Sequential Thermal and Optical Upgrades for Passive Solar Stills: Toward Sustainable Desalination in Arid Climates

Received: 30 August 2025 Revised: 16 October 2025 Accepted: 28 October 2025 Published: 03 November 2025

© 2025 The authors. This is an open access article under the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).

1. Introduction

Sustainable water management has become a critical priority in arid and semi-arid regions, where freshwater scarcity is exacerbated by rapid urbanization, population growth, and climate variability. To enhance the resilience of urban water systems, integrated approaches are increasingly adopted—combining scenario-based planning, urban regeneration strategies, and decentralized water technologies such as solar desalination and solar stills. Advanced planning frameworks, such as optioneering, facilitate the systematic evaluation of water infrastructure development by balancing technical feasibility, economic viability, and environmental sustainability [1]. Moreover, decision-making processes are increasingly supported by methodologies that incorporate sustainability indicators and stakeholder acceptability models, ensuring alignment with long-term goals for adaptive and resilient urban water management [2,3]. These holistic approaches promote the implementation of resource recovery systems and decentralized solutions as essential components of future-ready, sustainable urban environments [4,5].

In response to growing water scarcity in off-grid and arid regions, solar desalination technologies—particularly humidification-dehumidification (HDH) systems and solar stills—have emerged as sustainable and decentralized alternatives to conventional water treatment. HDH desalination systems offer the advantage of modularity and low-energy operation, especially when powered by solar thermal energy. Recent field-tested systems have demonstrated consistent year-round performance, producing up to 15–20 L per day per square meter under optimized thermal and airflow conditions [6]. Integration of heat recovery and humidity control mechanisms in HDH units has been shown to enhance efficiency by over 30%, underscoring their suitability for remote and resource-constrained settings [7,8]. Parallel advancements in solar still research emphasize the critical role of optical and thermal design in enhancing productivity. The optical characteristics of the glass cover and saline water directly affect solar transmittance and thermal absorption. For instance, optimization of glass cover thickness, implementation of anti-reflective coatings, and control of saline turbidity have been shown to increase incident solar energy absorption by up to 25%, with corresponding gains in daily freshwater yield reaching 30% in simulation models [9,10]. Furthermore, thermal storage enhancement through the integration of phase change materials (PCMs) has proven to be a pivotal innovation in stabilizing heat supply during fluctuating diurnal cycles. Adaptive PCM formulations, tuned to local climatic extremes, have demonstrated productivity improvements of up to 40%, while multi-stage PCM systems with variable mass ratios optimize the timing and duration of energy release [11,12]. Coupling PCMs with optically optimized solar stills further amplifies performance, as confirmed by both theoretical models and field trials in arid regions such as NEOM, where annual system efficiency increased by over 22% [13,14]. These integrated approaches—spanning optical, thermal, and material design—highlight the evolving capabilities of solar desalination technologies and their growing role in sustainable water supply strategies for vulnerable environments.

Despite their simplicity, low cost, and environmental compatibility, traditional single-basin solar stills are often limited by low daily productivity and modest thermal efficiency, which constrain their large-scale adoption in water-scarce regions. These limitations stem from several intrinsic design challenges, including poor solar energy absorption, high thermal losses through the basin and cover surfaces, and the intermittent nature of solar radiation. Consequently, the practical yield of conventional solar stills frequently falls below 3 L/m2/day under typical climatic conditions, which is insufficient for household or community-scale freshwater demands. Addressing these challenges requires systematic performance optimization strategies that enhance solar energy capture, minimize thermal losses, and extend the operational window beyond peak insolation hours. Advanced techniques—such as integrating reflective surfaces, applying thermal insulation, using phase change materials (PCMs) for energy storage, and optimizing the optical properties of transparent covers—have shown promising results in improving freshwater output and overall system efficiency. Therefore, developing and experimentally validating these enhancement methods under real-world conditions is critical to unlocking the full potential of solar stills as a viable, decentralized desalination technology for arid and off-grid regions.

Recent advancements in solar still desalination technologies have increasingly focused on enhancing system performance through optical, thermal, and structural modifications. AbdelMeguid and El Awady [9] developed a validated mathematical model integrating energy and mass transfer with optical properties of the glass cover, demonstrating that transmissivity, absorptivity, and reflectivity are pivotal in determining freshwater yield. Their results revealed that using a monthly variable optimal tilt angle (21.7° for Matroh City) improves annual distillate production by 2.5%, while increasing glass thickness from 5 mm to 20 mm reduces daily yield by over 20%, highlighting the detrimental effect of thicker covers on efficiency. Extending this work, AbdelMeguid [10] examined the dynamic optical behavior of saline solutions, incorporating factors such as saline depth, refractive index, and extinction coefficient. The study identified 20 mm as an optimal saline depth, balancing quick heat absorption with thermal retention. It also showed that increasing the extinction coefficient up to 300 m−1 can raise annual efficiency to 33.7%, underscoring the importance of dynamically modeling saline optical properties rather than assuming them constant.

In parallel experimental efforts, researchers have investigated the synergistic effect of nanofluids and reflectors. One study [15] compared conventional and modified single-slope stills incorporating Cerium Oxide nanoparticles and external reflectors, finding notable improvements in freshwater production due to enhanced solar energy absorption and heat transfer. Similarly, performance gains were achieved through hydrophilic wick structures and thermally insulated layers in floating solar evaporators, as demonstrated by a recent study [16], which produced up to 2.5 L/m2/day at a cost of only $3/m2. This design utilized advection-driven salt rejection and achieved a solar-to-water efficiency of 24%, showing promise for low-cost, off-grid desalination applications. Other investigations [17,18] have emphasized the roles of absorptive materials, side mirrors, and sun tracking systems in maximizing solar input and improving the cost-efficiency of solar stills. Notably, the integration of flat-plate collectors and glass cover cooling in double-slope designs has boosted productivity to over 10 L/m2/day, with efficiencies exceeding 80% in active configurations [19]. Notably, the performance of a simple single-basin solar still highlights that even basic design enhancements—such as utilizing a 3 mm thick glass cover set at an inclination of 33.3°—can lead to appreciable gains in productivity. The system delivered an average daily yield of 1.7 L for a 0.54 m2 basin, corresponding to an overall thermal efficiency of 30.65%. These findings affirm the viability of low-cost, small-scale solar distillation units for rural and decentralized applications, demonstrating that practical improvements in optical and thermal design can significantly enhance output without reliance on advanced technologies or expensive materials [20].

Recent research has extensively explored integrating optical enhancement techniques—particularly reflectors—to improve the thermal efficiency and freshwater productivity of solar still desalination systems. One of the most notable advancements involves the use of external mirrors to augment solar irradiation input. A proposed mirror-enhanced design demonstrated a remarkable increase in daily water production from 7.5 L/day to 24 L/day, primarily due to lowered glass temperatures and elevated basin water temperatures achieved through improved solar capture [21]. Similarly, the SS-TEG-WI-M configuration, which combines side mirrors, thermoelectric generators, and iron scrap-based thermal storage, achieved the highest freshwater yield of 0.796 L/m2 among several configurations, while also contributing to a 24.5% improvement in CO2 removal—underscoring the environmental and thermodynamic benefits of multi-functional solar desalination systems [22].

Building on these innovations, an advanced single-slope solar still employing flat reflectors and semi-transparent solar cells demonstrated strong multi-location performance, yielding up to 15.58 kg/day in Riyadh. This system was optimized using energy, exergy, and economic criteria along with decision-making algorithms such as TOPSIS, highlighting its potential adaptability across diverse climatic conditions [23]. Complementary studies have shown that incorporating reflective materials inside the solar still—such as glass mirrors and aluminum foil—can yield daily distillate outputs of 5.54 kg/m2 and 5.1 kg/m2, respectively. These represent performance increases of 68.57% and 48.57% compared to conventional black-painted surfaces, with the added advantage of shorter cost recovery periods (23 and 26 days, respectively) [24].

Additionally, combining reflector integration with sun-tracking mechanisms significantly amplifies system performance. One study reported a 7.6 °C increase in basin water temperature and a 34.3% increase in freshwater production during active operation when side mirrors were used in tandem with solar tracking. This configuration also lowered the cost per liter to $0.0225, making it economically competitive with conventional systems [18]. These findings collectively emphasize the critical role of optical concentration strategies—especially mirror integration and reflective surface optimization—in enhancing solar still efficiency, reducing operational costs, and expanding applicability in water-scarce, off-grid environments.

The comparative analysis of recent studies on solar still desalination (Table 1) reveals that integrating mirror reflectors—including flat, sidewall, internal, and external configurations—consistently improves the thermal performance and productivity of solar still systems. The most significant gains are observed when reflectors are combined with other enhancements, such as phase change materials (PCMs), thermoelectric generators (TEGs), sun tracking, and fins, with productivity increases reaching up to 191% and daily outputs up to 24 L/day.

Recent advancements in solar still technology have shown promising improvements in freshwater yield through the integration of various types of reflectors, phase change materials, thermoelectric modules, and optical optimizations. As summarized in Table 1, these modifications have led to significant gains in productivity—ranging from moderate increases of 10–40% to more substantial enhancements exceeding 90%—alongside reductions in cost and improvements in energy efficiency. Despite these encouraging outcomes, most studies either focus on individual components or lack comprehensive analyses under high solar flux conditions typical of arid zones. Moreover, limited attention has been given to the combined effects of reflector orientation, material selection, and thermal storage under real-world operational constraints. Therefore, this study aims to address these gaps by experimentally investigating the performance of a solar distiller integrated with both high and low melting point phase change materials (PCMs) and optimized east–west reflectors. The objective is to assess its suitability for deployment in arid oases, where water scarcity, high solar irradiance, and thermal inertia demand innovative, yet practical, design solutions.

While the fundamental design of single-slope solar stills is well-established, there remains a critical need for systematic experimental studies that quantify the cumulative impact of low-cost, incremental enhancements under real-world operational conditions. Therefore, this study addresses this gap by focusing on a systematic optimization approach for a practical and scalable technology. By sequentially evaluating a series of thermal and optical upgrades, this work provides an empirical roadmap for improving the performance of this accessible technology, especially for implementation in remote and arid regions.

Table 1. Comparative summary of experimental and conceptual studies on mirror-enhanced solar stills: Insights, methodologies, performance outcomes, and implications for sustainable desalination.

|

Refs. |

Reflector Type |

Integration Type |

Enhancement Elements |

Max Productivity |

Efficiency |

Productivity Gain |

Cost ($/L) |

Conclusions |

|---|---|---|---|---|---|---|---|---|

|

[21] |

Mirror reflectors |

External, conceptual |

Lower glass temp, higher basin temp |

24 L/day |

Not specified |

220% vs. 7.5 L/day (CSS) |

Not reported |

Significant improvement in water output; viable for arid regions. |

|

[22] |

Mirrors (absorber focused) |

External, combined |

TEG, iron scraps, mirror |

0.796 L/m2 |

Improved CO2 removal (24.5%) |

24.3% vs. 0.64 L/m2 (CSS) |

Not reported |

Integration of mirrors with TEG and thermal storage enhances water output and sustainability. |

|

[23] |

Flat reflectors |

External |

Semi-transparent PV cells, AI optimization |

11.15–15.58 kg/day |

Energy, exergy, and cost optimized |

Improved vs. base case |

Not reported |

Reflectors combined with solar cells yield significant multi-city desalination efficiency. |

|

[24] |

Glass mirrors, Al foil (inner) |

Internal |

Reflective walls (mirror vs. foil) |

5.54 kg/m2 |

Exergy: 7.97 (mirror), 7.25 (foil) |

68.57% (mirror), 48.57% (foil) |

Mirror: 0.019 (23-day ROI) |

Glass mirrors most effective among low-cost reflectors; rapid ROI. |

|

[18] |

Side mirrors + sun tracking |

External + Dynamic |

Tracking system, mirror concentration |

43.1% ↑ (passive mode) |

Efficiency: ↑22.3% (active) |

34.3% (active), 22.2–43.1% (various modes) |

0.0225 |

Tracking + side mirrors yield high gains in temp and yield with low cost per liter. |

|

[25] |

Flat Secondary Reflectors (East/West) |

External, fixed |

Optimum angle (130°), inclined still |

6.39 kg/day |

39.81% (non-conc), 21.34–30.49% (conc) |

10.17% |

Not reported |

Optimal reflector angles enhance yield, but may reduce thermal efficiency. |

|

[26] |

Internal Sidewall Reflector |

Internal, fixed |

Circular fins, nano-PCM (paraffin-Al2O3) |

1853 mL/day |

21.56% |

92% (nano-PCM), 61.36% (pure PCM) |

0.0199–0.022 |

Significant output and economic benefits using the reflector and nano-PCM. |

|

[27] |

Top/Bottom External Mirrors + Internal Reflector |

Internal + External |

Copper coil, PCM-Ag, external condenser |

Up to 191% over CSS |

Up to 62% |

42% (mirrors), 57% (condenser), 41% (PCM) |

0.018–0.024 |

Multifunctional MSS design offers the highest gains in performance and cost savings. |

|

[14] |

Not applicable |

Not applicable |

General review |

Not specified |

Not specified |

Not applicable |

Not applicable |

Conceptual overview of solar stills in NEOM; reflectors not discussed. |

|

[28] |

Not applicable |

Not applicable |

Thermoelectric modules (TE) |

35% improvement (vs. CSS) |

Enhanced condensation |

35% |

Not specified |

TE modules improve yield and condensation; no reflector is used. |

|

[29] |

Not applicable |

Not applicable |

Basin water level optimization |

2.38 L/m2-day |

High impurity removal (>99%) |

Optimum at 3.5 L (1.6 cm depth) |

Not specified |

Reflectors not used; productivity depends on optimized water depth. |

|

[30] |

Not applicable |

Not applicable |

Saltwater spraying + circulation |

28.75% over CSS |

65.18% over passive still |

28.75% |

0.059 |

Circulation system boosts evaporation, no reflector involved. |

|

[31] |

Not applicable |

Not applicable |

Stepped solar-still, sealed vs. unsealed |

Not specified |

Improved via reduced air gap |

Not quantified |

Not specified |

Innovative stepped design; reflectors not part of the experiment. |

|

[32] |

Not applicable |

Not applicable |

Photothermal double-layer film (hydrophilic/ hydrophobic) |

1.6 kg/m2·h |

Maintains performance for 24 days |

High evaporation rate |

Not specified |

High-rate desalination using a novel film; no reflector studied. |

|

[33] |

Not applicable |

Not applicable |

Air gap & water depth optimization |

Up to 23% improvement |

Salinity drop: 31,250 → 495 ppm |

11% (gap reduction), 23% (depth optimization) |

Not specified |

Performance enhanced by geometry tuning, not by reflectors. |

Therefore, this study aims to address these gaps by experimentally investigating the performance of a solar distiller integrated with sequential, low-cost upgrades. While theoretical modeling provides valuable insights, the primary focus of the present work is the empirical validation of physical modifications under real-world operational conditions. This approach is intended to generate concrete, reliable performance data and establish practical benchmarks free of the idealizations and assumptions often required in simulation-based analyses.

Objectives

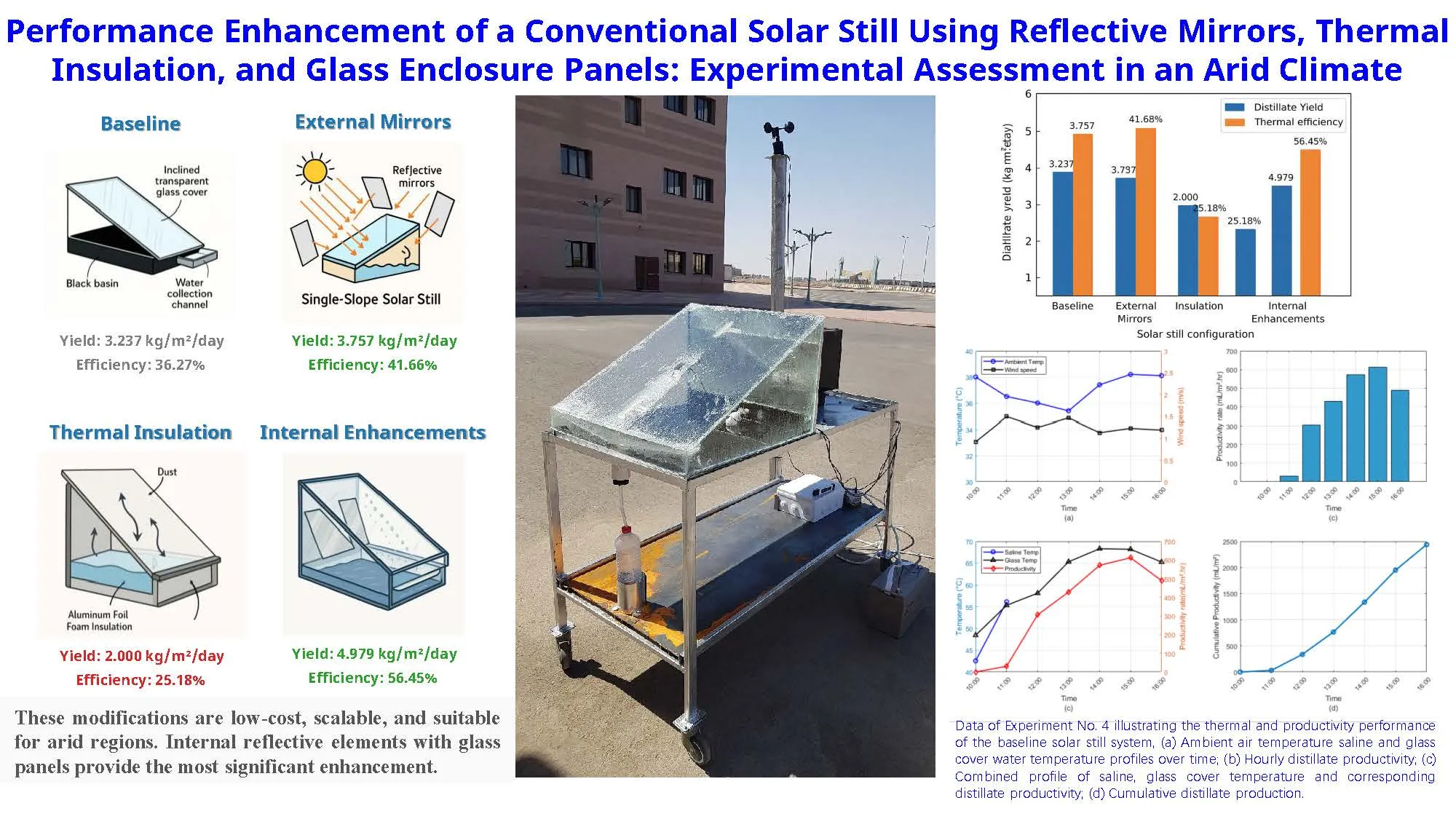

The primary objective of this study is to experimentally investigate the cumulative effects of three key passive enhancement strategies—reflective mirrors, thermal insulation, and glass enclosure—on the performance of a solar distillation system designed for arid environments. These modifications are individually known to improve various aspects of solar still performance, such as increasing solar radiation capture, reducing heat losses, and maintaining favorable thermal conditions for continuous evaporation and condensation. However, their combined influence has not been thoroughly examined under the high solar irradiance and harsh thermal gradients typically encountered in desert oases.

Specifically, this study aims to:

-

Evaluate the impact of reflective mirrors (east–west orientation) on solar energy concentration, incident radiation gain, and distillate yield during morning and afternoon periods.

-

Quantify the thermal performance improvements introduced by adding thermal insulation around the basin and side walls to minimize conductive and convective heat losses.

-

Assess the effect of a glass enclosure on maintaining a stable microclimate within the distiller, reducing convective heat exchange with ambient air, and enhancing condensation efficiency.

-

Analyze the cumulative effects of integrating all three enhancements simultaneously and compare them with baseline (unmodified) configurations to determine the synergistic gains in productivity and energy efficiency.

-

Provide performance benchmarks under real-world weather conditions typical of arid regions, including hourly variations in solar irradiance, ambient temperature, and humidity.

By addressing these objectives, the study aims to propose a cost-effective, scalable, and technically optimized solar distillation design suitable for deployment in rural or remote desert communities, particularly where water scarcity is coupled with abundant solar energy availability.

2. Materials and Methods

The experimental work was conducted in Tabuk, Saudi Arabia (28°23′50″ N, 36°34′44″ E), a region characterized by an arid desert climate and high solar irradiance, with average summer solar input ranging between 6.5 and 7.2 kWh/m2/day. The location’s climate provides an ideal environment for evaluating the performance of solar desalination systems. All experiments were carried out during peak solar hours, typically from 10:00 a.m. to 4:00 p.m., under predominantly clear skies, except for one instance of dusty weather that affected solar radiation.

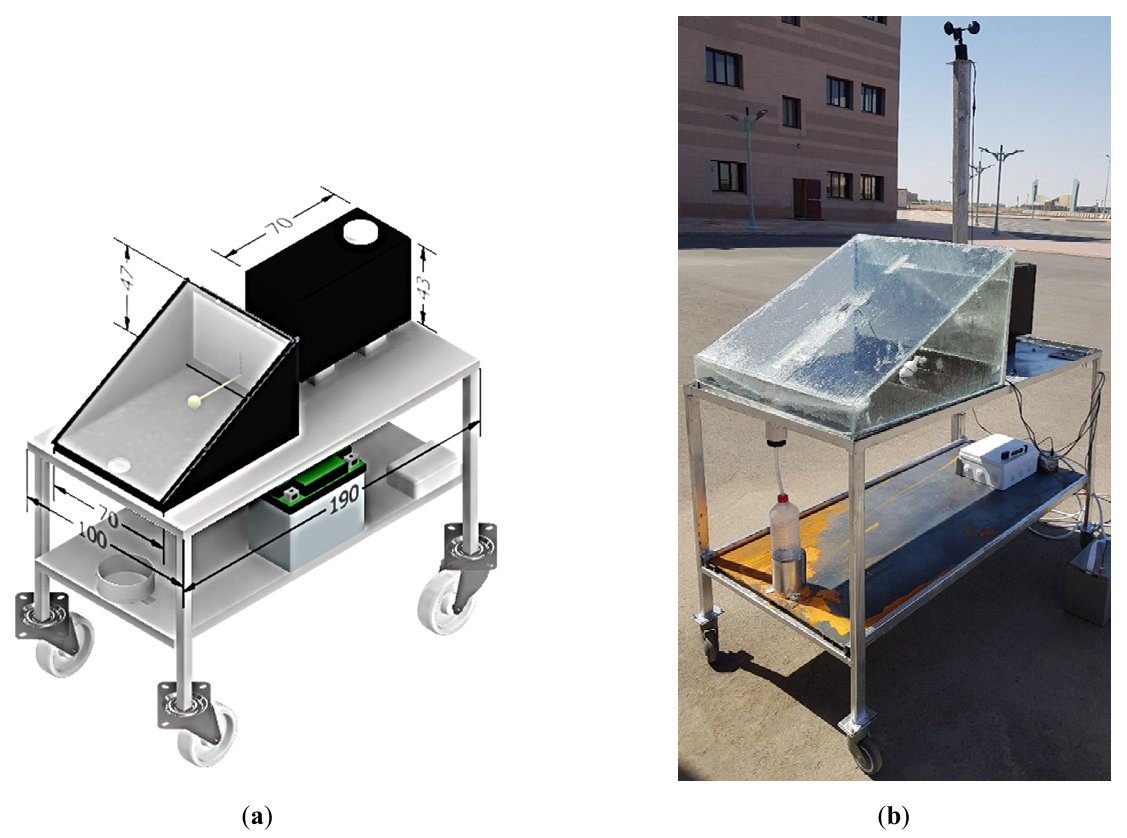

The baseline solar still (SS) system (Figure 1) was designed with a square basin with internal dimensions of 700 mm × 700 mm. The front and rear basin wall heights were 100 mm and 470 mm, respectively, resulting in an inclined transparent glass cover fixed at an angle of 28° to the horizontal to optimize solar incidence and facilitate condensate collection. The basin structure was fabricated from corrosion-resistant stainless steel 316 to withstand saline conditions and high temperatures. Three vertical sidewalls of the basin were made of 4 mm-thick transparent glass to maximize solar radiation penetration. The fourth wall was fitted with an internal aluminum mirror to enhance sunlight reflection toward the brine surface. For thermal insulation, 3 cm thick rock wool, with a thermal conductivity of 0.034 W/m·K, was applied to the basin’s underside and rear side. To prevent moisture ingress into the insulation, a waterproof PVC sheet was placed between the rock wool and the metallic basin wall.

The condensing cover was a single-pane glass sheet inclined along the basin’s diagonal axis and sealed to minimize vapor loss. A drainage channel was integrated to collect the condensed vapor into a separate measuring container. Additional components included a mechanical float valve to regulate feedwater level and dual collection channels for condensate recovery. The overall design ensured effective solar energy trapping, minimized thermal losses, and supported steady vapor condensation and collection.

Figure 1. (a) Schematic design of the solar still showing key components and dimensional specifications (in mm), (b) Photograph of the fabricated solar still system, including the inclined transparent cover, stainless steel basin, glass walls, and internal mirror.

A series of four experiments was performed to evaluate system performance under varying configurations. Experiment 1 (24 June 2025), the baseline system was tested under clear sky conditions. The solar still was filled with saline water and exposed to direct sunlight from 10:00 a.m. to 3:00 p.m. Condensation occurred on the inner surface of the inclined glass cover, and the collected distillate amounted to 780 mL per liter of feedwater.

Experiment 2 (29 June 2025), reflective aluminum mirrors were externally positioned along the east and west-facing sides of the still to enhance the solar flux reaching the basin. The configuration resulted in increased water temperatures and improved evaporation rates, with a measured distillate yield of 850 mL/L over a 6-h period.

Experiment 3 (2 July 2025) involved the addition of aluminum foil foam insulation to the base and rear sides of the basin to reduce heat losses. However, the test coincided with a dust event that significantly reduced solar irradiance. Consequently, productivity declined, and the results were deemed inconclusive for evaluating insulation performance under ideal conditions.

Experiment 4 (3 July 2025) examined a modified configuration that incorporated three enhancements: full glass sidewalls, internal aluminum mirror reinforcement, and retention of the foil-backed insulation used in Experiment 3. Favorable weather conditions enabled a clear comparison, and a substantial increase in distillate productivity was recorded relative to the previous setup. The improvements were attributed to enhanced solar trapping, thermal retention, and internal reflection of solar radiation within the enclosure.

Throughout the experimental campaign, performance monitoring was conducted using calibrated K-type thermocouples to measure basin water temperature, inner glass surface temperature, and ambient air temperature. A pyranometer was used to record real-time solar irradiance levels at 10-min intervals. Water quality analysis was performed on both feedwater and collected distillate, evaluating parameters such as total dissolved solids (TDS), pH, turbidity, and electrical conductivity to confirm effective desalination.

The primary performance indicators included distillate productivity, expressed in mL of fresh water per liter of saline feed, and thermal efficiency, calculated as the ratio of the latent heat associated with the evaporated mass of water to the total solar energy incident on the basin area.

3. Theory and Calculations

The performance of a solar still is primarily governed by the principles of solar thermal energy conversion and phase change processes. In a typical single-basin solar still, incident solar radiation is absorbed by the basin water, raising its temperature and driving evaporation. The generated vapor condenses on the cooler inner surface of the inclined transparent cover, from which it is collected as distilled water. The fundamental energy balance of the system can be expressed as:

where Qsolar is the total incident solar energy, Qevap is the energy used for water evaporation, and Qloss includes all thermal losses to the surroundings.

The rate of energy utilized for evaporation, assuming negligible heat storage, is given by:

where mevap is the mass of the evaporated water (in kg) and hfg is the latent heat of vaporization (in J/kg), typically around ~2260 kJ/kg for water at 100 °C.

The productivity of the solar still is defined as the volume of distilled water collected per unit basin area per day:

where Pd is the daily water productivity in L/m·day, Vd is the volume of fresh water collected per day (in liters), and A is the surface area of the solar still basin (in m2).

The thermal efficiency of the solar still is defined as the ratio of the useful energy utilized for evaporation to the total incident solar energy over the basin surface:

where I(t) represents the instantaneous solar irradiance (W/m2) integrated over time t. This formulation provided a consistent means of evaluating the energy conversion performance of each tested configuration under realistic environmental conditions.

Comparative analysis of each experimental modification (mirrors, insulation, glass walls) is quantified in terms of percentage improvement in productivity:

This formulation allows systematic evaluation of how each design enhancement impacts the overall distillate yield and system efficiency.

4. Results and Discussion

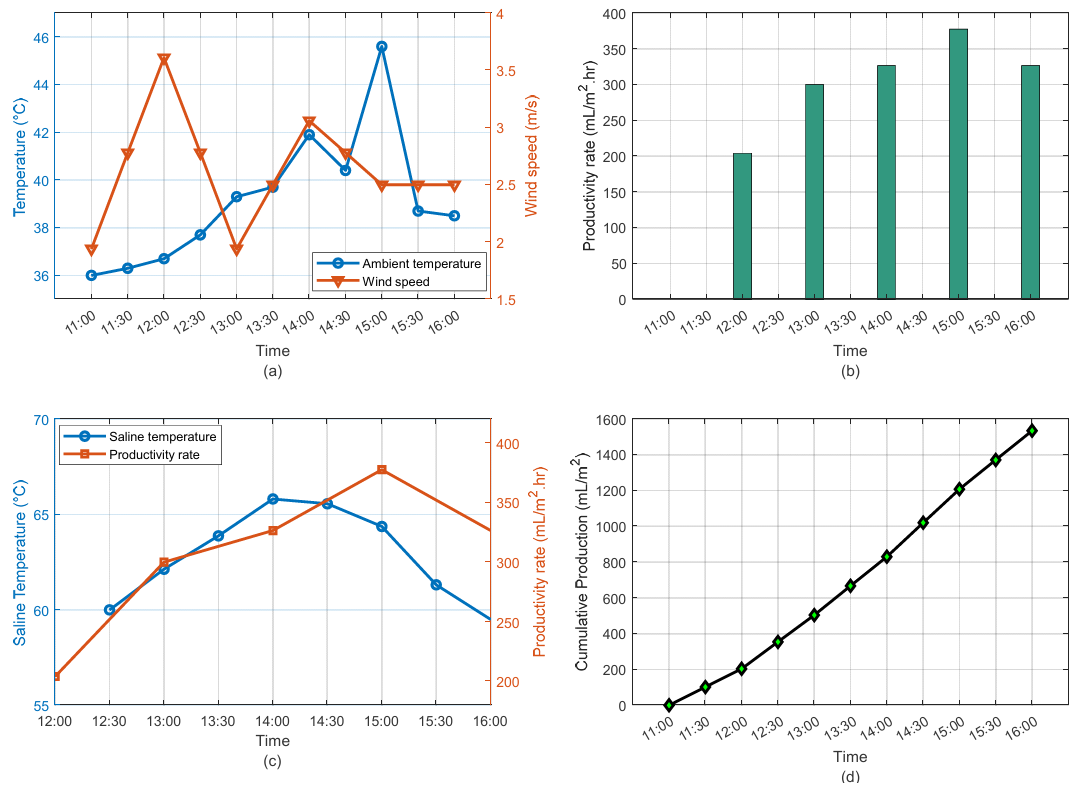

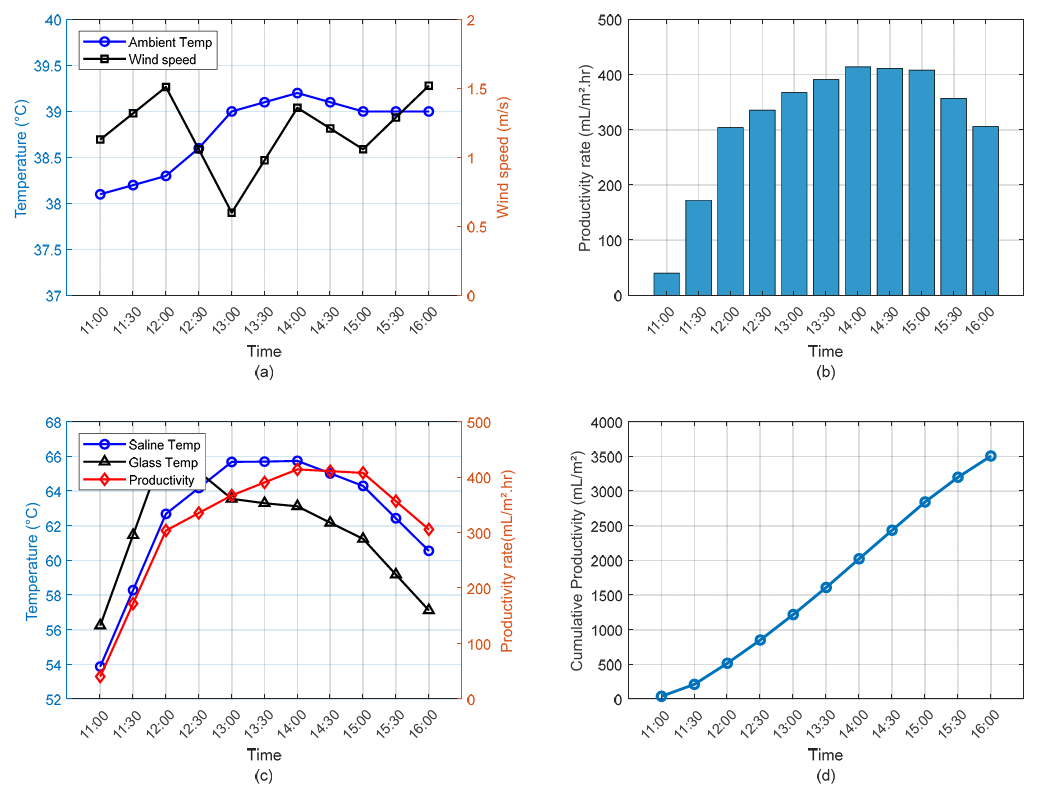

The baseline experiment was conducted on 24 June 2025, under clear solar conditions in Tabuk, Saudi Arabia, between 11:00 a.m. and 4:00 p.m. The hourly variation of ambient temperature, basin water temperature, and distillate productivity was monitored to evaluate the fundamental performance of the unmodified solar still system, the measured data is presented in Figure 2.

The experimental results of the baseline solar still configuration demonstrate favorable thermal performance under clear and sunny conditions in Tabuk, Saudi Arabia. With a total distillate output of 1.586 kg over 6 h, the system exhibited an average productivity of 264.3 mL/h, or 3.237 kg/m2/day on an area-normalized basis.

The distillate output showed a strong correlation with rising ambient and basin water temperatures, reaching peak productivity between 13:00 and 15:00, when the water temperature exceeded 65 °C. The solar still began to decline in productivity slightly after 15:00, likely due to the reduction in solar incidence angle and glass cover temperature despite elevated ambient values.

The calculated thermal efficiency of 36.27% reflects good energy utilization by the system under ideal solar exposure. This value is consistent with or higher than standard passive basin-type solar stills, indicating efficient heat retention and vapor condensation without additional enhancements.

Overall, these findings establish a reliable baseline for assessing the impact of further modifications such as external reflectors, insulation, and glass wall integration, which will be evaluated in subsequent experiments.

Figure 2. Data of Experiment No. 1 illustrating the thermal and productivity performance of the baseline solar still system, (a) Ambient air temperature and saline water temperature profiles over time; (b) Hourly distillate productivity; (c) Combined profile of saline water temperature and corresponding distillate productivity; (d) Cumulative distillate production.

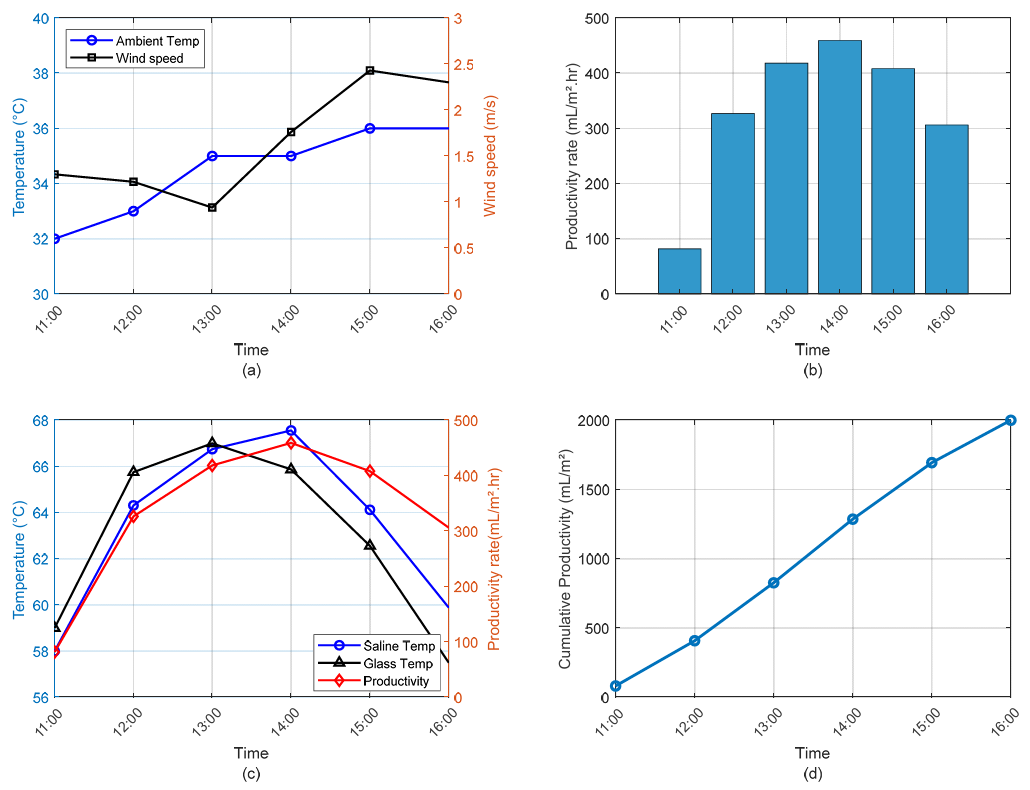

The incorporation of external reflective mirrors in Experiment No. 2 significantly enhanced the thermal performance and distillate yield of the solar still system compared to baseline conditions, as depicted in Figure 3. The temperature profiles revealed a steady rise in both saline water and glass cover temperatures, with peak water temperatures reaching 65.75 °C at 14:00. The temperature differential between the saline water and ambient air consistently exceeded 25 °C, creating favorable conditions for sustained evaporation and condensation cycles.

The results of Experiment No. 2, which incorporated external mirrors to augment solar energy input, demonstrate a clear performance enhancement compared to the baseline configuration. The total productivity increased to 1.84 kg, with a corresponding area-normalized yield of 3.757 kg/m2. This is a 16% improvement in cumulative production over the baseline case (Experiment 1), indicating the effectiveness of mirror reflectors in enhancing thermal performance.

The highest hourly productivity was recorded between 14:00 and 15:00, corresponding with peak water temperatures (~65.75 °C) and relatively low wind speeds (<1.4 m/s), which limited convective heat losses. The performance gain can be attributed to the additional solar radiation reflected from the mirrors, which increased the incident energy on both the water surface and the condensing cover, improving evaporation and condensation rates.

The calculated thermal efficiency of 41.66% also exceeds that of the baseline (36.27%), confirming improved energy utilization. This demonstrates that mirror augmentation is a low-cost and effective method for improving distillate output in passive solar distillation systems, especially in regions with high solar availability, such as Tabuk.

The improved productivity and efficiency in this experiment affirm the utility of reflectors as a simple enhancement that significantly boosts system performance without the need for external power sources.

Figure 3. Data of Experiment No. 2 illustrating the thermal and productivity performance of the baseline solar still system, (a) Ambient air temperature, saline and glass cover water temperature profiles over time; (b) Hourly distillate productivity; (c) Combined profile of saline, glass cover temperature and corresponding distillate productivity; (d) Cumulative distillate production.

The application of aluminum foil foam insulation in Experiment No. 3 was aimed at improving the system’s thermal efficiency by minimizing heat losses through the basin’s lower and rear surfaces. Despite these modifications, the dusty atmospheric conditions significantly impacted solar transmissivity, thereby reducing the effectiveness of solar radiation absorption and overall thermal performance. The recorded experimental data of Experiment No. 3 are illustrated in Figure 4.

The total distillate production was 0.980 kg, lower than the output in the previous experiment (1.840 kg with mirrors). The area-specific yield of 2.000 kg/m2 also underperformed compared to the mirror-enhanced configuration (3.757 kg/m2), largely due to reduced solar irradiance and airborne dust, which scattered incoming radiation.

Although the insulation helped maintain relatively high water temperatures (peaking at ~67.56 °C), the system’s thermal efficiency was calculated at 25.18%, indicating that a significant portion of the incoming solar energy was not converted into useful latent heat. This is in contrast to the 41.66% efficiency recorded in the previous experiment with mirrors under clearer skies.

The results suggest that thermal insulation alone, while beneficial, is not sufficient under poor irradiance conditions. It must be combined with effective solar capture strategies (e.g., mirrors, tracking) to optimize productivity. Moreover, the higher wind speeds observed later in the afternoon (up to 2.43 m/s) likely increased convective heat losses, further reducing evaporative efficiency despite the insulation layer.

Figure 4. Data of Experiment No. 3 illustrating the thermal and productivity performance of the baseline solar still system, (a) Ambient air temperature saline and glass cover water temperature profiles over time; (b) Hourly distillate productivity; (c) Combined profile of saline, glass cover temperature and corresponding distillate productivity; (d) Cumulative distillate production.

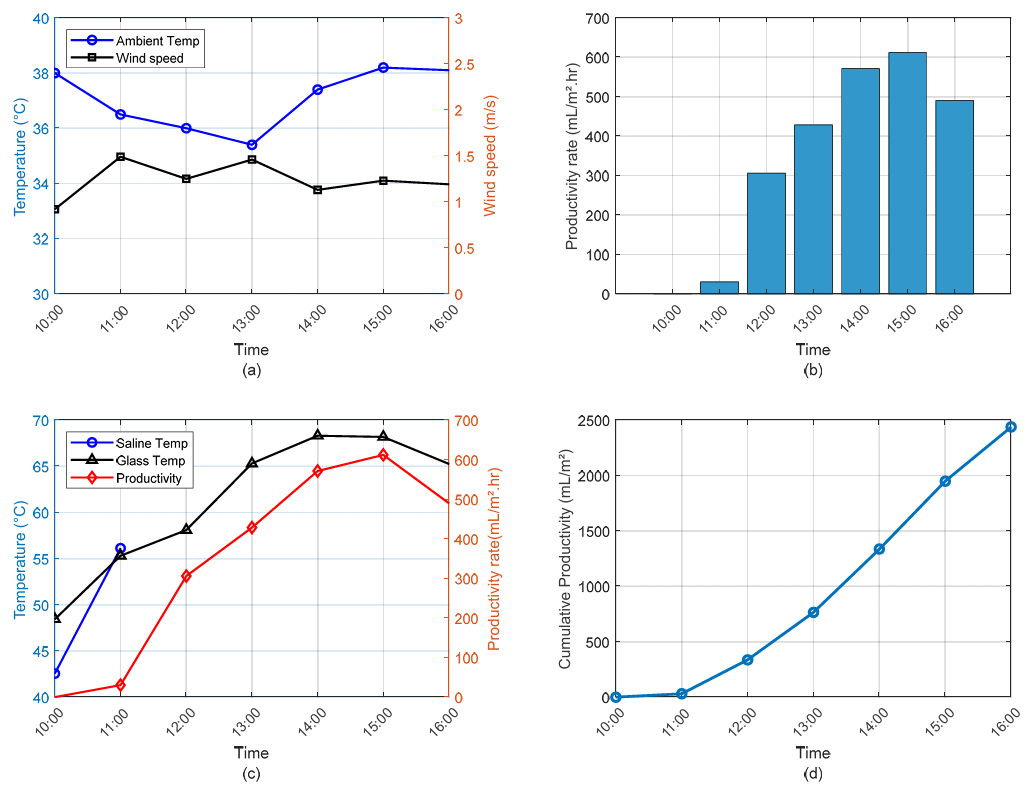

The fourth experimental configuration incorporated multiple enhancements to maximize solar energy absorption and minimize reflective losses. These included installing internal glass side panels to increase solar trapping and internal aluminum mirrors to redirect incident and scattered radiation toward the water surface. The experiment was conducted on a sunny day, ensuring high solar availability and consistent environmental conditions, which are ideal for evaluating performance improvements. The results are presented in Figure 5.

The cumulative distillate yield of 2.439 L/m2 (during 5 operating hours) represents a marked increase compared to the previous experiment (Experiment No. 3), which yielded 2.0 L/m2 under dusty skies and less intense solar input. The increase in solar irradiance from 847 W/m2 to 922 W/m2, along with improved internal reflectivity, contributed to enhanced energy utilization. Importantly, the early and late hour productivity improved, indicating the efficacy of the glass and mirror modifications in capturing low-angle solar rays.

Notably, productivity began rising rapidly from 11:00 onward, with a peak hourly yield of 612.2 mL/m2·h at 15:00, after which it declined as the solar angle decreased. The absence of water temperature readings after 11:00 due to instrument limitations does not obscure the overall thermal trend, as the productivity profile closely mirrors typical thermal gain and loss cycles in well-optimized stills.

The thermal efficiency of 56.45% confirms that the modifications improved the system’s capacity to convert solar input into latent heat for vaporization. Though slightly lower than the 60.6% achieved in the previous experiment, this difference is likely due to the increased evaporative losses associated with higher internal temperatures and potential glass-side condensation inefficiencies.

While the absolute productivity of any passive solar still is inherently modest compared to energy-intensive active desalination systems, its performance must be evaluated within the context of zero-energy, decentralized applications. The maximum yield of 2.439 kg/m2 (over 5 operating hours) achieved in the final configuration (Experiment 4) is highly competitive and positions this design at the upper end of the performance reported in the literature for passive solar stills.

Figure 5. Data of Experiment No. 4 illustrating the thermal and productivity performance of the baseline solar still system, (a) Ambient air temperature saline and glass cover water temperature profiles over time; (b) Hourly distillate productivity; (c) Combined profile of saline, glass cover temperature and corresponding distillate productivity; (d) Cumulative distillate production.

5. Discussion

It is important to interpret these results within the primary scope of our investigation. The goal of this study was not to invent a novel desalination device, but to provide clear empirical benchmarks for incremental upgrades on a simple, replicable design. The value of these findings lies in demonstrating a practical, data-driven optimization pathway for a widely accessible technology, rather than proposing a fundamentally new apparatus. This approach ensures the results are directly relevant for field implementation.

The experimental campaign investigated the performance enhancement of a passive solar still through a series of four successive modifications, each designed to improve thermal collection, retention, or radiation trapping under the arid climatic conditions of Tabuk, Saudi Arabia. The experiments were conducted under varying atmospheric conditions, with solar irradiance ranging from 847 to 943 W/m2. The modifications included the addition of external reflective mirrors (Experiment 2), thermal insulation (Experiment 3), and the integration of internal mirrors with glass side panels (Experiment 4). Table 2 summarizes the key performance metrics.

Table 2. Comparative summary of key results.

|

Experiment |

Modification |

Solar Irradiance (W/m2) |

Yield (kg/m2) |

Efficiency (%) |

Notes |

|---|---|---|---|---|---|

|

Exp. 1 |

Baseline (unmodified) |

934.4 |

3.237 |

36.27 |

Sunny conditions |

|

Exp. 2 |

External reflective mirrors |

943 |

3.757 |

41.66 |

Peak enhancement |

|

Exp. 3 |

Rear & base insulation (dusty day) |

847 |

2.000 |

25.18 |

Reduced irradiance |

|

Exp. 4 |

Internal glass + internal mirrors |

922 |

4.979 |

56.45 |

Best performance |

For context, conventional single-basin stills under similar high-irradiance conditions typically yield around 3.0 L/m2/day [14]. Studies incorporating single enhancements, such as improved thermal insulation or basic reflectors, have reported moderate improvements, often yielding around 4.0 L/m2/day [13]. More advanced passive designs incorporating internal modifications, such as phase change materials, have pushed productivity to the 4.5 L/m2/day range [12]. Therefore, the achieved yield of 2.439 L/m2 (during 5 operating hours), coupled with a high thermal efficiency of 56.45%, demonstrates a substantial improvement over baseline designs and surpasses many previously reported enhancement strategies. This confirms that the synergistic combination of internal optical and thermal management is a highly effective pathway to maximizing passive solar still performance.

5.1. Performance Trends and Interpretation

-

-

Baseline Configuration (Exp. 1):

The unmodified still served as a control for all subsequent enhancements. It exhibited stable operation with a respectable productivity of 3.237 kg/m2 and thermal efficiency of 36.27%. The distillate output closely followed the water temperature profile, which peaked at ~65.8 °C between 13:00 and 15:00. This configuration demonstrated effective passive solar distillation under ideal weather conditions. -

-

Mirror-Augmented Still (Exp. 2):

The integration of external reflective mirrors yielded a significant performance increase of ~16% over the baseline, with a cumulative production of 3.757 kg/m2 and enhanced thermal efficiency of 41.66%. The mirrors intensified solar flux on both the water surface and glass cover, elevating internal temperatures and boosting evaporation and condensation rates. The mirrors also improved performance during peak insolation hours, establishing them as a low-cost, high-impact modification. -

-

Insulated Still under Dusty Skies (Exp. 3):

In this experiment, aluminum foil foam insulation was applied to reduce conductive heat losses. However, despite the insulation’s intended benefits, dusty atmospheric conditions (with solar irradiance dropping to 847 W/m2) and elevated wind speeds undermined the still’s thermal performance. The resulting yield was 2.0 kg/m2—significantly lower than both baseline and mirror-enhanced configurations—and the efficiency dropped to 25.18%. This result suggests that insulation is more effective when paired with strong solar input, and may be insufficient alone under suboptimal conditions. -

-

Integrated Internal Mirrors and Glass Panels (Exp. 4):

This configuration produced the highest yield of 4.979 kg/m2 and a notable thermal efficiency of 56.45%. These enhancements improved internal reflectivity and prolonged solar trapping throughout the day. The design proved particularly effective in the early morning and late afternoon, as it facilitated the capture of low-angle solar radiation. The combination of reflective and transmissive surfaces created a more uniform thermal environment inside the still, significantly enhancing evaporation rates. This setup is especially promising for real-world applications in arid environments where maximizing daily yield is critical.

5.2. Practical Implications

The practical relevance of this enhanced solar still is best understood through its modular deployment potential to meet specific community needs. A single unit with a basin area of 0.49 m2 produces approximately 2.44 kg of fresh water per 5 h in its optimized configuration (~5 kg/m2/day × 0.5 m2). While this quantity is supplemental, it directly addresses the critical need for high-purity drinking water.

Considering that the World Health Organization suggests a minimum of 2–3 L of drinking water per person per day, a small, decentralized array of these units can achieve water security for a typical household. For example, an array of four such units, occupying a total footprint of just under 2 m2, could reliably produce nearly 10 L of distilled water daily. This output is sufficient to meet the essential drinking and cooking water needs of a small family in an off-grid, arid region. This scalability, combined with the system’s low cost and minimal maintenance requirements, underscores its significant practical value and viability as a sustainable solution to freshwater scarcity.

5.3. Technical Insights

-

-

Solar Irradiance and Weather Impact:

Solar irradiance strongly influenced system performance. Even with thermal insulation (Exp. 3), dusty conditions led to the lowest output, highlighting the dominant role of optical transmissivity in passive systems. -

-

Thermal Efficiency Trends:

Efficiency improvements aligned with enhancements that improved solar energy absorption and trapping (Exp. 2 and 4), while insulation (Exp. 3) alone could not compensate for reduced radiation input. -

-

Modular Enhancement Benefits:

The results underscore the benefits of combined passive design strategies. The best performing configuration (Exp. 4) integrated multiple enhancements, suggesting that performance gains are multiplicative when optical and thermal improvements are synergized.

5.4. Scalability and Practical Implementation

Beyond the demonstrated thermal performance, a critical aspect of the proposed solar still is its practical feasibility and potential for large-scale implementation, which are essential for assessing its real-world impact. The design was conceived with three key principles in mind: modularity, local manufacturability, and ease of operation.

Modularity: The design’s primary strength for scalability lies in its inherent modularity. Individual units, like the one tested, can be easily interconnected to form larger arrays to meet varying freshwater demands. This allows for flexible, demand-driven deployment, from a single unit for a household to a multi-unit array for a small community or clinic. For example, an array of four such units, occupying a total area of just under 2 m2, could reliably produce nearly 10 L of distilled water daily, sufficient to meet the critical drinking water needs of a family.

Local Material Sourcing and Manufacturing: The feasibility of local manufacturing is another key design consideration. The system is constructed from common, widely available materials, including stainless steel for the basin, standard glass panels, and aluminum for reflective surfaces. This deliberate choice of materials minimizes reliance on specialized, imported components and complex supply chains. Consequently, fabrication and repairs can be performed by local workshops using standard tools and techniques, thereby reducing costs, fostering local economic activity, and ensuring the long-term sustainability of the installation.

Ease of Operation and Maintenance: A major advantage for implementation in remote regions is the system’s ease of operation and low maintenance requirements. As a fully passive system, it operates without any electrical input, pumps, or complex moving parts. Daily operational tasks are limited to filling the basin with saline water (if not automated with a simple float valve) and collecting the fresh distillate. Periodic maintenance is straightforward and consists of cleaning the glass cover to remove dust and occasional flushing of the basin to remove brine concentrate. The simplicity of these tasks requires minimal user training, making the system ideally suited for deployment in off-grid communities where technical support and resources may be limited.

5.5. Economic Analysis

To validate the “low-cost” claim and assess the practical viability of the proposed modifications, a comprehensive economic analysis was performed. The primary metric for this evaluation is the Cost Per Liter (CPL) of fresh water produced, which provides a clear measure of the long-term economic feasibility of each configuration. This analysis is based on the capital cost of materials and the experimentally determined freshwater yield.

The capital costs for the solar still were estimated based on local market prices for the required materials. The baseline unit (Experiment 1) includes a stainless-steel basin, a transparent glass cover, rock wool insulation, and miscellaneous fittings. The costs for subsequent modifications—external mirrors (Experiment 2), aluminum foil foam insulation (Experiment 3), and internal glass panels with mirrors (Experiment 4)—were added incrementally to the baseline cost to determine the total capital investment for each configuration. These costs are itemized in Table 3.

The CPL was calculated by amortizing the total capital cost over the system’s projected lifetime production. The following conservative assumptions were made for the calculation:

-

-

Device Lifespan: 10 years.

-

-

Operating Days: 300 sunny days per year, a reasonable estimate for the arid climate of Tabuk.

-

-

Basin Area: 0.49 m2 (0.7 m × 0.7 m).

-

-

Operational & Maintenance Costs: Considered negligible due to the passive nature of the system, which requires no electricity and only periodic, simple cleaning.

The formula used for the calculation is:

Table 3. Economic analysis and Cost Per Liter (CPL) for each experimental configuration.

|

Configuration (Experiment) |

Modification Description |

Total Capital Cost (USD) |

Daily Yield (L/m2/day) |

Total Lifetime Production (L) |

Cost Per Liter (CPL) (USD/L) |

|---|---|---|---|---|---|

|

Exp. 1 |

Baseline (unmodified) |

85 |

3.237 |

4758 |

$0.0179 |

|

Exp. 2 |

Baseline + External Reflective Mirrors |

95 |

3.757 |

5523 |

$0.0172 |

|

Exp. 3 |

Baseline + Rear & Base Insulation (Dusty Day) |

100 |

2.000 |

2940 |

$0.0340 |

|

Exp. 4 |

Baseline + Insulation + Internal Glass & Mirrors |

120 |

4.979 |

7319 |

$0.0164 |

The economic analysis presented in Table 3 reveals several critical insights. The addition of external mirrors (Exp. 2) provided a modest reduction in the CPL, demonstrating that this simple enhancement is cost-effective. Conversely, the high CPL for Experiment 3 ($0.0340/L) starkly illustrates the poor economic return of investing in insulation when solar input is compromised by adverse weather, as the low yield fails to offset the added cost.

Most importantly, the fully enhanced configuration (Exp. 4) achieved the lowest Cost Per Liter at 0.0164/L. Although it required the highest initial capital investment (120), its substantially increased freshwater production (a 54% improvement over baseline) makes it the most economically advantageous option over the system’s lifespan. This CPL is highly competitive for decentralized water treatment systems and is orders of magnitude lower than the cost of bottled water, especially in remote regions. This quantitative analysis unequivocally substantiates the claim that the proposed sequential enhancements are not only technically effective but also represent an excellent cost-benefit proposition, justifying the investment for sustainable, long-term freshwater production.

6. Conclusions

This study comprehensively evaluated the performance of a passive solar still under four distinct configurations to identify cost-effective enhancements that can significantly improve freshwater productivity in arid environments. Conducted under the climatic conditions of Tabuk, Saudi Arabia, with solar irradiance ranging from 847 to 943 W/m2, the experiments demonstrated the effectiveness of targeted design modifications, including external mirrors, thermal insulation, and internal reflective/glass enhancements.

The baseline solar still achieved a cumulative distillate yield of 3.237 kg/m2/day and a thermal efficiency of 36.27%, serving as the reference point for comparative evaluation. The introduction of external reflective mirrors in Experiment 2 increased solar capture and increased daily yield by 16% to 3.757 kg/m2, with an efficiency of 41.66%, confirming the value of optical enhancement through mirror augmentation.

In contrast, Experiment 3, which employed aluminum foil foam insulation under dusty atmospheric conditions, yielded a reduced output of 2.000 kg/m2 and a lower efficiency of 25.18%, highlighting the limitations of insulation when solar input is compromised. Nevertheless, insulation helped maintain elevated basin temperatures, suggesting that its benefit is conditional upon adequate solar irradiance.

The most substantial improvement was observed in Experiment 4, where internal mirrors and side glass panels were employed. This configuration achieved a maximum productivity of 4.979 kg/m2/day and the highest recorded thermal efficiency of 56.45%, representing a 54% improvement in distillate yield relative to the baseline. The integration of internal optical enhancements effectively captured low-angle radiation during early and late hours, extending the effective distillation period.

In summary, the study confirms that combining passive enhancements—particularly those that increase solar radiation absorption and internal reflectivity—can substantially improve the thermal performance and water yield of solar stills. These findings are directly applicable to water-scarce, high-insolation regions, where simple, low-cost design optimizations can dramatically improve the viability of decentralized solar desalination systems.

7. Future Work

Building on the robust experimental data gathered in this study, a logical next step is the development and validation of a comprehensive thermal and optical model. Such a model will enable detailed parametric optimization—for instance, exploring the effects of varying glass cover angles, insulation thicknesses, or mirror dimensions without the need for further extensive physical prototyping. Furthermore, it will allow for the performance prediction of the optimized solar still across diverse climatic zones, thereby generalizing the findings of this study and facilitating its wider adoption in different arid regions globally. This future work will bridge the gap between empirical validation and broader predictive capability, enhancing the scientific and practical impact of the research.

Statement of the Use of Generative AI and AI-Assisted Technologies in the Writing Process

During the preparation of this work, the authors utilized ChatGPT-4o to enhance readability. Following its use, the authors carefully reviewed and revised the content as necessary and assume full responsibility for the publication’s content.

Acknowledgments

The authors gratefully acknowledge the staff of the University of Tabuk workshop for their invaluable technical assistance and consistent support during the experimental work. Their dedication and expertise were instrumental in the successful completion of this study.

Author Contributions

H.A. and K.A. contributed to study design, data interpretation, manuscript writing, and overall project coordination. O.A.-T., M.N., A.F.A.-S., A.A. and N.A.-S. were responsible for experimental execution and data acquisition. All authors critically revised the manuscript and agreed to its submission.

Ethics Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Funding

The authors did not receive support from any organization for the submitted work.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

-

Butler D, Farmani R, Abdelmeguid H. Optioneering development-scale water systems. In The Future of Urban Water: Solutions for Liveable and Resilient Cities; UNESCO: Paris, France, 2011; p. 24e26. [Google Scholar]

-

Ward S, Abdelmeguid H, Farmani R, Memon FA, Butler D. Sustainable Water Management—Modelling Acceptability for Decision Support: A Methodology. In Proceedings of the Urban Water Management: Challenges and Oppurtunities—11th International Conference on Computing and Control for the Water Industry, CCWI 2011, Exeter, UK, 5–7 September 2011.. [Google Scholar]

-

Memon FA, Butler D, Farmani R, Abdelmeguid H, Atkinson S, Rogers C, et al. Urban Futures—Sustainability (Resilience) Evaluation of Water Infrastructure. In Proceedings of the 2011 AEESP Education & Research Conference, Tampa, FL, USA, 10–12 July 2011. . [Google Scholar]

-

Farmani R, Butler D, Memon F, Abdelmeguid H, Ward S. Sustainable water management for urban regeneration. In The Future of Urban Water: Solutions for Livable and Resilient Cities; UNESCO: Paris, France, 2011. [Google Scholar]

-

Farmani R, Butler D, Hunt DVL, Memon FA, Abdelmeguid H, Ward S, et al. Scenario-based sustainable water management and urban regeneration. Proc. Inst. Civ. Eng.-Eng. Sustain. 2012, 165, 89–98. doi:10.1680/ensu.2012.165.1.89. [Google Scholar]

-

AbdelMeguid H. Year-round performance evaluation of a solar-powered compact HDH desalination system for remote water scarce regions. Int. J. Green Energy 2025, 22, 2223–2245. doi:10.1080/15435075.2025.2454255. [Google Scholar]

-

Alshamrani K, Asiri A, Alqarni A, AbdelMeguid H. Numerical Investigation of the Performance of Fully Solar Driven Compact HDH Desalination System. Int. J. Eng. 2023, 15, 23–41. [Google Scholar]

-

Elsharkawy M, AbdelMeguid H, El-Sharkawy I, Rabie L. Experimental and Theoretical Investigation of Decentralized Desalination System. MEJ-Mansoura Eng. J. 2014, 39, 22–35. doi:10.21608/bfemu.2020.102887. [Google Scholar]

-

AbdelMeguid H, El Awady WM. Optimizing solar still performance through glass cover optical properties: A mathematical modeling and theoretical investigation. Ain Shams Eng. J. 2024, 15, 102589. doi:10.1016/j.asej.2023.102589. [Google Scholar]

-

AbdelMeguid H, El Awady WM. Theoretical investigation into saline optical properties for enhancing solar still performance: Mathematical modeling approach. Therm. Sci. Eng. Prog. 2024, 54, 102846. doi:10.1016/j.tsep.2024.102846. [Google Scholar]

-

AbdelMeguid H. Multi-stage PCM-enhanced solar distiller desalination: Investigating energy storage dynamics, phase transition behavior, and system performance with variable PCM/saline mass ratios. J. Energy Storage 2025, 122, 116687. doi:10.1016/j.est.2025.116687. [Google Scholar]

-

AbdelMeguid H. Adaptive thermal buffering in solar desalination: Seasonally optimized PCM selection for extreme diurnal climates. Sol. Energy Mater. Sol. Cells 2025, 289, 113687. doi:10.1016/j.solmat.2025.113687. [Google Scholar]

-

AbdelMeguid H. Examining the performance of optically optimized solar stills with phase change materials: A theoretical perspective on ongoing debates. Sol. Energy Mater. Sol. Cells 2025, 282, 113394. doi:10.1016/j.solmat.2024.113394. [Google Scholar]

-

AbdelMeguid H, Gherissi A, Elsawy M, Aljohani Z, Asiri A, Saber M, et al. Potential application of solar still desalination in NEOM region. Appl. Water Sci. 2024, 14, 53. doi:10.1007/s13201-024-02115-4. [Google Scholar]

-

Kumar Panangipalli V, Hallika Pindiprolu MS, Maharana D, Ghanapuram N. Performance of single slope solar stills: A comparative study of conventional and modified stills with nanofluid and reflectors. E3S Web Conf. 2024, 552, 01023. doi:10.1051/e3sconf/202455201023. [Google Scholar]

-

Ni G, Zandavi SH, Javid SM, Boriskina SV, Cooper TA, Chen G. A salt-rejecting floating solar still for low-cost desalination. Energy Environ. Sci. 2018, 11, 1510–1519. doi:10.1039/C8EE00220G. [Google Scholar]

-

Ayoub GM, Malaeb L. Developments in Solar Still Desalination Systems: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2012, 42, 2078–2112. doi:10.1080/10643389.2011.574104. [Google Scholar]

-

Sohani A, Hoseinzadeh S, Berenjkar K. Experimental analysis of innovative designs for solar still desalination technologies; An in-depth technical and economic assessment. J. Energy Storage 2021, 33, 101862. doi:10.1016/j.est.2020.101862. [Google Scholar]

-

Morad MM, El-Maghawry HAM, Wasfy KI. Improving the double slope solar still performance by using flat-plate solar collector and cooling glass cover. Desalination 2015, 373, 1–9. doi:10.1016/j.desal.2015.06.017. [Google Scholar]

-

Ali Samee M, Mirza UK, Majeed T, Ahmad N. Design and performance of a simple single basin solar still. Renew. Sustain. Energy Rev. 2007, 11, 543–549. doi:10.1016/j.rser.2005.03.003. [Google Scholar]

-

Soltanian M, Hoseinzadeh S, Astiaso Garcia D. Proposal of a Reflector-Enhanced Solar Still Concept and Its Comparison with Conventional Solar Stills. Water 2024, 16, 355. doi:10.3390/w16020355. [Google Scholar]

-

Shoeibi S, Saemian M, Parsa SM, Khiadani M, Mirjalily SAA, Kargarsharifabad H. A novel solar desalination system equipped with thermoelectric generator, reflectors and low-cost sensible energy-storage for co-production of power and drinking water. Desalination 2023, 567, 116955. doi:10.1016/j.desal.2023.116955. [Google Scholar]

-

Ziapour BM, Afzal S, Mahdian J, Reza Miroliaei A. Enhancing solar still performance through innovative modeling, integration with reflectors, and semi-transparent solar cells: A 3E analysis and multi-objective optimization. Appl. Therm. Eng. 2024, 242, 122464. doi:10.1016/j.applthermaleng.2024.122464. [Google Scholar]

-

Chandrika VS, Attia MEH, Manokar AM, Marquez FPG, Driss Z, Sathyamurthy R. Performance enhancements of conventional solar still using reflective aluminium foil sheet and reflective glass mirrors: energy and exergy analysis. Environ. Sci. Pollut. Res. 2021, 28, 32508–32516. doi:10.1007/s11356-021-13087-2. [Google Scholar]

-

Venkata Sai P, Reddy KS. Theoretical and experimental investigations of inclined solar still using secondary reflectors on east-west for enhanced distillate yield. Appl. Therm. Eng. 2024, 236, 121836. doi:10.1016/j.applthermaleng.2023.121836. [Google Scholar]

-

Tuly SS, Ayon ABS, Hassan R, Das BK, Khan RH, Sarker MRI. Performance investigation of active double slope solar stills incorporating internal sidewall reflector, hollow circular fins, and nanoparticle-mixed phase change material. J. Energy Storage 2022, 55, 105660. doi:10.1016/j.est.2022.105660. [Google Scholar]

-

Abdullah AS, Alawee WH, Mohammed SA, Majdi A, Omara ZM, Younes MM. Utilizing a single slope solar still with copper heating coil, external condenser, phase change material, along with internal and external reflectors—Experimental study. J. Energy Storage 2023, 63, 106899. doi:10.1016/j.est.2023.106899. [Google Scholar]

-

Mandev E, Muratçobanoğlu B, Manay E, Şahin B. Desalination performance evaluation of a solar still enhanced by thermoelectric modules. Sol. Energy 2024, 268, 112325. doi:10.1016/j.solener.2024.112325. [Google Scholar]

-

Hoque A, Abir AH, Paul Shourov K. Solar still for saline water desalination for low-income coastal areas. Appl. Water Sci. 2019, 9, 104. doi:10.1007/s13201-019-0986-9. [Google Scholar]

-

Khanmohammadi S, Khanjani S, Hashemi N. Experimental and analytical examinations of a single-glazed solar still desalination with a spray-feeding water system with an artificial neural network. Appl. Therm. Eng. 2024, 249, 123408. doi:10.1016/j.applthermaleng.2024.123408. [Google Scholar]

-

Pillai R, Libin AT, Mani M. Study into solar-still performance under sealed and unsealed conditions. Int. J. Low-Carbon Technol. 2015, 10, 354–364. doi:10.1093/ijlct/ctt045. [Google Scholar]

-

Yu J, Zhang W, Zhi S, Qi X, Chen Y. Long Life and Salt Repellent Evaporator for Efficient Continuous Solar Desalination. Sol. RRL 2023, 7, 2300347. doi:10.1002/solr.202300347. [Google Scholar]

-

Al-Helal IM, Alsadon A, Marey S, Ibrahim A, Shady MR. Optimizing a Single-Slope Solar Still for Fresh-Water Production in the Deserts of Arid Regions: An Experimental and Numerical Approach. Sustainability 2024, 16, 800. doi:10.3390/su16020800. [Google Scholar]