Found 7 results

Open Access

Review

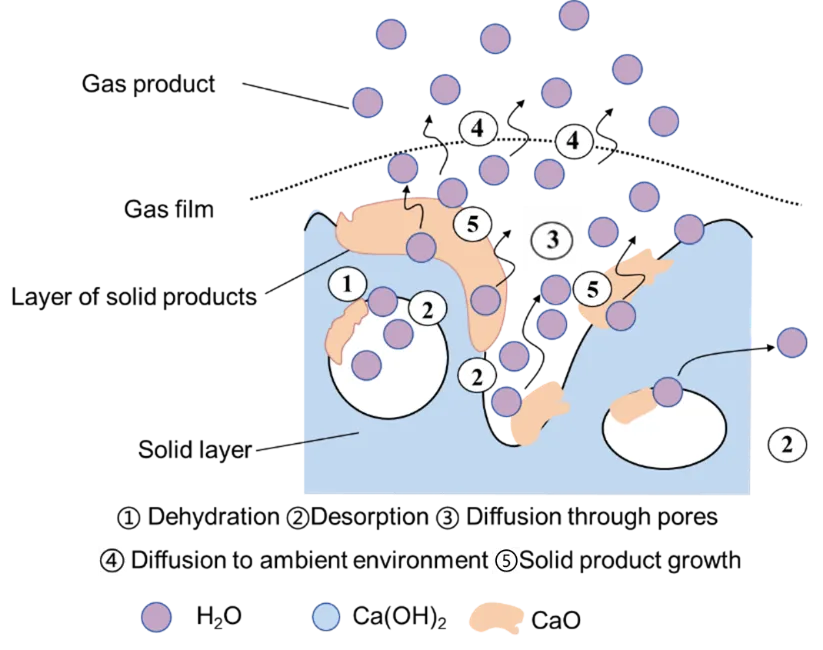

12 June 2025Research Progress and Key Technical Barriers in CaO/Ca(OH)2 Based Energy Storage: A Systematic Review

The CaO/Ca(OH)2 thermochemical energy storage system has garnered significant attention due to its cost-effectiveness, abundant raw material availability, optimal decomposition thermodynamics, high energy density, and recyclability as a promising candidate for large-scale renewable energy integration. Significant progress has been made in the research field of the CaO/Ca(OH)2 energy storage system, while there are still key issues that require further investigation. This comprehensive review summarizes recent advancements in CaO/Ca(OH)2 thermochemical energy storage systems, focusing on reaction mechanism and optimization through material engineering strategies, thermal-fluid dynamics in reactor configurations, cyclic degradation mechanisms under operational stresses, and scalability constraints in system integration. Persistent technical bottlenecks requiring resolution are discussed, particularly sintering-induced capacity decay and suboptimal heat transfer efficiency. The reactor design and optimization with advanced material modification techniques targeting enhanced stability are introduced as well. These discussions and derived suggestions provide a potential opportunity to bridge fundamental material science discoveries with engineering implementation for enabling deployment in stable utilization of renewable energy.

Open Access

Article

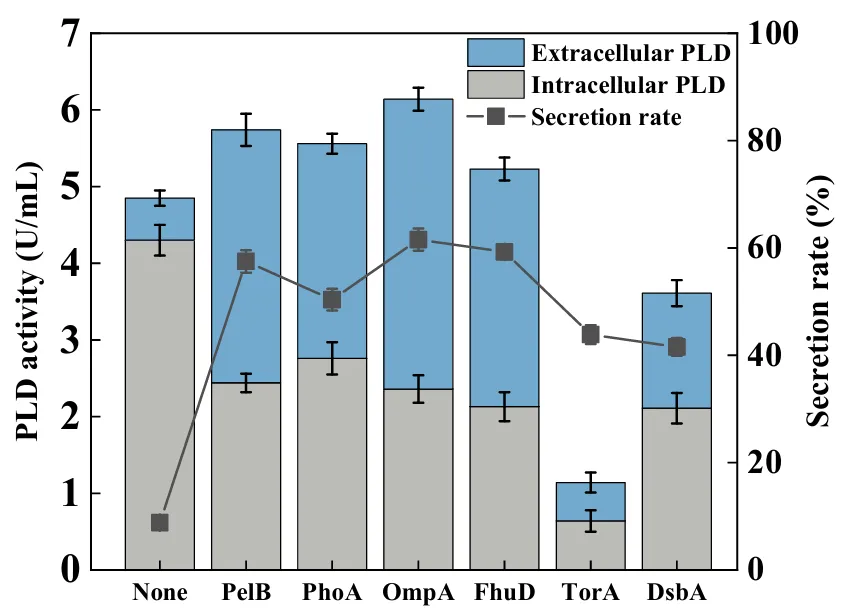

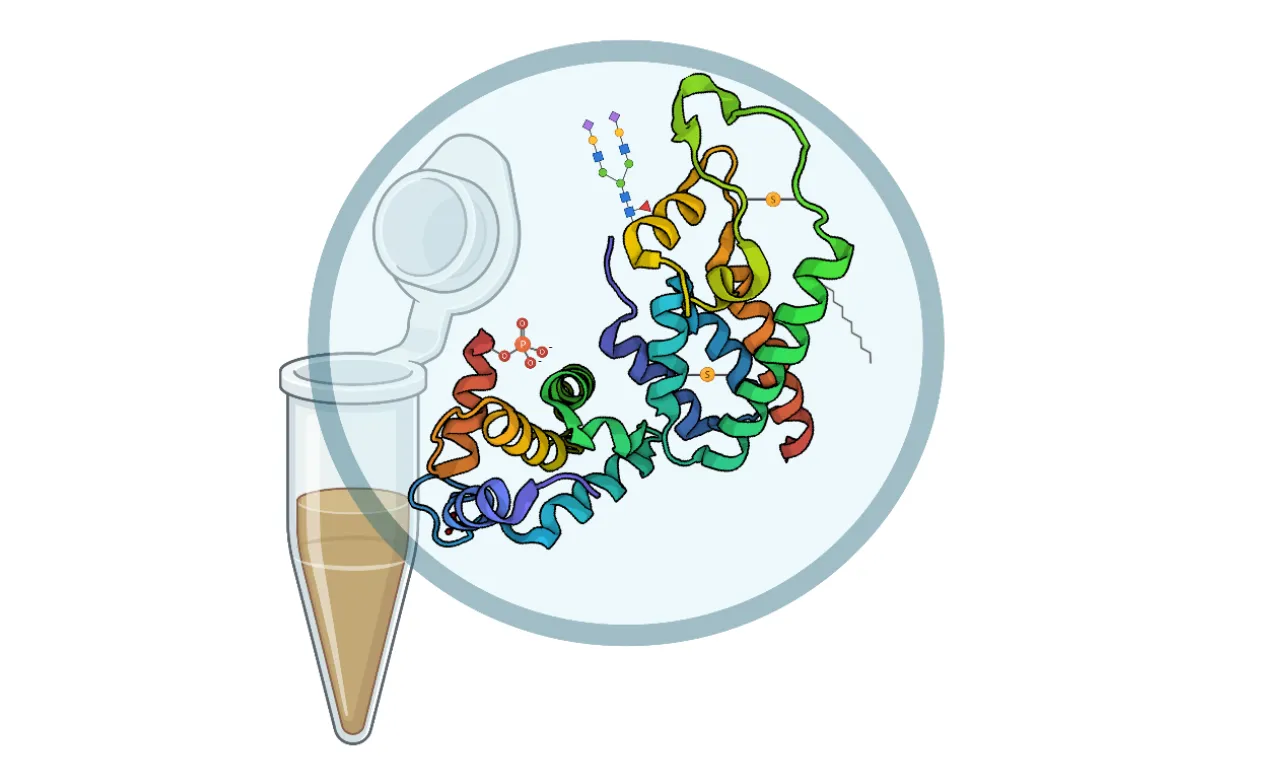

14 April 2025Efficient Extracellular Production of Phospholipase D in Escherichia coli via Genetic and Process Engineering Modification

Phospholipase D (PLD) is the key enzyme in the catalytic production of rare phospholipids including phosphatidylserine. It was considered a promising method via genetic manipulation for the heterologous production of PLD in the model chassis. Few works focused on the extracellular production of PLD in engineered microbes. Herein, genetic and process engineering modification strategies were developed to achieve secretory production of PLD in Escherichia coli. The N-terminal fusion secretion signal peptide OmpA and the plasmid pBAD-gⅢC with pBAD promoter were proven to be the most effective in promoting the secretory production of PLD. Given the limitation of the cell membrane, the regulation of the key protein expression in the cell membrane as well as the addition of surfactants, were explored to accelerate the secretory production of PLD further. It was indicated that adding 0.5% (w/v) Triton X-100 was more conducive to producing PLD. Finally, fed-batch fermentation was conducted, and the maximum extracellular PLD activity achieved was 33.25 U/mL, which was the highest level reported so far. Our work demonstrated the effectiveness of genetic and process engineering strategies for the secretory production of PLD in E. coli, which provided an alternative platform for the industrial production of PLD.

Open Access

Review

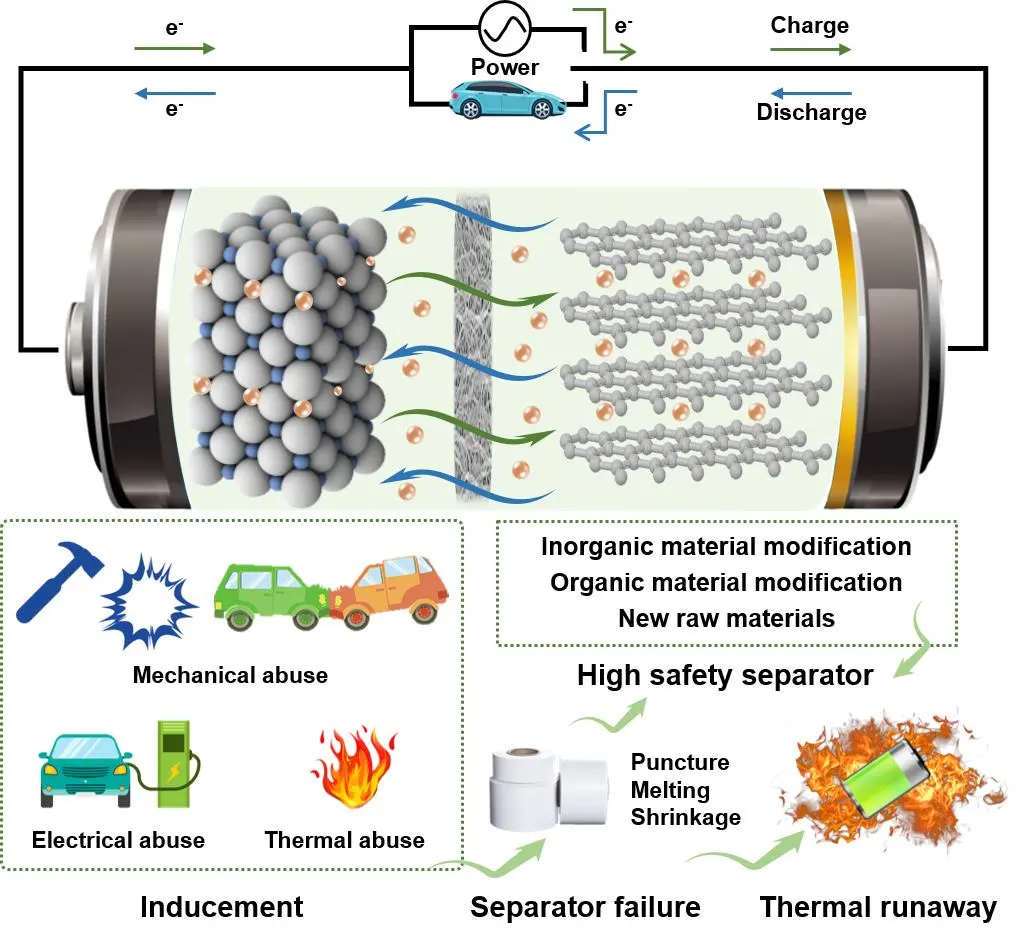

06 December 2024Recent Progress of High Safety Separator for Lithium-Ion Battery

With the rapid increase in quantity and expanded application range of lithium-ion batteries, their safety problems are becoming much more prominent, and it is urgent to take corresponding safety measures to improve battery safety. Generally, the improved safety of lithium-ion battery materials will reduce the risk of thermal runaway explosion. The separator is a key component of lithium-ion batteries. It plays a crucial role in battery safety, serving as one of the most effective measures against internal short circuits.Separator failure is a direct cause of the thermal runaway and can be specifically divided into three categories: puncture, melting, and thermal shrinkage. The requirements for an ideal lithium-ion battery separator have a synergistic effect on the electrochemical performance, safety, and scalability of lithium-ion batteries. Focus on the separator, this review summaries the mechanism of separator in thermal runaway process, and reports the recent progress of high safety separator from the perspective of material preparation.

Open Access

Article

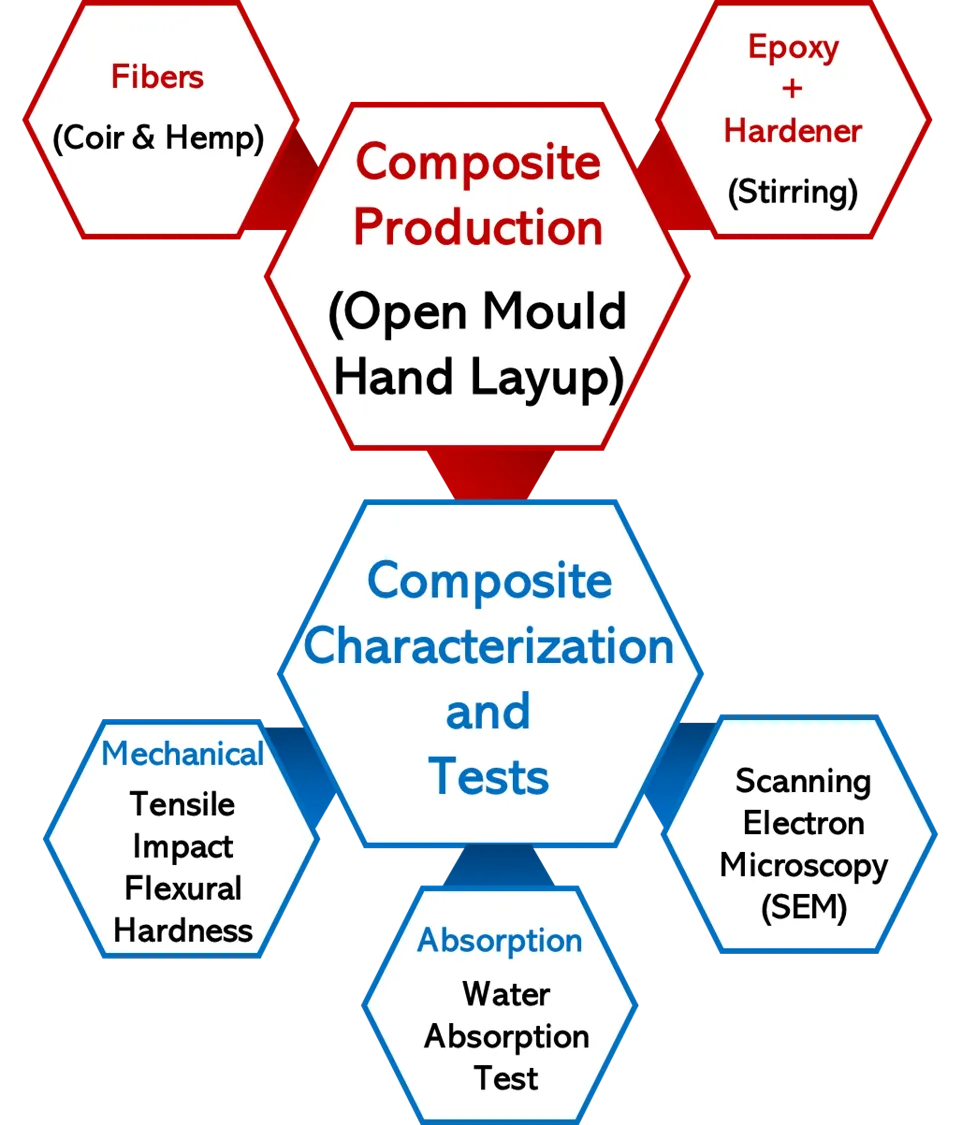

01 November 2024Alkaline Modified Coir and Unmodified Hemp Fiber Reinforced Epoxy Based Composite for Automotive Application

The growing demand for sustainable materials in the automotive industry has prompted research into natural fiber-reinforced composites. To reduce carbon footprints and enhance product sustainability, the sectors increasingly focus on renewable and biodegradable materials. Composites made from natural fibers, such as coir and hemp, offer a promising solution for creating lightweight, high-performance components with a reduced environmental impact.In this study, an experimental investigation was conducted to examine the impact of single and hybrid and treated and untreated fibers, on the properties of epoxy-based composites. Untreated hemp fiber with treated Coir fiber was used for the research. The composites were fabricated through the open mould hand lay-up technique. Samples were prepared by randomly dispersing the fibers in the epoxy matrix before pouring them into the respective moulds prepared according to ASTM standards. Tensile, impact, and hardness tests were conducted on the cured samples to determine their mechanical properties, while a scanning electron microscope was used to evaluate the fractured surface. Water absorption tendencies were also determined. The results showed that the sample denoted as 5CF wt.% had the best property combination with tensile strength (32.4 MPa), tensile modulus (11.9 GPa), flexural strength (167.0 MPa), and impact strength (46.8 kJ/mm2). It was discovered that hemp fiber-based composites were not enhanced properly due to lack of fiber surface modifications. Though optimum results were obtained from treated coir fiber-based single/distinct composite, untreated hemp fiber was discovered to aid some flexural modulus and hardness properties in the hybrid composite based on the best results obtained in its distinct-based composite. Therefore, untreated hemp fiber can be used in hybrid form with treated coir fiber where one of the fibers is scarce or when fiber surface medication is difficult to achieve. Thus, the results showed that 5CH-based composites are the most suitable composition for automotive components development where high-mechanical properties are essential.

Open Access

Review

27 August 2024A Novel Comprehensive Program Combining Optimal Medical Treatment with Lifestyle Modification for Type 2 Diabetes

There are more and more individuals with type 2 diabetes (T2D) in the globe. It’s a huge burden of public health and a great challenge in clinical due to a high linkage with atherosclerosis, cardiovascular disease (CVD), stroke, and cancer. However, little is known about a comprehensive program of management and self-management of T2D. This article introduces briefly the current status in T2D and an updated classical standardized comprehensive program which combines optimal medical treatment (OMT) (the glucagon-like peptide-1 receptor agonists, the sodium-glucose cotransporter 2 inhibitors, and the ultralong-acting, once-daily basal insulin) with lifestyle modification, that is, intervention of RT-ABCDEFG (iRT-ABCDEFG) for control and prevention of T2D, and discusses its advantages and prospects. As an effective comprehensive program and strategy for interventions of diabetes, this program can be used as a reversible, right, and routine treatment. Several pivotal goals including less major adverse cardiocerebrovascular events (MACCE) and diabetic complications, less medical costs, longer life expectancy, lower morbidity and mortality, and higher quality of life, will be realized by consistently practicing this program due to early diagnosis, OMT, and lifestyle modification for overall prevention. All in all, since T2D highly links to CVD and cancer, as well as other MACCE, this novel iRT-ABCDEFG program is very helpful in comprehensive management and self-management of T2D and worth recommending for further application and health care of T2D due to better clinical efficacy and cost-effective relationship.

Open Access

Review

28 July 2023Challenging Post-translational Modifications in the Cell-free Protein Synthesis System

Post-translational modifications (PTMs) represent a cornerstone in the complexity of the proteome, significantly contributing to diversifying protein structure and function. PTMs can considerably influence protein function, stability, localization, and interactions with other molecules. Therefore, it is important when choosing a protein expression system to ensure the precise incorporation of PTMs during protein synthesis, which is paramount for producing biologically active proteins. The cell-free protein synthesis (CFPS) system has emerged as a powerful protein synthesis platform and research toolkit in synthetic biology. The open nature of the system allows the reaction environment to be tailored to any protein of interest to promote specific PTMs, thus allowing for the production of a protein with desired modifications. This review presents various PTMs achieved in the CFPS systems, providing insights into current challenges, successes, and future prospects.

Open Access

Review

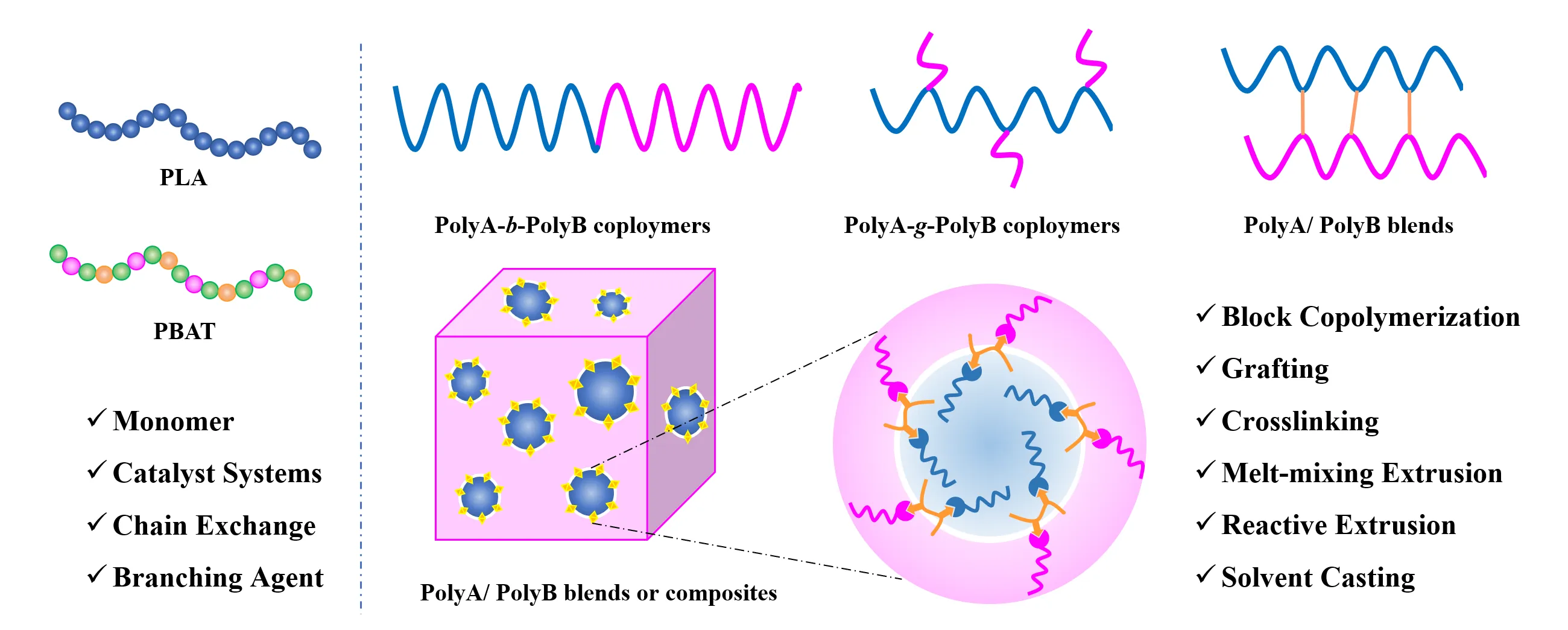

12 April 2023Recent Progress in Modification and Preparations of the Promising Biodegradable Plastics: Polylactide and Poly(butylene adipate-co-terephthalate)

The acquisition of high-performance biodegradable plastics is of great significance in addressing the problem of environmental pollution of plastics. Polylactide (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) are the most promising biodegradable polymers and have excellent functional properties. However, low elongation at break and impact strength of PLA and low tensile modulus and flexural strength of PBAT hinder their application. A large number of studies focus on improving the performance of PLA and PBAT and broadening their applications. In terms of polymer modification, this paper summarized recent progresses in both chemical and physical modification methods for PLA and PBAT, respectively. The properties of PLA can be improved by co-polymerization, grafting, cross-linking and blending. The properties of PBAT can be improved mainly through blending with other degradable polymers, natural macromolecules and inorganic materials. This review can provide the reference and ideas for the modification of biomass-based biodegradable plastics like PLA and fossil-based biodegradable plastics like PBAT.