Found 18 results

Open Access

Article

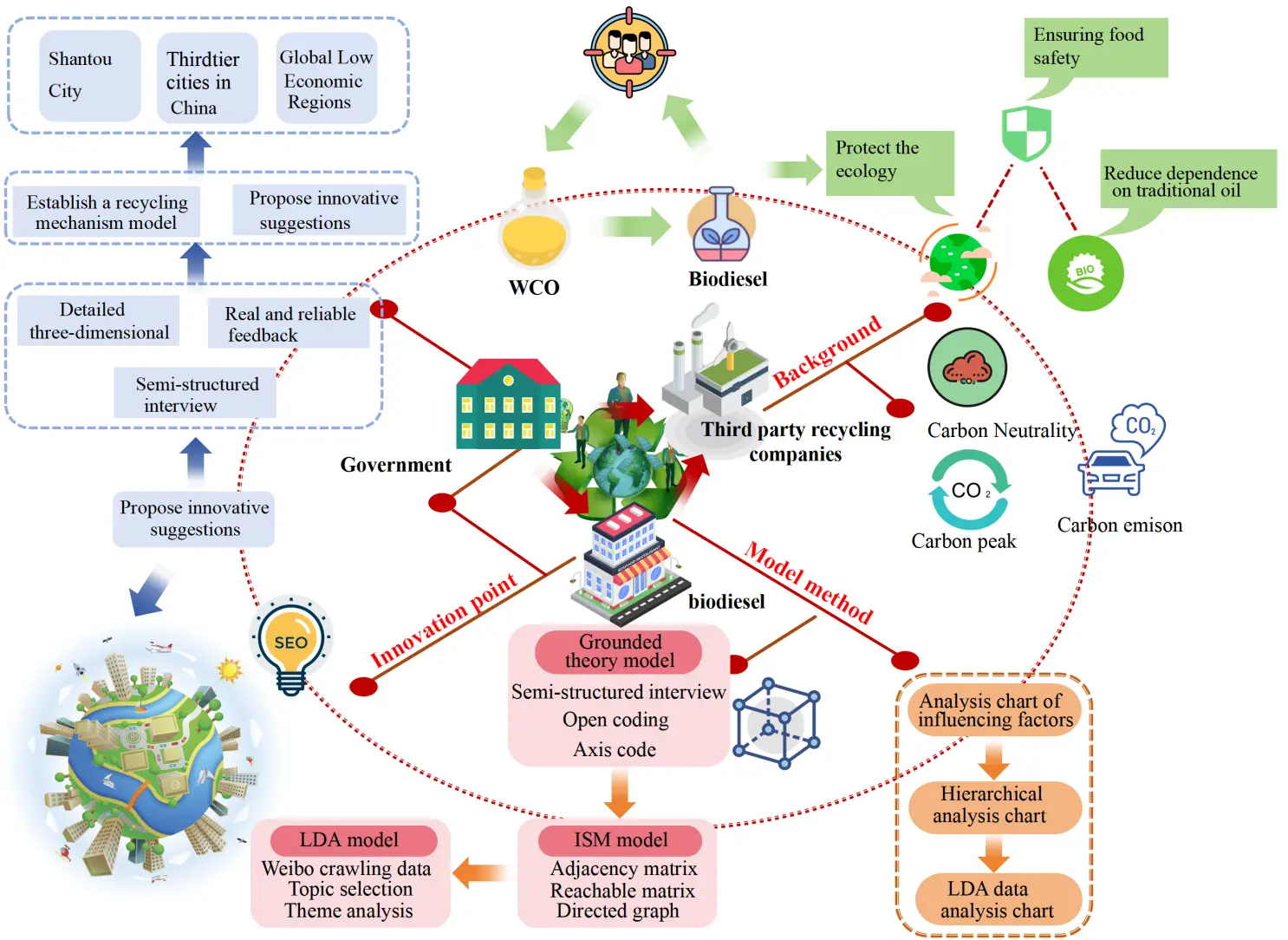

06 November 2025Sustainable Recycling Mechanisms for Waste Cooking Oil in China’s Third-Tier Cities: Evidence from Restaurant Practices

The conversion of waste cooking oil (WCO) into biodiesel is a key strategy for advancing energy sustainability, particularly within China’s rapidly expanding restaurant industry. In third-tier cities such as Shantou, Guangdong Province, WCO collection faces unique challenges. Through in-depth interviews with 20 restaurant operators, this study identifies multiple barriers to effective WCO management, including an aging population, underdeveloped local economies, limited technological infrastructure, and unequal access to educational opportunities, all of which hinder the adoption of advanced filtration systems and broader environmental sustainability initiatives. Moreover, the non-standardized operations of third-party WCO collection services, coupled with space constraints in small restaurant kitchens, further exacerbate inefficiencies in recovery processes. To address these challenges, this study develops a comprehensive framework for WCO collection that is adaptable to regions with similar socio-economic conditions. Integrating grounded theory, Interpretive Structural Modeling (ISM), and Latent Dirichlet Allocation, the framework fills critical gaps in existing research. The analysis reveals that government financial incentives occupy the foundational layer of the ISM hierarchy and serve as a key driver of recycling behavior among restaurant operators; educational attainment enhances awareness and compliance but is moderated by structural constraints; and trust in third-party recyclers exerts a relatively limited influence. Correspondingly, H1 receives qualitative support, H2 is partially supported, and H3 gains only limited support. Building on these findings, the study proposes a multi-stakeholder governance framework that includes a “community-school-family” education system, an intelligent third-party management platform, and a government-led industrial chain to promote the formation of a closed-loop circular economy. The results demonstrate that the proposed framework not only offers actionable policy recommendations but also facilitates the adoption of sustainable practices and deepens the understanding of socio-economic and operational factors affecting WCO management, thereby providing strong support for energy and environmental sustainability.

Open Access

Review

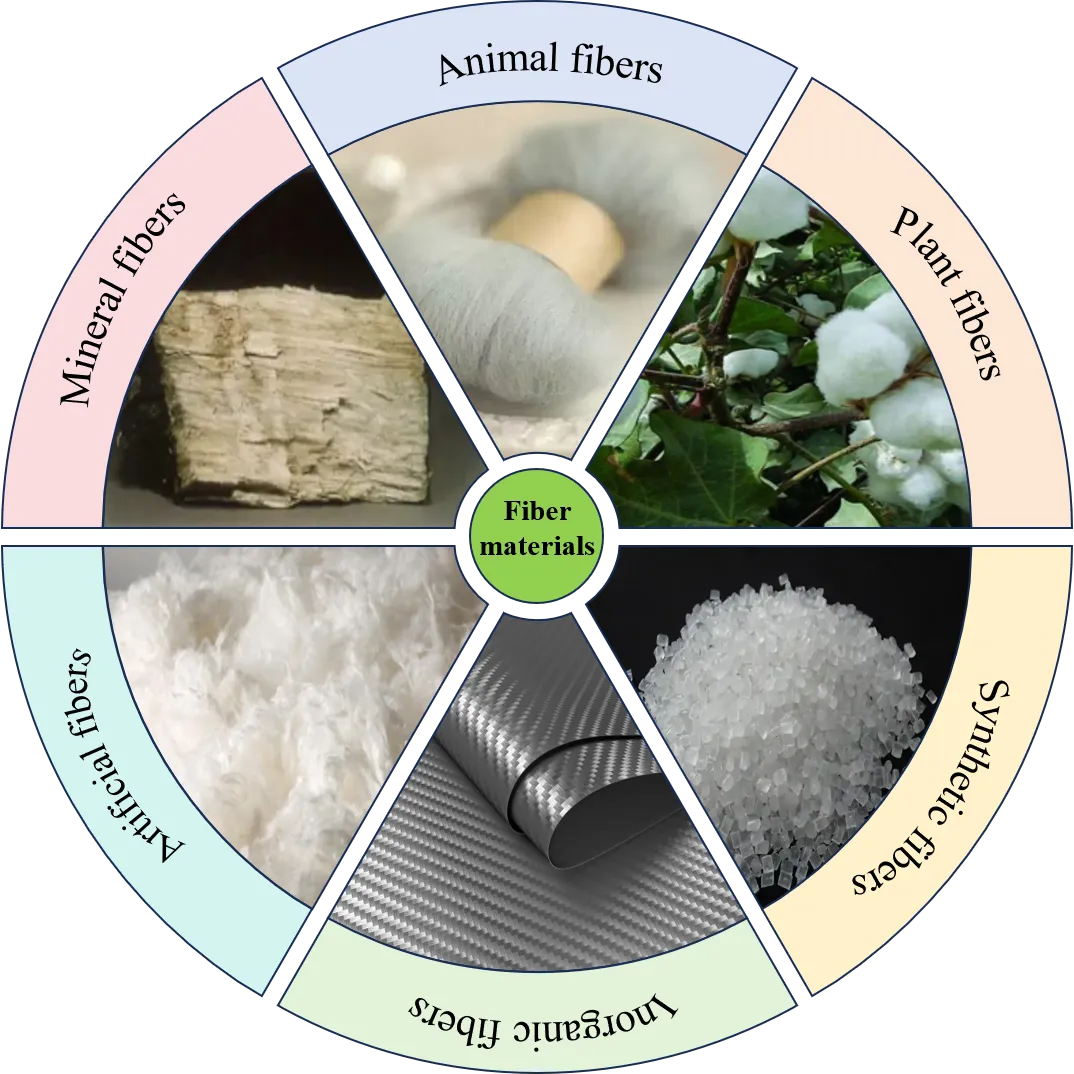

22 September 2025Advances in Recycling and Reuse Technologies for Textile Fiber Material Products

Global industrialization and rising living standards have driven widespread adoption of fiber materials. However, the rapid growth of the textile industry has also caused substantial resource depletion and environmental pollution. Each year, over 92 million tons of textile waste are generated worldwide, most of which is landfilled or incinerated, while only a small proportion is recycled. This paper systematically reviews the latest advancements in the recycling and reuse of fiber-based products, focusing on mechanical, chemical, and biological recycling technologies and the reapplication of recycled fibers. Mechanical recycling is a mature and cost-effective process, but it results in reduced fiber quality. Chemical recycling can produce high-purity raw materials, yielding regenerated fibers with properties close to virgin fibers, but the process is complex and energy-intensive. Biological recycling operates under mild conditions with low energy consumption but is limited by low efficiency and long reaction times. This paper also explores the applications of recycled fibers in regenerated apparel, automotive textiles, construction materials, medical supplies, and eco-friendly filtration materials. Fiber recycling technologies should advance toward greener, more innovative, and circular economy-oriented approaches. Technological innovation, industrial collaboration, and policy guidance can significantly enhance the resource utilization of textile waste.

Open Access

Review

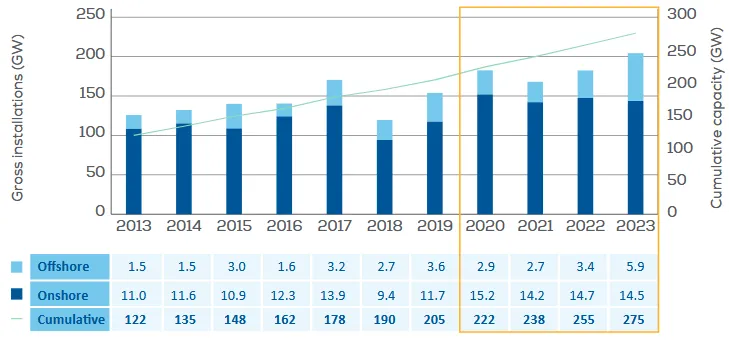

22 August 2025The Recyclability of Wind Turbine Blade Material, Manufacturing Process, and Recycling Technology

As wind energy continues to be deployed at a significantly increasing rate, the number of decommissioned wind turbines is expected to increase accordingly. To improve material efficiency, a large amount of waste requires appropriate identification and recycling, particularly the composite materials used in wind turbine blades (WTB). This study focuses on two life cycle stages, manufacturing and the decommissioning stage, which contribute most to the waste generation of WTB. This study investigates the material efficiency factors in WTB and organises fragmental information in manufacturing waste management, focusing on the recycling factor and quantifying the recyclability of wind turbine blade material regarding the different recycling technologies. This study fills the gap in existing research by evaluating recycling methods for specified carbon fibre-reinforced polymers (CFRPs) and glass fibre-reinforced polymers (GFRPs) using a revised recyclability index. Additionally, innovative sustainable materials and recent composite recycling studies have also been incorporated into the quantification and evaluation to update the current progress. The current source of WTB post-production waste, the corresponding disposal method, and opportunities were also reviewed and identified. The findings quantified recyclability and revealed that the recyclability of WTB materials varies significantly depending on the specific composite type and the recycling method employed. Furthermore, the calculated recyclability, combined with other factors such as global warming potential (GWP), cost, and technology readiness level (TRL), is discussed, along with the potential for improving material efficiency by selecting future material recycling technology and effective manufacturing waste management.

Open Access

Article

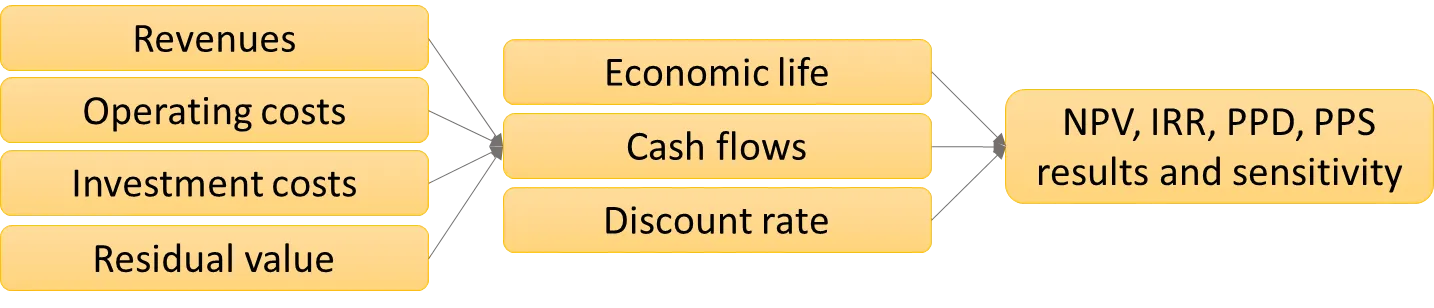

09 May 2025Modeling and Assessing Economical Feasibilities for Waste to Energy Conversion/Incineration Process in Context of Municipal Solid Waste

At the time of the study, most of the municipal waste, including solid municipal waste, in the city of St. Petersburg and in the connected larger Leningrad region is processed by landfilling. This sort of waste processing in open landfills causes environmental damage, uncontrollable landfill fires, bad and dangerous odors, nearby rivers/streams, groundwater pollution, CH4 and CO2 emissions, to mention a few. Additionally, landfilling is a waste of energy and material resources present in the content dumped into landfills. In this context, Waste-to-Energy (WtE) incineration is a process that we use to recover the energy the materials have back to usable form, which we use in the form of heat and electricity. Even though a lot of resources and energy are available in the (municipal solid) waste, it does not mean that recovering it would always make sense. Our study analyses and estimates the profitability of a WtE incineration plant(s) in the city of St. Petersburg and the connected Leningrad region. With the available data and following analysis, we have concluded that the WtE incineration is economically feasible in this specific region and city areas, given that the implementations follow more traditional (economically less expensive and easier) technical and process model solutions. As a note of results stability, it needs to be pointed out that the changes in estimates of gate fees, cost of electricity and heat, and so on do impact the economic feasibility a lot, and larger scale changes in the assumed revenues would have a high impact on the outcome of repeatability of the results.

Open Access

Article

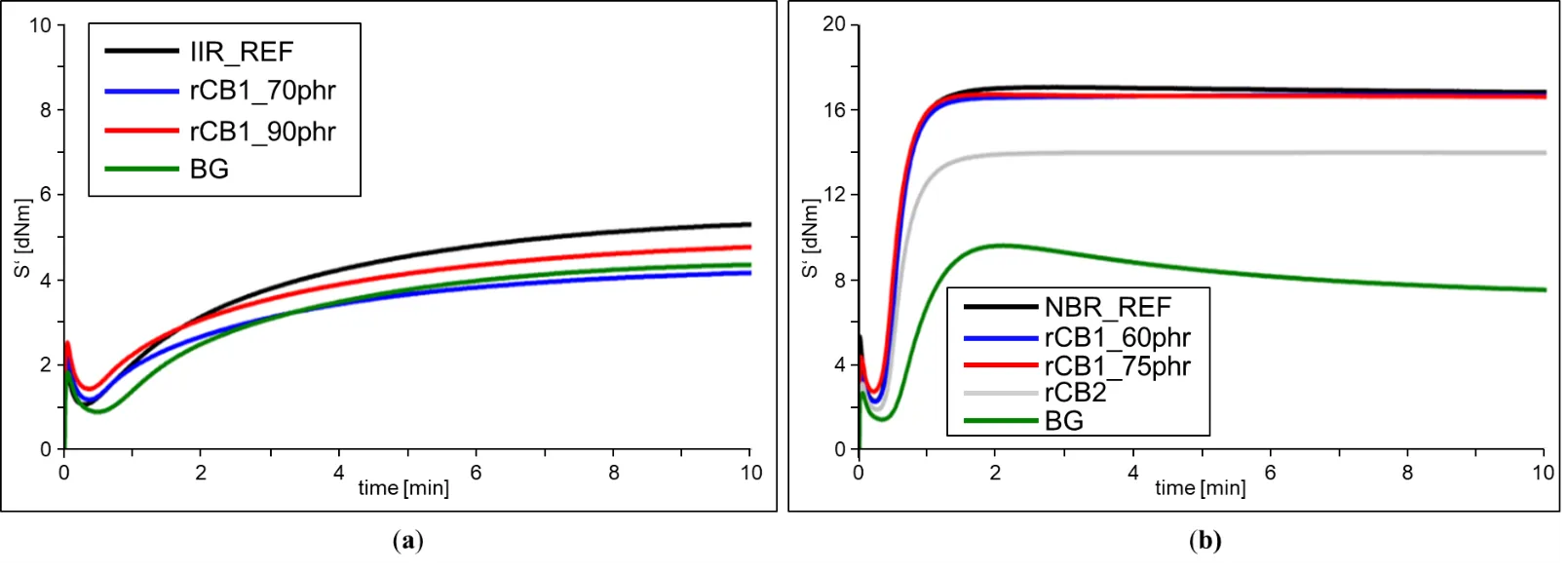

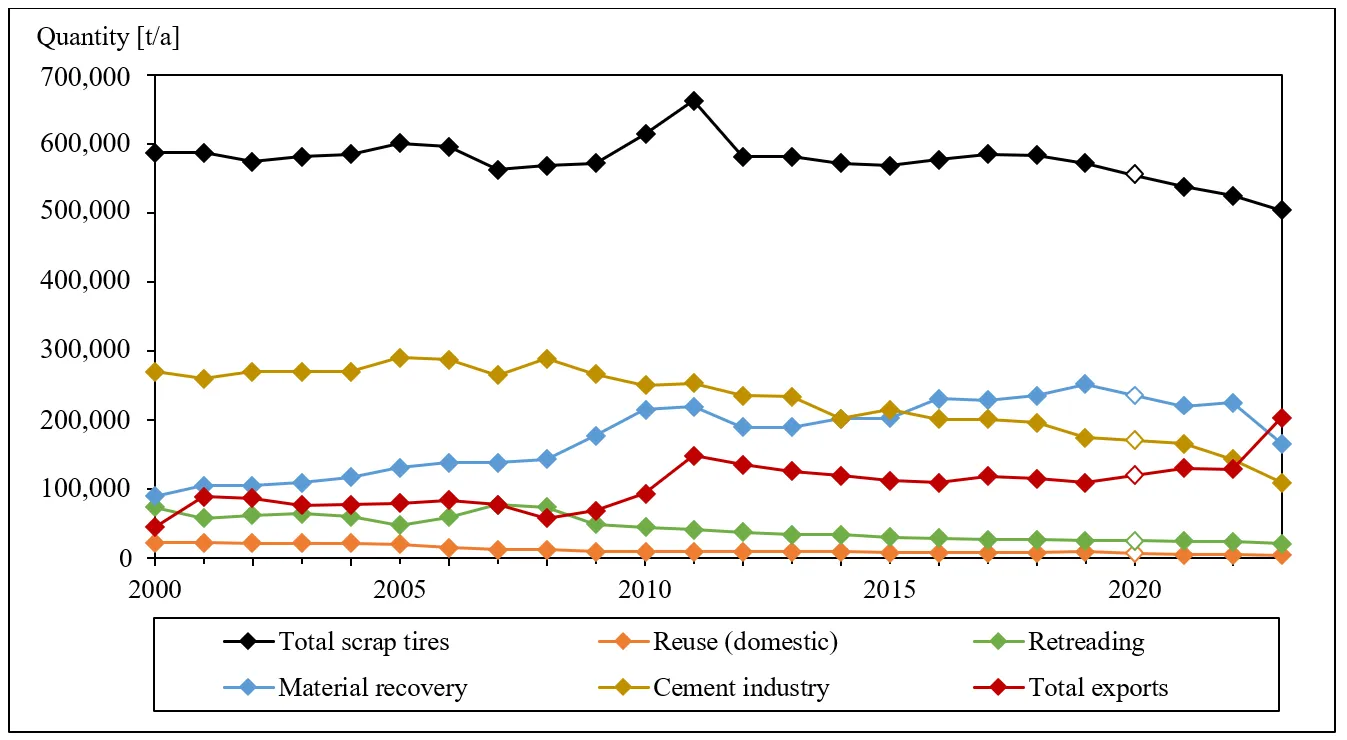

29 April 2025Application of recovered Carbon Black (rCB) by Waste Tire Pyrolysis as an Alternative Filler in Elastomer Products

The increasing global accumulation of End-of-Life (EoL) tires and the growing demand for fossil industrial Carbon Black (CB) call for sustainable alternative solutions. In this context, tire pyrolysis and the resulting recycled raw material recovered Carbon Black (rCB), are considered potential alternatives. In the study, various rCBs were incorporated into new elastomer compounds using a laboratory internal mixer and their properties were investigated. The compounds were selected based on examples of applications such as bicycle inner tubes and hydraulic membranes. By comparing the in-rubber properties of rCB-based compounds with CB reference compounds, an initial assessment of the potential use of rCB for the chosen products was derived. Compared to industrial carbon black, the use of rCB leads to a reduction in performance. Although increasing the filler content partially compensated for the mineral content in rCB and led to a slight improvement, it could not fully offset the performance loss.

Open Access

Article

28 April 2025Production and Characterization of Recovered Carbon Black (rCB) by Waste Tire Pyrolysis as a Potential Carbon Black (CB) Substitute

Recovered Carbon Black (rCB) from scrap tire pyrolysis offers a potential alternative to fossil-based virgin Carbon Black (CB) in the context of a circular economy. This study investigated the influence of pyrolysis process parameters on rCB yield and quality at laboratory and semi-industrial scales. The resulting rCBs were characterized and found to have surface and structural properties comparable to N500 and N600 series CBs, but with higher mineral and volatile contents. The quality of rCB is influenced by the feedstock composition, particularly the ratio of organic to inorganic components as well as key process parameters such as heating rate, pyrolysis temperature and residence time. Higher heating rates accelerate degradation and shift product distribution toward increased oil yield and reduced rCB formation, while higher pyrolysis temperatures lead to lower volatile content in rCB. Additionally, reactor and process design affect heat distribution, transfer efficiency, and mixing behavior, further shaping rCB properties. However, further testing is required to evaluate the actual in-rubber properties of rCBs. Therefore, additional tests are planned, incorporating rCB into butyl and nitrile rubber-based elastomer compounds, which will be addressed in a follow-up study. In addition, data from the current experiments will support a comprehensive Life Cycle Assessment (LCA) to evaluate the environmental impacts of tire pyrolysis and rCB production compared to other recycling methods, with details to follow in a future publication.

Open Access

Review

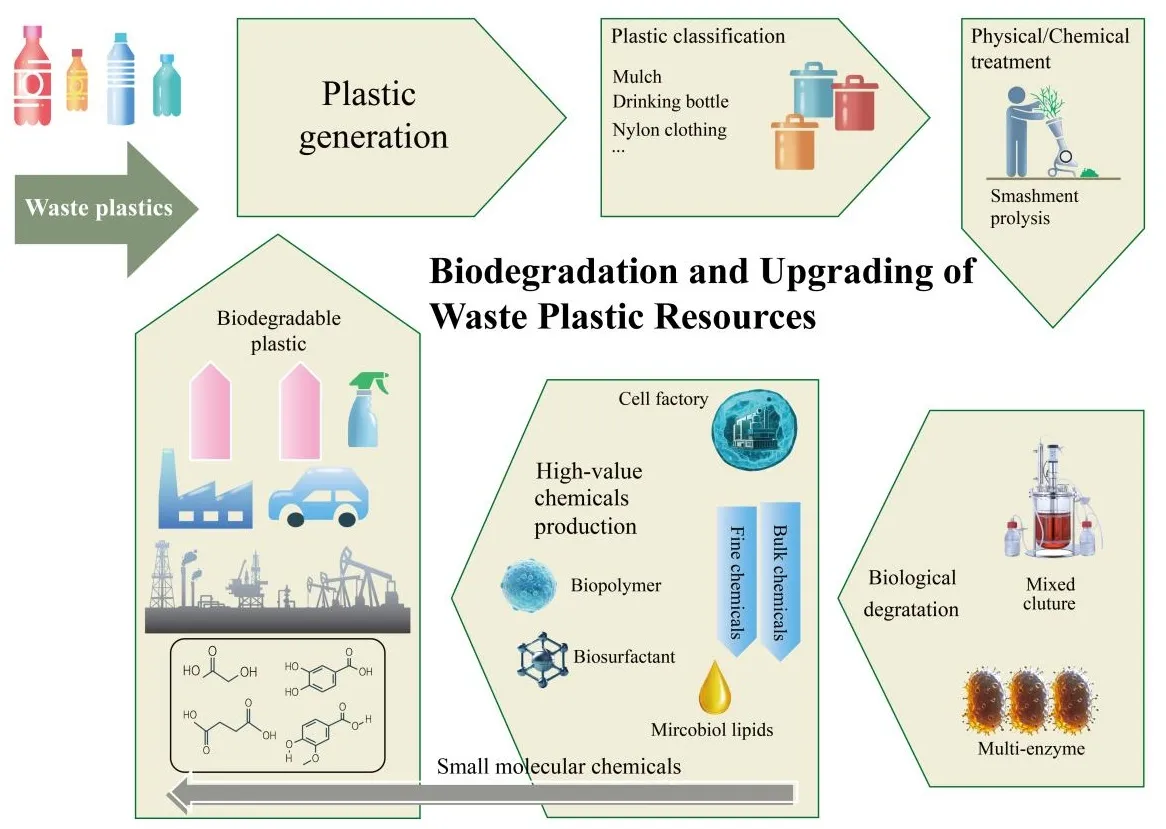

28 February 2025Synthetic Biology Boosts the Biological Depolymerization and Upcycling of Waste Plastic Resources

The high molecular weight, hydrophobicity, and strong chemical bonds of petroleum-based synthetic plastics make them highly resistant to both abiotic and microbial degradation. This resistance plays a significant role in the growing problem of “white pollution” where the accumulation of plastic waste has become a major environmental issue worldwide. Currently, plastic waste management relies largely on landfill disposal and incineration, with only about 20% of plastic waste being recycled. However, both methods create secondary environmental risks, such as contamination of groundwater, soil, air, and oceans. Therefore, developing a sustainable and efficient approach for recycling and reusing plastic waste is essential for tackling plastic pollution and promoting a circular plastic economy. One promising solution involves utilizing microorganisms and enzymes to break down plastics into oligomers or monomers, which can then be transformed into valuable chemicals. This method provides a more environmentally friendly and milder alternative to conventional waste management techniques. This review explores recent progress in biodepolymerization and biotransformation processes for plastic waste, including the identification of plastic-degrading microorganisms and enzymes, the creation of microbial consortia and enzyme mixtures, an investigation into the mechanisms of plastic depolymerization, and the conversion of degradation products into useful materials such as chemicals, energy, and other resources. Despite these advancements, several challenges remain, such as the limited availability of effective degradation enzymes, low degradation efficiency, and difficulties in utilizing the breakdown products. However, emerging technologies in synthetic biology, such as high-throughput screening, evolutionary metabolic engineering, and bioinformatics to study catalytic mechanisms of degradation enzymes, offer promising solutions to address these issues. By improving enzyme design, optimizing microbial consortia interactions, and developing efficient metabolic pathways for plastic degradation products, these innovations could greatly enhance plastic biodegradation. These advancements hold the potential to provide environmentally sustainable, economically feasible, and technically viable solutions for promoting a circular plastic economy, particularly in countries like China.

Open Access

Review

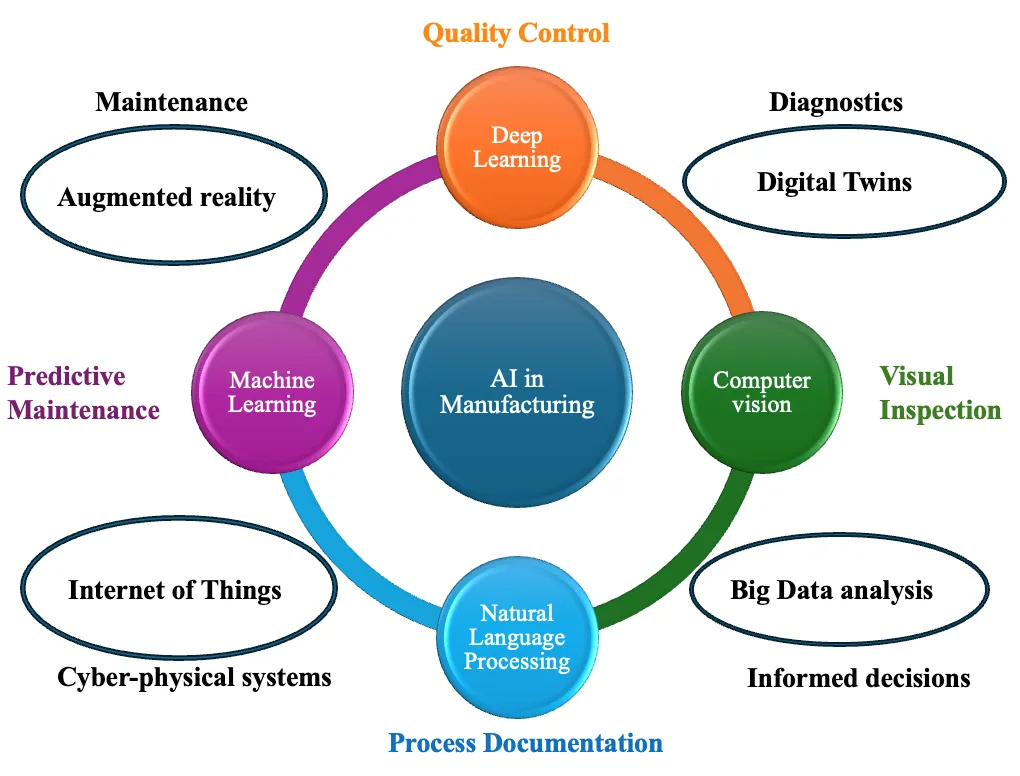

14 January 2025Artificial Intelligence and Machine Learning for Sustainable Manufacturing: Current Trends and Future Prospects

Artificial Intelligence (AI) and Machine Learning (ML) are transforming manufacturing processes, offering unprecedented opportunities to enhance sustainability and environmental stewardship. This comprehensive review analyzes the transformative impact of AI technologies on sustainable manufacturing, focusing on critical applications, including energy optimization, predictive maintenance, waste reduction, and circular economy implementation. Through systematic analysis of current research and industry practices, the study examines both the opportunities and challenges in deploying AI-driven solutions for sustainable manufacturing. The findings provide strategic insights for researchers, industry practitioners, and policymakers working towards intelligent and sustainable manufacturing systems while elucidating emerging trends and future directions in this rapidly evolving field.

Open Access

Review

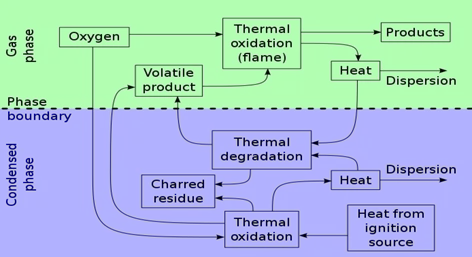

30 December 2024

Fire-Retardant

Wastepaper Reinforced Waste Polyethylene Composite: A Review

The increase in fire

outbreaks recently and the need for eco-friendly and fire-resistant materials

have inspired a wave of studies, focusing on producing innovative composite

materials with effective fire-resistant properties. This review delves into the

world of fire-resistant wastepaper-reinforced waste polyethylene composites.

Using wastepaper as a strengthening factor in polyethylene matrices, combined

with fire-retardant additives like nanoparticles, introduces a hopeful path for

waste management and improved material properties. This work carefully

considers the combining approaches, physical and mechanical properties,

fire-resistant mechanisms, and environmental impacts of these composites. The

review underscores the possible and potential applications, difficulties, and

prospects of such environmentally friendly materials in various industries.

Understanding these composites’ blending, attributes, and conceivable

utilization is essential for advancing maintainable and fire-safe material innovation

in pursuing a greener future.

Open Access

Article

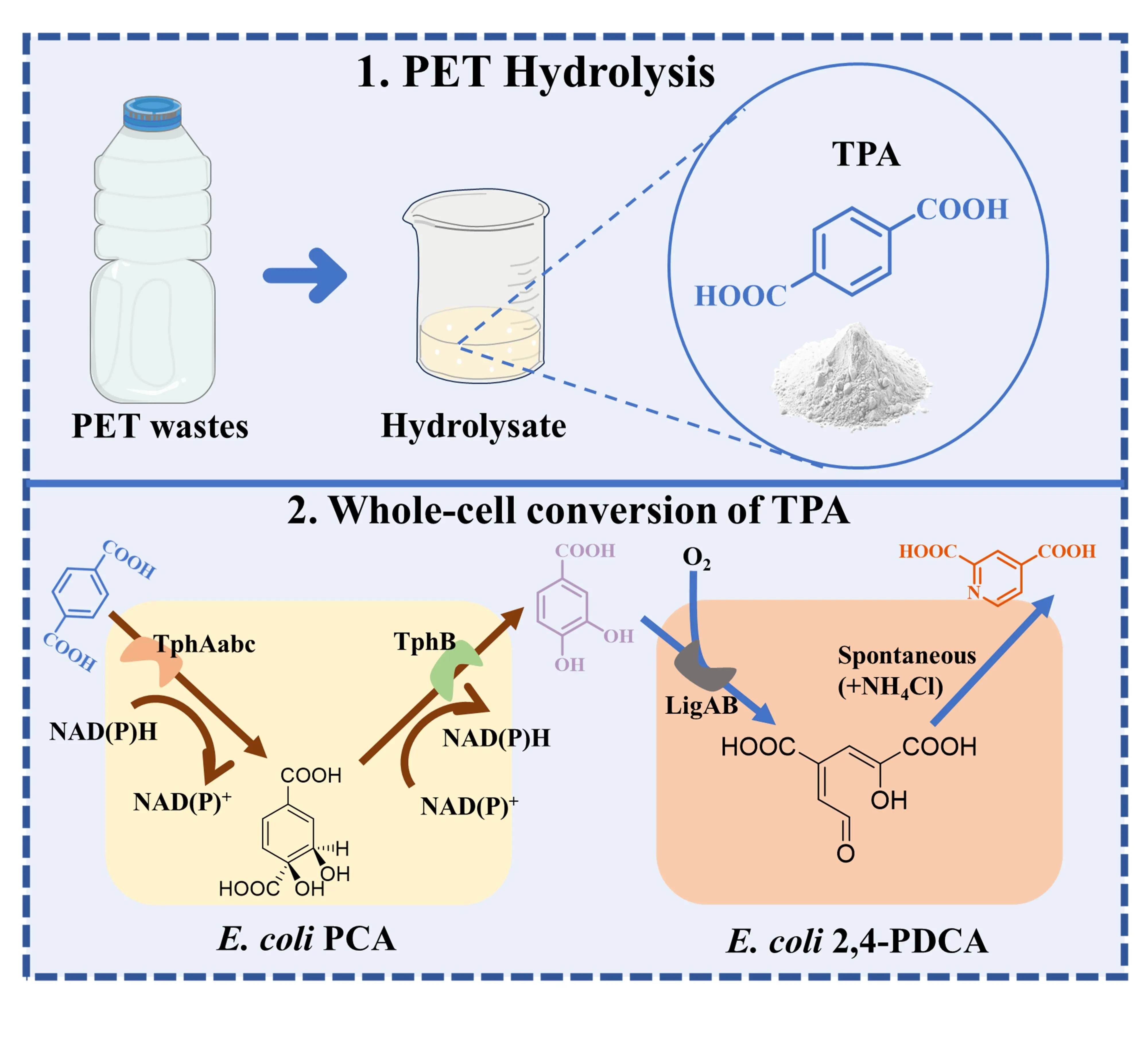

17 December 2024Upcycling of Waste Poly(ethylene terephthalate) into 2,4-Pyridine Dicarboxylic Acid by a Tandem Chemo-Microbial Process

This study presents a chemo-microbial cascade process for the upcycling of waste poly(ethylene terephthalate) (PET) into valuable compound 2,4-pyridine dicarboxylic acid (2,4-PDCA). Initially, waste PET undergoes efficient hydrolysis to terephthalic acid (TPA) with a high yield of 92.36%, catalyzed by p-toluenesulfonic acid (PTSA). The acid catalyst exhibits excellent reusability, maintaining activity over five cycles. Subsequently, a one-pot, two-step whole-cell conversion system utilizing genetically modified Escherichia coli strains (E. coli PCA and E. coli 2,4-PDCA) converts the generated TPA into 2,4-PDCA. By integrating the PET hydrolysis module with the 2,4-PDCA biosynthesis module, the study achieves an impressive overall efficiency of 94.01% in converting challenging PET waste into valuable 2,4-PDCA. Our research presents a rational design strategy for PET upcycling and 2,4-PDCA synthesis methods. This research provides a systematic approach to PET upcycling, demonstrating its feasibility and potential for industrial application.