Found 10 results

Open Access

Review

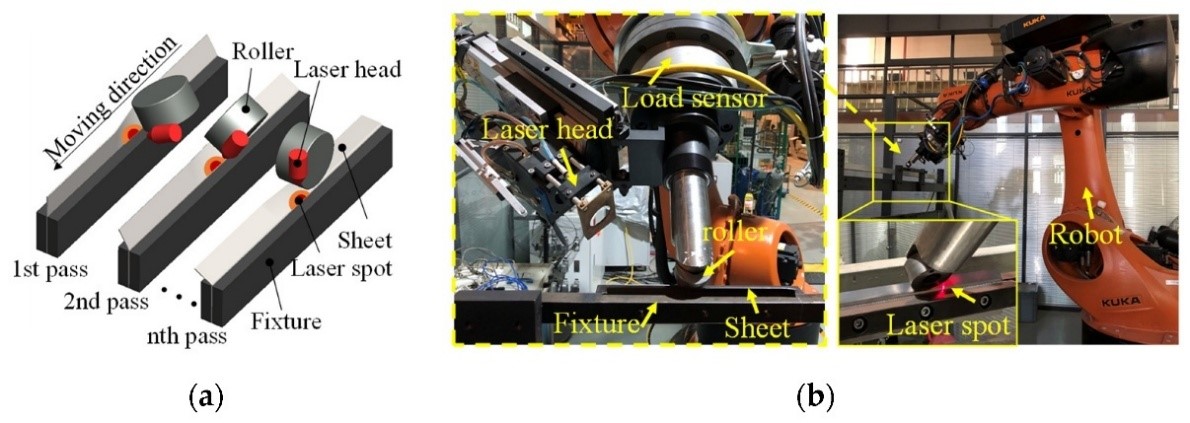

28 July 2025Laser-Assisted Forming of Ultra-High Strength Steels: A Critical Review of Mechanisms, Processes, and Future Directions

Ultra-high strength steels (UHSS) are critical for lightweighting in the automotive and aerospace industries, but their poor room-temperature formability presents a significant manufacturing barrier. Laser-assisted forming (LAF) has emerged as a key enabling technology that utilizes localized laser heating to reduce forming forces, enhance ductility, and mitigate springback. This paper provides a critical review of the state-of-the-art in LAF of UHSS. It begins by elucidating the governing principles, including the coupled thermo-mechanical and metallurgical mechanisms such as thermal softening, dynamic microstructure evolution, and non-equilibrium phase transformations. The review then systematically surveys the major LAF process variants—including bending, roll forming, and incremental forming—and their applications in fabricating complex UHSS components. Despite its proven advantages, significant challenges impede its widespread industrial adoption. The most critical issues are identified and discussed, including local mechanical property degradation due to uncontrolled thermal cycles, the complexity of predictive multi-physics modeling, and the need for robust in-situ process monitoring and control. Ultimately, this review presents a forward-looking perspective, proposing future research directions that focus on microstructure management, the development of high-fidelity digital twins, and the implementation of intelligent closed-loop control systems to ensure process stability and part integrity. This work provides a comprehensive roadmap for advancing the science and technology of LAF for next-generation lightweight manufacturing.

Open Access

Review

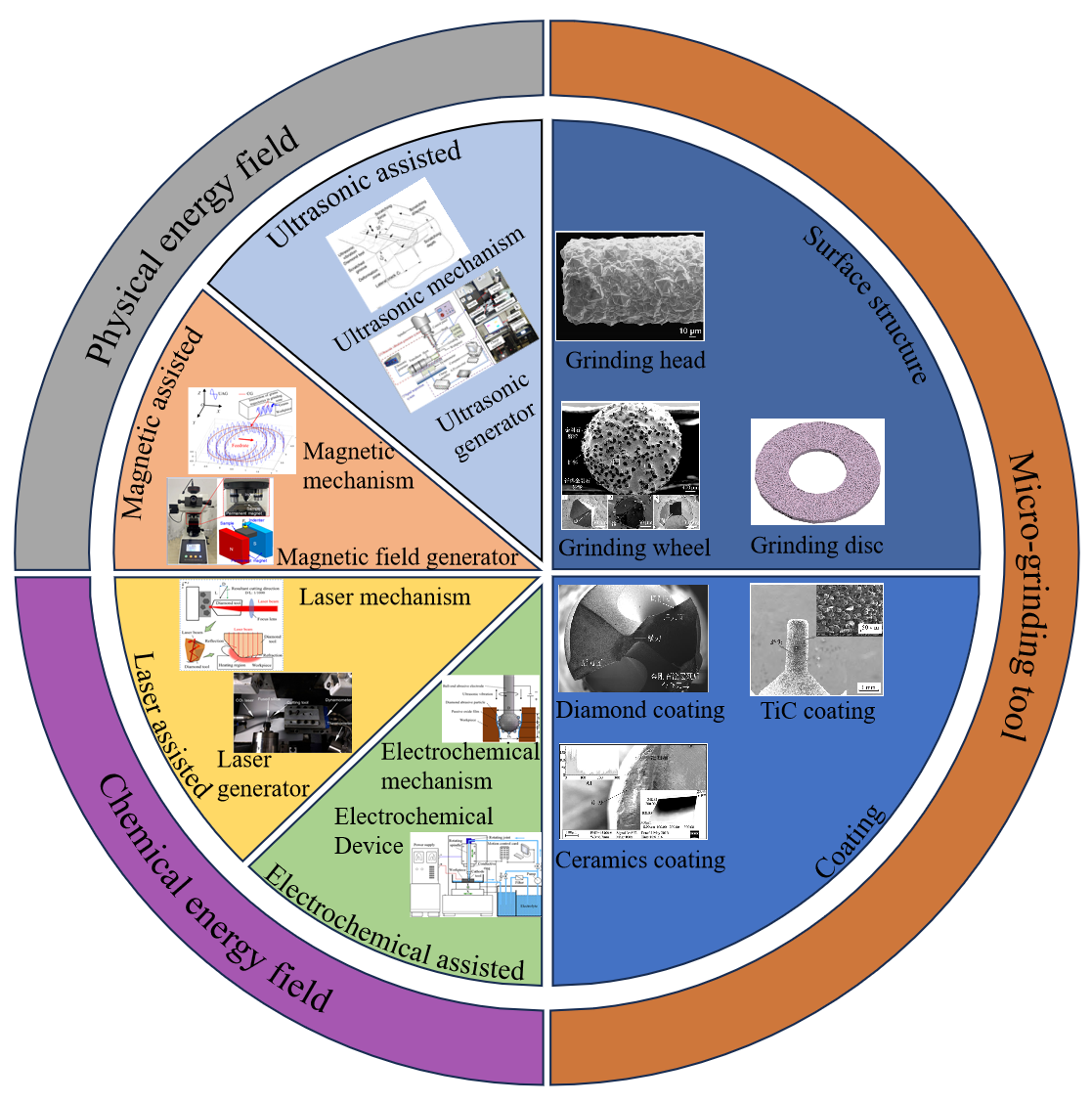

09 July 2025Muti-Energy Field-Assisted Grinding of Hard and Brittle Materials: Tools, Equipment and Mechanisms

Hard, brittle and difficult-to-machine materials are prone to surface cracks, subsurface damage and other defects in the traditional grinding process, accompanied by low processing efficiency and severe tool wear. As a new type of processing technology, energy field-assisted grinding provides a new approach for the efficient and high-quality processing of hard and brittle materials. This paper reviews the latest research progress of muti-energy field-assisted grinding from aspects such as the types and selection of grinding tools, processing equipment and physical-chemical coupled mechanisms. Firstly, micro-grinding tools are classified based on different surface structures and coating materials, with the aim to enhance processing efficiency, improve the surface quality and geometric accuracy of workpieces, and reduce tool wear. Secondly, the processing mechanisms, parameter selection and current difficulties faced by four energy field-assisted grinding methods, including laser-assisted grinding, electrochemical-assisted grinding, magnetic-assisted grinding and ultrasonic field-assisted grinding, are discussed under both chemical and physical effects. Thirdly, different equipment and auxiliary devices developed for energy field-assisted grinding have been introduced, providing reliable platforms for the distribution design and efficient regulation of the energy field. Finally, the cutting-edge progress, main challenges and development trends of energy field-assisted grinding are prospected, illustrating the great potential of this technology in fields such as aerospace, electronics, and optical components.

Open Access

Review

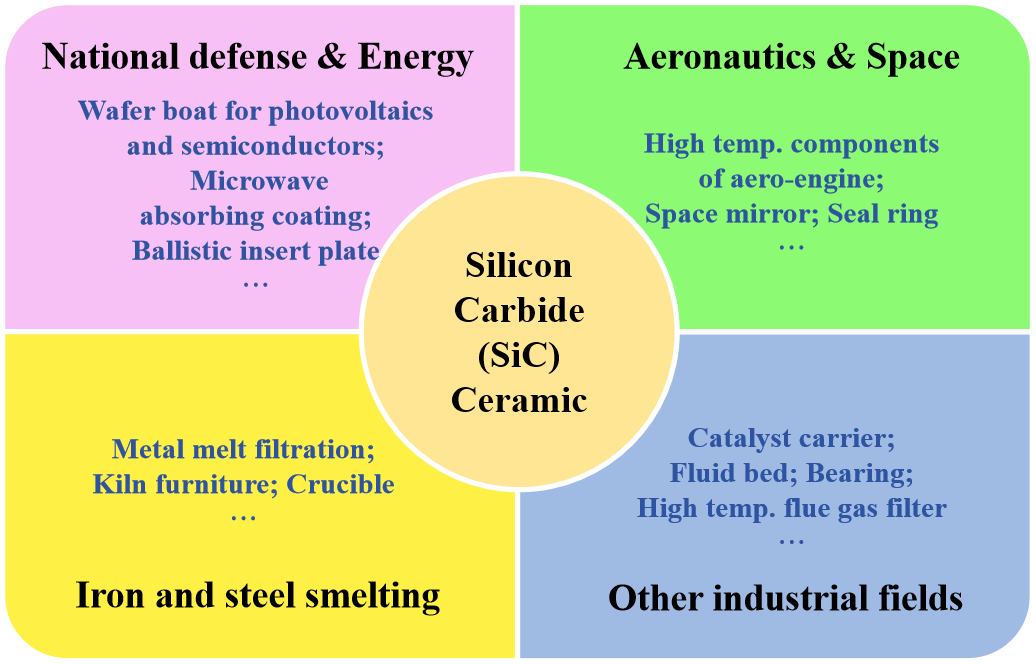

13 June 2025Advances in Sintering Technologies for SiC Ceramics: Mechanisms, Challenges, and Industrial Applications

Silicon carbide (SiC) ceramics have become critical materials for high-temperature engineering applications because of their exceptional mechanical strength, thermal conductivity, and chemical stability. In order to meet the diverse needs of industrial applications, various sintering methods have been developed. These include traditional methods such as pressureless sintering, reaction-bonded sintering, hot pressing, and recrystallization, as well as advanced technologies like spark plasma sintering, oscillatory pressure sintering, and flash sintering. This review provides a systematic analysis of both traditional and advanced sintering techniques for SiC ceramics. It highlights their mechanisms, critical process parameters, and impacts on the final material properties. Key challenges, including high sintering temperatures, additive selection, microstructural control, and scalability, are examined. Strategies for balancing cost-efficiency with performance are also discussed. In addition, recent advancements in SiC-based composite materials for applications ranging from aerospace components to catalytic filtration systems are presented. Finally, future research directions are proposed. These focus on precise additive engineering, microstructure tailoring, and innovative sintering methodologies to speed up the transition of high-performance SiC ceramics from laboratory prototypes to large-scale industrial implementation.

Open Access

Article

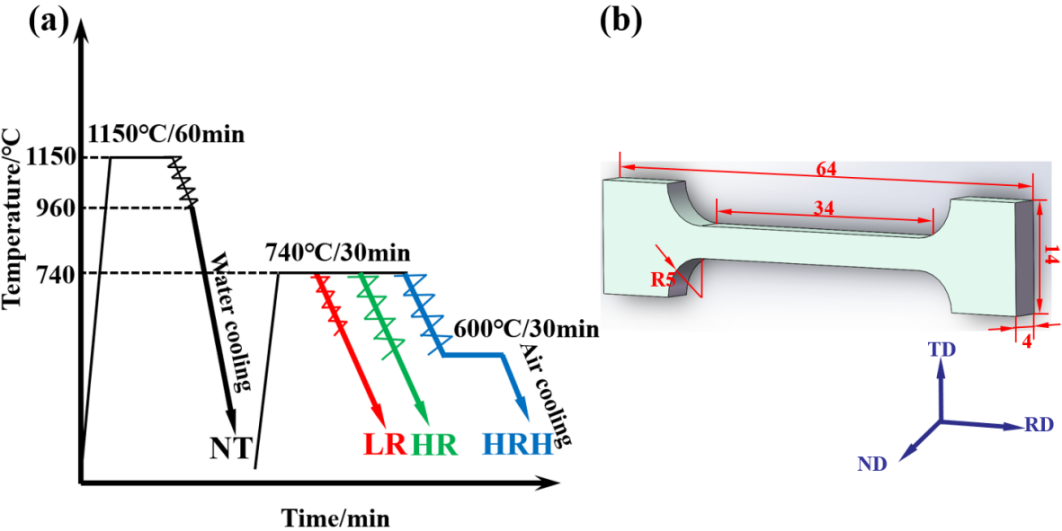

11 June 2025Effect of Post Rolling Strategies on Microstructure and Mechanical Properties of Martensitic Heat-Resistant Steel

Four different rolling strategies were applied to comparatively study the post-rolling process on the microstructure and high-temperature mechanical properties of a high-boron P92 martensitic heat-resistant steel. Both the characteristics of martensitic lath structures and the evolution of precipitation and texture states are illustrated. Their influence on mechanical properties was also discussed based on the recrystallization state, dislocation density, precipitation state, and also the activation tendency of slipping systems of the dominated texture component. Results revealed that the post-rolling process can significantly improve the plasticity of quenched P92 steel while leading to the reduction of strength simultaneously. However, a high reduction and post isothermal holding sample (HRH) shows the best high-temperature mechanical performance with a balanced tensile strength of 352 MPa and elongation of 33.6%. It is the enhanced precipitation strengthening, recrystallization refinement, and lower Schmid values of main texture components that contribute to the mechanical property improvement of the HRH sample.

Open Access

Article

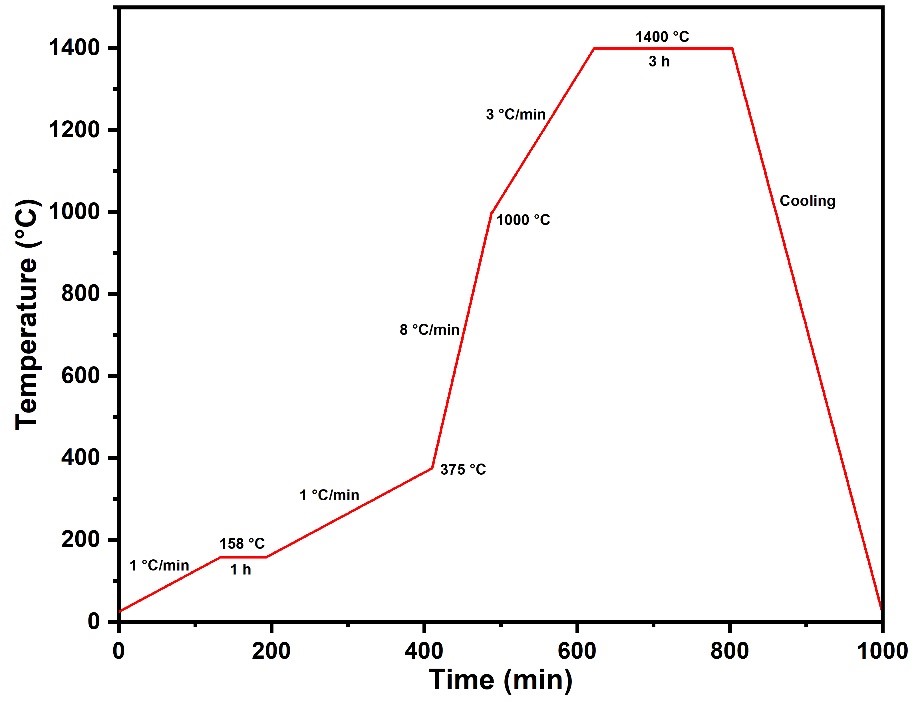

26 March 2025Evaluation of the Effect of Fe2O3 as a Sintering Additive on Densification, Microstructure, and Thermal Stability of Al2O3

This study investigates the fabrication of alumina-based (Al2O3) ceramics using pressureless sintering, employing hematite (Fe2O3) as a sintering aid. Fe2O3 powders were synthesized via combustion and incorporated into Al2O3 concentrations of 0.5, 1.0, and 2.0 wt.%. The samples were sintered at 1400 °C and characterized by X-ray diffraction (XRD) with Rietveld refinement, thermogravimetric analysis (TG/DTG), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), and density measurements using the Archimedes method. The results demonstrated that the addition of Fe2O3 increased the densification of Al2O3 ceramics, with the highest densification (~85%) observed in samples containing 1.0 and 2.0 wt.% Fe2O3. XRD analysis identified only the corundum phase of Al2O3, suggesting that Fe2O3 was incorporated without forming secondary phases. However, Rietveld refinement calculations revealed distortions in the unit cell volume, which contributed to lowering the melting temperature of Al2O3, thereby facilitating sintering. SEM images showed that Fe2O3 acted as a grain growth inhibitor, resulting in finer microstructures with smaller grains. EDX mapping indicated that Fe ions preferentially accumulated in regions with higher pore concentrations. Thermal analysis demonstrated improved thermal stability in Fe2O3-containing samples. Overall, the study confirms that Fe2O3 serves as an effective sintering aid, enhancing densification and thermal stability while refining the microstructure of Al2O3 ceramics. These findings contribute to the development of optimized ceramic materials for high-performance applications.

Open Access

Article

24 February 2025Effect of Recycled High-Density Polyethylene on the Impact Strength of Polybutylene Terephthalate/Polyamide 6

Recycling high-density polyethylene (HDPE) is crucial to addressing plastic waste challenges. This study investigates the mechanical properties of blends composed of HDPE, polybutylene terephthalate (PBT), and polyamide 6 (PA6). Blends with varying HDPE content (0, 70, 80, 90, and 100%) were analyzed using injection molding to determine their impact toughness and structural characteristics. PBT and PA6 (blended in a 50:50 ratio) were combined with HDPE to create composites with enhanced properties. Testing included unnotched impact strength analysis and scanning electron microscopy (SEM). HDPE, a flexible thermoplastic, was paired with PBT and PA6, known for their strength and heat resistance, to produce a blend with superior mechanical performance. Results reveal that incorporating HDPE enhances the impact toughness of the composites compared to the pure PBT/PA6 blend, offering promising potential for many diverse applications in materials engineering in the automotive industry, household products, and protective casings of electronic products.

Open Access

Article

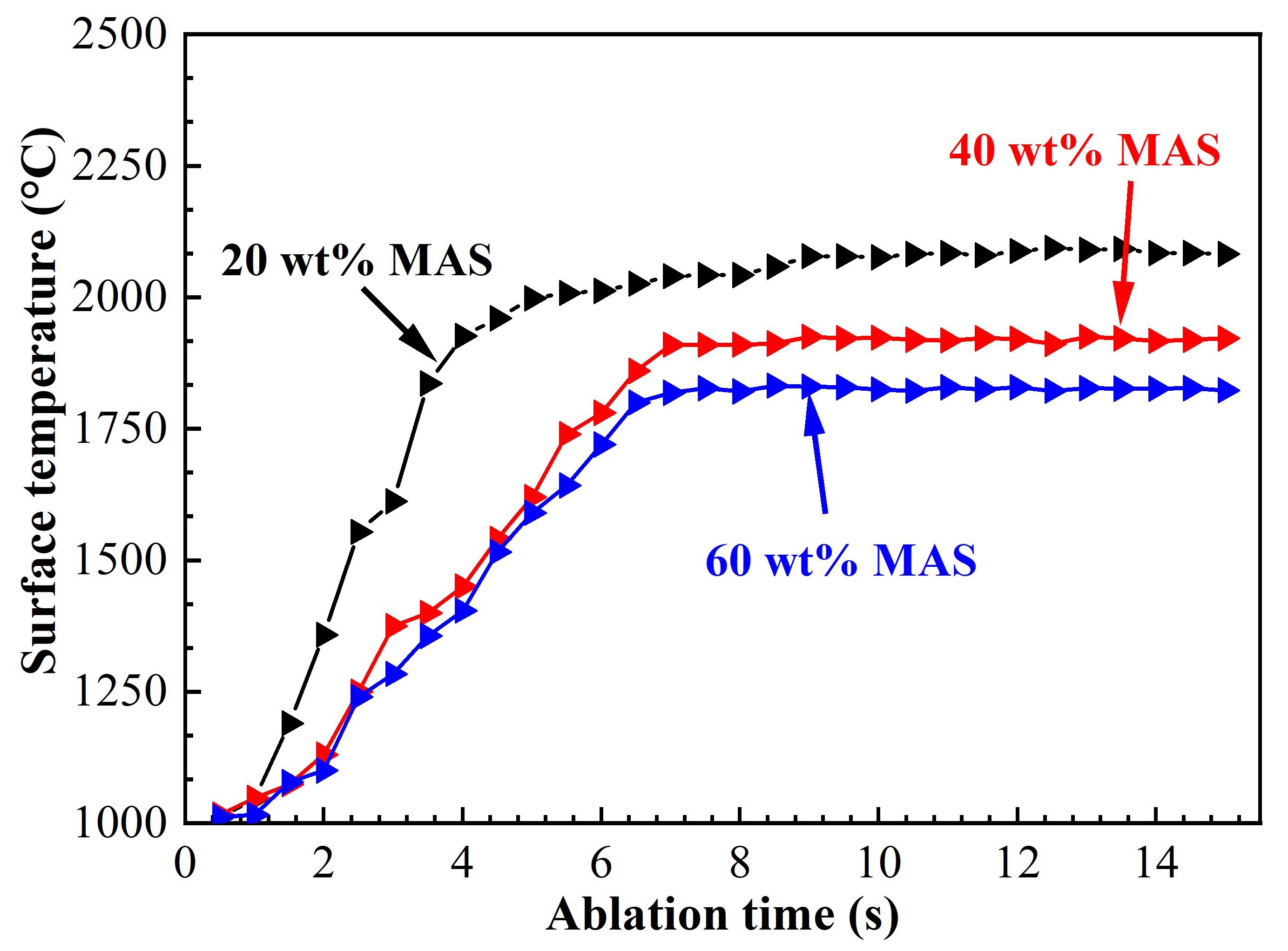

27 December 2024Effect of Magnesium Aluminum Silicate Addition on the Ablation Resistance of BN Matrix Ceramics

Ablation resistance is a critical factor in evaluating the performance of BN-based ceramic composites under extreme service conditions. This study investigates the ablation behavior and underlying mechanisms of BN-MAS wave-transparent ceramic composites with varying magnesium aluminum silicate (MAS) content through oxyacetylene torch tests. The results reveal that increasing the MAS content reduces the mass ablation rate from 0.0298 g/s to 0.0176 g/s and the linear ablation rate from 0.149 mm/s to 0.112 mm/s. The incorporation of MAS into h-BN ceramics significantly lowers the surface ablation temperature, primarily due to the evaporation of B2O3 (g) and MAS ceramics. Cross-sectional analysis of the ablated composites indicates the presence of micro- and macro-spallation in the ablation center. The primary ablation products are magnesium-aluminum borosilicate glass and mullite. Key ablation mechanisms include the oxidation of h-BN under flame exposure, the erosion of viscous oxidation products, and the physical degradation of the matrix caused by the high-velocity gas flow.

Open Access

Article

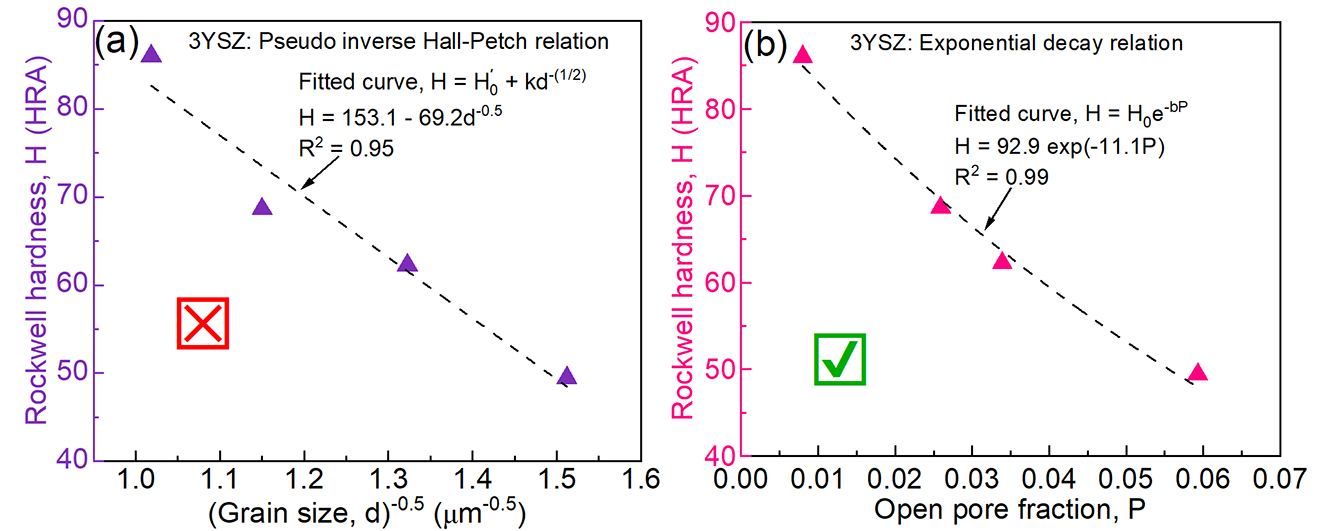

14 November 2024Hardness-Porosity-Grain Size Interrelationship in Conventionally Sintered 3 mol% Yttria Stabilized Zirconia

Considerable research has been done in the past on expensive, <50 nm particle size 3 mol% yttria-stabilized zirconia (3YSZ) using advanced sintering techniques. However, insights are still needed to reveal which factors among grain size and porosity, when both are changing simultaneously, more strongly control the hardness of conventionally sintered, relatively coarse, 250 nm 3YSZ powder, which can be used to make large industrial engineering ceramic parts at a lower cost. This investigation showed that elevating the sintering temperature from 1500 °C to 1650 °C increased the Rockwell hardness from 49.4 HRA to 86.0 HRA, which was concomitant with an increase in grain size and bulk density. A pseudo-inverse Hall-Petch relationship between hardness and grain size was observed given by H (in HRA) = 153.1 − 69.2/$$\small\sqrt{(\mathrm{grain}\,\mathrm{size})}$$ with a somewhat low R2 of 0.95, which was mainly due to the porosity being an additional important variable. Compared to grain size, the impact of open pore fraction (P) on hardness was stronger, inferred from a higher R2 of 0.99 while fitting the data into the well-known exponential decay equation, H = 92.9 exp(−11.1P). Finally, it was observed that the 3YSZ conventionally sintered at 1650 °C for 2 h had 0.8% open porosity, 6.08 g/cm3 bulk density, 960 nm grain size and consisted of only tetragonal ZrO2.

Open Access

Review

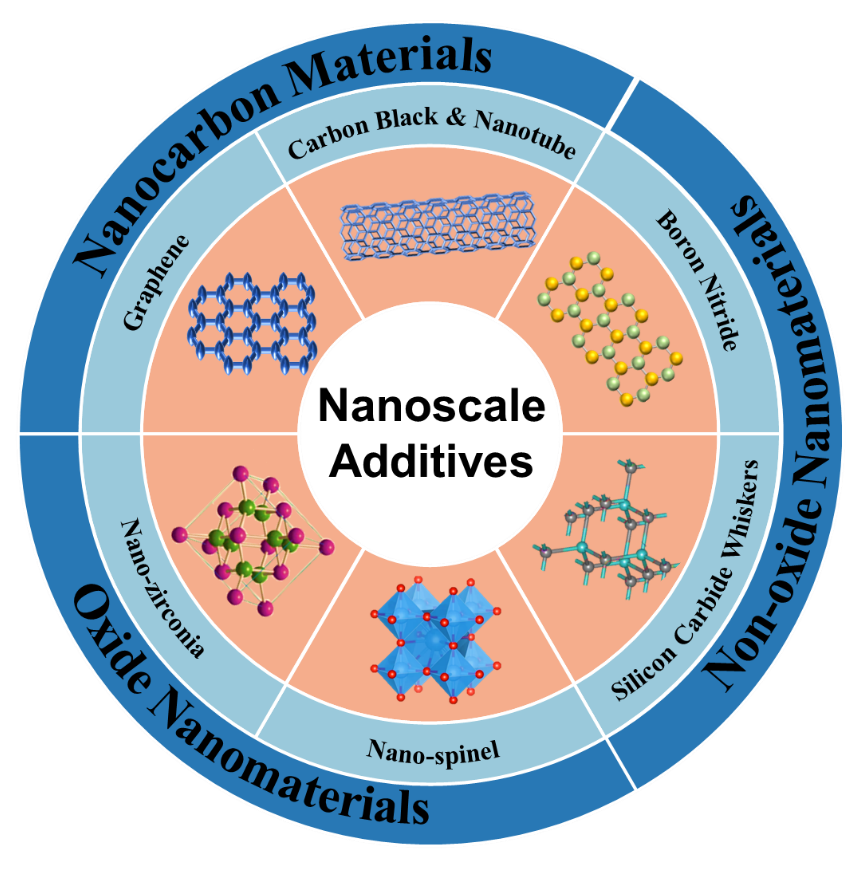

02 September 2024A Review on the Application of Nanomaterials to Boost the Service Performances of Carbon-Containing Refractories

To meet the high-quality requirements for clean steel production and fully exploit the performance advantages of carbon-containing refractories, nanomaterial has been introduced into the matrix to develop advanced carbon-containing refractories. Nanomaterials, as critical additives, play a crucial role in developing novel refractories. The service performances of carbon-containing refractories are affected not only by their physical and chemical properties but also by their microstructure. This review provides a comprehensive overview of the latest research on oxide-carbon composite refractories containing nanomaterials, categorized by their composition: nanocarbons, nano oxides, and nano non-oxides. Incorporating nanomaterials can enhance the service performances of the refractories, optimizing phase composition and microstructure. Furthermore, future research directions in nanomaterial technology for carbon-containing refractories are discussed.

Open Access

Article

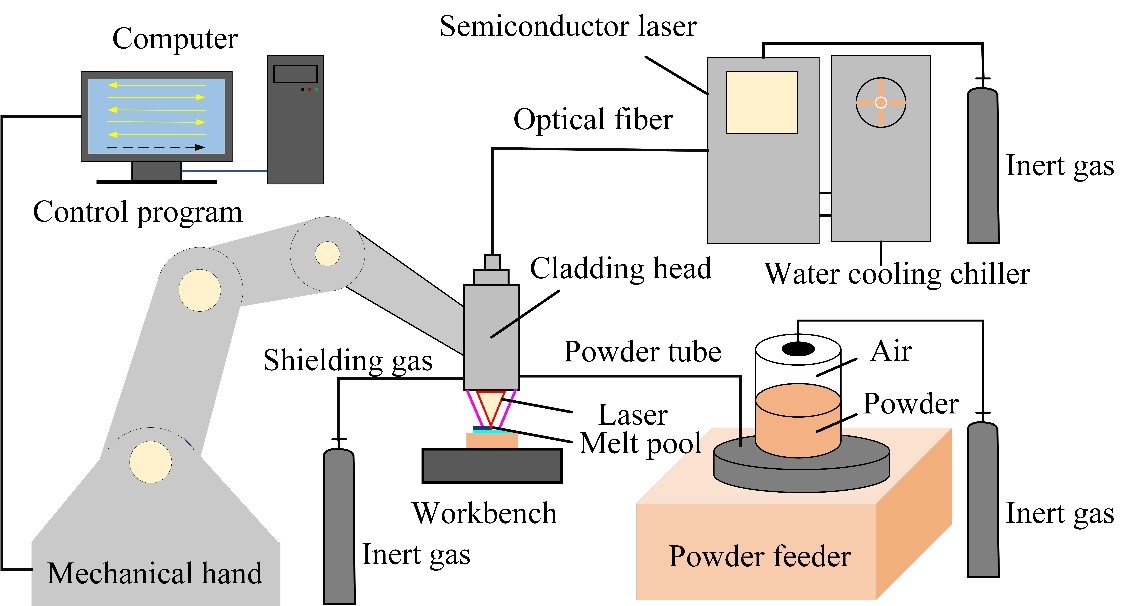

28 August 2024Metallurgical Characteristics of 316L Stainless Steel by Laser Additive Manufacturing

Laser Additive Manufacturing (LAM), an avant-garde technology in manufacturing, harnesses the precision of laser energy to fabricate intricate parts through the meticulous process of melting and subsequently depositing layers of metal powders. Among the esteemed materials employed, 316L stainless steel (316L SS) stands out for its unparalleled corrosion resistance, exceptional high-temperature tolerance, and remarkable creep strength, making it a ubiquitous choice in the aerospace, medical, and nuclear power sectors. LAM has distinguished itself in the fabrication of intricate 316L SS components, yet enhancing the metallurgical bonding strength within these structures remains a pivotal area of ongoing research. This research endeavor delves into the intricate microstructure and mechanical properties that characterize the interface between the LAM-produced 316L SS cladding layer and its substrate, further investigating how varying laser energy densities (E) subtly influence these properties within the additive manufactured components. Remarkably, the interface region exhibits a tensile strength of 615.1 MPa, surpassing that of both the deposited layer and the substrate by 5.4% and 7.4% respectively, underscoring a robust bond between the two layers. This investigation not only sheds light on the unique process capabilities and performance merits of LAM in crafting 316L SS cladding layers but also pioneers novel approaches and conceptual frameworks for bolstering the metallurgical bonding strength of this esteemed material. As such, it constitutes a treasure trove of insights for subsequent research endeavors and practical applications across related disciplines.