology, engender equitable dissemination of abrasive particulates, thereby guaranteeing isotropic material excision across labyrinthine internal topologies. The fusion of AFF with ancillary energetic or mechanical stimuli encompassing sonic oscillations, electromagnetic gradients, or photonic irradiation has empirically demonstrated profound escalations in material removal rates (MRR) and interfacial topography. This confluence of modalities instigates a synergistic augmentation, conferring unparalleled metrological exactitude and operational efficacy in ameliorating recalcitrant substrates. Such paradigms permeate high-fidelity superficial honing within aeronautical, vehicular, and biomedical implant domains. Notwithstanding, conventional AFF paradigms are encumbered by attenuated MRR and suboptimal kinetics when interrogating refractory compositions exhibiting convoluted morphologies.

Traditional Abrasive Flow Finishing (AFF) uses abrasive media to remove material, which is effective for general finishing on soft or homogeneous materials. However, it struggles with hard-to-machine materials or ultra-fine finishes on complex geometries. This modality grapples with intrinsic hurdles, including attenuated material removal rates (MRR) and heterogeneous superficial fidelity, particularly for assemblies exhibiting disparate rigidity profiles or non-Euclidean morphologies, thereby curtailing its viability in metrology-grade regimes [73].

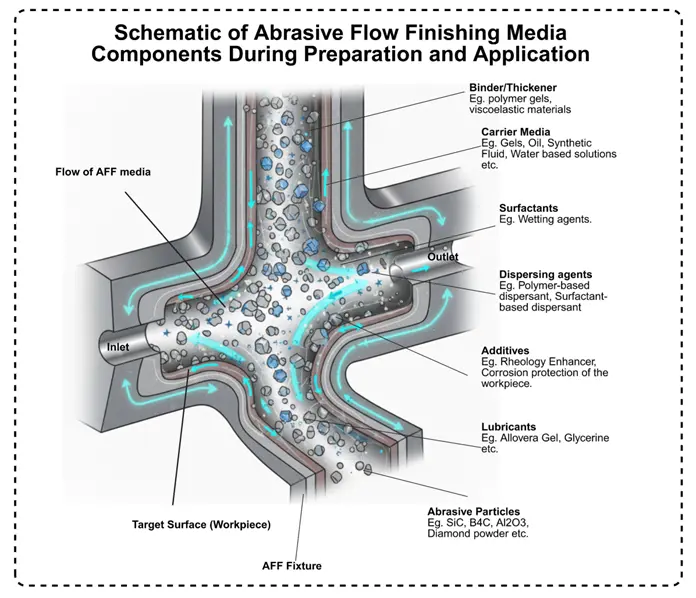

The abrasive matrix constitutes the paramount constituent of the AFF paradigm, inasmuch as its formulation governs the throughput and superficial caliber of interfacial amelioration [97]. The abrasive matrix ordinarily comprises a viscoelastic oligomeric substrate, exemplified by urethane or silicone, amalgamated with abrasive grits such as silicon carbide (SiC), aluminum oxide (Al2O3), or diamond [98,99,100,101]. The oligomeric scaffold imparts abrasion resilience while sustaining deformability to conform to substrate contours. The granularity, tenacity, and volumetric fraction of abrasive grits are calibrated to the substrate composition and targeted interfacial topography. Diamond grits, renowned for their superlative tenacity, engender nanometric interfacial asperity, rendering them apt for refractory substrates [11,43].

The principal components of the Abrasive Flow Finishing (AFF) paradigm are schematized, including the hydraulic actuator, the superior and inferior abrasive reservoirs, and the AFM restraint. The traversal of the abrasive matrix is modulated via hydraulic actuators, effectuating substrate attrition and superficial amelioration. This architecture elevates interfacial fidelity and metrological exactitude, preeminently for non-linear topologies such as iso-contoured thermal conduits, as rendered in Figure 8.

Figure 8. Diagrammatic depiction of the Abrasive Flow Finishing (AFF) paradigm: (a) AFF apparatus configuration illustrating superior and inferior hydraulic actuators, AFF matrix circulation, restraint, structural chassis, and pressure regulator; (b) Ablation kinetics (nanoscale perspective) delineating the viscoelastic macromolecular lattice incorporating abrasive grits (SiC) in micro-shear and micro-plowing interactions with substrate interfacial protuberances (sub-micrometric topography, Ra ≈ 0.005 μm), culminating in ameliorated superficial integrity and regulated material excision devoid of volumetric distortion [102].

Figure 9 delineates the temporal progression of Abrasive Flow Finishing (AFF) paradigms, tracing their evolutionary trajectory from foundational rheological principles in the mid-20th century to contemporary hybrid integrations and cogent fabrication ecosystems, underscoring pivotal milestones in process augmentation and intelligent automation [65,103].

Jain and Adsul (2000) elucidated the pivotal influence of matrix formulation on interfacial topography and material excision kinetics [104]. Sankar et al. (2010) demonstrated the efficacy of matrix deformability in ameliorating internal voids and labyrinthine architectures [105]. Jain and Sidpara (2011) accentuated the salience of abrasive grit tenacity and granularity exemplified by diamond particulates in engendering nanometric superficial fidelity [106]. Rhoades (1991) interrogated the rheological attributes of oligomeric scaffolds within Abrasive Flow Finishing (AFF) paradigms and their congruence with grits such as SiC and Al2O3 [107]. Kumar et al. (2016) scrutinized the ramifications of abrasive grit volumetric density on excision throughput and superficial integrity [108].

Om et al. (2024) accentuated the salience of matrix formulation in modulating interfacial asperity and material excision kinetics [109]. Shaik et al. (2024) evinced that matrix deformability propels the amelioration of internal voids and labyrinthine architectures [110]. Gupta et al. (2021) accentuated the salience of abrasive grit tenacity and granularity exemplified by diamond particulates in engendering nanometric superficial fidelity [111]. Zhang et al. (2022) probed the rheological dynamics of disparate oligomeric scaffolds in Abrasive Flow Finishing (AFF) paradigms and scrutinized their congruence with abrasive grits such as SiC and Al2O3 [97]. Kumar et al. (2024) scrutinized the ramifications of abrasive grit volumetric density on excision throughput and superficial integrity [112].

2.1.1. Formulation and Efficacy Determinants of AFF Media

The proficiency of abrasive flow matrices in AFF paradigms is chiefly modulated by the rheological viscoelasticity of the oligomeric scaffold, the tribological attributes of embedded abrasive grits, and their volumetric dispersity. These constitutive facets, coupled with the matrix’s erosional fortitude, are susceptible to bespoke calibration for domain-specific imperatives, thereby dictating excision throughput and superficial topography. The ensuing exposition dissects the contributory salience of each determinant in sculpting the holistic efficacy and operational sophistication of abrasive flow media.

- I

-

Viscoelastic Polymeric Base: The viscoelastic rheology of the oligomeric scaffold endows the abrasive matrix with compressive deformability, engendering isotropic interfacial adhesion while imparting uniform shear transduction for substrate ablation [113]. Archetypal oligomeric exemplars, such as urethane and silicone, are preferentially employed owing to their amalgamated structural tenacity and erosional fortitude.

- II

-

Abrasive Particles: Abrasive grits sequestered within the oligomeric scaffold delineate the erosive potency of the matrix. Their granularity, tenacity, and volumetric dispersity are meticulously calibrated vis-à-vis the substrate recalcitrance. Hu et al. (2024) accentuated that grits of superlative tenacity, such as diamonds, are indispensable for engendering nanometric interfacial topography on ultrarefractory substrates [101].

- III

-

Particle Concentration: The volumetric dispersity of abrasive grits modulates both the erosive intensity of material excision and superficial topography. Shaik et al. (2024) found that higher concentrations lead to faster removal rates, whereas lower concentrations are better suited for precision finishing [110].

- IV

-

Customization for Applications: The composition of the medium can be tailored to specific applications, such as aerospace components or biomedical implants. Previous studies have highlighted the importance of using diamond abrasives to polish ultra-hard surfaces to ensure nanoscale surface roughness [114].

- V

-

Durability of Media: The polymer’s resistance to wear determines the longevity of the abrasive media. Repeated usage can degrade the media, necessitating periodic replacement to maintain the process efficiency [115].

As delineated in Section 2.1.1., the proficiency of abrasive flow matrices in Abrasive Flow Finishing (AFF) paradigms is modulated by pivotal operational variables, encompassing extrusion actuation, volumetric transit rate, and grit dispersity. The bidirectional Abrasive Flow Machining (AFM) modality, wherein the abrasive matrix traverses substrate internal conduits propelled by reciprocating ram excursions, catalyzes regulated substrate ablation and ameliorates interfacial topography [116]. This paradigm is pivotal for attaining superlative interfacial refinements on labyrinthine morphologies, as schematized in Figure 10, which delineates the formulation, preconditioning, and deployment of abrasive flow matrices within the Abrasive Flow Finishing (AFF) framework.

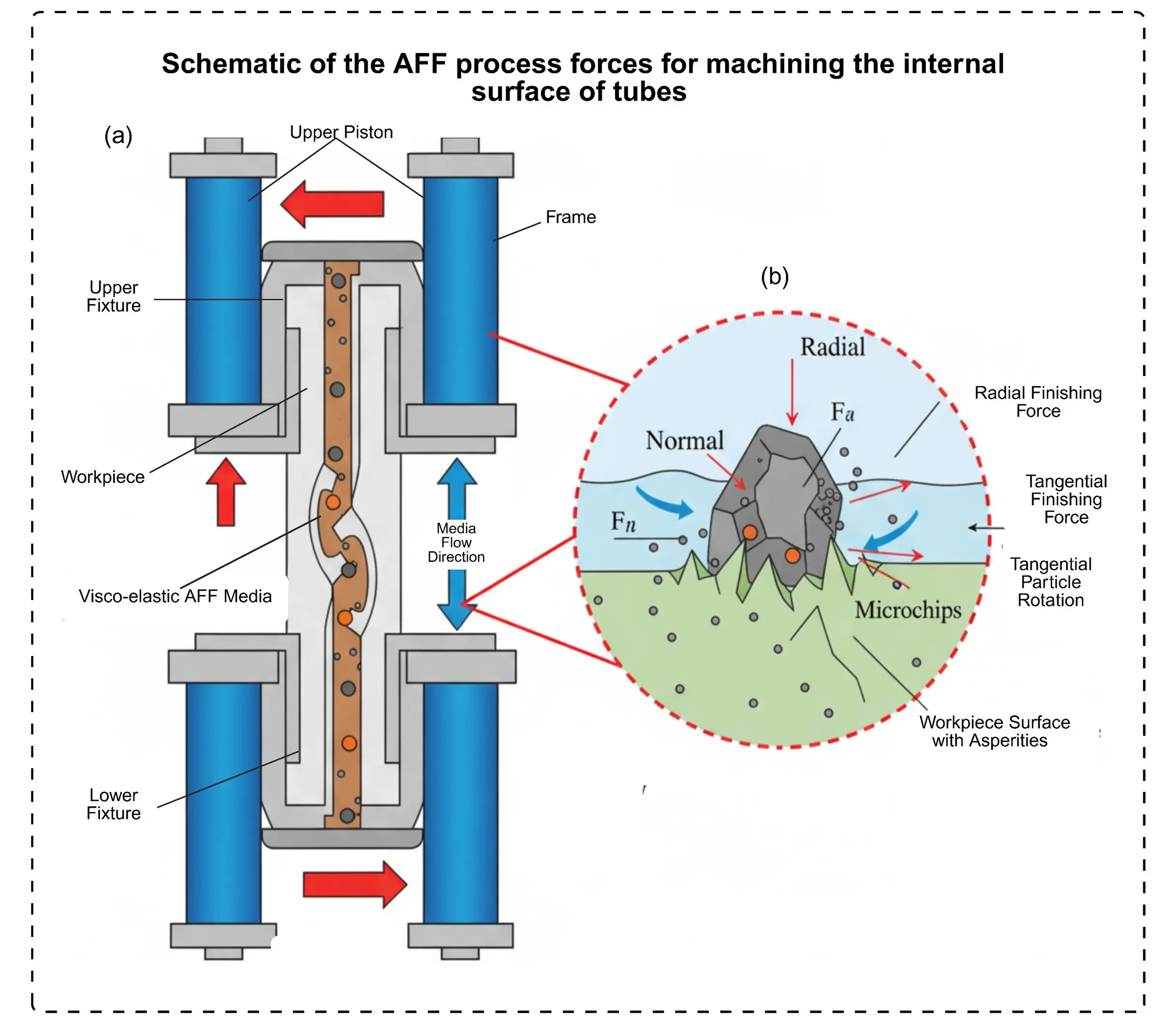

Figure 10. Diagrammatic representation of force vectors in the Abrasive Flow Finishing (AFF) paradigm for internal tubular substrate refinement: (a) AFF restraint assembly for interfacial amelioration within tubular geometries, delineating superior ram, superior restraint, structural chassis, viscoelastic AFF matrix with traversal vector, and inferior restraint; (b) Excision kinetics at tubular interfacial stratum (nanoscale vantage), portraying orthogonal force (Fn), centripetal force (Fr), centripetal refinement vector, circumferential refinement vector, circumferential grit gyration, ablation fragments, and substrate interfacial protuberances [117].

2.1.2. Pivotal Operational Determinants in the AFF Processes

The proficiency and metrological exactitude of Abrasive Flow Finishing (AFF) paradigms are profoundly modulated by manifold pivotal determinants, each orchestrating the material removal rate (MRR) and superficial topography [97]. The ensuing delineations elucidate the salient determinants and their ramifications on the holistic efficacy of the Abrasive Flow Finishing (AFF) paradigm.

- I

-

Extrusion Pressure: This determinant embodies the compressive actuation imparted to the abrasive matrix during its propulsion across or within substrate interfaces. Augmented actuation intensities increase material removal rates (MRR) by intensifying particulate impingement on the interfacial stratum [118]. Nevertheless, surfeit actuation may precipitate matrix and fixture erosion, thereby undermining the metrological fidelity of the paradigm [119]. The compressive actuation imparted to the abrasive matrix during its propulsion across or within substrate interfaces elevates material removal rates (MRR) by intensifying particulate impingement on the interfacial stratum. Nevertheless, surfeit actuation may precipitate matrix and fixture erosion, thereby undermining metrological fidelity. Optimal actuation equilibrates excision kinetics with matrix cohesion [42].

- II

-

Media Flow Rate: The volumetric transit rate of the abrasive matrix profoundly modulates particulate-substrate interfacial dynamics. Augmented transit velocities accelerate procedural cadence; nonetheless, they attenuate residence duration at salient loci, predisposing to heterogeneous superficial amelioration [120]. In contrast, a decreased flow rate promotes extended interaction, which enhances the uniformity of the surface, although it results in a longer duration for the process [112]. The volumetric transit rate of the abrasive matrix profoundly modulates interfacial dynamics between abrasive grits and substrate strata. Augmented transit velocities expedite procedural cadence but predispose to anisotropic superficial amelioration, whereas subdued transit velocities elevate interfacial topography while prolonging operational durations [50].

- III

-

Cycle Time: The temporal span of abrasive matrix engagement with the substrate, denoted as cycle time, wields a paramount influence on superficial topography. Elongated cycle durations attenuate interfacial protuberances, thereby engendering superlative refinement. Conversely, inordinately protracted cycles precipitate erosion in procedural cadence [121]. Longer cycle times improve surface finishes by smoothing asperities, but must be optimized to avoid inefficiency and unnecessary resource use [51].

- IV

-

Abrasive Concentration: The volumetric dispersity of abrasive grits within the matrix constitutes a pivotal determinant modulating the erosive intensity of substrate ablation. Augmented dispersities amplify material removal rates (MRR) yet predispose to amplified interfacial asperity, whereas subdued dispersities confer preferential aptitude for nanometric superficial refinements [112,121]. Higher abrasive concentrations result in higher material removal rates (MRR); however, they may also produce a rougher surface finish. In contrast, lower abrasive concentrations are ideal for achieving ultra-fine finishes, making them suitable for precision applications [71].

- V

-

Interaction Among Parameters: The interplay among these determinants manifests as a multifaceted nexus. For instance, escalated extrusion actuation may mandate recalibration of volumetric transit rates or temporal spans to avert matrix decalescence or hyper-refinement. Such interlinkages impel rigorous parametric harmonization to consummate targeted outcomes [122]. The flow characteristics of viscoelastic media [123], particularly their contraction and expansion within various geometrical configurations, are crucial in influencing material removal and surface roughness [123].

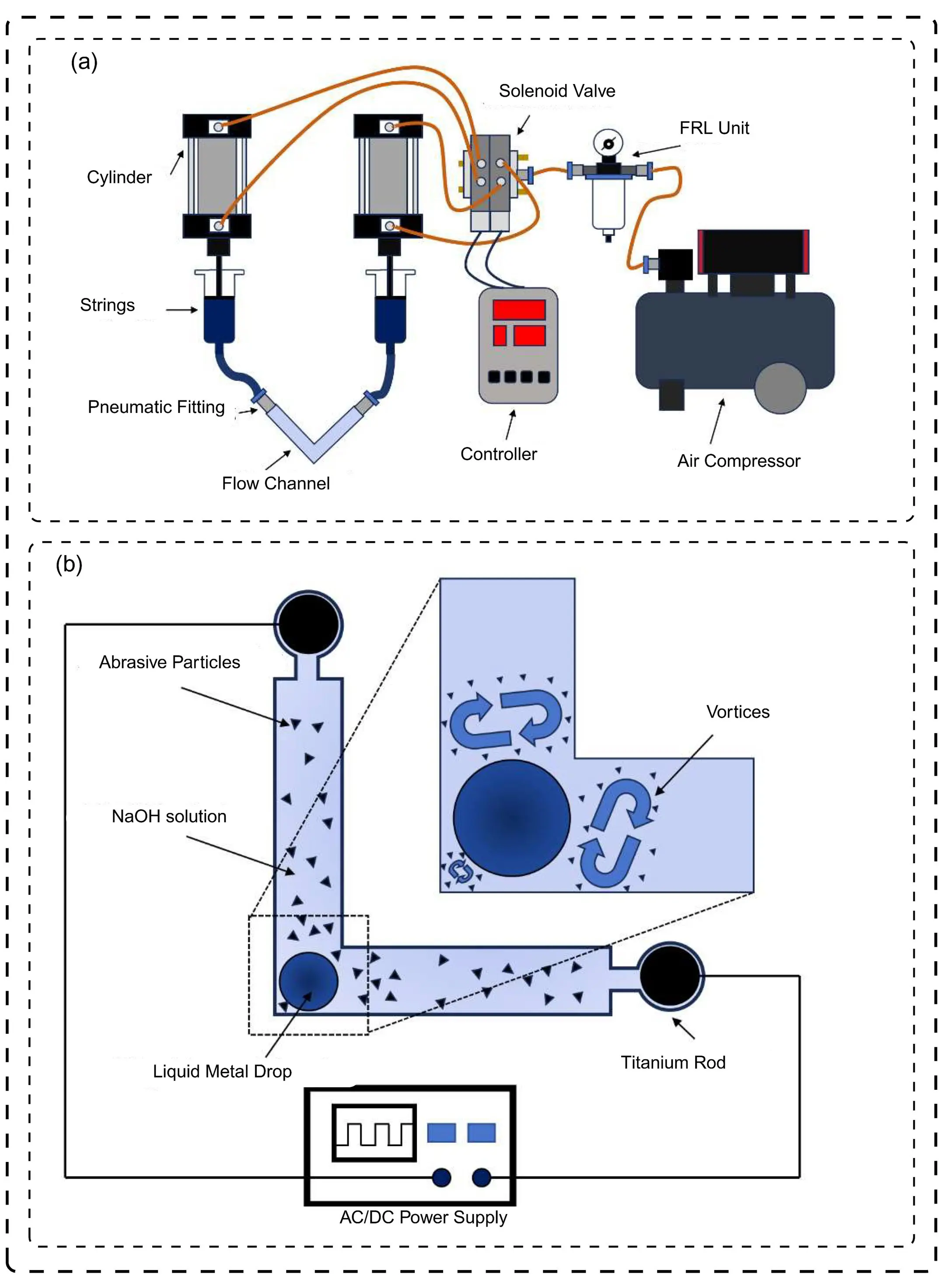

The upper panel depicts the pneumatic system with dual cylinders, strings, pneumatic fittings, a flow channel, a solenoid valve, an FRL unit, a controller, and an air compressor for media control. The lower panel details the localized material removal mechanism, where abrasive particles in NaOH solution interact with a liquid metal drop under an alternating electric field from an AC/DC power supply, inducing vortices for erosion of a titanium rod workpiece. The influence of conduit morphology on refinement dynamics and superficial amelioration is graphically delineated in Figure 11.

Figure 11. Diagrammatic representation of the solid-liquid two-phase Abrasive Flow Machining (AFM) experimental apparatus: (a) two-phase Abrasive Flow Machining (AFM) apparatus configuration, delineating reservoirs, conduits, pneumatic connectors, traversal conduit, regulatory module, electromagnetic valve, filtration-regulation-lubrication assembly, and compressed air source; (b) Site-specific ablation dynamics via liquid metal-propelled abrasive traversal under oscillatory electromagnetic field, portraying abrasive grits in NaOH electrolyte, metallic droplet, titanium anode, eddy formations, and AC/DC voltage source [124].

2.2. Material Removal Mechanisms in AFF

Substrate ablation in Abrasive Flow Finishing (AFF) paradigms is orchestrated by an ensemble of nanoscale ablation modalities, chiefly micro-incision, micro-displacement, and micro-fracture, precipitated by the interfacial impingement of abrasive grits on the target stratum. Micro-incision entails the orthogonal severance of substrate strata by indurated abrasive particulates, whereas micro-displacement denotes the transverse relocation of material via particulate elastic distortion. Micro-fracture, conversely, arises from circumferential shear stresses imposed by grits, engendering the delamination of ultrathin substrate laminae. The rheological viscoelasticity of the refinement matrix permits these concurrent ablation vectors, thereby conferring isotropic excision across non-Euclidean substrate morphologies. This rheological adaptability facilitates conformal adhesion to convoluted topologies, perpetuating equanimous ablation across tortuous features. Perpetual matrix circulation introduces nascent abrasive grits to the interfacial locus, thereby sustaining ablation constancy across protracted operational iterations. Such conformability confers salient utility in realizing homogeneous superficial refinements on assemblies exhibiting disparate topographical variances [72].

- I

-

Micro-Cutting: Micro-cutting predominates as the cardinal ablation modality in Abrasive Flow Finishing (AFF), wherein abrasive grits perforate and sever substrate material from interfacial protuberances. This ablation vector is profoundly modulated by the tenacity and granularity of the abrasive grits. Indurated abrasives, exemplified by diamond particulates, exhibit exceptional prowess in excising material from ultra-refractory interfacial strata [101].

- II

-

Micro-Plowing: In micro-plowing, abrasive particles exert lateral pressure, causing surface plastic deformation rather than material removal. Previous studies have emphasized the regulation of extrusion pressure to reduce adverse plowing effects, which can lead to surface irregularities [125,126].

- III

-

Micro-Shearing: Micro-shearing manifests when abrasive grits impose circumferential shear stresses upon the interfacial stratum, precipitating the delamination of ultrathin substrate laminae. This ablation vector exhibits exceptional aptitude for ameliorating assemblies with convoluted morphologies, as the rheological viscoelasticity of the refinement matrix confers conformal adhesion to disparate topographical variances [127,128].

- IV

-

Conforming to Geometries: The viscoelastic nature of the polymer base ensures close conformity to intricate features, enabling consistent material removal from complex surfaces. Previous studies have highlighted the adaptability of AFF for finishing biomedical implants with nanoscale precision [127,129].

- V

-

Self-Renewing Abrasive Action: The perpetual flow of media ensures that fresh abrasive particles are brought into contact with the workpiece surface, thereby maintaining consistent removal rates over extended cycles. This continuous renewal mitigates grit dulling and sustains erosive potency, which is pivotal for protracted superfine honing regimens [130].

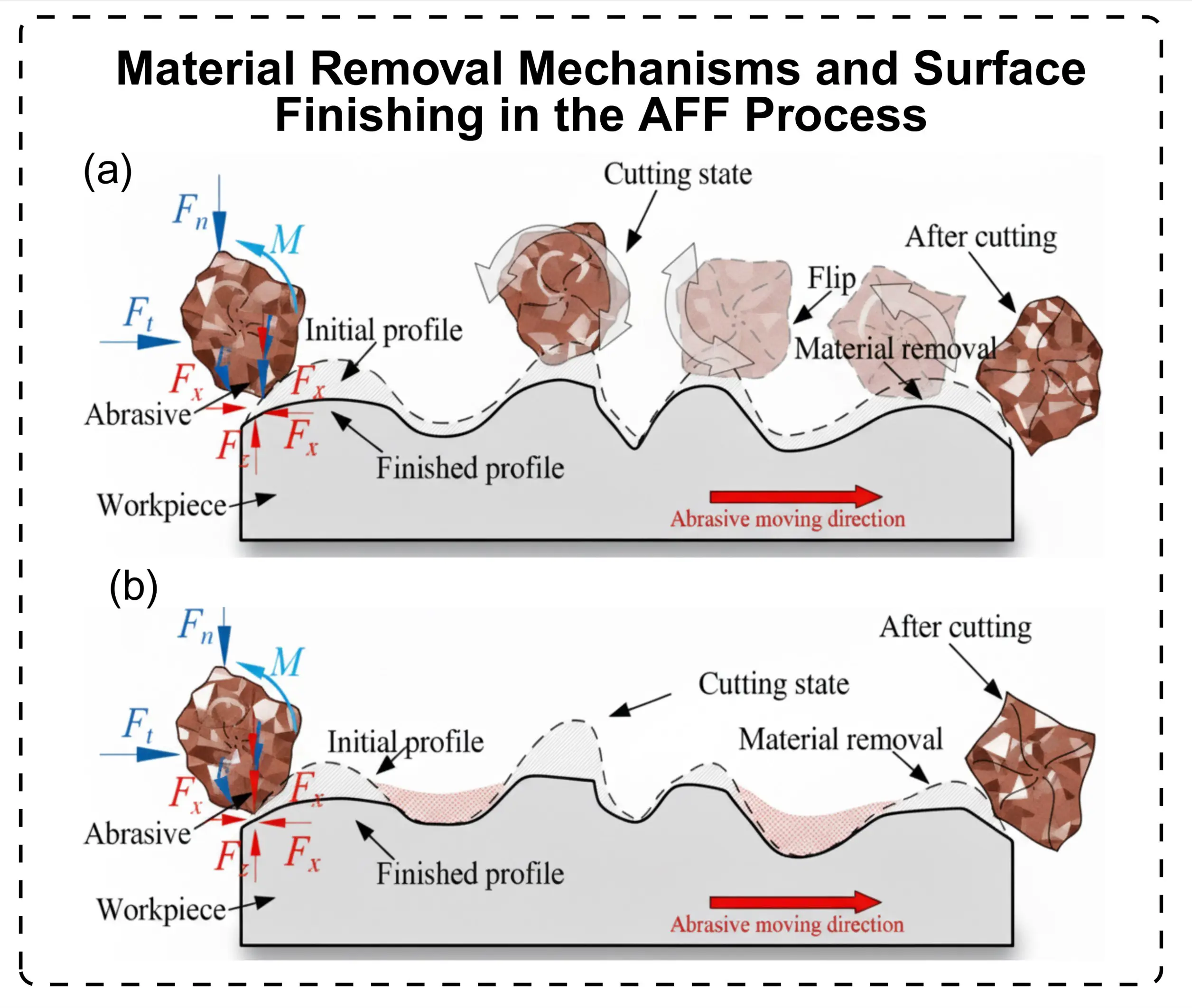

As delineated in Section 2.1.2., the ablation modalities in the AFF paradigm encompassing micro-plowing, micro-cutting, and micro-shearing are profoundly orchestrated by salient operational determinants, including extrusion actuation, volumetric transit rate, and grit dispersity. Figure 12 schematizes these ablation vectors, elucidating the interfacial impingement of the abrasive matrix upon substrate strata to catalyze regulated excision and superficial amelioration.

Figure 12. Dual-Phase Grit Engagement and Shear-Driven Material Removal in Abrasive Flow Finishing (AFF): (a) Forward Flip-Cutting and (b) Reverse Fracture-Shearing.

The diagrammatic representation elucidates the operational kinematics of the AFF paradigm, highlighting the reciprocating excursions of the rams and the traversal of abrasive media, which catalyse substrate ablation via longitudinal and centripetal force vectors impinging on the interfacial stratum, as shown in Figure 13.

The operational kinematics and apparatus of AFF are schematized, including extrusion actuation and abrasive media traversal. The microstructural morphology and constitutive attributes of the abrasive media are portrayed, alongside their ramifications on ablation dynamics, dimensional constraints, and excision throughput (Figure 13).

Figure 13. Enhanced schematic of the AFF process for hollow cylinder polishing: (a) updated AFF setup with bidirectional media cylinders, alternating piston drives, and optimized flow paths for hollow cylinder, and (b) advanced material removal mechanism (micro-view with bidirectional abrasive dynamics and shear forces [131].

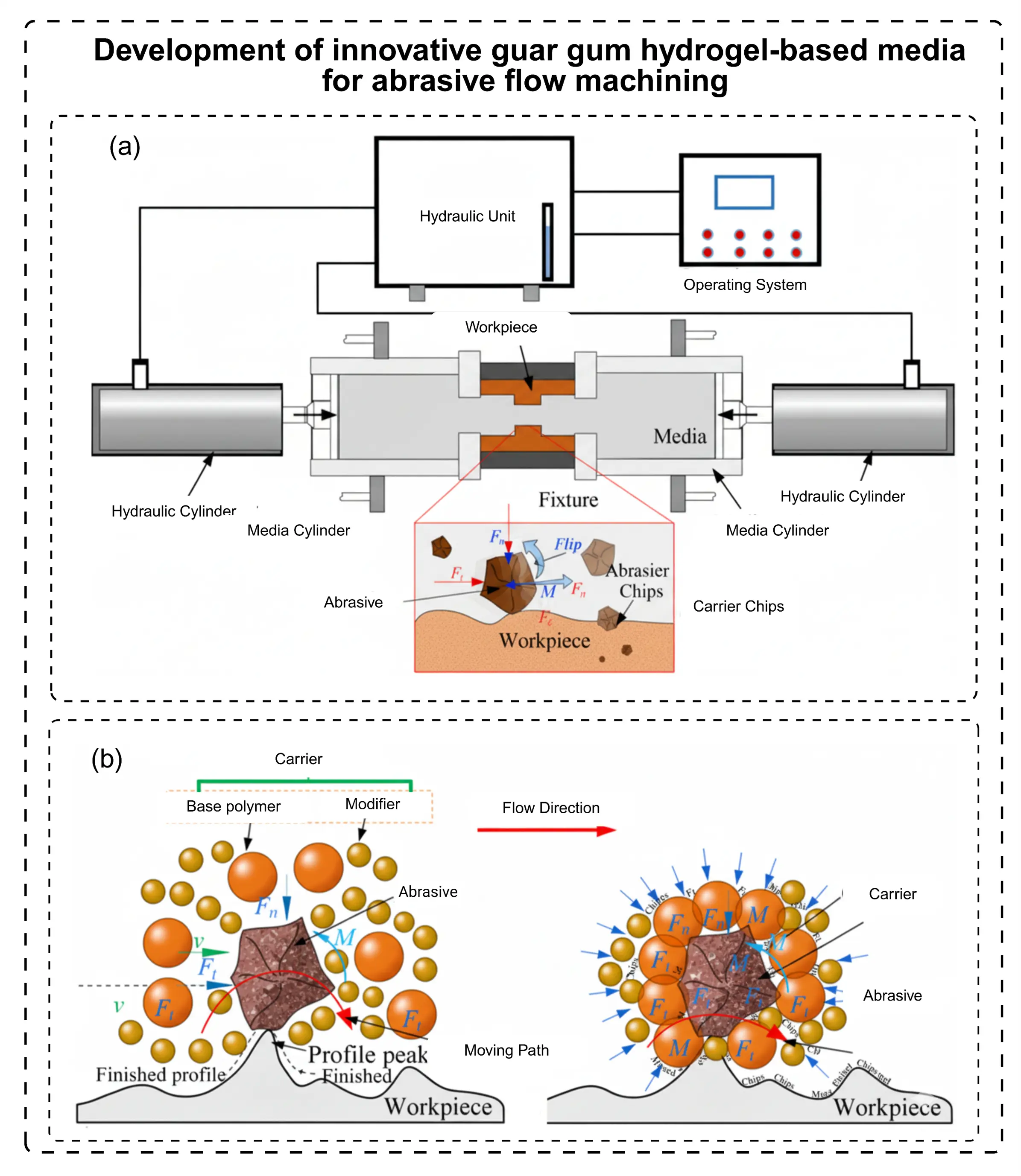

Wei et al. (2019) proffered a pioneering guar gum hydrogel-derived abrasive matrix manifesting shear-thickening rheology for integration into Abrasive Flow Machining (AFM) paradigms, as schematized in Figure 14. Their empirical inquiries evinced that within shear-thickening regimes, the material removal rate (MRR) surged from 69 to 351 mg/h, paralleled by a marked amelioration in surface roughness (Ra) from 120.12 to 6.48 nm. This escalation in refinement potency arises from the matrix’s resilience to shear deformation, enabling efficacious abrasive grit conveyance at augmented shear gradients. Additionally, guar gum hydrogel matrices constitute an ecologically benign surrogate to conventional petroleum-derived media, harnessing aqueous dispersibility and streamlined recyclability to curtail anthropogenic perturbations [45].

2.3. Challenges in Conventional AFF

Although conventional Abrasive Flow Finishing (AFF) excels at achieving high-quality surface finishes, it faces significant limitations in high-precision, high-performance manufacturing contexts. Specifically, this process struggles with slow material removal rates (MRR), limited effectiveness on hard-to-machine materials, and challenges in processing intricate internal features. For instance, superalloys and ceramics, commonly used in aerospace and medical applications, resist abrasive action, necessitating extended processing times and reduced efficiency. Furthermore, AFF often produces inconsistent surface finishes on complex geometries, particularly those with varying hardness or internal passages, impeding its applicability in industries that demand precision.

- I

-

Slow Material Removal Rates (MRR): Conventional AFF paradigms are typified by attenuated material-removal rates, thereby curtailing procedural throughput in exigencies that mandate elevated excision kinetics, emblematic of the aeronautical and vehicular sectors. The unmitigated dependence on abrasive matrix interfacial impingement, devoid of supplementary force vectors, engenders protracted operational spans, rendering it suboptimal for voluminous or chronosensitive enterprises.

- II

-

Inconsistent Surface Finish: Although AFF generally enhances surface quality, its capacity to achieve uniform finishes across complex geometries and materials with varying hardnesses is limited. Media flow often fails to uniformly address all surface features, resulting in variations in surface roughness and finish quality, particularly in components with intricate geometries or heterogeneous materials.

- III

-

Challenges in Processing Hard Materials: The efficacy of AFF decreases with hard materials such as superalloys, ceramics, and high-strength steels. These materials resist abrasive media, requiring longer processing or increased media flow, thereby reducing process efficiency. Thus, conventional AFF is less effective in industries working with advanced or hard-to-machine materials.

- IV

-

Difficulty with Intricate Internal Features: A notable challenge is the inefficiency of traditional AFF in processing internal features such as blind holes, narrow passages, or intricate geometries. The abrasive media may not effectively traverse these areas, causing inconsistent material removal and suboptimal finishing.

These intrinsic impediments underscore the imperative for sophisticated remedial paradigms, notably hybrid AFF modalities. Such frameworks synergize conventional abrasive flow kinematics with ancillary force fields or energetic infusions to amplify material removal rates, homogenize superficial topography, and extend viability to ultra-refractory substrates and non-Euclidean morphologies.

2.4. Need for Hybridization of AFF Processes

The escalating imperatives for metrological superfine refinement within aeronautical, vehicular, and biomedical engineering domains accentuate the exigency for ingenious remedial architectures to amplify procedural throughput and interfacial topography of substrate assemblies. The synergistic amalgamation of the AFF paradigm with ancillary dynamic stimuli encompassing ultrasonic oscillations, electromagnetic gradients, and rotational kinematics profoundly escalates material removal rates (MRR) and superficial fidelity, mitigating salient bottlenecks and augmenting the operational envelope of conventional AFF methodologies.

- I

-

Enhanced Material Removal Rates (MRR): Hybrid AFF techniques, using external forces such as ultrasonic energy or magnetic fields, accelerate material removal, making the process more efficient for high-demand applications, particularly in time-sensitive industries that require large-scale production.

- II

-

Improved Surface Finish Consistency: Hybrid AFF enhances surface finish uniformity, particularly for complex geometries or materials with varying hardness. Techniques such as ultrasonic-assisted AFF ensure better control over media flow, delivering consistent, high-quality finishes essential for precision applications, such as medical device manufacturing.

- III

-

Expanded Applicability to Hard-to-Machine Materials: Hybrid AFF effectively finishes hard-to-machine materials, such as superalloys and ceramics. Supplementary forces enhance the efficiency of abrasive media, enabling precise finishing of challenging materials.

- IV

-

Enhanced Precision for Complex Geometries: The growing complexity of components requires enhanced finishing precision, particularly for internal features. Hybrid AFF methods, including ultrasonic and rotational-assisted processes, provide superior control, ensuring effective material removal and surface smoothing in intricate geometries.

- V

-

Customization and Process Flexibility: The hybrid AFF paradigm exhibits inherent malleability, enabling bespoke parametric orchestration to address domain-specific exigencies encompassing substrate compositions, non-Euclidean morphologies, and interfacial topographies. Through meticulous calibration of ancillary stimuli such as sonic amplitude, electromagnetic flux density, and gyratory cadence, metrological dominion over conventional and elite-grade assemblies is realized.

- VI

-

Sustainability and Reduced Environmental Impact: Hybrid Abrasive Flow Finishing (AFF) processes enhance sustainability by reducing energy consumption, processing time, and material waste. Ultrasonic-assisted and magnetic field-assisted AFF offers eco-friendly alternatives, boosting efficiency and minimizing environmental impact, particularly in the aerospace and automotive sectors.

Hybrid paradigms have been engineered to surmount the endemic constraints of conventional AFF methodologies. These modalities amalgamate ancillary dynamic stimuli, including sonic oscillations, electromagnetic gradients, and rotational kinematics, within the canonical AFF framework, thereby amplifying procedural sophistication. The confluence of such supplementary force vectors mitigates the salient bottlenecks of conventional AFF, driving substantial increases in material removal rate (MRR), interfacial topography, and overall process governance.

Figure 15 delineates the classificatory hierarchy of Hybrid-based Abrasive Flow Finishing (HAFF) paradigms, accentuating remedial architectures for refining interfacial topography and excision throughput. The diagram categorizes these into Energy-Assisted AFF, Force-Assisted AFF, Combined Energy and Force-Assisted AFF, Other Hybrid Approaches, and Emerging Techniques. Each category includes mechanisms such as electrochemical polishing, ultrasonic vibrations, and magnetic fields, as well as technologies such as plasma and microbubbles. These classifications highlight the innovations that address the challenges of precision manufacturing.

Figure 15. Hierarchical taxonomy of Hybrid-based Abrasive Flow Finishing (HAFF) paradigms delineated by physical principles.

3. Technological Developments in Hybrid-Based Abrasive Flow Finishing

Hybrid Abrasive Flow Finishing (HAFF) techniques represent a major advancement in precision manufacturing, addressing the challenges posed by complex geometries, hard-to-machine materials, and stringent surface-finish requirements [63,64]. HAFF processes are categorized into three types: (1) Energy-Assisted AFF, (2) Force-Assisted AFF, and (3) Combined Energy and Force-Assisted AFF. The classificatory schema subsumes remedial innovations engineered to amplify excision kinetics, refine superficial topography, and augment procedural versatility, as schematized in Figure 16. Hybrid Abrasive Flow Finishing (AFF) paradigms synergize ancillary dynamic stimuli encompassing sonic oscillations, electromagnetic gradients, and rotational kinematics with canonical abrasive flow kinematics to amplify excision kinetics, superficial topography, and procedural governance. These remedial architectures attenuate the endemic constraints of conventional AFF, catalyzing efficacious refinement of non-Euclidean morphologies.

The metamorphosis of AFF paradigms into hybrid architectures signifies a watershed in realizing superlative interfacial topographies, amplified material removal rates (MRR), and augmented procedural sophistication. These fused modalities engraft ancillary dynamic stimuli encompassing sonic oscillations, electromagnetic gradients, and rotational kinematics upon canonical AFF frameworks, thereby surmounting the endemic constraints of conventional methodologies. This exposition interrogates the evolutionary trajectory and ramifications of hybrid AFF variants, each conferring bespoke prerogatives in metrological nanofinishing.

3.1. Energy-Assisted Hybrid AFF

Energy-assisted Abrasive Flow Finishing (AFF) paradigms incorporate extraneous energetic infusions to augment the interfacial kinetics between the abrasive media and the substrate [55]. This confluence engenders amplified procedural sophistication, escalated material removal rates (MRR), and a refined superficial topography.

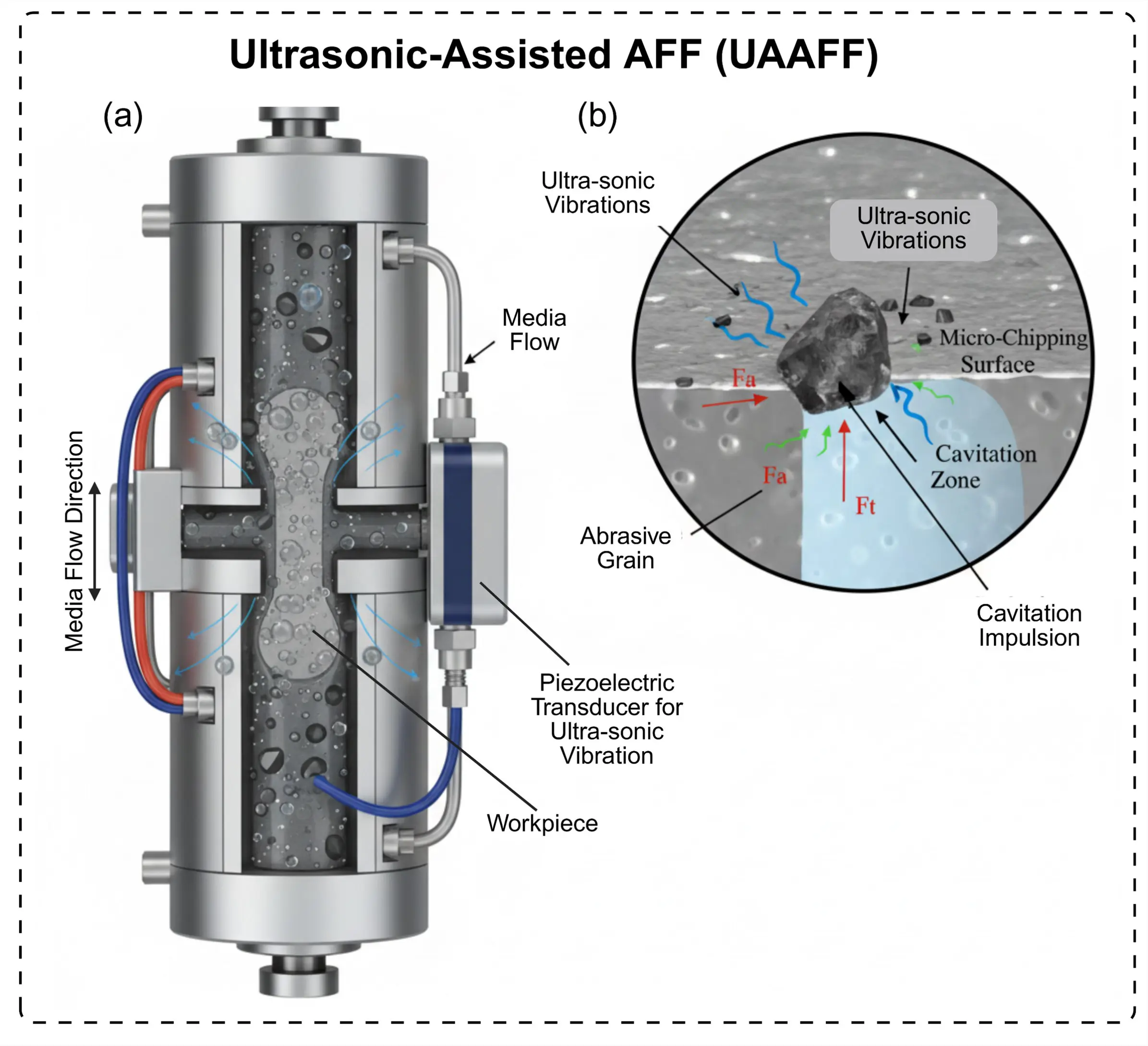

3.1.1. Ultrasonic-Assisted AFF (UAAFF)

Ultrasonic-Assisted Abrasive Flow Finishing (UAAFF) constitutes an evolved augmentation of the Abrasive Flow Finishing (AFF) paradigm. By engrafting ultrasonic oscillations at elevated frequencies (20–40 kHz), UAAFF amplifies the interfacial kinetics between abrasive media and substrate strata. Sonic energy elicits nanoscale perturbations within abrasive grits, thereby escalating excision throughput and refining superficial topography [62].

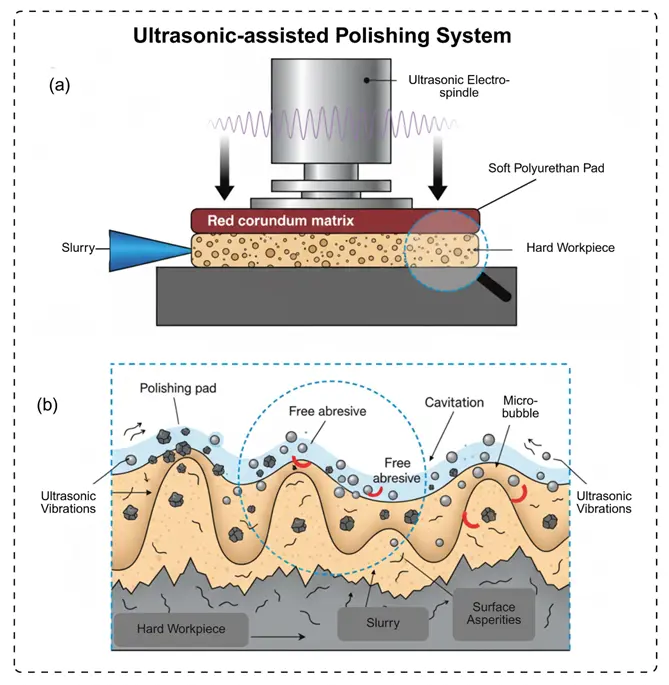

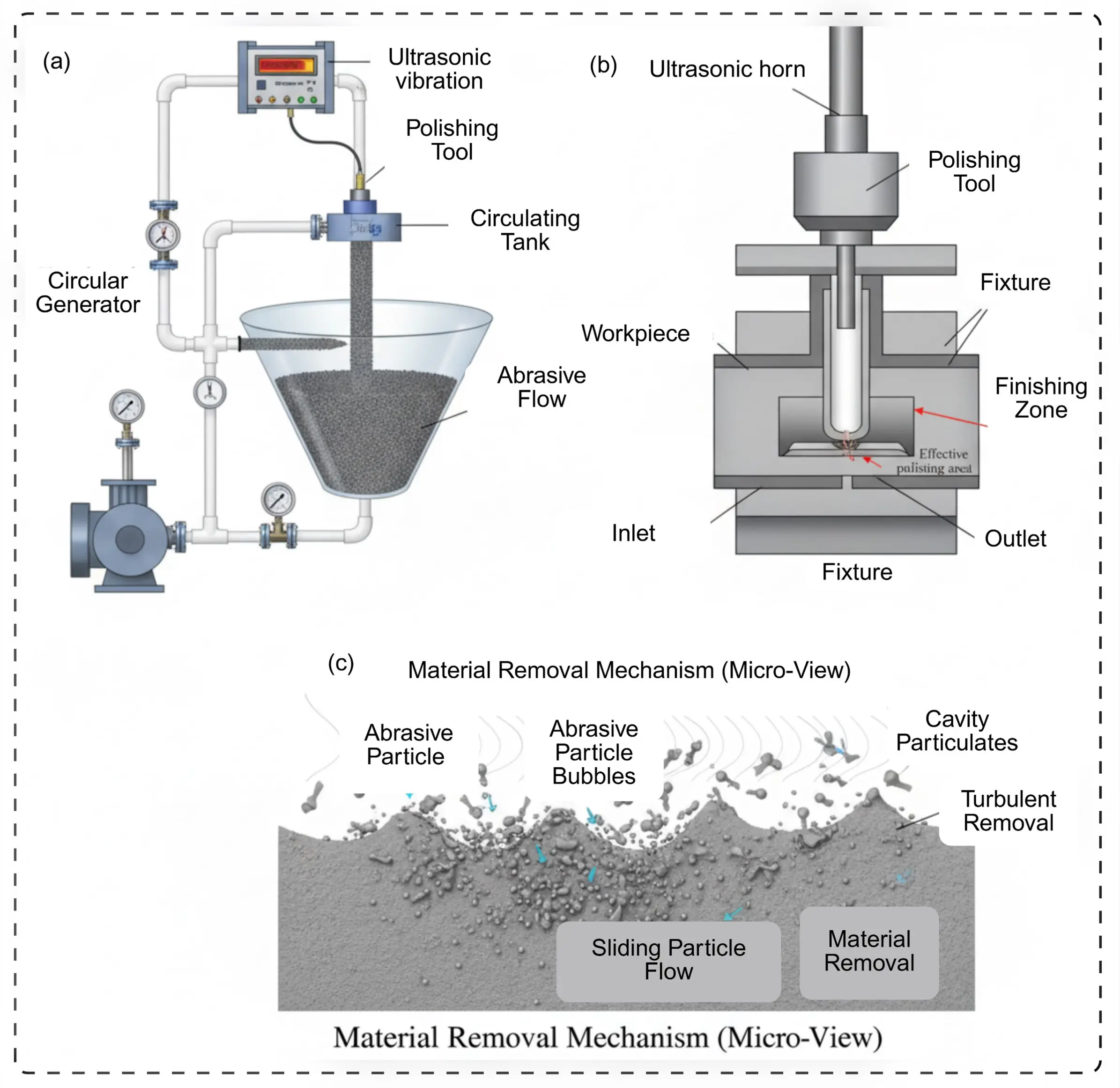

Ultrasonic vibrations profoundly modulate the interfacial boundary stratum between abrasive grits and substrate surfaces, augmenting particulate dispersity and kinetic engagement. This ablation vector confers metrological precision in excision, ameliorated superficial topography, and escalated material removal rates (MRR), with salient efficacy for recalcitrant substrates such as superalloys and ceramics. UAAFF attains sub-micrometric interfacial asperity (Ra ≈ 0.05 µm), rendering it preeminently apt for exigencies mandating superlative planarity, including osseointegrative prostheses, aeronautical fixtures, and refractive optics [73,74,132]. Sonic oscillations attenuate rheological impedance in the abrasive media, thereby amplifying procedural sophistication and excision homogeneity, even across labyrinthine morphologies. Figure 16 presents the diagrammatic archetype and empirical instantiation of the UAAFM apparatus deployed for bevel-gear interfacial amelioration.

The Ultrasonic-Assisted Abrasive Flow Polishing (UAAFP) apparatus is schematized, wherein Figure 17a delineates the systemic architecture, incorporating the sonic oscillator, centrifugal impeller, and recirculatory traversal of the abrasive slurry to the refinement effector. Figure 17b highlights the Strongly Constrained Space (SCS) regime, in which sonic wavefronts impinge on abrasive grits to amplify refinement potency. Figure 17c portrays the synergistic confluence of sonic wavefronts, cavitation effervescence, and vortical hydrodynamics, catalyzing efficacious substrate ablation at the interfacial stratum [133]. As schematized in Figure 17, this architecture profoundly amplified both excision throughput and superficial integrity.

Figure 17. Setup for Ultrasonic-Assisted Abrasive Flow Polishing (UAAFF), Featuring Ultrasonic Waves and Abrasive Particles in the Strongly Constrained Space (SCS) to Enhance Material Removal via Cavitation-Induced Bubbles and Turbulent Sliding Flow, Incorporating Circulating Abrasive Tank, Vibration Actuation, and Teflon Tooling Configuration: (a) UAAFF Integrated Schematic and Hydraulic Drive System, (b) Ultrasonic Horn Assembly with Workpiece Fixture and Effective Polishing Zone, and (c) Microscopic MRR Mechanism [133].

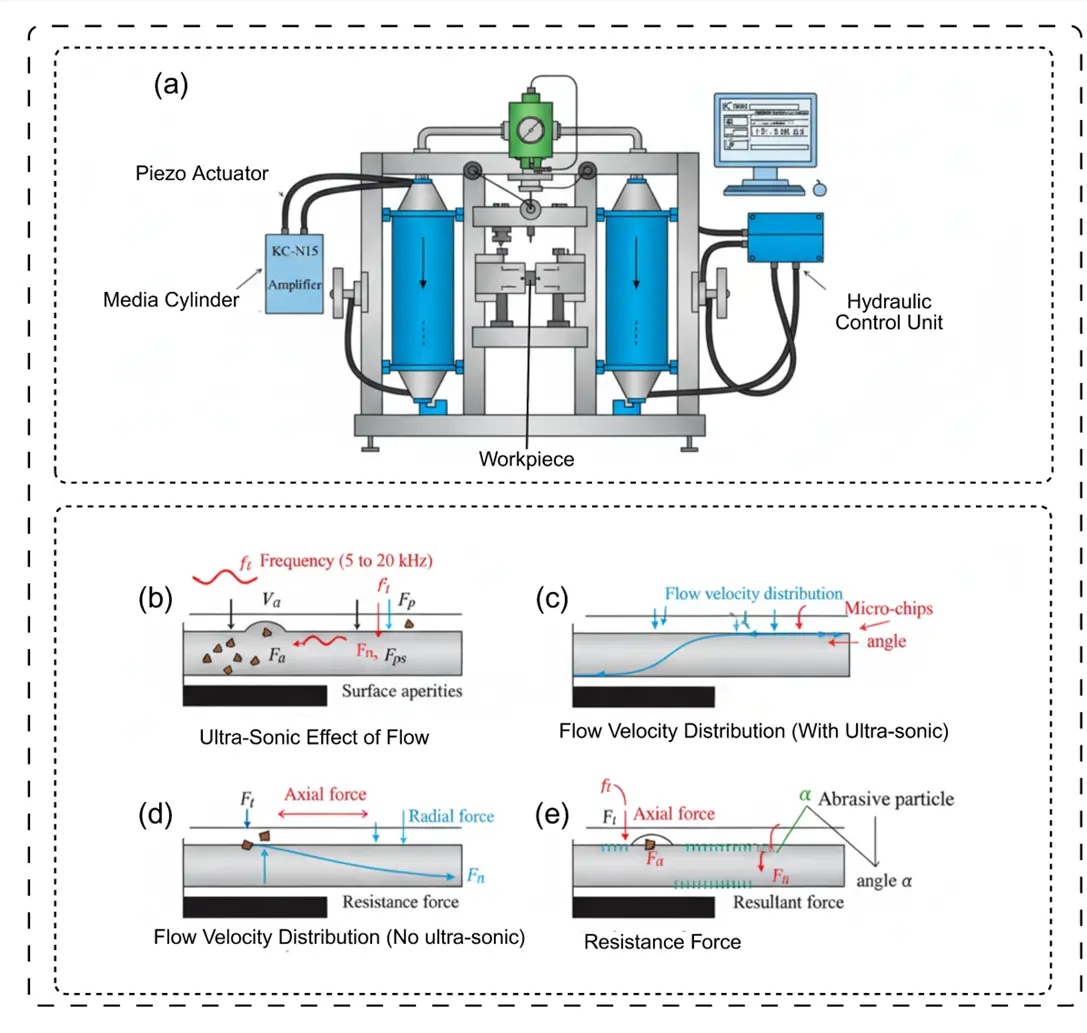

Venkatesh et al. (2015) examined the effects of sonic oscillations on abrasive matrix traversal in Ultrasonic-Assisted Abrasive Flow Machining (UAAFM) paradigms using computational fluid dynamics (CFD) modeling. Their findings evinced that sonic perturbations (5–20 kHz) amplified grit-substrate interfacial impingement, thereby escalating material removal rates (MRR) and superficial topography. This inquiry underscores the salience of oscillation amplitude in modulating interfacial shear gradients, exerting negligible influence on matrix kinematics and pressure contours [67]. Such ingenuity profoundly refines the sophistication of canonical Abrasive Flow Machining (AFM) frameworks. As schematized in Figure 18, the empirical apparatus and simulational outputs corroborate the augmented efficacy of UAAFM through sonic augmentation [134].

Figure 18. Schematic representation of the UAAFM setup and simulation results, showcasing the effect of ultrasonic vibrations on MRR mechanism and AFF media flow behavior: (a) Integrated hydraulic and piezoelectric actuation system with media cylinders and control Unit, (b) Ultrasonic effect on abrasive flow with frequency-induced cavitation and particle dispersion, (c) Simulated flow velocity distribution and micro-chip formation under ultrasonic influence, (d) Baseline flow velocity distribution without ultrasonic vibration, and (e) Resultant force analysis including axial, radial, & abrasive particle impact angles on resistance [134].

Compared to conventional AFF, UAAFF has been shown to reduce processing time by up to 30% while maintaining or even improving surface quality. This reduction in processing time, combined with high precision, renders UAAFF particularly beneficial for high-volume manufacturing applications, where cost-effectiveness and efficiency are critical [135,136,137]. The enhanced performance in UAAFF arises from the synergy between ultrasonic vibrations and the abrasive media, which generate localized regions of high pressure and temperature within the flow. This localized energy facilitates aggressive material removal without the need for excessive force, which is especially beneficial for processing hard-to-machine materials, complex geometries, and components that are susceptible to work hardening [73,138,139].

The Ultrasonic-Assisted Abrasive Flow Finishing (UAAFF) apparatus is schematized, delineating systemic architecture (A), grit-substrate interfacial kinetics (B), empirical instantiation (C), refinement effector morphology (D), and topographical contrast (E). The synergistic engraftment of sonic perturbations with electromagnetic governance amplified abrasive grit dispersity and vectorial exactitude, as rendered in Figure 19.

Ultrasonic-Magnetic AFF (UMAFF)

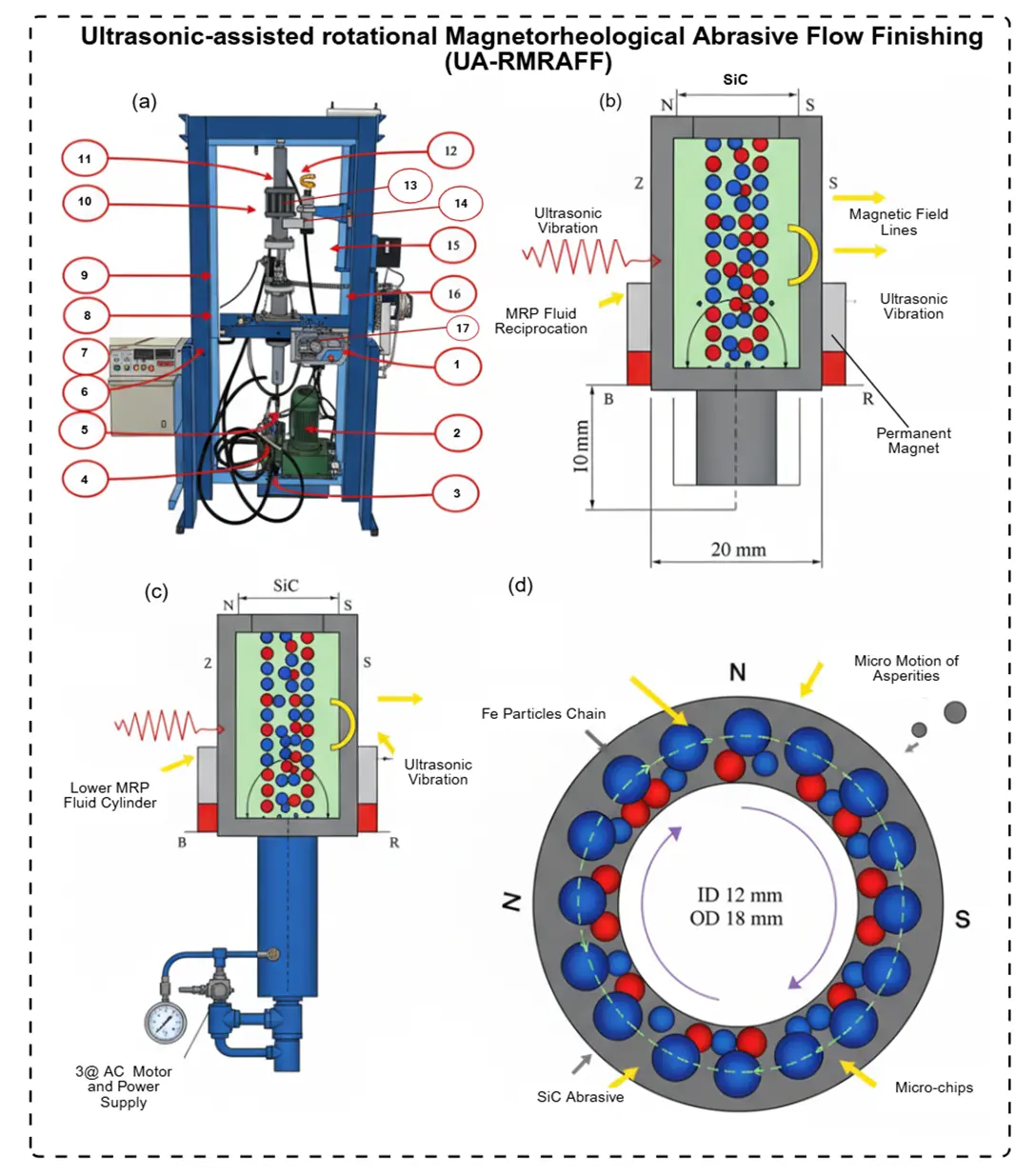

The Ultrasonic Magnetic-Assisted Abrasive Flow Finishing (UMAFF) paradigm synergizes sonic oscillations with electromagnetic governance to amplify grit dispersity and vectorial exactitude. The Ultrasonic-Assisted Rotational Magnetorheological Abrasive Flow Finishing (UA-RMRAFF) apparatus and regulatory interface for orchestrating the UA-RMRAFF framework are schematized in Figure 20.

Figure 20. UA-RMRAFF apparatus and finishing mechanism: (a) An overview of UA-RMRAFF apparatus and method: 1: Operation panel, 2: 3-ɸ. A.C. (three-phase motor and pump, 3: hydraulic power unit, 4: pressure adjusting screw, 5: pressure gauge, 6: lower hydraulic cylinder, 7: limit switch, 8: Lower MRPF cylinder, 9: Upper MRPF Cylinder, 10: limit switch, 11: upper hydraulic cylinder, 12: upper plate, 13: mechanism of the upper MRPF cylinder mounting arm, 14: variable frequency drive (VFD), 15: gear wheel with chain, 16: motor, 17: Ultrasonic power supply, (b) Finishing zone schematic, (c) MR fluid cylinder cross-section, (d) Abrasive action details [141].

3.1.2. Laser-Assisted AFF (LAAFF)

Laser energy is introduced to the workpiece surface to facilitate better material removal while minimizing thermal damage. In LAFF, localized laser heating softens the workpiece material, enabling deeper abrasive penetration and more efficient material removal [142].

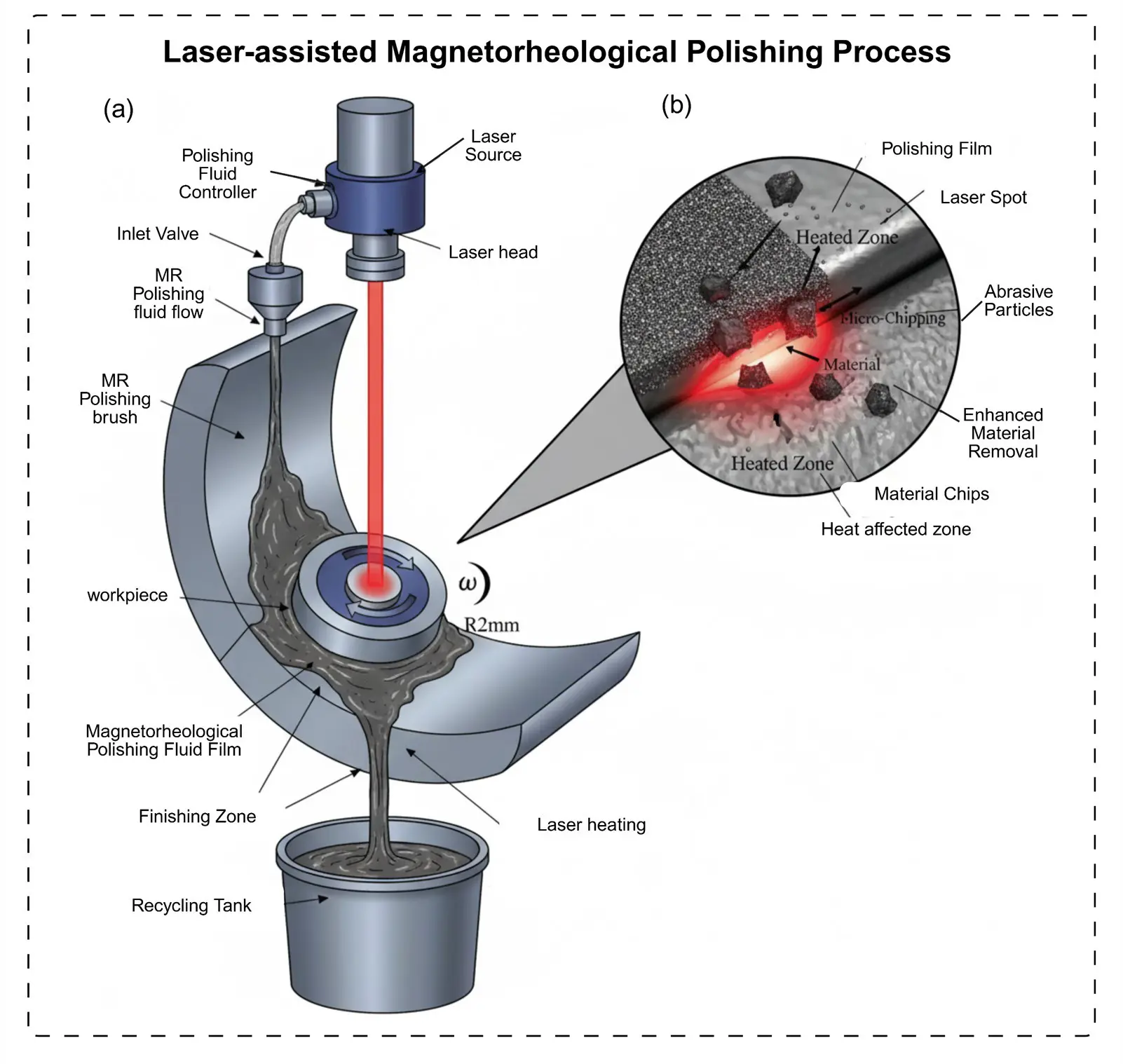

The Laser-Assisted Abrasive Flow Finishing (LAAFF) paradigm synergizes focalized photonic irradiation with canonical abrasive flow kinematics to amplify substrate ablation via localized interfacial tempering. This attenuation in substrate tenacity facilitates enhanced grit incursion, thereby catalyzing escalated excision efficacy, with a pronounced aptitude for recalcitrant substrates such as ceramics and case-hardened alloys [136]. An advanced variant of LAAFF, Laser-Assisted Magnetorheological Polishing (LAAFF-MRP), incorporates controlled laser energy applications to facilitate ultra-fine surface finishes. In this approach, the localized thermal effects of the laser are precisely applied to specific regions of the workpiece, minimizing thermal damage to surrounding areas. The integration of laser technology into the material removal process enables precise management, ensuring uniform polishing even on intricate geometries while preserving surface integrity. This hybrid approach is particularly beneficial for industries demanding ultra-fine surface finishes, such as optics, aerospace, and precision tooling, where achieving high precision is paramount [136,137,143].

As shown in Figure 21, this innovative approach highlights the potential of hybrid techniques integrated with the laser-assisted magnetorheological polishing technique to deliver a superior surface quality in demanding applications.

3.1.3. Electrochemical-Assisted Abrasive Flow (ECAFF)

This method combines electrochemical effects with abrasive flow, enhancing material removal in hard alloys.

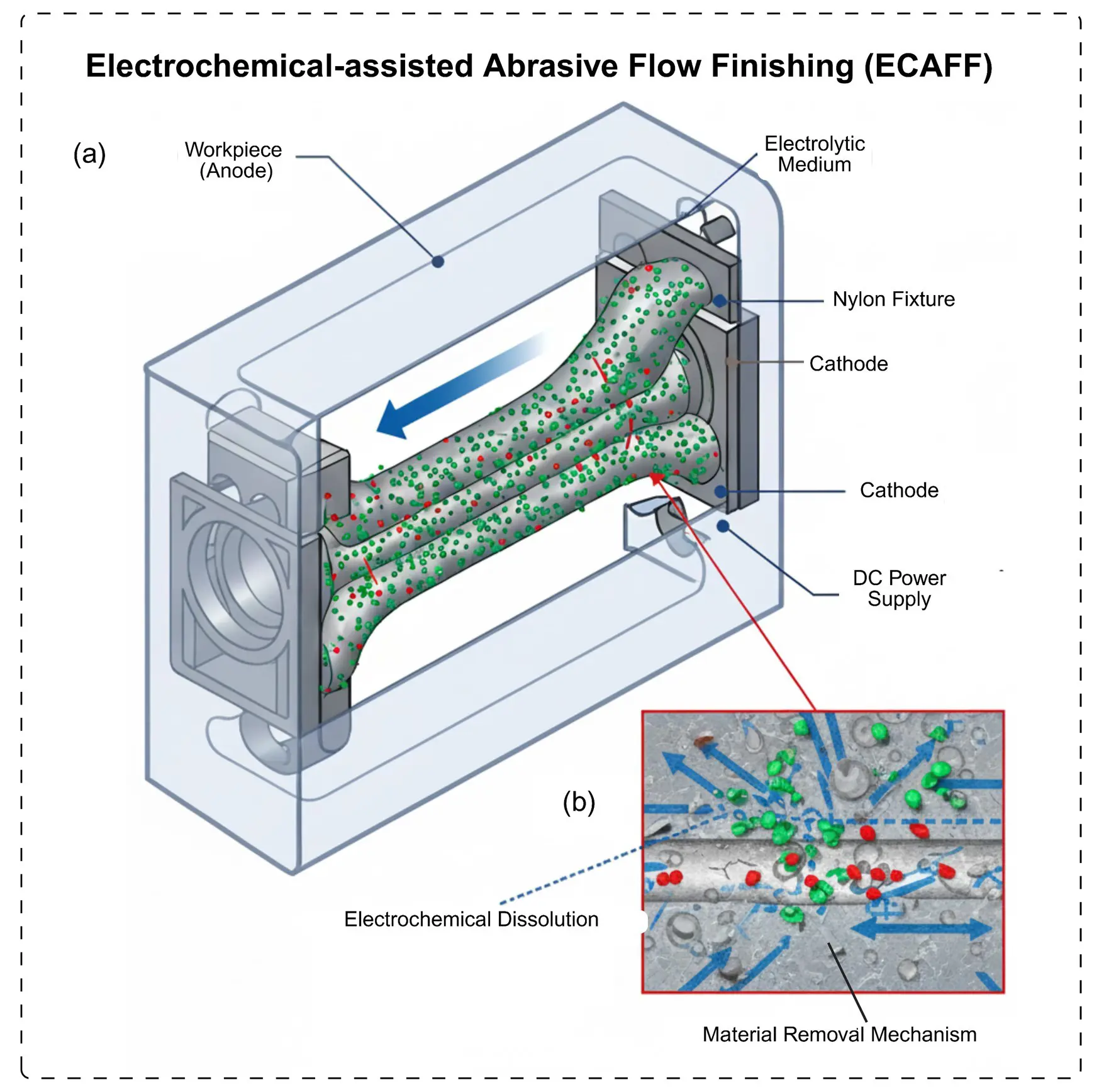

Electrochemical-Assisted Abrasive Flow Finishing (ECAFF) synergizes the tenets of Electrochemical Machining (ECM) with Abrasive Flow Finishing (AFF) paradigms. Within this fused modality, the substrate manifests anodic decoalescence via electrolytic catalysis, engendering localized interfacial tempering. This attenuation of superficial tenacity diminishes abrasive impedance, thereby catalyzing efficacious excision kinetics. ECAFF evinces preeminent aptitude for galvanically responsive substrates, including Inconel superalloys and titanium matrices, yielding superlative outcomes in ameliorating recalcitrant metallic architectures [74,139].

The Electrochemical-Assisted Abrasive Flow Finishing (ECAFF) apparatus ordinarily incorporates a bespoke restraint for substrate immobilization and an electrolytic chamber catalyzing anodic decoalescence. Figure 22 schematizes the ECAFF paradigm, accentuating the synergistic interplay of electrolytic catalysis and abrasive impingement. The empirical instantiation of this configuration is depicted in Figure 22, which delineates the nylon restraint engineered for metrological alignment during operational iterations.

Figure 22. Schematic of the electrochemical-assisted abrasive flow finishing (ECAFF) process: (a) experimental setup with anodic workpiece, electrolytic slurry flow, and cathodic configuration, (b) detailed view of synergistic electrochemical dissolution and abrasive material removal at the interface [75].

Enhanced Surface Finish: ECAFF delivers ultra-fine finishes on complex geometries, often surpassing those achieved with traditional methods. Reduced Tool Wear: The electrochemical reaction reduces the mechanical load on the abrasives, prolonging the media life and decreasing costs. This method is ideal for the aerospace, biomedical, and high-precision engineering industries [74,135,139].

3.2. Force-Assisted Hybrid AFF

These techniques incorporate mechanical forces to improve precision and material removal.

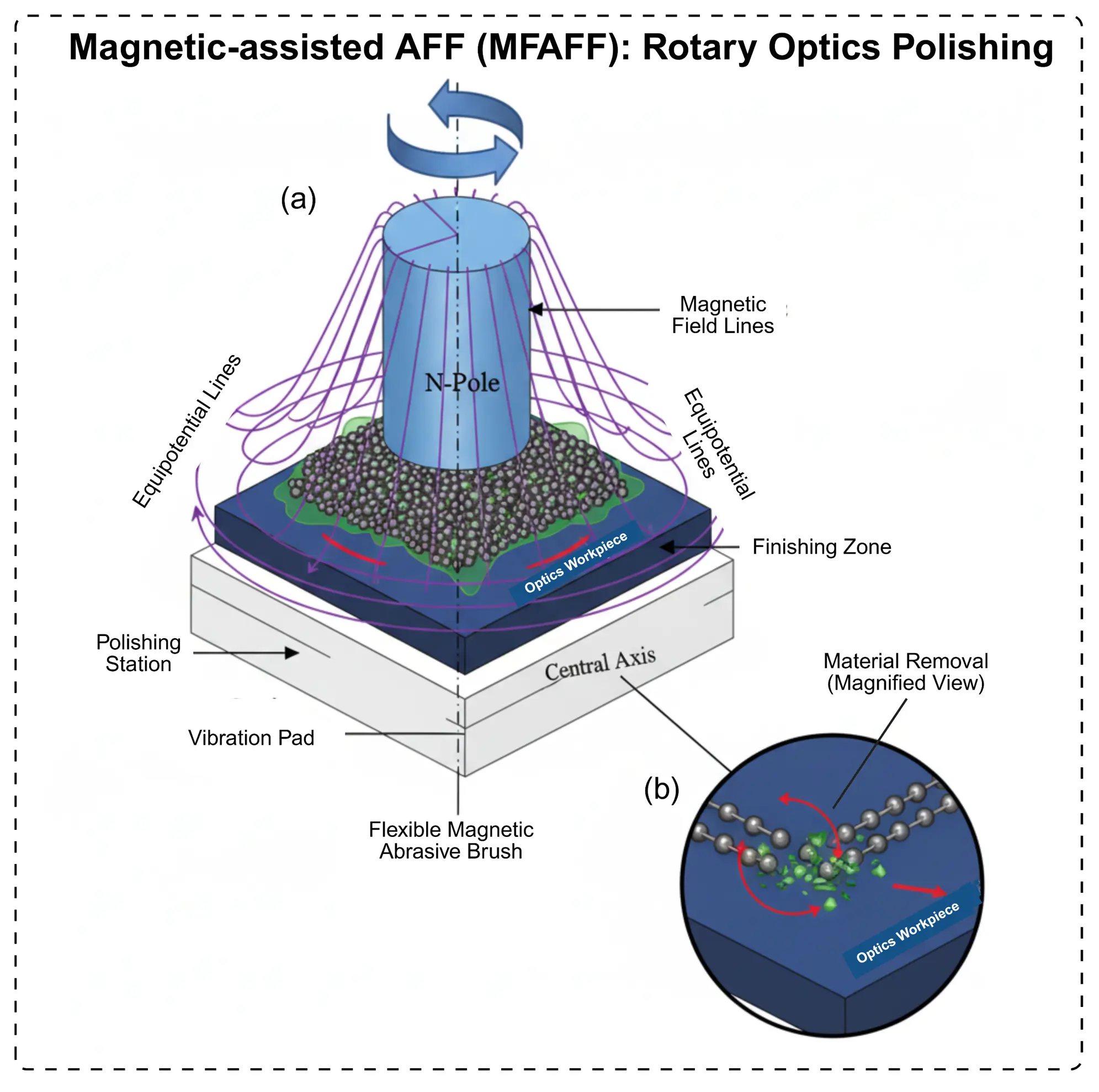

3.2.1. Magnetic-Assisted AFF (MFAFF)

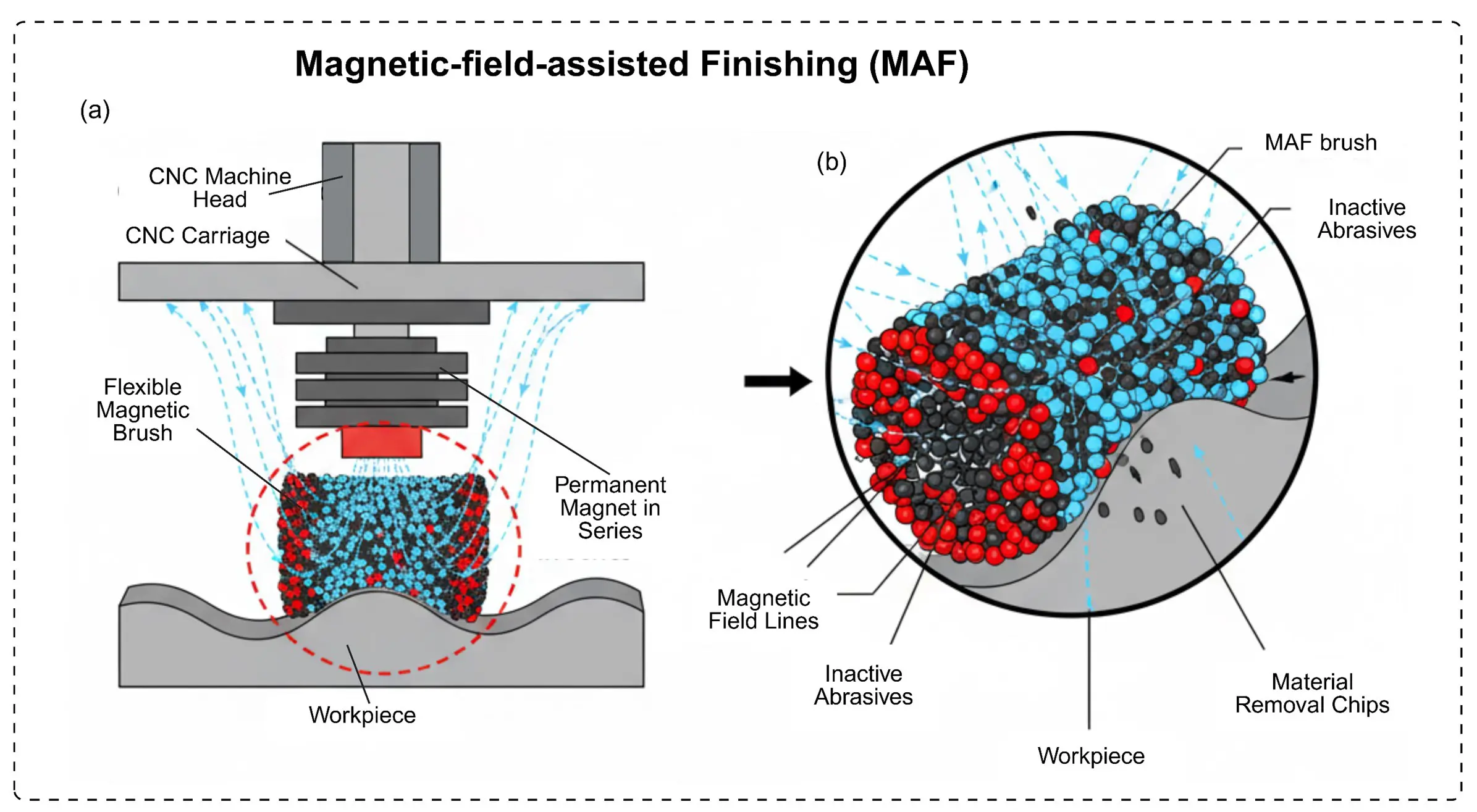

Magnetic Field-Assisted Abrasive Flow Finishing (MFAFF) harnesses electromagnetic gradients to modulate the kinematics of ferromagnetic abrasive grits sequestered within the refinement matrix. These gradients confer oriented alignment and enhanced impingement kinetics on the grits at substrate interfaces, engendering nanometric interfacial asperities and regulated excision trajectories. This technique is particularly advantageous for finishing ferromagnetic materials, where precise control of abrasive forces is essential for achieving the desired surface characteristics. It provides controlled particle alignment for the superior finishing of ferromagnetic materials [132]. The designed MAF tool for flat-surface finishing is illustrated in Figure 23.

Figure 23. Schematic of the magnetic-assisted abrasive flow finishing (MFAFF) process for rotary optics: (a) integrated setup with rotating workpiece, n-pole magnet, and field-controlled abrasive brush, (b) close-up of flexible brush interaction and directional material removal at the optics interface [144].

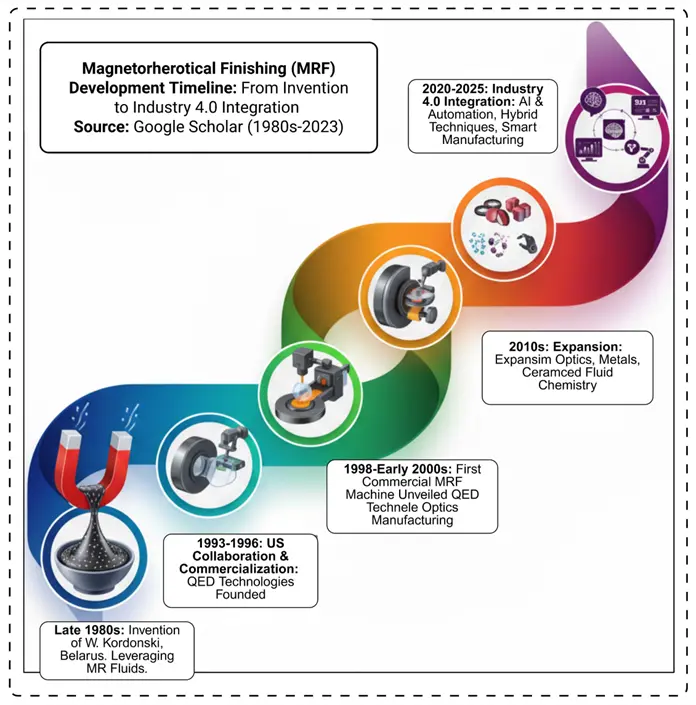

The development of magnetorheological (MR) polishing technology, as illustrated in Figure 24, originated from the identification of magnetic fluid properties in 1948. In 1974, the concept of MR polishing was formulated, leading to the creation of the prototype in 1992. Subsequent advancements facilitated its commercialization in 1997 by QED Technologies, establishing MR polishing as a critical tool for precision applications. This technology has since been employed in the defense, medical, and civil engineering sectors for high-precision tasks, such as semiconductor wafer and optical mirror polishing. Recent advancements in the 2020s have further integrated with Industry 4.0, enhancing control and efficiency, thereby rendering MR polishing indispensable for producing advanced optical and precision components.

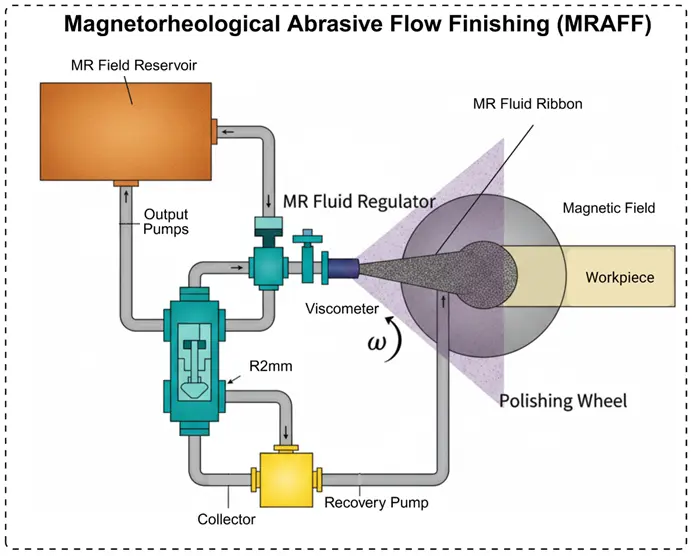

Magnetorheological Abrasive Flow Finishing (MRAFF) harnesses magnetorheological (MR) fluids to govern the trajectories of abrasive grits. Electromagnetic gradients precipitate instantaneous rheological reconfiguration of the MR matrix, thereby imparting meticulous oversight of particulate impingement and elevating refinement metrology, with salient efficacy for labyrinthine morphologies. This technique is particularly suitable for microtools, MEMS components, and advanced optical systems. MRAFF is distinguished by its high adaptability, exceptional precision, and enhanced control over the abrasive medium, rendering it an indispensable process in advanced manufacturing and microfabrication sectors. The MRAFF setup, illustrated in Figure 25, comprises critical components such as the MR fluid reservoir, polishing wheel, nozzle, and workpiece, all of which are regulated by a magnetic field to ensure precise finishing.

Magnetic Field-Assisted Abrasive Flow Finishing (MFAFF) harnesses electromagnetic gradients to govern the trajectories of abrasive grits, thereby amplifying metrological exactitude and procedural sophistication. Through calibrated modulation of flux density and vectorial disposition, MFAFF confers meticulous dominion over interfacial topography, with pronounced efficacy in ameliorating [73,74,132]. The effectiveness of Magnetic Field-Assisted Abrasive Flow Finishing (MFAFF) paradigms hinges primarily on the use of engineered ferromagnetic abrasive matrices. These matrices comprise ferromagnetic grits such as iron or cobalt alloy particulates sequestered within a viscoelastic oligomeric scaffold. Under electromagnetic gradients, these grits orient along flux trajectories, engendering vectorial abrasive impingement. This orchestrated alignment not only escalates shear transduction but also confers meticulous governance, thereby enabling MFAFF to realize nanometric interfacial homogeneity surpassing that of canonical Abrasive Flow Finishing (AFF) methodologies [135,136].

The Magnetic Field-Assisted Finishing (MAF) paradigm within a CNC milling architecture is schematized, in which a ferromagnetic effector, driven by the spindle, interfaces with the MAF brush. The substrate remains immobilized upon the translational carriage, facilitating unidirectional traversal during refinement. Abrasive grits sequestered within the MAF brush coalesce into ferromagnetic lattices oriented along flux trajectories. The interfacial grits engaging the substrate constitute active abrasives, orchestrating substrate ablation. Figure 26 delineates this procedural instantiation.

Magnetic Field-Assisted Abrasive Flow Finishing (MFAFF) produces superlative interfacial topographies, with nanometric asperity (Ra ≈ 0.02 µm), and demonstrates preeminent efficacy for non-Euclidean or fragile assemblies. The controlled magnetic field precisely modulates abrasive force, preventing over-finishing and damage while enhancing abrasive particle impact, leading to higher material removal rates (MRR). This combination of fine surface quality and efficient material removal renders MFAFF ideal for hard, wear-resistant materials and complex geometries [137,138]. A key advantage of the MFAFF is its exceptional process control and flexibility. The ability to adjust the magnetic field strength and orientation in real time allows operators to fine-tune the finishing process. This capability makes Magnetic Field-Assisted Finishing (MFAFF) highly adaptable to various materials and geometric shapes. MFAFF evinces preeminent aptitude for metrological exigencies, notably in aeronautical and biomedical implant domains. Its malleability and potency are corroborated by the reproducible attainment of superlative interfacial topographies across heterogeneous implementations [73,139].

3.2.2. Rotational-Assisted AFF (RAFF)

Rotational Abrasive Flow Finishing (RAFF) augments canonical Abrasive Flow Finishing (AFF) paradigms by engrafting gyratory kinematics to either substrate assemblies or abrasive matrices. This rotational augmentation amplifies grit-substrate interfacial impingement, perpetuating the stochastic redistribution of abrasive particulates. It attenuates localized erosional heterogeneity, engendering isotropic superficial homogeneity and mitigating the endemic constraints of traditional AFF methodologies, notably procedural constancy and topographical uniformity [73,74]. The engraftment of gyratory kinematics in Rotational Abrasive Flow Finishing (RAFF) paradigms profoundly amplifies the interfacial mechanics between abrasive grits and substrate assemblies, thereby catalyzing escalated excision throughput. This modality evinces preeminent utility for axi-symmetric or rotational contours, wherein topographical isotropy is paramount. Interfacial topography underpins superlative functional efficacy, and RAFF manifests exceptional aptitude in ameliorating precision artifacts, such as helical gears and rotary shafts. The stochastic reconfiguration of abrasive grits amid erosional attrition attenuates superficial undulations, rendering RAFF singularly apt for metrological nanofinishing imperatives [132,135].

Rotational Abrasive Flow Finishing (RAFF) paradigms profoundly amplify material removal rates (MRR) and interfacial topography relative to traditional Abrasive Flow Finishing (AFF) methodologies. Gyratory kinematics attenuate superficial anomalies encompassing nanoscale incisions and anisotropic erosional gradients, thereby engendering homogeneous and compliant topographies aligned with sectoral imperatives. Moreover, through calibrated modulation of rotational cadence and vectorial disposition, procedural adaptability is realized, conferring bespoke aptitude for ultra-minute interfacial refinements on metrological artifacts [136,137,138].

The inherent malleability of Rotational Abrasive Flow Finishing (R-AFF) paradigms confers bespoke applicability across heterogeneous substrate compositions and non-Euclidean morphologies, enabling parametric orchestration for domain-specific refinement imperatives. Beyond canonical Abrasive Flow Finishing (AFF) governance, R-AFF engrafts vectorial rotational calibration, thereby amplifying interfacial topography and homogeneity. This configurational versatility evinces preeminent utility in vehicular, aeronautical, and metrological engineering landscapes. The proficiency of R-AFF in interrogating disparate substrates and architectures enshrines it as a cornerstone modality in contemporary nanofinishing frameworks [73,139]. The R-AFF paradigm augments substrate excision kinetics and interfacial topography by engrafting gyratory kinematics into canonical Abrasive Flow Finishing (AFF) frameworks. Empirical inquiries evince that R-AFF attenuates surface roughness (ΔRa) by 44% and escalates material removal by 81.8%, wherein micro-crosshatch lattices engender lubricative facilitation [148].

Figure 27 schematizes an evolved Abrasive Flow Machining (AFM) paradigm augmented with gyratory kinematics (R-AFF). The superior segment delineates the systemic instantiation, incorporating a DC servo actuator for rotational propulsion, a hydraulic ram and lubricant reservoir for matrix extrusion, a thermal regulation module, and a command interface. It further portrays AFF matrix formulation via the amalgamation of an oligomeric scaffold with Sic grits. The inferior segment furnishes a sectional orthographic projection of the rotational effector, accentuating the gear train (drive gear, idler gear, subordinate gear), restraint plinths (superior and inferior), substrate cradle, and the traversal locus of AFF media through the interfacial conduit for metrological refinement.

Figure 28 schematizes the bimodal ablation dynamics in Rotational Abrasive Flow Finishing (R-AFF), wherein a viscoelastic AFF matrix (SBR + SiC + oil) is propelled into a gyratory cylindrical substrate under longitudinal actuation (Fa) and hydrodynamic transit, precipitating centripetal force (Fr) and circumferential force (Ft). This engenders micro-incision trajectories via abrasive severance at the vanguard interface and micro-fracture loci through decoalescence at the rearguard, with expelled ablation fragments catalyzing isotropic superficial homogeneity.

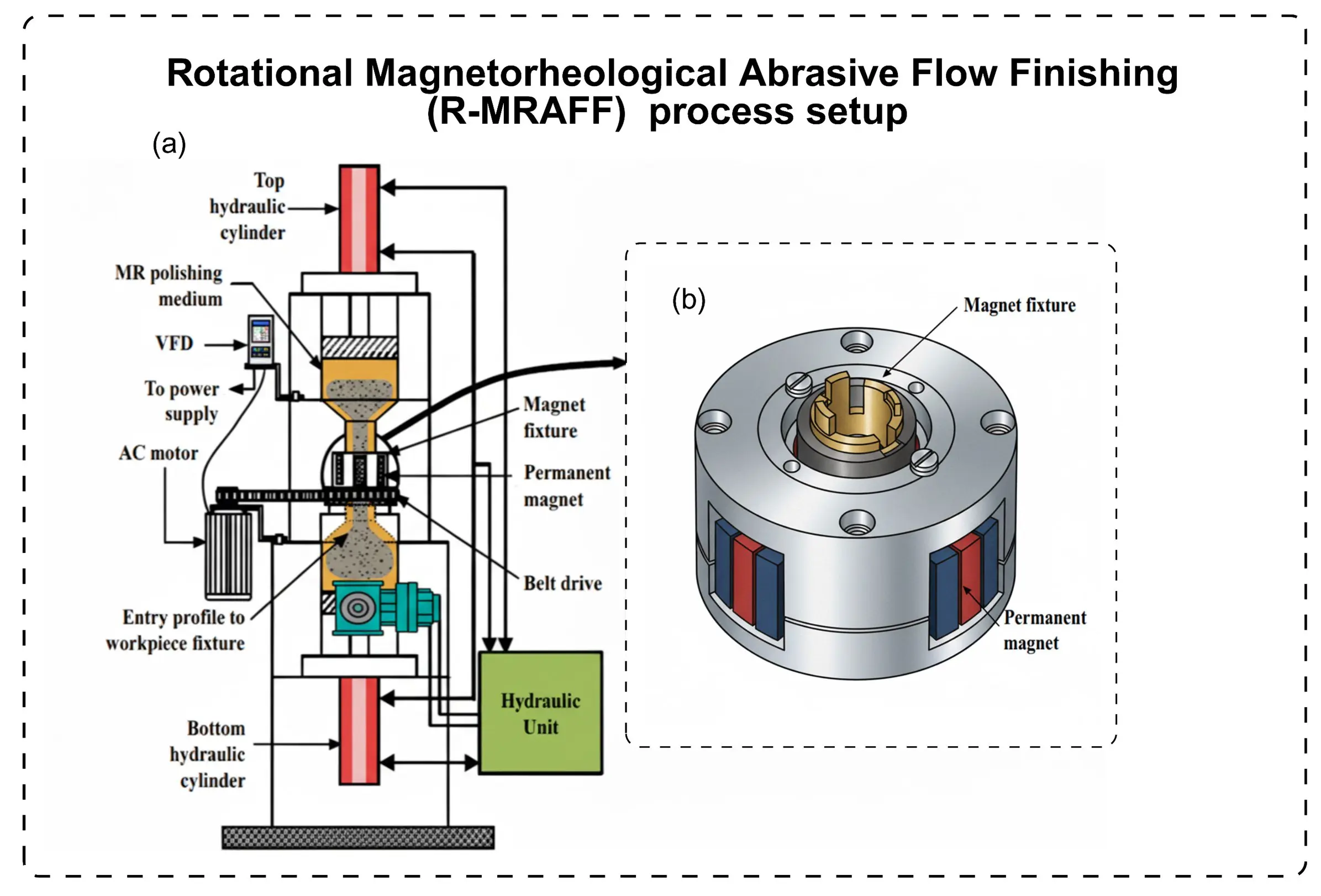

The instantiation of the Rotational Magnetorheological Abrasive Flow Finishing (R-MRAFF) paradigm is schematized in Figure 29a, delineating its cardinal constituents, and in Figure 29b, the intricate substrate restraint.

Figure 29. Diagrammatic archetype of the Rotational Magnetorheological Abrasive Flow Finishing (R-MRAFF) paradigm: (a) Synergistic hydraulic propulsion, MR matrix conveyance, and belt-propelled gyratory architecture; (b) Magnified depiction of permanent magnetic restraint with polar array and spindle linkage [150].

3.2.3. Helical-Assisted AFF (HLX-AFF)/Drill Bit-Guided AFF (DBG-AFF)

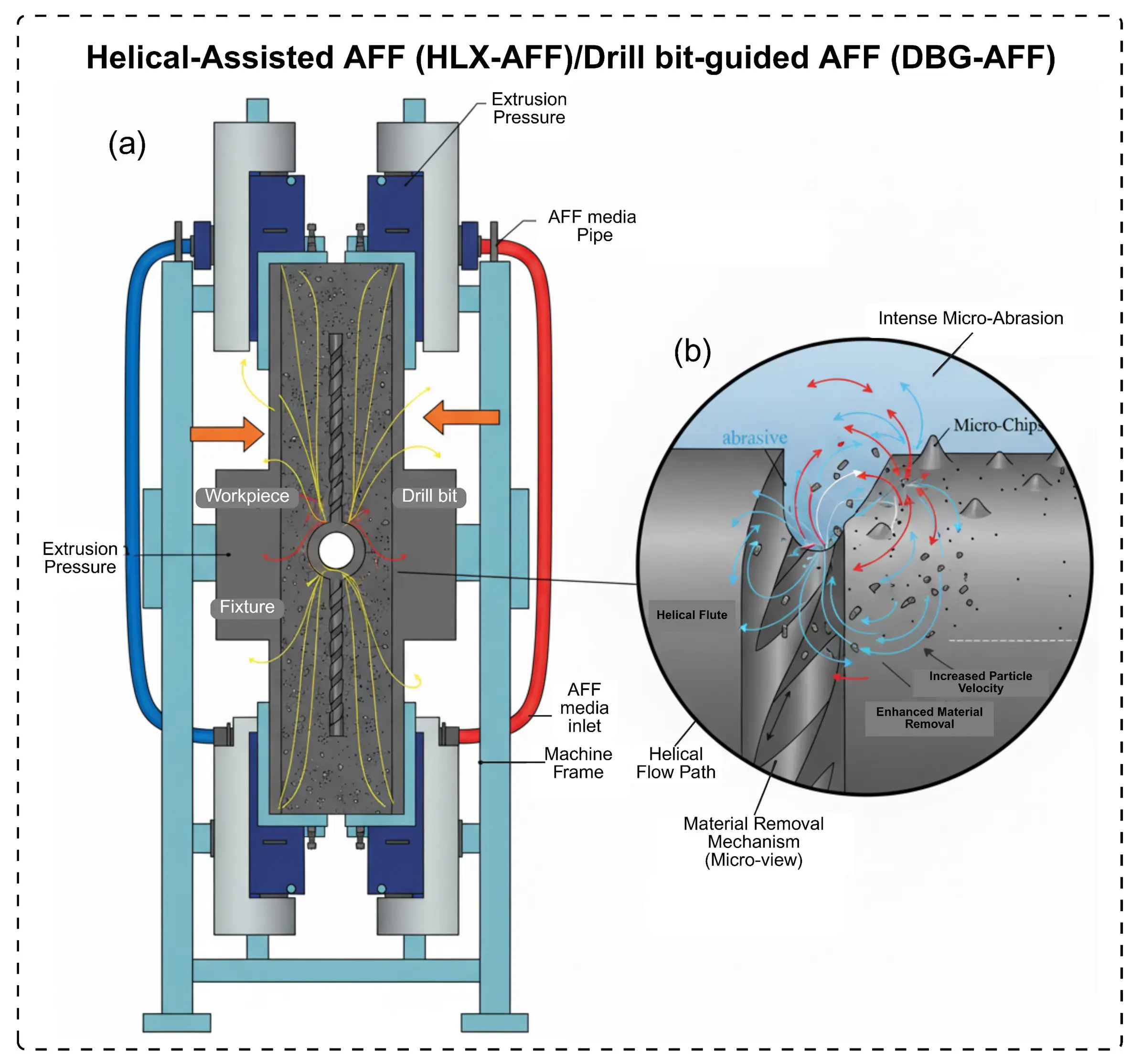

Helical-Assisted Abrasive Flow Finishing (HLX-AFF) engrafts vortical kinematics into canonical Abrasive Flow Finishing (AFF) paradigms. This helical traversal profoundly augments the rheological kinetics of the abrasive matrix, thereby escalating material removal rates (MRR) and engendering interfacial homogeneity. HLX-AFF manifests exceptional aptitude for refining non-Euclidean morphologies and recalcitrant substrates, as the vortical propulsion catalyzes exhaustive areal coverage and optimized grit-substrate impingement. Figure 30 illustrates schematic and underlying mechanisms of two advanced abrasive flow finishing (AFF) variants: Helical-Assisted AFF (HLX-AFF) and Drill Bit-guided AFF (DBG-AFF). The unified diagram depicts the experimental apparatus and tooling assembly for both processes. The HLX-AFF system enhances the traditional AFF process by incorporating a helical flux path within the fixture. This design imparts a controlled spiral motion to the abrasive media, significantly intensifying particle vorticity and contact dynamics. This confluence engenders an optimized micro-abrasive ablation vector, catalyzing amplified material removal rates (MRR) and isotropic superficial homogeneity, with preeminent utility for labyrinthine internal architectures [75].

Conversely, the DBG-AFF process utilizes a rotating drill bit as a guiding and activating tool for the abrasive media. This setup precisely controls extrusion pressure and abrasive flow, generating an Intense Micro-AFF action that effectively removes microchips from the workpiece surface. The right side of Figure 30 details this internal material-removal mechanism, highlighting the synergistic interaction between the guided tool and the abrasive medium to achieve precise finishing [151,152].

Figure 30. Diagrammatic archetype of Helical-Assisted and Drill Bit-Guided Abrasive Flow Finishing (HLX-AFF/DBG-AFF) paradigms: (a) Restraint instantiation incorporating propulsion conduits, helical borer, and hydrodynamic traversal vectors; (b) Magnified portrayal of vortical abrasion augmentation, helical channel impingement, and micro-ablation genesis [153].

3.3. Specialized Hybrid AFF

3.3.1. Cryogenic-Assisted AFF (CAFF)

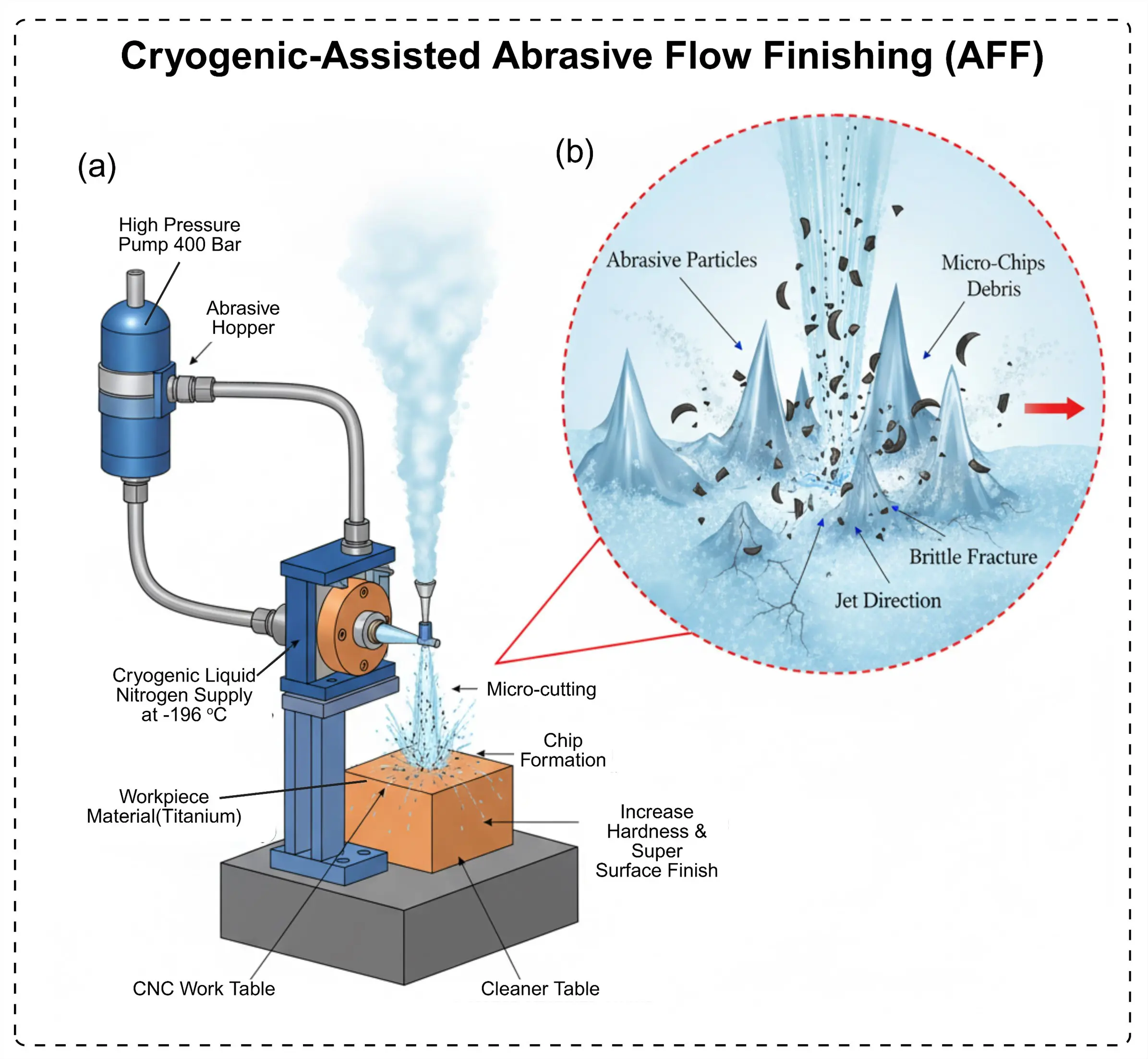

Cryogenic-Assisted Abrasive Flow Finishing (AFF) utilizes cryogenic cooling [154], wherein the deployment of liquid nitrogen (LN2) or analogous cryofluids augments the tenacity and incisive potency of abrasive grits. This thermodynamic modulation catalyzes escalated material removal rates, attenuated thermal perturbations, and refined superficial topography, conferring preeminent efficacy for ultrarefractory substrates, including aeronautical superalloys and engineered ceramics. Cryogenic-Assisted AFF (CAFF) enshrines a cornerstone modality for metrological nanofinishing imperatives within aeronautical and vanguard fabrication landscapes.

Cryogenic temperatures applied during abrasive waterjet cutting improve the surface integrity by lowering wear, plowing, and particle contamination. CAFF additionally leads to increased compressive residual stress and hardness, and a more uniform roughness profile with improved functional performance compared with conventional methods. This minimizes the thermal damage during CAFF, making it highly effective for precision manufacturing [155]. Zhang et al. (2025) interrogated the ramifications of disparate cryogenic cooling gradients on abrasive grit incorporation during cryogenic abrasive air-jet machining (CAJM) of polydimethylsiloxane (PDMS) substrates. Their empirical delineation pinpointed threshold operational regimes that attenuate particulate embedment and catalyze ameliorated interfacial topography [156]. Figure 31 depicts the configuration for Cryogenic-Assisted Abrasive Flow Finishing (CAAF) and includes micrographs comparing the surface finishes of the AWJ and CAAWJ.

Figure 31. Schematic of Cryogenic-Assisted Abrasive Flow Finishing (AFF) Process: (a) High-Pressure Abrasive Hopper, Nozzle Jetting, and Cryogenic Nitrogen Integration on CNC Table, (b) Detailed Abrasive Particle Impact, Brittle Fracture Propagation, and Micro-Chip Formation for Enhanced Surface Hardness [155].

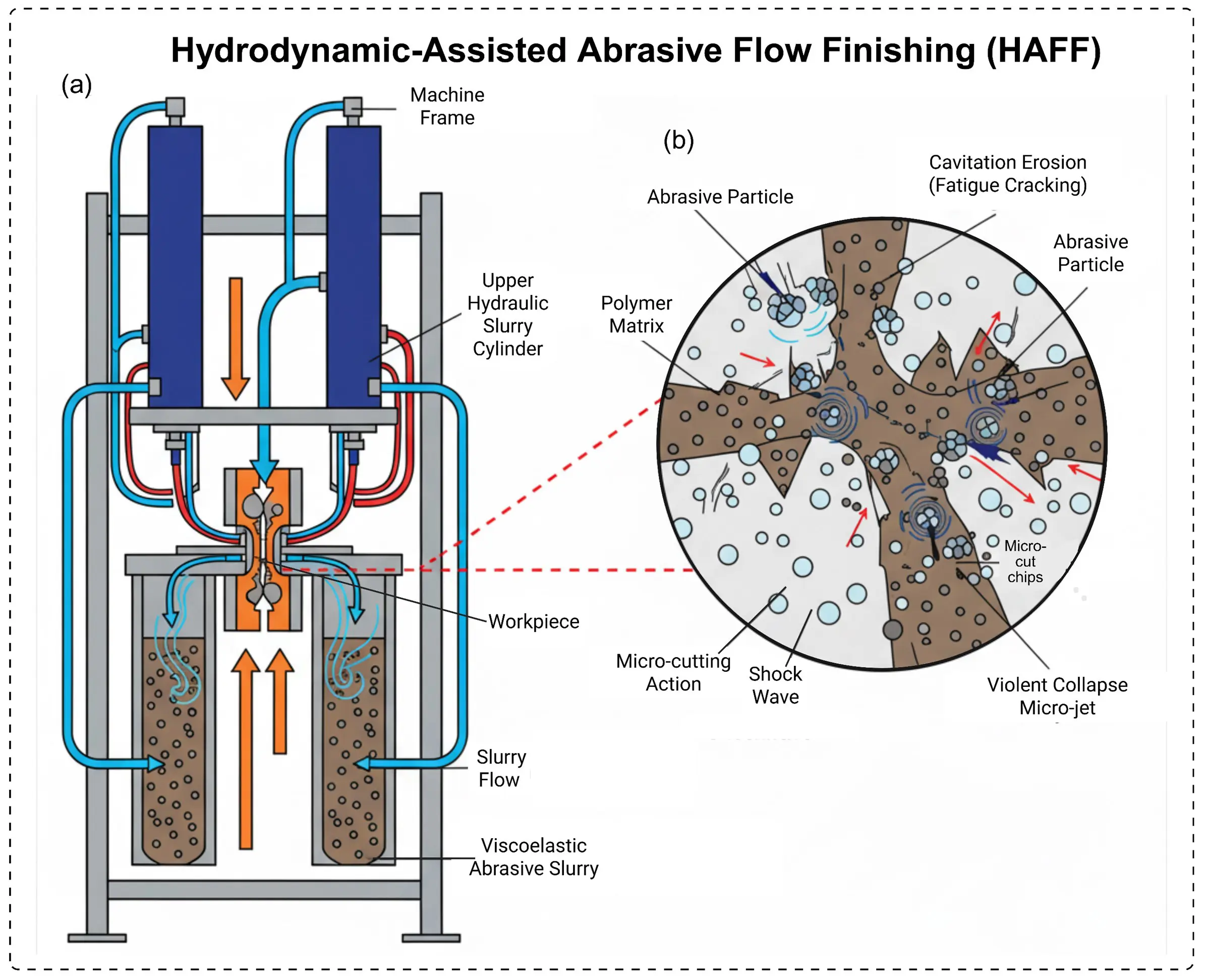

3.3.2. Hydrodynamic-Assisted AFF (HAFF)

Hydrodynamic-Assisted Abrasive Flow Finishing (HAFF) synergizes elevated-pressure hydrodynamic regimes with abrasive matrices to amplify material removal rates (MRR) and refine superficial topography. This modality propels traditional Abrasive Flow Finishing (AFF) paradigms by leveraging fluidic traversal to orchestrate abrasive grit kinematics, thereby catalyzing efficacious refinement of non-Euclidean morphologies and recalcitrant substrates [157,158]. Contemporary inquiries evince that Hybrid Abrasive Flow Finishing (HAFF) paradigms attenuate surface roughness (Ra) by exceeding 90% while amplifying material removal rates (MRR) by 80%, ascribable to the confluence of hydrodynamic cavitation and micro-abrasive interfacial kinetics. This method is particularly effective for internal features in additively manufactured components, where conventional techniques are often inadequate. Wang et al. (2024) proffered a cavitation-augmented abrasive flow refinement modality that leverages a Venturi conduit, resulting in a 60% increase in excision kinetics relative to traditional paradigms [159]. Furthermore, Nagalingam et al. (2023) proffered a pioneering hydrodynamic cavitation abrasive finishing (HCAF) modality for ameliorating laser-powder-bed-fused Inconel 625 interfacial topographies, evincing profound refinements in superficial fidelity concomitant with amplified excision kinetics [160].

Figure 32 schematizes the architectural instantiation and parametric orchestration of the Hydrodynamic Cavitation Abrasive Finishing (HCAF) paradigm, accentuating cardinal constituents such as the HCAF enclosure, manometric indicators, and hydrodynamic regulators, which catalyze efficacious grit-mediated refinement.

Figure 32. Schematic of Hydrodynamic-Assisted Abrasive Flow Finishing (HAFF) (a) Integrated Machine Frame, Dual Hydraulic Slurry Cylinders, and Bidirectional Viscoelastic Flow Path, (b) Microscale Cavitation Dynamics with Bubble Collapse, Shockwave/Microjet Generation, and Abrasive Fatigue Erosion [160].

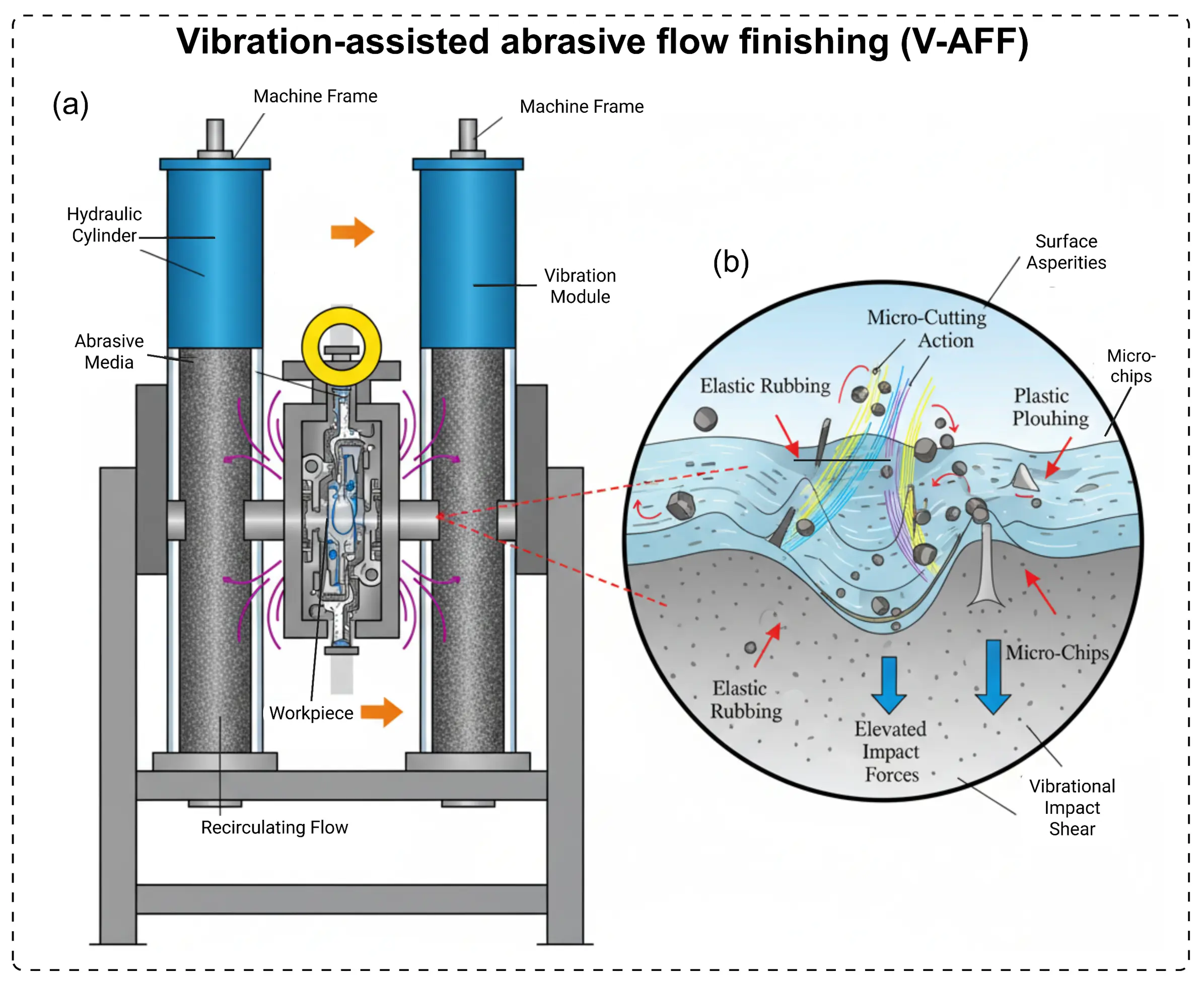

3.3.3. Vibration-Assisted AFF (V-AFF)

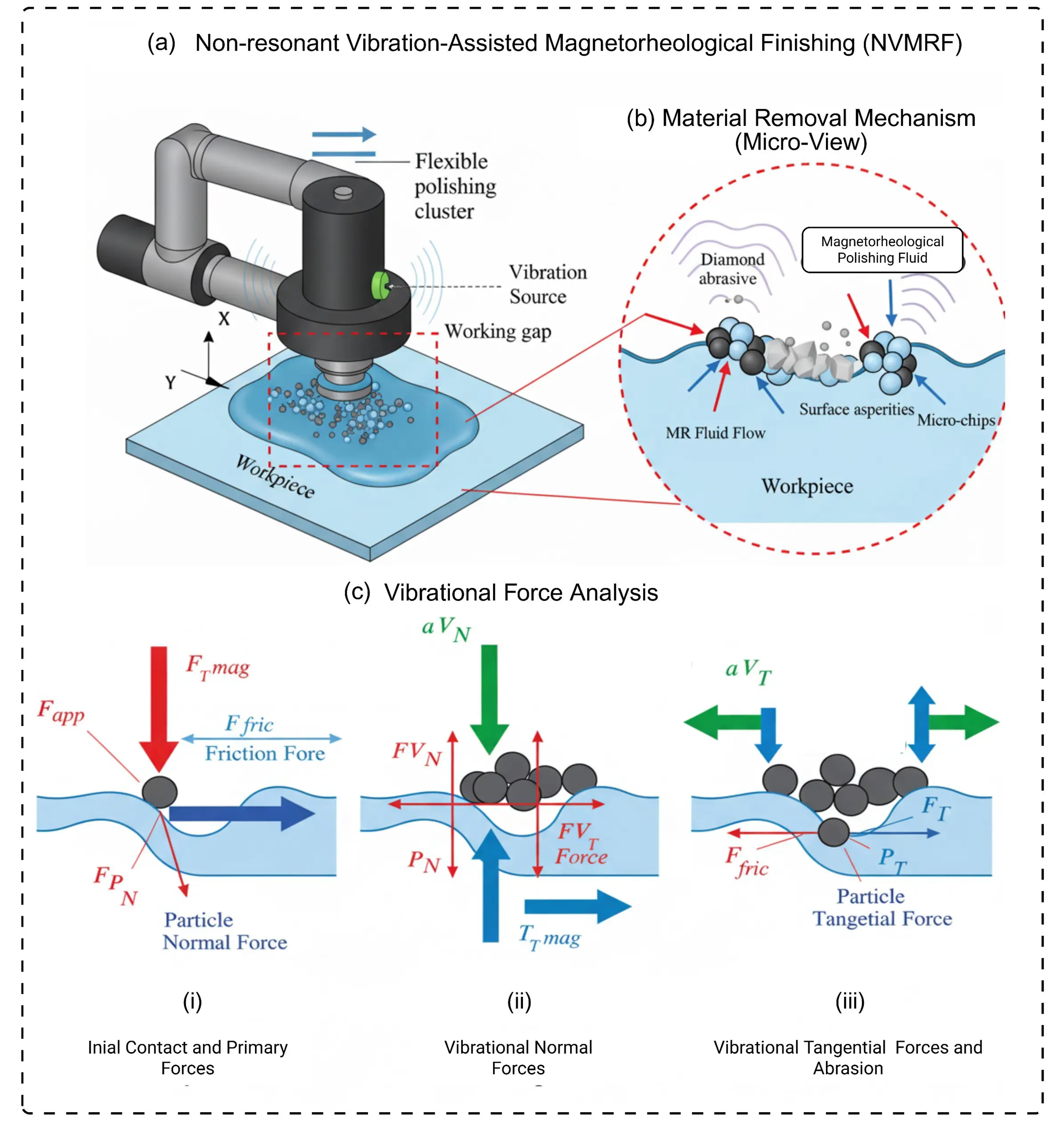

Vibration-Assisted Abrasive Flow Finishing (V-AFF) engrafts oscillatory kinematics into the interfacial kinetics between the abrasive media and substrate, as schematized in Figure 33. This augmentation escalates frictional cadence between abrasive grits and the interfacial stratum, thereby catalyzing amplified excision throughput. Consequently, V-AFF confers superlative superficial planarity through attenuated asperity (Ra) and augmented homogeneity. The nanoscale perturbations engendered by these oscillations disrupt the boundary stratum, propelling equanimous and ultraminute refinements via deepened grit incursion into substrate architectures. Moreover, V-AFF evinces escalated material removal rates (MRR) concomitant with preserved or refined superficial integrity, rendering it preeminently apt for interrogating recalcitrant substrates and labyrinthine morphologies [161,162].

Gu et al. (2021) proffered a non-resonant vibration-augmented magnetorheological finishing paradigm, leveraging oscillatory impacts to amplify shear transduction and elevate interfacial topography. This modality resonates with Vibration-Assisted Abrasive Flow Finishing (V-AFF), wherein sonic perturbations catalyze escalated excision kinetics and refined superficial homogeneity [163]. In Non-resonant Vibration-Assisted Magnetorheological Finishing (NVMRF), the ablation kinetics are profoundly augmented by synergistic interfacial engagements between the polishing aggregate and abrasive grits, engendering ameliorated superficial topography, as schematized in Figure 34.

Figure 34. Schematic of Non-Resonant Vibration-Assisted Magnetorheological Finishing (NVMRF): (a) Flexible Polishing Cluster, Vibration Source, and MR Fluid Delivery in Working Gap, (b) Diamond Abrasive Interactions, Surface Asperity Fracture, and Micro-Chip Ejection in MR Flow, (c) Multi-Stage Analysis of Normal, Axial, and Tangential Force Components Under Vibration [163].

3.3.4. Plasma-Assisted AFF

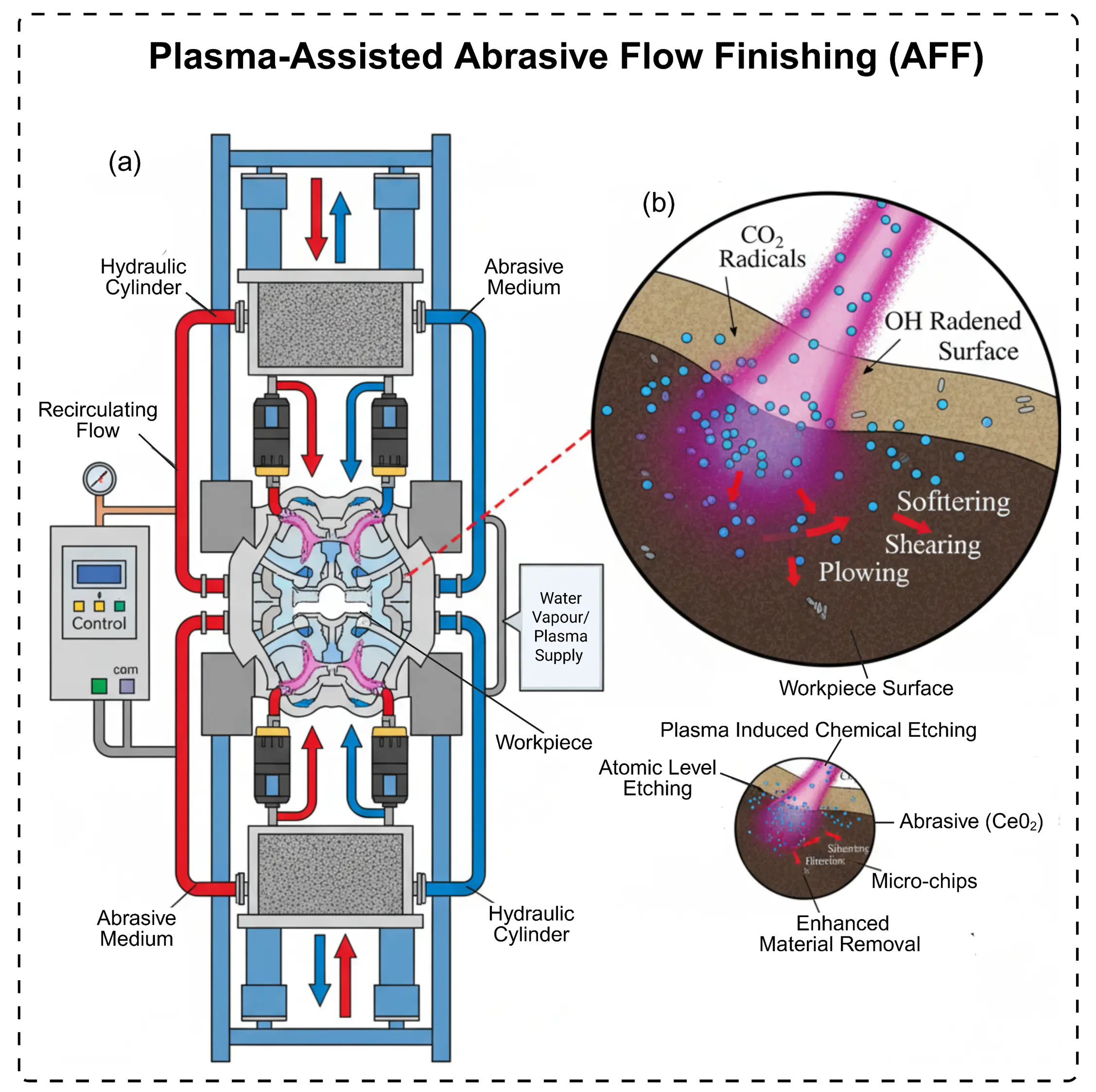

Plasma-Assisted Abrasive Flow Finishing (AFF) employs plasma energy to enhance material removal rates, surface quality, and hardness. By softening the material surface, smoother interactions with the abrasive media are facilitated, thereby improving efficiency. This technique is highly effective for hard-to-machine metals, coatings, and additive manufacturing, and offers faster processing, superior finishing, and modified surface properties. Figure 35 schematizes the Plasma-Assisted Abrasive Flow Finishing (AFF) paradigm, delineating the systemic architecture and nanoscale ablation dynamics.

Sun et al. (2021) proffered an innovative non-dressing refinement paradigm synergizing plasma-assisted polishing (PAP) with plasma-assisted dressing (PAD) to amplify material removal rates (MRR) in densified AlN substrates. Harnessing Ar-infused CF4 plasma, this modality perpetually rejuvenates vitrified-bonded abrasive wheels, sustains nascent grit engagement, and bifurcates MRR vis-à-vis traditional desiccant polishing regimens, even amid subminimal actuation gradients [164]. Figure 35 schematizes the plasma-assisted interfacial reconfiguration and abrasive rejuvenation apparatus, concomitant with representational archetypes of the tribological refinement kinetics for AlN substrates, evincing profound ameliorations in superficial topography pre- and post-processing.

Figure 35. Schematic of Plasma-Assisted Abrasive Flow Finishing (AFF): (a) Hydraulic Recirculation, Abrasive Medium Delivery, and Water Vapor Plasma Integration, (b) Radical-Induced Etching, Surface Softening, CeO2 Abrasive Shearing, and Micro-Chip Dynamics for Enhanced MRR.

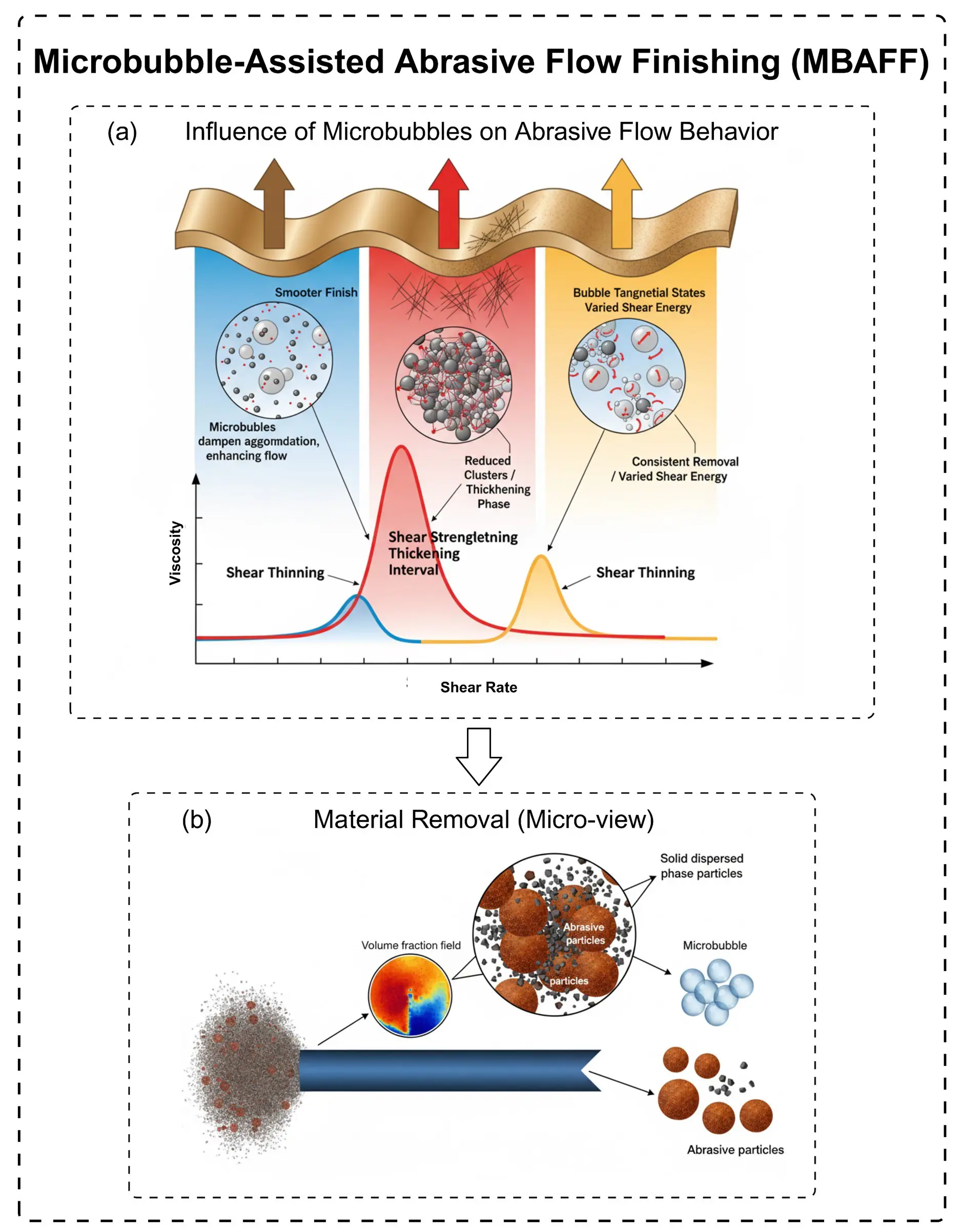

3.3.5. Microbubble-Assisted AFF

Microbubble-Assisted Abrasive Flow Finishing (MBAFF) examines the influence of microbubbles on abrasive flow behavior, thereby significantly affecting particle interactions and surface finishing efficiency. Microbubbles in abrasive media alter the dynamics of shear-thickening fluids by influencing interfacial evolution and abrasive transport, leading to improved or diminished grinding efficiency based on bubble behavior. Microbubbles dampen abrasive agglomeration, enhancing flow and reducing unwanted particle clustering, resulting in smoother finishes and isotropic substrate ablation.

Nevertheless, as evinced in the empirical delineation by Wu et al. (2024), bubble tangential states and non-uniform shear energy transfer can cause variations in the thickening failure regions, thereby impacting overall grinding effectiveness. The interaction between bubbles and abrasive particles has a complex relationship with fluid viscosity profiles and interfacial forces, making it a critical aspect for optimizing polishing processes in challenging applications, such as wafer surface finishing [165]. Figure 36 illustrates the microbubble-assisted abrasive flow finishing (MBAFF) process, showing the shear thickening process and bubble dynamics, along with the numerical model of the STP flow field.

Figure 36. Schematic of Microbubble-Assisted Abrasive Flow Finishing (MBAFF): (a) Rheological Modulation with Shear Thinning/Strengthening Curves, Bubble Cluster Effects, and Viscosity-Shear Rate Profiles, (b) Volume Fraction Field, Dispersed Phase Interactions, and Microbubble-Enhanced Abrasive Particle Removal at the Interface [165].

3.3.6. Thermal-Assisted AFF (TAAFF)