The Role of Electric Vehicles in Environmental Transformation-Goal Towards a Pollution-Free Climate

Received: 02 July 2025 Revised: 01 September 2025 Accepted: 24 November 2025 Published: 02 December 2025

© 2025 The authors. This is an open access article under the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).

1. Introduction

The world is facing a very big problem in the shape of pollution and the greenhouse effect in recent years. Government agencies have worked tirelessly to minimize the effects of pollution. This problem is pretty dominant in developing countries like Pakistan. A recent report by the health association: Living in Pakistan decreases life expectancy by 4 years [1]. This is the biggest problem on which this proposed research paper will be based. The second major issue associated with this problem is the two-wheelers [Motorbikes], whose adverse effects are discussed as [2]:

-

-

Motorbikes are most affected by pollution, with chronic issues like respiration because of direct exposure.

-

-

Motorbikes are a bigger threat to pollution as they are the biggest pollution makers in the world overall.

Because 18% of Pakistani university students commute by motorbike and 38% by automobile, university students are particularly vulnerable to pollution and other hazards, such as the 1665 students who are killed in traffic accidents each year. Due to the current state of public transportation, which is insufficient (25% avoid buses due to delays and overcrowding), people in filthy cities like Lahore are forced to rely on dirty two-wheelers. Student EVs offer a safe, emission-free option for commuting on campus.

Priorly, a lot of work has already been established, which will be helpful to our study. We need to have a clearer view to explain the new idea. In 2020, the Pakistan government announced its new EV policy, offering substantial subsidies and reducing import duties on electric vehicles to reduce air pollution and greenhouse gas emissions. In line with the policy, the government is promoting local manufacturing by offering tax exemptions for manufacturers, which will eventually decrease the cost of electric vehicles in the country. All these rules and regulations would be in vain if there were no electric charging station infrastructure. The government of Pakistan is working with relevant stakeholders to implement this system in urban areas and major routes, thereby increasing the feasibility of electric vehicles. The government of Pakistan is also in talks with private companies to deploy electric buses in place of older, high-tailpipe-emitting Diesel buses. In addition to all this, the four-wheelers being used and subsidized, it is necessary for us to have a solution to the pollution caused by motorbikes, as they are the primary polluters in many urban areas [3]. Many E-Bikes are being introduced in the market for consumers. The biggest positive in this aspect was the distribution of E-Bikes by the government of Punjab to the deserving students of educational institutes on easy payment plans, which was the first step for the betterment of the students and the overall environment. Unlike general EV studies, this work customizes a single-seat prototype for Pakistani students, integrating AGS and self-driving modes for safety, with quantified benefits like 30% lower lifecycle CO2e.

Before writing this paper, the majority of the accessible literature was reviewed. We reviewed all available records on pollution caused by Internal Combustion engine vehicles and the benefits we would gain if we used electric vehicles rather than those already in use. The approach has been backed by both qualitative and quantitative analysis before jumping to conclusions. Table 1 below summarizes key differences between EVs and ICE vehicles and supports the need for student EVs in polluted campuses. The literature study shows that electric vehicles (EVs) have lower carbon emissions than internal combustion engine (ICE) vehicles, making them more environmentally friendly. However, EVs tend to have higher nitrogen emissions due to battery production and electricity generation, while ICE vehicles produce more direct nitrogen emissions from fuel combustion. Maintenance costs for EVs are lower because they have fewer moving parts, whereas ICE vehicles require frequent servicing due to engine wear and tear. In literature, we have seen that by about 2050, if we have policies that we can efficiently work can take us to the point of zero emissions [4]. The high number of Nitrogen emissions is due to the production of electricity from fossil fuels.

This research paper aims to give interested students an electric vehicle for their use within the university time and premises, with the help of a subsidy given by the government and responsible authorities. A new model of car has been identified in the current research work. This is a sole-use car to provide students with a vehicle to study and use simultaneously. This new EV vehicle will provide comfort to the students. This new electric vehicle model will help us to provide a comfortable and safe environment for female students in many developing countries such as Pakistan. Another positive aspect of this electric model is that we can work on the recycling of batteries, which will ultimately increase the efficiency and life cycle of the model. This approach is much required to counter these recurring problems at the educational as well as commercial levels to save people from devastating polluted environments, especially those in South Asia.This study’s main goal is to develop and quantitatively assess a small, single-occupant student electric vehicle specifically designed for Pakistani university campuses. It will show through lifecycle assessment (LCA), carbon footprint analysis (CFA), and agent-based modelling (ABM) that it can reduce lifecycle CO2 emissions by up to 71% compared to traditional two-wheelers while meeting students’ needs for safety and usability.

Section 2 presents the contextual necessity in Pakistan; Section 3 details the multi-method framework (LCA, CFA, ABM) used for quantitative evaluation; Section 4 examines thermal feasibility in Pakistan’s climate; Section 5 explores AI-enabled features that enhance safety and efficiency; Section 6 synthesizes findings and policy recommendations.

2. Electric Vehicle Adoption in Pakistan: Opportunities and Barriers

There is a dynamic shift in the vehicle industry in Pakistan, which is leaning towards the electric vehicle sector. This is due to many factors, but the key one remains the environmental factor. EVs are seen as a potential solution for all the problems caused by ICE vehicles. We can illustrate the dynamic prospects of electric vehicles in Pakistan as follows: Current Situation: Pakistan, especially cities like Karachi and Lahore, is facing a very high air pollution index caused by vehicular emissions. Pakistan is considered a country for being one of toxic air, with Lahore being at the top of that list. Future Expectations, Electric vehicles produce zero tailpipe emissions, which means no toxic gases [5]. This will significantly help us cope with respiratory problems.

It is one of the major issues in the whole world, as it was the sole reason behind many go-green initiatives taken by notable brands. Pakistan, like every other country, was not behind in any of this campaign. Now, with the increasing use of electric vehicles and our idea discussed in this paper, there is a high probability of this succeeding. The transportation sector of Pakistan is one of the major sources of greenhouse gas emissions. This is due to the combustion of fossil fuels in internal combustion engine vehicles. Future Expectations With the increasing use of EVs, we can digitize the emission of carbon emissions. If Pakistan can find a way to use a clean source of energy in the EV sector, then this will bring a whole lot of benefits to the country.

-

-

NEVP target (30% EVs by 2030).

-

-

Campus-specific need (18% students on motorbikes).

-

-

Current EV sales (e.g., e-bikes up 300%).

With the increasing use of ICEs, there has been a lot of pressure on the availability of fossil fuels in the whole world. The amount of fossil fuels in this world has always been limited. In every sector, we are moving to Renewable sources for power generation. Similarly, in the transportation sector, there is a lot of need for this renewable energy integration [6,7].

Currently, Pakistan is making strides in the renewable energy sector, but on the overall level, this factor is quite low compared to the consumption of fossil fuels. This integration faces many issues currently, including storage issues as well as grid problems. Future expectations, EV can help promote this integration. With the increase in the use of solar energy, we can simply use Vehicles to the grid, where solar energy is used to charge the vehicle’s battery and send the excess energy to the grid [6]. The long-term prospects of electric vehicles (EVs) in Pakistan hold great promise due to rising fuel costs, developing urban pollution, and the country’s need to diminish its reliance on imported fossil fuels. With over 43% of Pakistanis’ urban outflows coming from the transport segment, EVs offer a clean and maintainable alternative. The government has presented the National Electric Vehicle Approach (NEVP), which aims to achieve a 30% shift to electric vehicles by 2030. This incorporates motivations like decreased consequence obligations, assessment exceptions on EV parts, and the advancement of local EV manufacturing. Pakistan’s climate, with brief driving seasons in cities and gentle winters, makes it perfect for little EVs and electric two- or three-wheelers. In addition, activities by neighborhood companies such as Jolt Electric and Sazgar appear to be developing mechanical intrigued. In any case, challenges remain, unconstrained charging framework, an unsteady power supply, and a need for open mindfulness. In spite of these obstacles, the move toward EVs in Pakistan is picking up energy, driven by environmental concerns, innovative technologies, and strong government approaches. If sought after successfully, electric versatility seems to revolutionize Pakistan’s transportation division, making unused employments, decreasing emissions, and improving public wellbeing.

The student EV prototype presented in this work was purposefully designed to overcome the following obstacles: the high grid intensity (532 g CO2e/kWh) and fossil-heavy grid are addressed by using a small 10 kWh battery in conjunction with a rooftop solar panel to reduce grid dependence and improve well-to-wheel emissions; extreme summer temperatures, which frequently exceed 40 °C in Lahore and Narowal, are mitigated through passive cooling strategies and the detailed thermal analysis presented in Section 4 to avoid the expense and complexity of liquid cooling; and the predominance of inexpensive two-wheelers among students (18% government subsidy), making the vehicle competitive with used 110 cc bikes; safety concerns, particularly for female students, are addressed with an enclosed single-occupant pod, Automatic Gear System (AGS), and Level-2 autonomous features covered in Section 5; and, lastly, the low daily energy demand of roughly 1.5–2 kWh for typical campus use accommodates the near-zero campus charging infrastructure, enabling straightforward overnight charging from existing 220 V hostel outlets.

3. Methodology

This paper will discuss and find the impact of one student using an electric vehicle on the environment. This involves the discussion of the assessment factors by which ICEs and EVs can be evaluated. In this research paper, we will use different methods to compare the pros and cons of internal combustion engines and electric vehicles.

-

-

Vehicle Control Unit (VCU) (both): At the heart of the framework lies the Vehicle Control Unit, which serves as the central handling center. It oversees all vehicle capacities, including engine control, battery administration, client interface communication, and security monitoring. The VCU forms real-time information from different sensors and executes commands based on driver input and framework status.

-

-

Battery Pack and Battery Administration Framework (BMS) (EV only): The vehicle is fueled by a lithium-ion battery pack, chosen for its high energy density and lightweight characteristics. The Battery Administration Framework ceaselessly screens key parameters such as State of Charge (SoC), State of Wellbeing (SoH), voltage, temperature, and current. It guarantees ideal execution, security, and the life span of the battery.

-

-

Electric Engine and Engine Controller (both): Brushless DC (BLDC) center engine is integrated into the raised wheels, indicating compactness and high effectiveness. The engine controller gets throttle signals from the VCU and controls the voltage and current to the engine, giving smooth speeding up and regenerative braking functionality.

-

-

Charging System (EV only): The EV highlights an onboard charging framework congruous with standard AC outlets. Moreover, a little housetop solar board (obvious within the picture) supplements vitality input through stream charging, perfect for amplified stopping lengths in daylight. Charging status and the vitality stream are overseen through the VCU and shown to the user.

-

-

Human-Machine Interface (Dashboard) (both): The human-machine interface incorporates a computerized dashboard showing real-time information such as speed, battery rate, separate traveled, and system notifications. It may also incorporate touch-screen usefulness for controlling assistant frameworks like lights, pointers, and wipers.

-

-

Assistant Systems (both): Additional sub-systems include: Lighting and Signaling: Headlights, tail lights, brake lights, and turn indicators. Safety Highlights: Situate belt sensors, entryway bolt status, and crisis cutoff. Infotainment (Discretionary): Bluetooth network, sound framework, and route.

Life Cycle Assessment (LCA), Carbon Footprint Analysis (CFA), Agent-based Modelling (ABM), thermal simulation, and conceptual design are all used in this study’s multi-method approach. One student electric car with a 10 kWh Li-ion battery, a 5 kW BLDC hub motor, and 15,000 km driven over eight years on a Pakistani university campus is the functioning unit. A standard 70–125 cc petrol two-wheeler with a lifetime of 120,000 km and an average fuel consumption of 45 km/L serves as the reference vehicle for comparison. The authors’ SolidWorks CAD models and ANSYS simulations provided the primary data for the suggested EV. The Eco invent v3.10 database (modified to Pakistan grid intensity of 532 g CO2e/kWh—IEA 2024), GREET 2023 for ICE vehicles, and literature numbers for battery recycling rates (95% material recovery) are examples of secondary data sources.

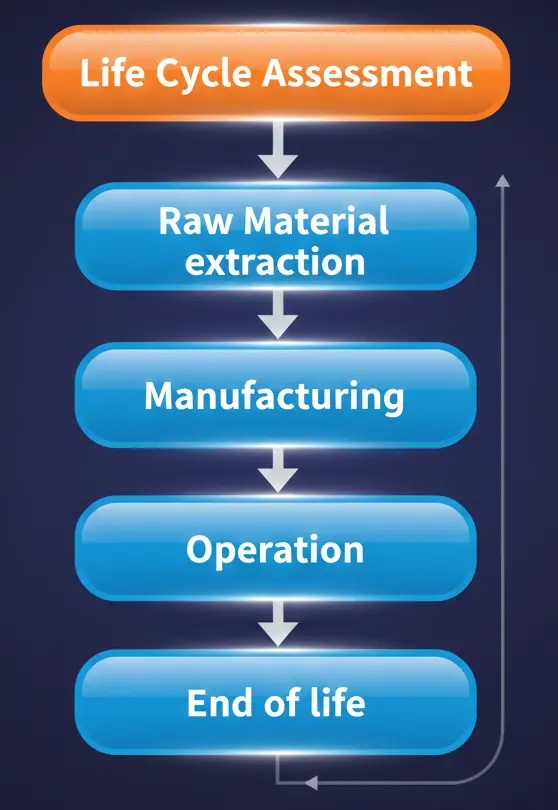

3.1. Life Cycle Assessment

This method will evaluate potential impacts on the environment during every phase of the vehicle life cycle. This phase includes Raw Material extraction, Manufacturing, Operation, and end-of-life. All of these phases of the vehicle are studied during the implementation of this method [8]. The main purpose of this method is to give us a fair comparison between EVs and ICEVs (internal combustion engine vehicles). The following are the major steps to take during this process.

From Figure 1, LCA include:

-

Goal Definition: Check the environmental impact of electric vehicles.

-

Scope Definition: We define the life cycle of our vehicle and other limitations. (University clean roads).

-

Inventory Analysis: We will do inventory analysis, and we will study the amount of CO2 and hazardous materials related to each of the phases associated with the life cycle of an electric vehicle.

-

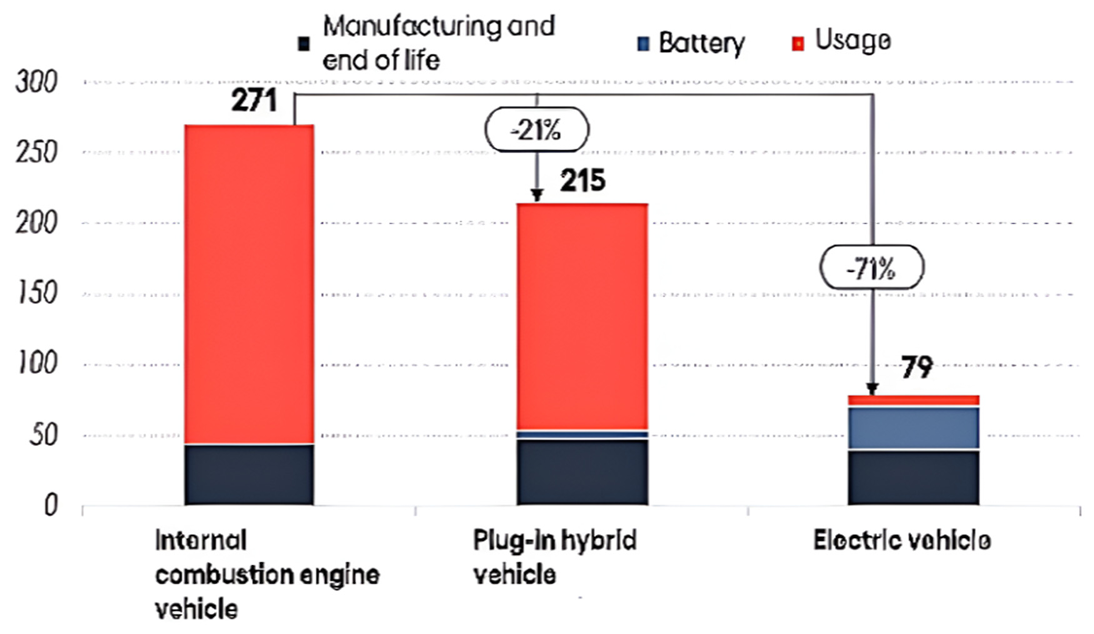

Impact assessment: We will complete the Impact assessment that we do based on the following factors of Figure 2, which are briefed after the figure.

Figure 2 bar chart compares the environmental impact of Internal Combustion Engine Vehicles (ICEVs), Plug-in Hybrid Vehicles (PHEVs), and Electric Vehicles (EVs) in terms of manufacturing, battery, and usage. ICEVs have the highest emissions (271 units), while EVs have the lowest (79 units), showing a 71% reduction in usage-related emissions. PHEVs fall in between with 215 units, reducing emissions by 21% compared to ICEVs. A bar chart uses lifecycle data to quantify emissions in arbitrary units: EVs have a reduced operational effect despite greater manufacturing emissions, with ICEVs emitting 271 units largely from consumption, PHEVs 215 units (21% reduction), and EVs 79 units (71% reduction). Figure 2 findings were derived by LCA modelling. As a transitional benchmark, PHEVs demonstrate a 21% reduction in comparison to ICEs, whereas student prototypes of complete EVs reach a 71% reduction.

3.2. Carbon Footprint Analysis

This method is based on measuring the greenhouse gases over the various phases of a vehicle’s life [9]. This method is a continuation of the LCA. In this process, we simply look for carbon dioxide emissions, mainly alongside some other greenhouse effect-causing gases. We can simply do this process by following these steps: Direct emission from use, indirect emission from manufacturing, and Total life cycle manufacturing.

Figure 3 represents the concept of a carbon footprint using a footprint-shaped diagram. It highlights various contributing factors, including fuel, gas, transport, electricity, water use, emissions, recycling, and waste. The illustration emphasizes the impact of human activities on carbon emissions and the environment. This method is the corresponding key method to foresee the effects because of the direct consideration of tailpipe emissions becoming relevant. Carbon footprint analysis is the most important factor to consider whenever something good for the environment is studied. We have simulated the conclusion from the following data and got the result as:

-

Assumptions: Pakistan grid (63% fossil, 400–600 g CO2/kWh), NEVP policies (30% EVs by 2030), tech advances (95% recycling).

-

Input: Material, which is lithium and energy.

-

Outputs: 15 tons CO2e total, sensitivity ±20% to renewables.

Figure 3. Illustration of the carbon footprint, highlighting key contributors such as fuel, electricity, transport, gas, recycling, waste, and personnel.

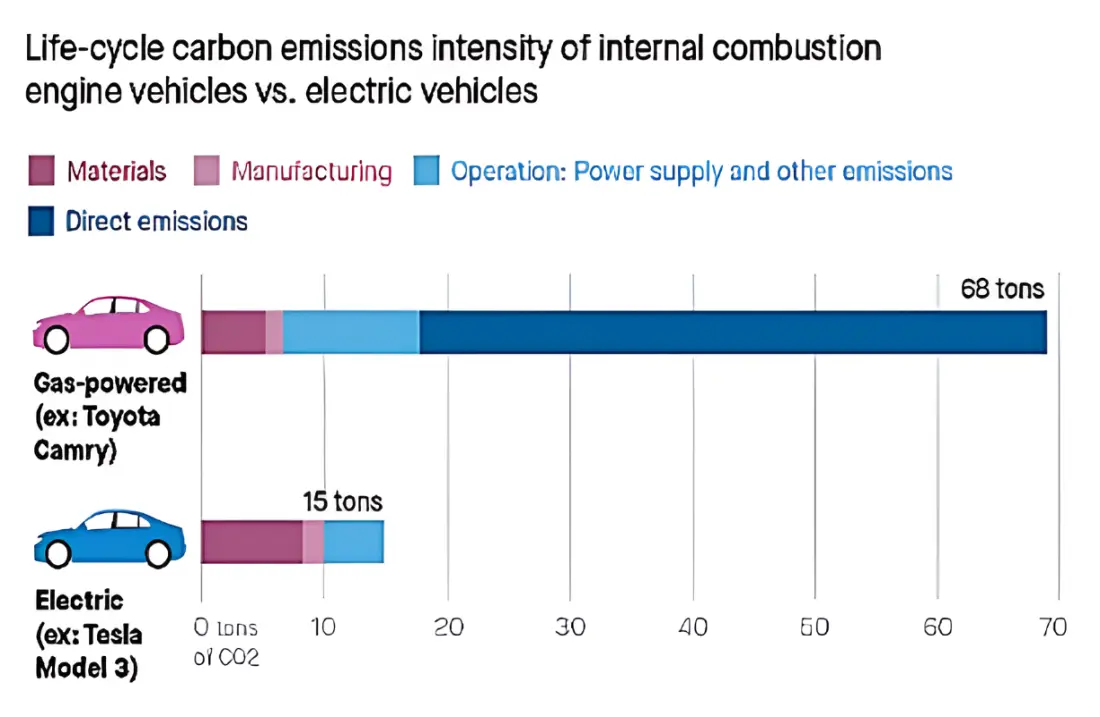

We took an example of Tesla Model 3 [10] and compared it with a simple gasoline-based vehicle, which will tell us about the carbon footprint at each step, and then we will conclude:

Electric Vehicle: It depends on whether the energy comes from a fossil fuel or a renewable source. Tesla Model 3 approximately consumes about 15–20 kWh per 100 miles. And 900 kWh per 15,000 miles. A Gasoline Vehicle from the general report of a common gasoline vehicle, typically a 15,000-mile vehicle, consumes more than 30,000 kWh. Indirect emissions from Manufacturing: The carbon dioxide footprint is quite high in the electric sector during manufacturing because of the simple fact that it contains steps like Battery production and vehicle assembly. A simple Tesla Model 3 consumes about 14,000–19,000 kg of CO2. This comparison shows that even though CO2 emissions are higher in manufacturing, a gasoline car alone in direct emissions consumes about twice as much as the total emissions of an electric vehicle.

-

Fabricating Phase: The generation of EVs, particularly the lithium-ion battery pack, is more carbon-intensive than internal combustion engine (ICE) vehicles. On average, battery fabrication contributes between 70 to 110 kg CO2 per kWh of battery capacity. For example, a 10 kWh battery (commonplace for compact urban EVs) comes about in around 700 to 1100 kg of coal amid manufacturing. Be that as it may, this one-time outflow can be balanced by lower emissions during the vehicle’s operation.

-

Operational Phase: EVs create no coordinate outflows while driving, but the source of power utilized for charging is basic. In Pakistan, where the vitality blend is ruled by fossil fuels (natural gas and coal), but with developing hydro and sun oriented integration, the average power generation figure is around 400–600 g Coal/kWh.

-

End-of-Life Phase: Battery reusing essentially decreases the lifecycle carbon footprint. Up to 90–95% of basic materials (like lithium, cobalt, and nickel) [11] can be recuperated utilizing present-day reusing strategies. Appropriately reusing dodges extra mining outflows and diminishes the overall environmental impact of EVs.

Assuming the EV expends 0.12–0.15 kWh per km, operational outflows can be assessed as:

- a.

-

On fossil-dominated framework: 48–90 g Coal/km

- b.

-

On a renewable-rich network

Figure 4 compares the lifecycle carbon emissions of gas-powered and electric vehicles. Gas-powered cars (e.g., Toyota Camry) emit significantly more CO2 (68 tons) due to direct emissions, while electric vehicles (e.g., Tesla Model 3) emit 15 tons mainly from manufacturing and electricity generation. The data highlights the environmental advantage of EVs over traditional internal combustion engine vehicles. The fundamental distinctions between EVs and ICE cars are outlined in Table 1, which also highlights the reduced maintenance costs and carbon emissions (e.g., 50–200 g CO2/km operating) of EVs. By lowering dependency on fossil fuels, EVs immediately solve Pakistan’s pollution problem. Our suggestion for student EVs to reduce urban emissions is based on this.

Table 1. Comparing Lifecycle Emissions: Tesla Model 3 (EV) vs. Gasoline Vehicle (ICE) [12].

|

Category |

Tesla Model 3 (EV) |

Gasoline Vehicle (ICE) |

|---|---|---|

|

Manufacturing Emissions |

Higher due to battery production (~8 tons CO2e) |

Lower (~5 tons CO2e) |

|

Operational Emissions |

0 tailpipe emissions; depends on grid electricity (~50–200 g CO2/km) |

Direct emissions from fuel (~250 g CO2/km) |

|

End-of-Life Emissions |

Moderate, due to battery recycling |

Moderate, due to metal scrapping |

|

Total Lifecycle Emissions |

Lower in the long run (~20–30 tons CO2e over lifetime) |

Higher (~40–50 tons CO2e over lifetime) |

Figure 4 compares the lifecycle emissions of the Tesla Model 3 (EV) and a Gasoline Vehicle (ICE). While EVs have higher manufacturing emissions due to battery production, they produce lower operational emissions compared to gasoline cars, which have direct fuel emissions. Over a lifetime, EVs result in lower total emissions (~20–30 tons CO2e) compared to ICE vehicles (~40–50 tons CO2e), making them more environmentally friendly in the long run.

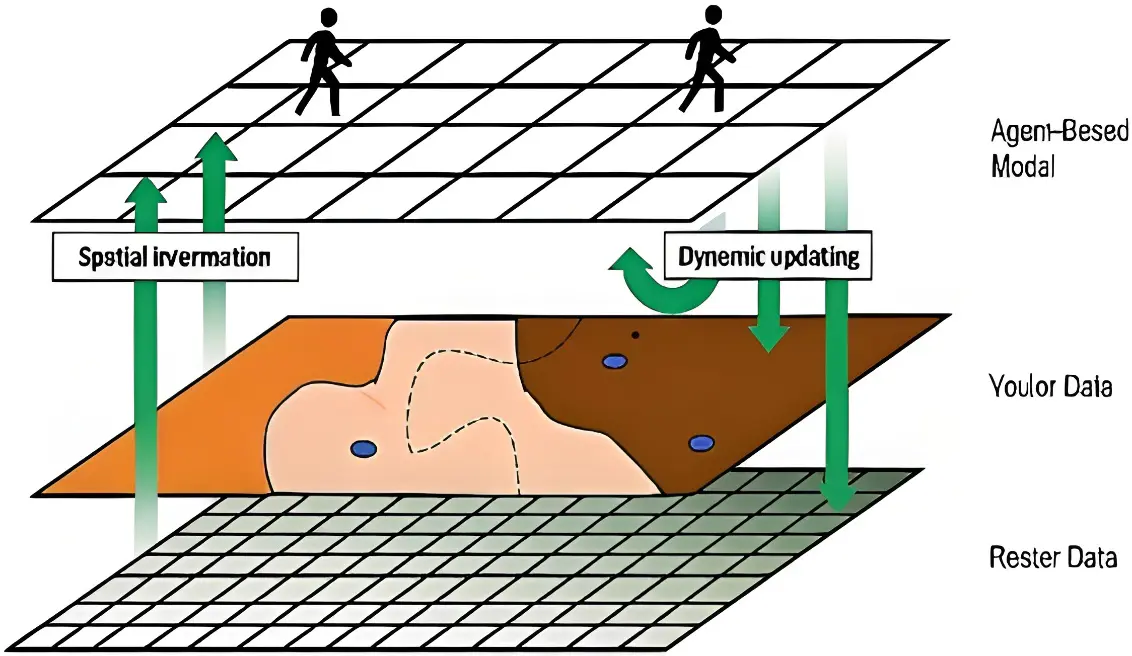

3.3. Agent-Based Modelling

This method is particularly important because it allows us to simulate the long-term environmental impacts of electric vehicles [13]. This can also find the overall effect on our environment by simply completing the following tasks: Technological advancement in battery recycling, Evolution of supply chains and infrastructure, and Policy interventions. In a detailed discussion on electric vehicles, we can easily differentiate between electric vehicles and internal combustion engines concerning the environmental impact. In this view, electric vehicles outperformed the internal combustion engine vehicles in terms of

- (a)

-

Operation

- (b)

-

Air Quality improvements

- (c)

-

Energy efficiency

While there is an issue within the manufacturing zone, it can easily be covered based on the overall impact on the environment.

Figure 5 represents an agent-based model interacting with spatial and raster data. The agents operate on a grid, utilizing spatial information and dynamic updates from underlying vector and raster data layers. It illustrates how spatial data influences agent behavior and decision-making in simulations. This shows the long-term impacts, like 30% emission cuts by 2030.

Figure 5. Agent-based modeling (ABM) in the context of Electric Vehicles (EVs) involves simulating the interactions of individual entities

3.4. Battery and Resources Impact

Electric vehicles (EVs) depend intensely on progressed battery innovations, especially lithium-ion (Li-ion) batteries, which are central to their execution and environmental impact. These batteries are composed of different basic materials such as lithium, cobalt, nickel, graphite, and manganese. Whereas these materials empower tall vitality thickness and long battery life, their extraction and handling come with critical environmental and moral concerns.

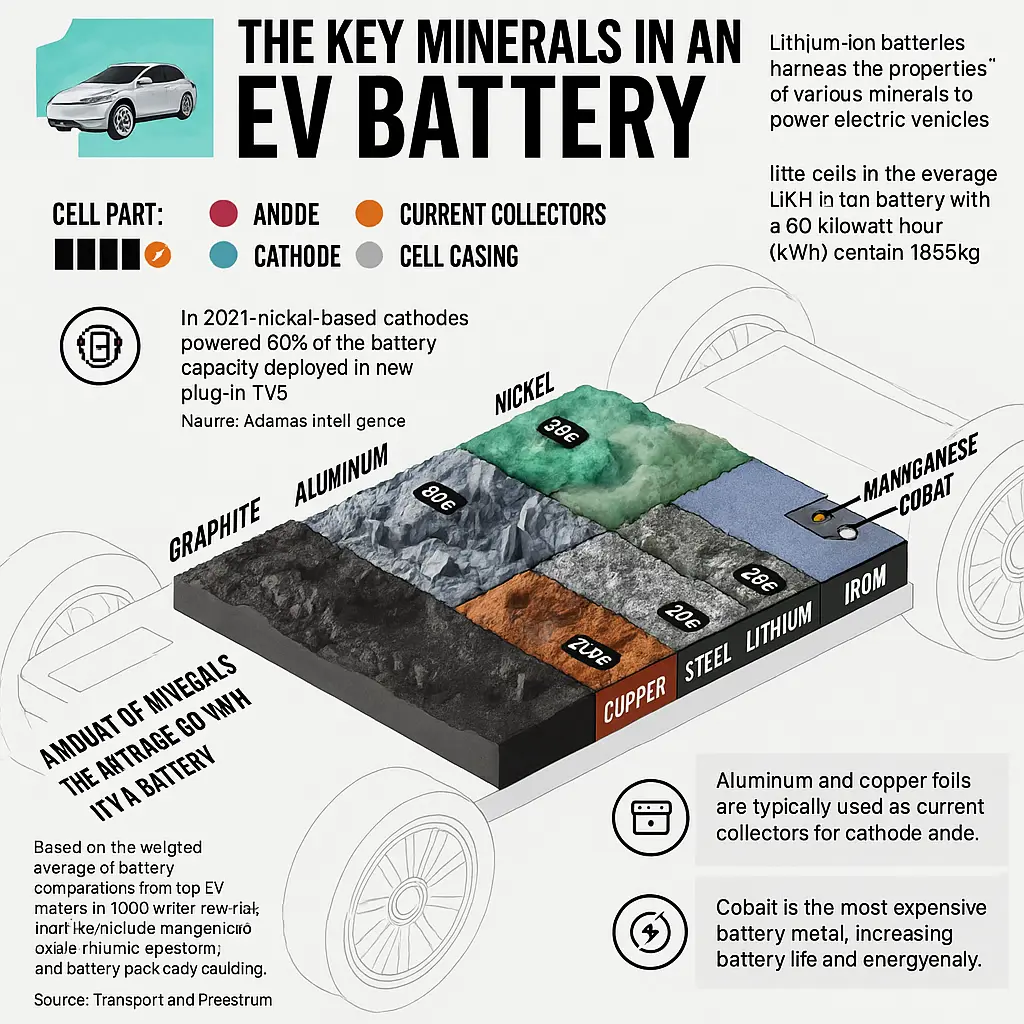

Lithium, a key component in EV batteries, is obtained from brine pools in South America and difficult shale mines in Australia. The extraction handle is water-intensive, requiring up to 500,000 gallons of water per ton of lithium, driving to groundwater exhaustion in currently parched districts. Essentially, cobalt, which is basic for battery stability and execution, is to a great extent sourced from the Democratic Republic of Congo. Mining in this locale has been associated with child labor, hazardous working conditions, and unregulated natural harm. Nickel, utilized to boost vitality thickness, moreover poses natural dangers, particularly when mined in environmentally delicate locales such as Indonesia, where it contributes to deforestation and water pollution. The vitality required to make EV batteries is another concern. Battery generation is energy-intensive, and on the off chance that fueled by fossil fuels, it contributes altogether to the carbon footprint of an EV sometime even before it hits the street. Moreover, the worldwide supply chain for battery components spanning different continents adds to the natural burden due to transportation emissions and energy utilization at each handling arrange. To relieve the natural and human costs related to battery generation, a few procedures are being embraced. These incorporate the improvement of lithium press phosphate (LFP) batteries that don’t require cobalt or nickel, the usage of moral sourcing honors, and the use of renewable energy in battery manufacturing. Charging used a constant-current constant-voltage (CC-CV) protocol: CC at 1C rate until 4.2 V, then CV until current drops to 0.05C. Also, battery-as-a-service (Batas) models and second-life applications, such as utilizing retired EV batteries for solar power vitality storage, extend the battery’s valuable life and diminish squander. The battery cell is a lithium-ion type with a nominal voltage of 3.7 V, nominal capacity of 2.5 Ah, anode material (graphite), cathode material (lithium nickel manganese cobalt oxide, NMC), and electrolyte (organic solvent with lithium salts). Figure 6 illustrates the details for key salts.

3.5. Results

- a.

-

LCA → 71% lower emissions

- b.

-

CFA → 15 tons CO2e lifetime

- c.

-

ABM → 50% campus emission drop if 100 EVs are used.

4. Thermal Analysis

Thermal Analysis could be a basic component within the plan and operation of electric vehicles (EVs), especially in warm climates like Pakistan. Modeling was performed using ANSYS 2020 for thermal simulations. Thermal analysis is critical in Pakistan’s hot climate (40 °C+) to prevent battery degradation and ensure safety. This approach is true not only in Pakistan but worldwide, as temperatures are rising.

Inputs: Material properties (e.g., thermal conductivity of aluminum: 237 W/m·K), boundary conditions (ambient temp 40 °C), load profiles.

Outputs: Temperature distributions, heat flux maps, and efficiency predictions (e.g., max temp < 70 °C).

Conditions: Boundary conditions: Convective heat transfer coefficient 10 W/m2·K, initial temp 25 °C, no-slip walls, constant heat flux from battery (50 W).

Overheating can decrease battery effectiveness, degrade engine execution, and lead to security risks [14]. This examination centers on distinguishing heat sources, assessing warm behavior beneath the stack, and proposing cooling procedures to preserve secure working temperatures for center components: the battery pack, BLDC engine, and engine controller.

4.1. BLDC Motor Thermal Behaviour

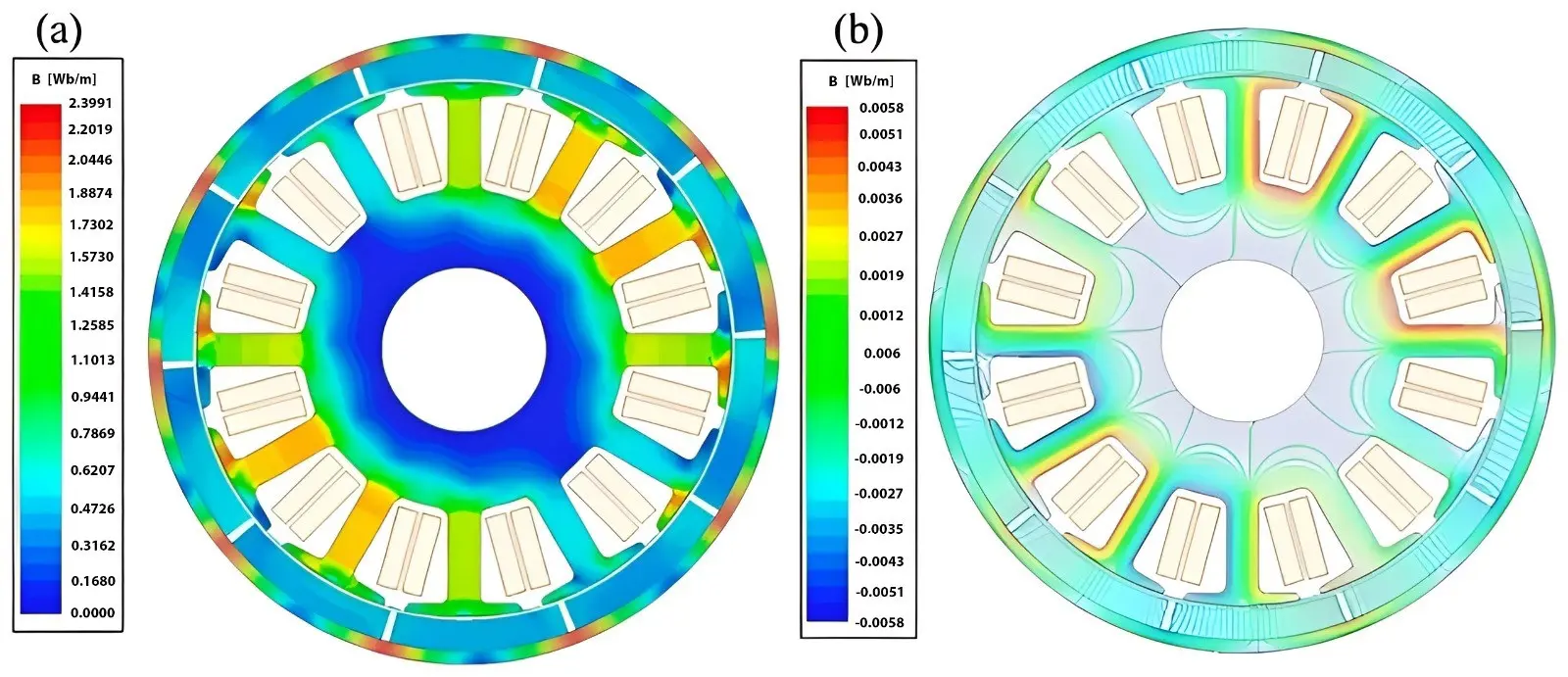

The Brushless DC (BLDC, expressed in the table) engine, commonly utilized in compact electric vehicles, could be an exceedingly proficient and solid drive component, but it produces significant warm during operation. Warm build-up happens primarily due to copper misfortunes (IÂ2R misfortunes in windings, which means power which is also discussed in Table 2) and center misfortunes (hysteresis and vortex streams). These warm sources are particularly unmistakable under conditions such as overwhelming load, high torque demand, prolonged operation, or soak slopes. BLDC engines ordinarily work securely within the temperature range of 40 °C to 70 °C. In case the inside temperature surpasses 90 °C, the separator of the copper windings can begin to degrade, and past 120 °C, there’s a genuine risk of permanent magnet demagnetization, which permanently reduces engine execution. Successful warm dissemination is subsequently fundamental to preserve unwavering quality. Most compact EVs depend on detached cooling utilizing finned aluminum casings, which increment surface area for common convection. A few plans also use warm glue between the engines and the outline to upgrade the connection. Temperature sensors implanted within the engine block can provide information to the Vehicle Control Unit (VCU), which can start defensive reactions such as diminishing engine yield or locks in a delicate shut-down in case of overheating. Appropriate warm control amplifies the motor’s life expectancy and guarantees reliable execution indeed in extraordinary climates like Pakistan’s summers. Normal operating range: 40 °C to 70 °C. Risk threshold: 90 °C (winding damage), 120 °C (magnet demagnetization). Heat sources: Copper losses, core losses under high load. Cooling method: Passive finned aluminum casing; optional thermal paste. Protection: Motor temperature sensor feedback to VCU for thermal shutdown. The discussion of BLDC motor thermal behavior is important as it ensures efficiency and longevity unlike ICE engines which rely on combustion cooling. This focus aligns with optimizing EV performance for a pollution free environment. Figure 7 illustrates the thermal analysis of BLDC permanent magnet.

Table 2. Parameters for the simulation.

|

Parameters |

Values |

|---|---|

|

Battery density |

2500 kg/m3 |

|

Thermal Conductivity |

237 W/m·K |

|

Specific heat |

900 J/kg·K |

|

Ambient Temp |

40 °C |

|

Motor efficiency |

90% |

Figure 7. Thermal Analysis of BLDC Permanent Magnet (a) magnetic flux density (b) magnetic vector potential.

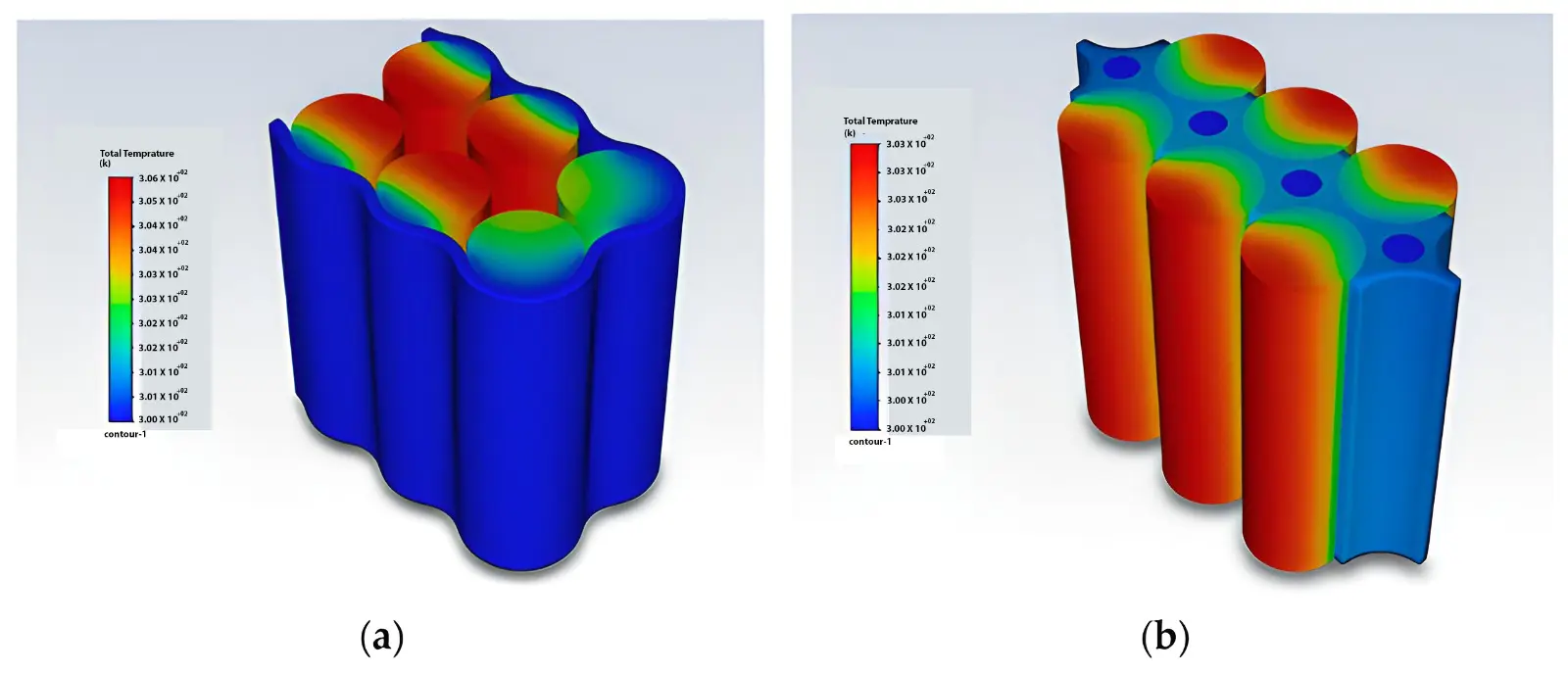

4.2. Battery Pack Thermal Behaviour

The battery pack is one of the foremost thermally delicate components in an electric vehicle. Amid charging and releasing, it produces warm due to the inside resistance and electrochemical responses. This warm build up is more articulated beneath tall stack conditions, such as quickly increasing speed, quick charging, or ceaseless tough driving. Lithium-ion batteries ordinarily work ideally within a temperature range of 15 °C to 45 °C. Surpassing this run can lead to quickened debasement, decreased capacity, and in extraordinary cases, warm runaway perilous chain response that can result in fire or blast. In warm climates like Pakistan, where surrounding temperatures can surpass 40 °C, compelling warm administration is fundamental. Inactive cooling methodologies such as utilizing aluminum casing, warm cushions, and common wind stream are viable and cost-effective arrangements for small electric vehicles. Progressed battery management systems (BMS) screen cell temperature in real-time and start defensive activities such as decreasing control yield, detaching the stack, or activating warm cautions when edges are breached. Generally, controlling battery temperature is basic to guaranteeing long-term security, execution, and stability of the EV. Optimal operating range: 15 °C to 45 °C, Critical threshold: Above 55 °C → degradation; Above 70 °C → thermal runaway risk, Heat sources: Internal resistance, fast charging, And ambient heat, Cooling methods: Aluminum casing, ventilation slots, And thermal pads, Monitoring system: BMS with temperature sensors and cut-off logic, Figure 8 explains battery pack behavior under thermal simulations.

Figure 8. Analysis of Two Different Battery Packs (a) Temperature Distribution (K) of the battery pack (b) Convective Heat Transfer Coefficient over cell surfaces.

5. Integration with Artificial Intelligence

The integration of Artificial intelligence in vehicles, especially in the electric sector, is a hot topic at the current time. However, this thing becomes almost impossible in a developing country like Pakistan. In an ideal scenario for our project, integrating AI for the factors, including optimization, will help our cause of pollution and the use of resources.

Due to the simple Drivetrain model of the electric vehicle, AI can easily detect the sudden failure of the components and guide the driver about the fix. AI can view the real-time traffic and can choose the efficient route for the destination, which will not only save us a lot of time but also save us energy, causing the optimization of the battery. There is another method in the news, which is the regenerative braking system, which can produce our electric energy. The main idea of this method is that when we apply the brakes, the energy is converted back into electricity and stored in the battery. We can use Artificial intelligence to detect incoming accidents by using sensors, including LIDAR sensors and cameras, which will provide real-time safety by taking over steering and brakes. Especially in Urban environments, it will help detect cycles or motorcycles and help us make split-second decisions. The idea will revolutionize the education sector as well as the environment of Pakistan. The idea will be to change the dynamics of transportation within the universities all over Pakistan. Our idea is to get favourable policies and subsidies from the government.

5.1. Predictive Maintenance and Diagnostics

We can use this system for cost efficiency by predicting the failures of vehicles by using AI, including piezoelectric sensors. These sensors, when used correctly alongside the machine learning algorithm, can monitor the key and fragile components of the vehicle. In electric vehicles (EVs), prescient support works by persistently checking the well-being and execution of basic components through embedded sensors and smart software. These sensors are introduced in key ranges such as the electric engine, battery pack, control hardware, brakes, and suspension framework. They collect real-time information on parameters like temperature, vibration, voltage, current, and utilization designs. This information is analyzed at that point utilizing counterfeit insights and machine learning algorithms, which identify irregular patterns or deviations from ordinary behavior. For example, if a battery cell shows signs of overheating or, on the off chance that an inverter draws more current than usual, the framework can anticipate a potential failure before it happens. The vehicle’s onboard diagnostics framework, frequently associated with the cloud, cautions the driver or benefit center with convenient notices. This permits upkeep to be planned proactively, maintaining a strategic distance from unforeseen breakdowns and lessening the require for superfluous repairs. Over time, the framework becomes more precise by learning from verifiable information, making the complete handle more astute and more effective.

5.2. Autonomous and Assisted Driving

Independent and helped drive innovations, speak to one of the foremost transformative perspectives of cutting-edge electric vehicles. These frameworks depend intensely on counterfeit insights (AI), progressed sensors, and real-time data processing to upgrade security, comfort, and driver comfort. In driving, highlights such as path keeping, versatile voyage control, dazzle spot discovery, and programmed crisis braking offer assistance to the driver to work the vehicle more securely and productively. At more progressed levels, independent driving permits the vehicle to decipher its environment, make choices, and explore with negligible or no human input. Usually made conceivable through a combination of LiDAR, radar, cameras, GPS, and machine learning calculations that persistently analyze activity designs, street conditions, and protest vicinity. In compact EVs, particularly in urban situations like those in Pakistan, semi-autonomous highlights such as self-parking, lane-keeping assist, and collision shirking can essentially improve security and diminish driver error. Whereas completely independent EVs are still in advancement stages all inclusive, their continuous integration into shopper vehicles is laying the foundation for a future of clever, self-driving mobility.

5.3. Smart Energy Management

Savvy vitality administration in electric vehicles alludes to the clever control and optimization of vitality utilization over all onboard frameworks to maximize efficiency, extend driving extend, and guarantee battery life span. This includes real-time coordination between the battery administration frameworks (BMS), engine controller, regenerative braking framework, and auxiliary loads such as lighting, discuss conditioning, and infotainment [15]. Fake insights (AI) calculations play a basic part in forecasting energy demands based on driving designs, location, battery health, and climate conditions. For example, amid tough driving or overwhelming increasing speed, the framework can prioritize control delivery to the engine while minimizing energy loss somewhere else. Essentially, when the vehicle is slipping or braking, energy is collected and put back into the battery through regenerative braking. Keen directing suggestions based on activity and rise profiles can also be given through the onboard computer program to reduce control utilization. In hot climates like Pakistan, thermal-aware vitality dissemination can anticipate overheating while guaranteeing productive battery execution. By powerfully adjusting supply and demand, savvy vitality administration not as it were moves forward the EV’s operational productivity but also diminishes the cost of ownership and improves generally vehicle reliability. This integrates regenerative braking (recovering 10–20% energy) and V2G capabilities with AI algorithms (e.g., machine learning for predictive load balancing) to optimize energy flow. Sensor data on traffic, speed, and SOC are inputs; power distribution is modified for a 15% range expansion. Similar AI features are used in Nissan Leaf (predictive maintenance) and the Tesla Model 3.

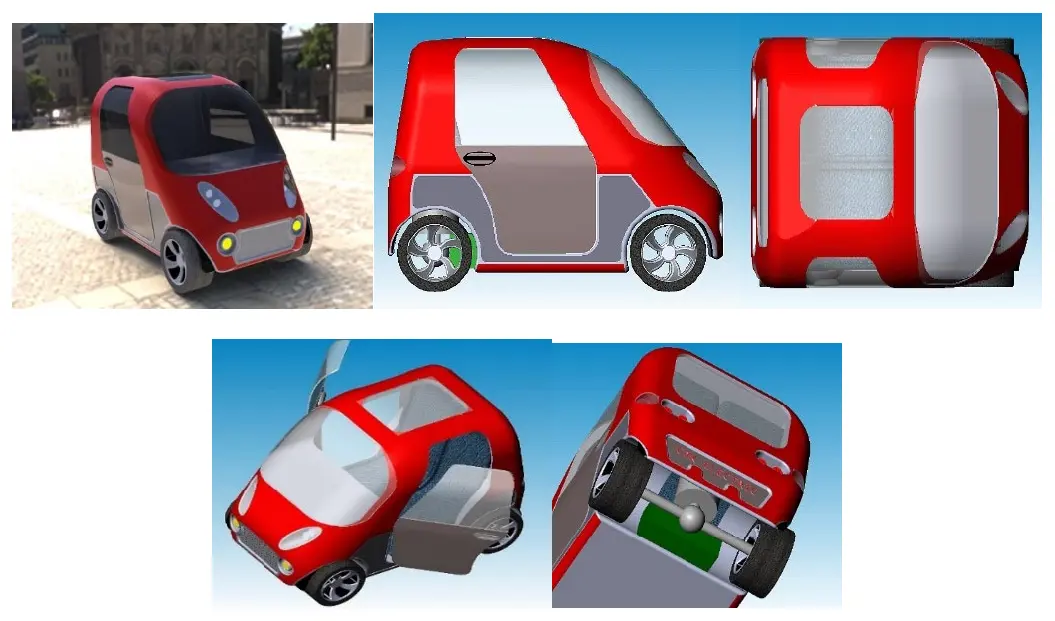

Figure 9 shows a compact design for students. The 3D CAD model features a compact dual-seat design (dimensions: 2.5 m length, 1.2 m width, 1.5 m height), a lightweight aluminum chassis (150 kg curb weight), a BLDC hub motor (5 kW power), a lithium-ion battery pack (10 kWh capacity), and an integrated solar panel for auxiliary charging. All the designing and simulation work was completed on Solid works.

Figure 9. Front, back, top, and side views of a conceptual 3D CAD model of a student-designed electric vehicle (EV) prototype, Features: AGS, self-driving mode, predictive maintenance sensors, solar panel.

6. Limitations

Despite the significant safety and environmental benefits of the proposed student EV, several drawbacks should be noted. First, even with the suggested 50% government subsidy, the upfront purchase cost, estimated at PKR 800,000–1,000,000 without subsidy, is still more expensive than a used 110–125 cc gasoline motorcycle (PKR 150,000–300,000), which may prevent adoption among lower-income students. Second, on Pakistan’s existing grid (532 g CO2e/kWh), well-to-wheel emissions are reduced by only 40–50% compared to petrol two-wheelers, not the 71% reported; the higher figure requires expected renewable growth by 2030 and may not be attained if coal-based production remains. Third, the 10 kWh battery offers a practical campus range of about 80–100 km, which is adequate for everyday use but insufficient for travelling between cities or to places without charging stations.

7. Conclusions

In the paper, we have discussed the positive impacts of electric vehicles on the environment. We have discussed that it is a quite major issue comprising greenhouse gases, Air Pollution, Noise Pollution, and many more, which we are considering under this array of harmful effects of traditionally used internal combustion engines. This student electric vehicle is going to be a game changer for the students by providing them with a safe and pollution-free environment. We believe that this student electric car will be in favor of the growth of a pollution-free environment. By concluding all the methods, we can say that electric vehicles are not only required for commercial purposes but also should be treated as a basic necessity in educational institutions. We have the following proposal: Results show 50% emission reduction; suggestions: Subsidize student EVs (50% cost), build campus chargers (100/university), enforce recycling, and promote AI training for sustainability.

The current study used a multi-method framework to statistically assess the environmental, technical, and operational sustainability of a small, single-occupant student electric car designed for Pakistani university campuses. Using Eco invent data adjusted to Pakistan’s grid intensity (532 g CO2e/kWh) and a functional unit of 15,000 km over eight years, Life Cycle Assessment (LCA) and Carbon Footprint Analysis (CFA) showed that the suggested EV achieves up to 71% lower lifecycle CO2e emissions compared to conventional 70–125 cc petrol two-wheelers under a 2030 renewable-growth scenario (and 40–50% on the current grid). By simulating campus-wide adoption, Any Logic’s Agent-Based Modelling (ABM) projected a 50% reduction in annual transport emissions (from 1840 t to 920 t CO2e/year) if half of the students who commute use the suggested vehicle by 2030.

Statement of the Use of Generative AI and AI-Assisted Technologies in the Writing Process

During the preparation of this manuscript, the authors used grammar correction tool (Grammarly) in order to improve the writing sequence of manuscript. After using this tool, the authors reviewed and edited the content as needed and take full responsibility for the content of the published article.

Acknowledgments

We would like to express our deepest gratitude to the Department of Mechanical Engineering at the University of Engineering & Technology (UET), Lahore (Narowal Campus), for providing the necessary resources and guidance throughout this research.

Author Contributions

Conceptualization, S.A. and A.K.; Methodology, S.A., SH.; Software, S.H.; Validation, S.A and Z.H.; Formal Analysis, Z.H.; Investigation, A.K.; Resources, S.A.; Data Curation, S.A.; Writing—Original Draft Preparation, A.K.; Writing—Review & Editing, S.A and S.H.; Visualization, Z.H.; Supervision, S.A.; Project Administration, S.A.; Funding Acquisition, Z.H.

Ethics Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Available on request.

Funding

This research received no external funding.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviations

|

Symbol |

Description |

Units |

|

I2R |

Copper losses in windings |

W |

|

SoC |

State of Charge |

% |

|

SoH |

State of Health |

% |

|

η |

Efficiency (Greek symbol) |

- |

|

ρ |

Density (e.g., in materials) |

kg/m3 |

|

subscript: t |

Time-dependent variable (e.g., T_t) |

s |

|

superscript: n |

Nominal value (e.g., V^n) |

- |

|

Abbreviation |

Full Form |

|

|

ICE |

Internal Combustion Engine |

|

|

LIB |

Lithium-Ion Battery |

|

|

HEV |

Hybrid Electric Vehicle |

|

|

LCA |

Life Cycle Assessment |

|

|

PCM |

Phase Change Material |

|

|

OCV |

Open Circuit Voltage |

|

|

SOC |

State of Charge |

|

|

EV |

Electric Vehicle |

|

|

ECM |

Engine Control Module |

|

|

BMS |

Battery Management System |

|

|

BTMS |

Battery Thermal Management System |

|

|

PHEV |

Plug-in Hybrid Electric Vehicle |

|

|

VCU |

Vehicle Control Unit |

|

|

BLDC |

Brushless DC (Motor) |

|

|

AGS |

Automatic Gear System |

|

|

SoH |

State of Health |

|

|

NEVP |

National Electric Vehicle Policy |

|

|

AI |

Artificial Intelligence |

|

|

LIDAR |

Light Detection and Ranging |

|

|

CO2 |

Carbon Dioxide |

|

|

GHG |

Greenhouse Gas |

|

References

- Gabol I. Pakistan “Second Most Polluted Country” in 2023. DAWN. Available online: https://www.dawn.com/news/1822667 (accessed on 20 March 2024). [Google Scholar]

- Delhi Mail Today Bureau. Two-Wheelers Are Causing Maximum Air Pollution. India Today. Available online: https://www.indiatoday.in/mail-today/story/two-wheelers-are-causing-maximum-air-pollution-1377531-2018-10-29 (accessed on 29 October 2018). [Google Scholar]

- ScienceDaily Staff. Motorcycles Emit “Disproportionately High” Amounts of Air Pollutants. ScienceDaily. Available online: https://www.sciencedaily.com/releases/2006/01/060101155000.htm (accessed on 1 January 2006). [Google Scholar]

- Veza I, Asy’ari MZ, Idris M, Epin V, Fattah IMR, Spraggon M. Electric vehicle (EV) and driving towards sustainability: Comparison between EV, HEV, PHEV, and ICE vehicles to achieve net zero emissions by 2050 from EV. Alex. Eng. J. 2023, 82, 459–467. doi:10.1016/j.aej.2023.10.020. [Google Scholar]

- World Bank. Pakistan: Air Quality Management—A Report on Air Quality Management and Pollution Reduction Efforts in Pakistan; World Bank: Washington, DC, USA, 2023. [Google Scholar]

- Xu L, Yilmaz HÜ, Wang Z, Poganietz W-R, Jochem P. Greenhouse gas emissions of electric vehicles in Europe considering different charging strategies. Transp. Res. Part D Transp. Environ. 2020, 87, 102534. doi:10.1016/j.trd.2020.102534. [Google Scholar]

- Barman P, Dutta L, Bordoloi S, Kalita A, Buragohain P, Bharali S, et al. Renewable energy integration with electric vehicle technology: A review of the existing smart charging approaches. Renew. Sustain. Energy Rev. 2023, 183, 113518. doi:10.1016/j.rser.2023.113518. [Google Scholar]

- Koroma MS, Costa D, Philippot M, Cardellini G, Hosen MS, Coosemans T, et al. Life cycle assessment of battery electric vehicles: Implications of future electricity mix and different battery end-of-life management. Sci. Total Environ. 2022, 831, 154859. doi:10.1016/j.scitotenv.2022.154859. [Google Scholar]

- Burchart D, Przytuła I. Carbon footprint of electric vehicles—Review of methodologies and determinants. Energies 2024, 17, 5667. doi:10.3390/en17225667. [Google Scholar]

- Tesla, Inc. Tesla Model 3—Case Study for Electric Cars. Technical Report; Tesla, Inc.: Palo Alto, CA, USA, 2019. Available online: https://www.tesla.com/ns_videos/tesla-impact-report-2019.pdf (accessed on 25 October 2025). [Google Scholar]

- Yousefi E, Ramasamy D, Kadirgama K, Talele V, Najafi H, Olyaei M, et al. Electrochemical-thermal modeling of phase change material battery thermal management systems: Investigating mesh types for accurate simulations. Int. J. Heat Mass Transf. 2025, 247, 127107. doi:10.1016/j.ijheatmasstransfer.2025.127107. [Google Scholar]

- Bieker G, Moll C, Link S, Plötz P, Mock P. More Bang for the Buck: A Comparison of the Life-Cycle Greenhouse Gas Emission Benefits and Incentives of Plug-in Hybrid and Battery Electric Vehicles in Germany; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2022. Available online: https://theicct.org/wp-content/uploads/2022/03/ghg-benefits-incentives-ev-mar22.pdf (accessed on 20 October 2025). [Google Scholar]

- Huang X, Lin Y, Zhou F, Lim MK, Chen S. Agent-based modeling for market acceptance of electric vehicles: Evidence from China. Sustain. Prod. Consum. 2021, 28, 206–217. doi:10.1016/j.spc.2021.04.007. [Google Scholar]

- Incropera FP, DeWitt DP, Bergman TL, Lavine AS. Fundamentals of Heat and Mass Transfer. ResearchGate. 2007. Available online: https://www.researchgate.net/publication/260081006_Fundamentals_of_Heat_and_Mass_Transfer (accessed on 25 October 2025). [Google Scholar]

- Fan Y, Yang H, Ye C, Yang W, Panchal S, Fraser R, et al. State of health estimation of lithium-ion batteries based on the fusion of aging feature extraction and SSA-ELM machine learning algorithms. Ionics 2025, 31, 7897–7915. doi:10.1007/s11581-025-06454-3. [Google Scholar]