Found 21 results

Open Access

Article

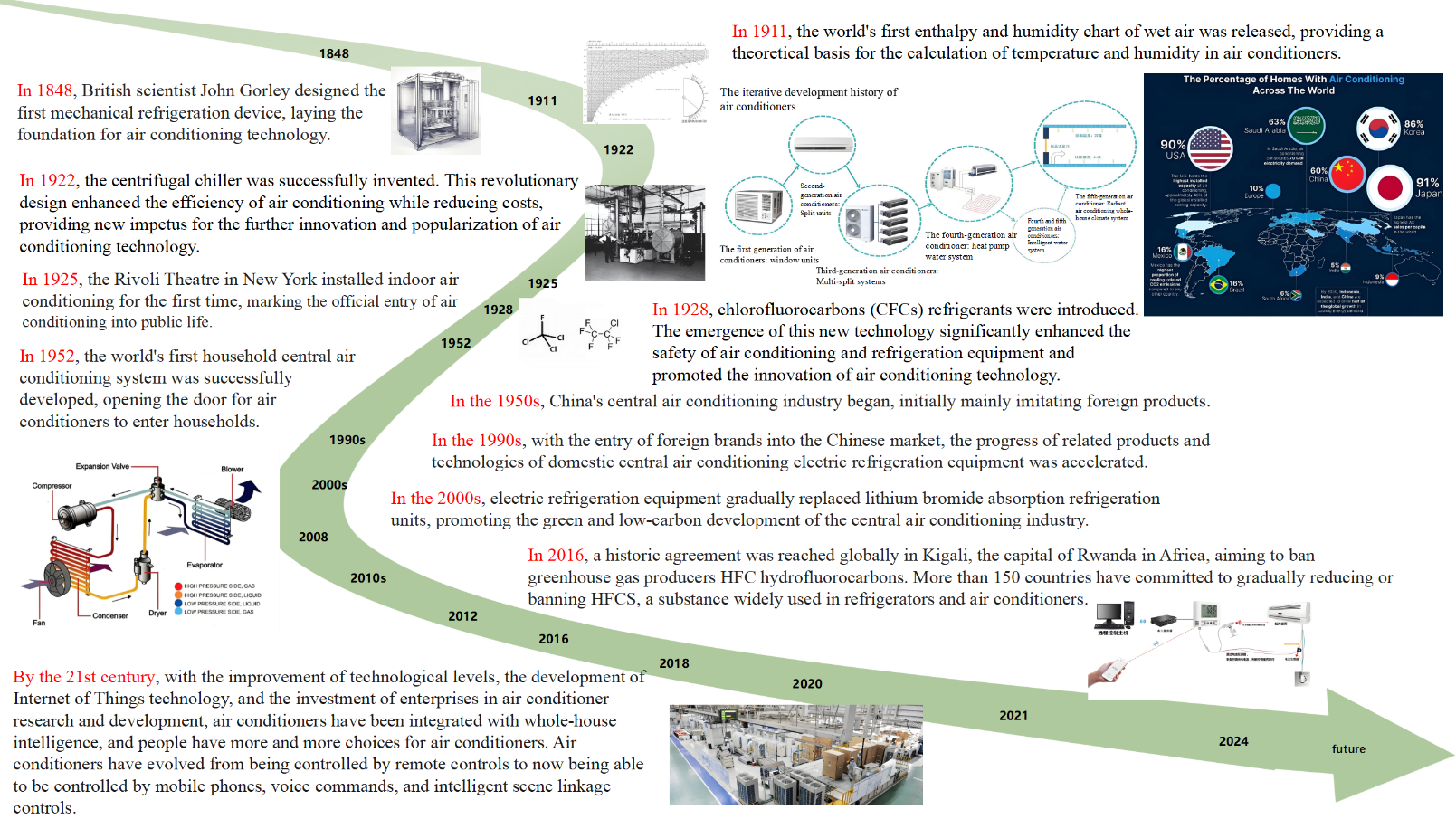

29 July 2025Air Conditioning Heat Exchanger Intelligent Production Line: Design Methodologies and Applications

As a key component in modern building environmental control systems, the production quality and performance of multi-split central air conditioning systems directly influence the comfort, energy efficiency, and operational stability of buildings. However, the current manufacturing process primarily relies on a combination of traditional manual labor and automated equipment, resulting in low efficiency, high energy consumption, and limited automation. This paper first presents an optimized design for an intelligent manufacturing production line for multi-split central air conditioning heat exchangers to address these issues. It details the design of key systems for the intelligent production line and ensures continuous production and processing. Additionally, the paper analyzes the production process of the intelligent manufacturing line, with particular emphasis on the mechanism of the heat exchanger tube expansion process. Furthermore, it designs the fixture structure of the transfer robot for each process in the production line and discusses the principles of workpiece positioning and clamping. Utilizing technologies such as sensor networks, PLC, and industrial Ethernet, the system completes the closed-loop process of perception, transmission, analysis, decision-making, and execution within the production line, enabling transparency, fault predictability, and automated management. The results show that the intelligent assembly production line has significantly improved the assembly efficiency, achieving a 300% increase in the daily production capacity of a single line. While enabling the continuous and intelligent production of multi-split central air conditioning heat exchangers.

Open Access

Review

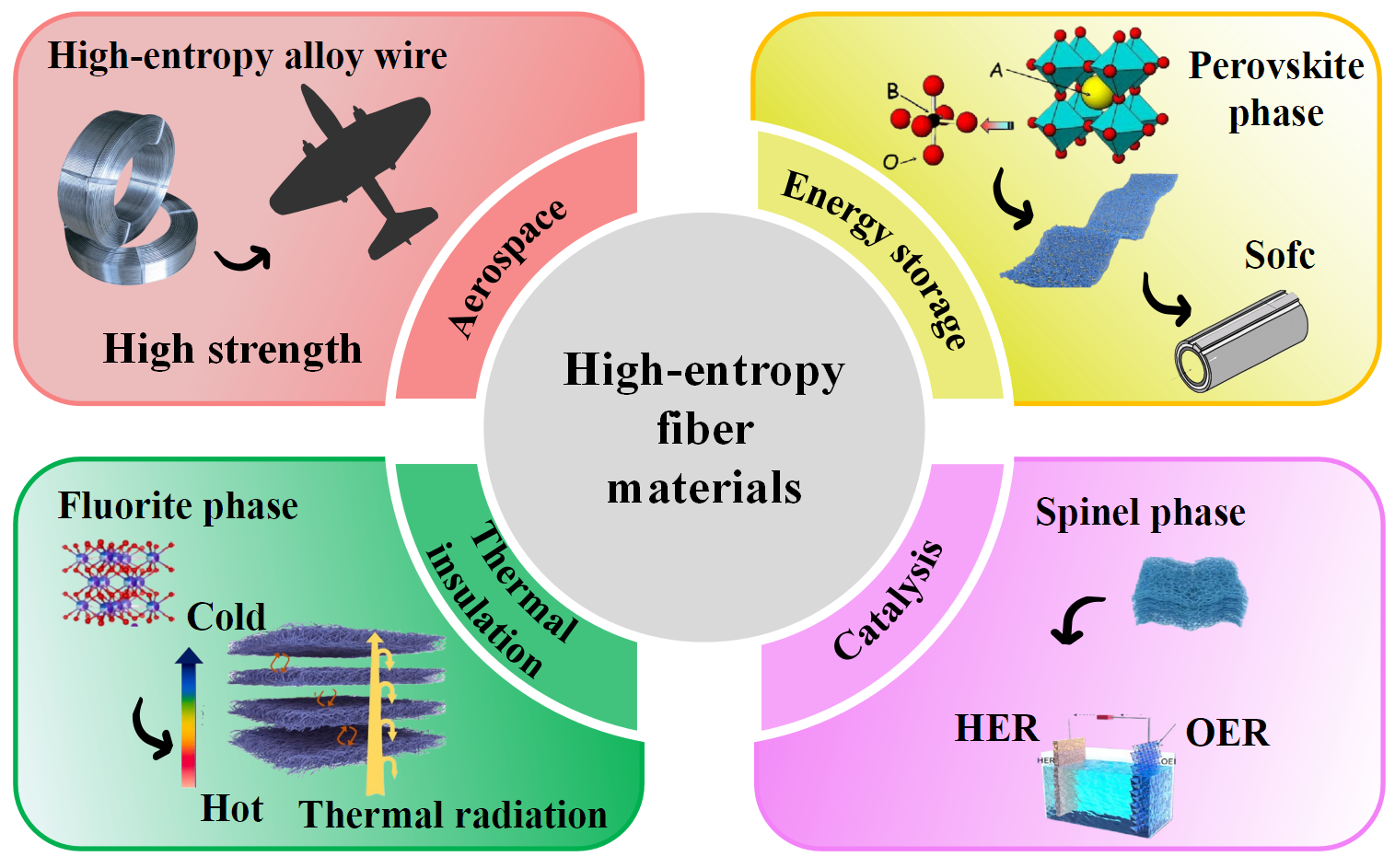

19 June 2025Research Progress on High-Entropy Fibrous Materials

Due to their lightweight, high strength, and thermal resistance, HEFMs exhibited significant potential in aerospace, energy storage, environmental protection, and defense. This review systematically presented the research progress on high-entropy fibrous materials (HEFMs), covering their fundamental concepts, fabrication methods, crystal structure characteristics, performance advantages, and application fields. The different crystal structure types and fabrication techniques of high-entropy ceramic fibers and high-entropy alloy fibers were discussed. Additionally, the mechanical property advantages of HEFMs and their applications in thermal insulation materials, catalysis, and energy storage were analyzed. Finally, the current challenges in HEFM research and provide an outlook on future development directions.

Open Access

Review

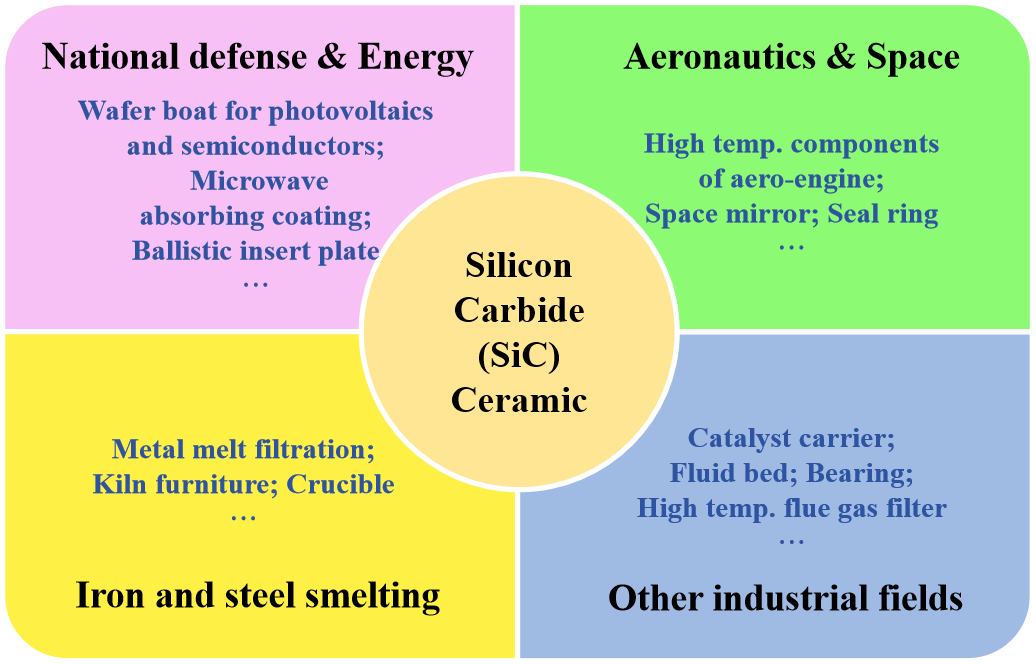

13 June 2025Advances in Sintering Technologies for SiC Ceramics: Mechanisms, Challenges, and Industrial Applications

Silicon carbide (SiC) ceramics have become critical materials for high-temperature engineering applications because of their exceptional mechanical strength, thermal conductivity, and chemical stability. In order to meet the diverse needs of industrial applications, various sintering methods have been developed. These include traditional methods such as pressureless sintering, reaction-bonded sintering, hot pressing, and recrystallization, as well as advanced technologies like spark plasma sintering, oscillatory pressure sintering, and flash sintering. This review provides a systematic analysis of both traditional and advanced sintering techniques for SiC ceramics. It highlights their mechanisms, critical process parameters, and impacts on the final material properties. Key challenges, including high sintering temperatures, additive selection, microstructural control, and scalability, are examined. Strategies for balancing cost-efficiency with performance are also discussed. In addition, recent advancements in SiC-based composite materials for applications ranging from aerospace components to catalytic filtration systems are presented. Finally, future research directions are proposed. These focus on precise additive engineering, microstructure tailoring, and innovative sintering methodologies to speed up the transition of high-performance SiC ceramics from laboratory prototypes to large-scale industrial implementation.

Open Access

Review

06 May 2025Genetic Insights into Ancient Kinship and Human History: Methods, Applications, and Implications

Recent advances in ancient DNA analysis have transformed our understanding of kinship and underlying social structures in past populations. The application of next-generation sequencing technologies has enabled researchers to reconstruct the genetic makeup of ancient individuals with unprecedented precision, providing new insights into lineage, ancestry, and social organization. Ancient DNA evidence has revealed a wide range of kinship systems, including patrilineal and matrilineal descent, consanguineous marriages, female exogamy, and family-based burial practices. These findings underscore the complexity of human social relationships and the dynamic interactions between genetic inheritance, cultural traditions, and environmental factors in ancient societies. By examining case studies across different geographic and temporal contexts, this review highlights the transformative potential of ancient DNA in deciphering past human relationships. However, it also addresses key ethical concerns, including the importance of respecting cultural sensitivities and avoiding overly deterministic interpretations of genetic data. The integration of genetic evidence with archaeological and anthropological perspectives enables a more comprehensive reconstruction of ancient social systems, moving beyond simplistic genetic determinism to appreciate the intricate interconnections between biology, culture, and identity.

Open Access

Review

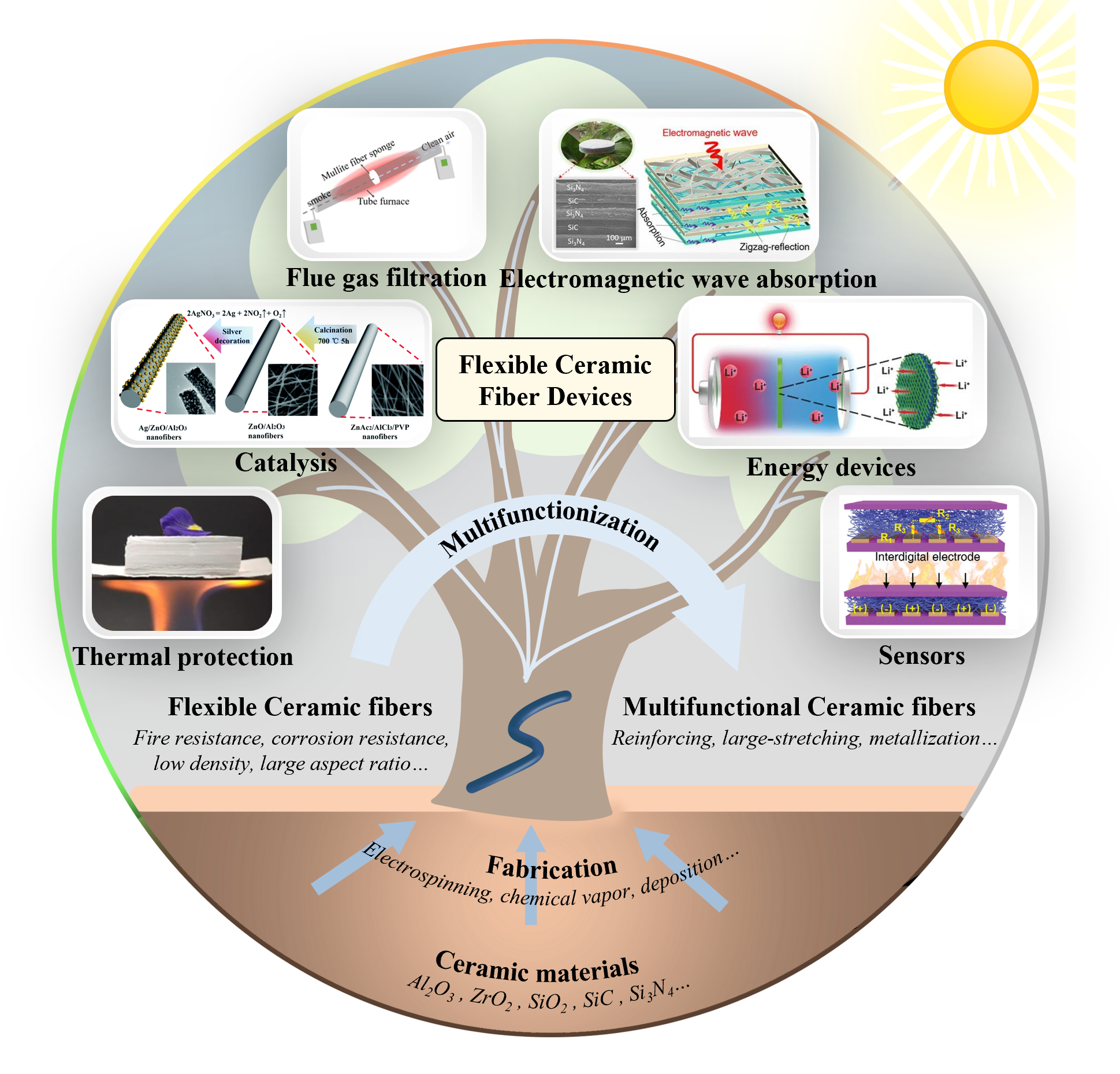

14 April 2025Advancements in Flexible Ceramic Fibers for High-Temperature Applications: A Comprehensive Review

Flexible ceramic fibers (FCFs) have emerged as a highly promising material for high-temperature applications, effectively combining the excellent thermal stability of ceramic materials with the robust mechanical properties of flexible fibers. This review provides a comprehensive overview of recent advances in multifunctional FCF devices, focusing on innovative methods across material selection, structural design, and fabrication techniques to enhance their functional properties. These improvements, i.e., mechanical strength, thermal conductivity, and oxidation resistance, make FCFs particularly suitable for a wide range of applications, including energy storage, sensing, and high-temperature filtration. Notably, advancements in fabrication techniques have enabled the creation of novel FCF devices for thermal insulation and high-temperature sensing, such as stretchable ceramic membranes and printable ceramic fiber papers. The review concludes by discussing the future potential of FCFs, especially in multifunctional applications in high-temperature environments, where they can serve as essential components of advanced technologies. This work highlights the versatility and potential of FCFs as a transformative material for next-generation high-temperature applications.

Open Access

Review

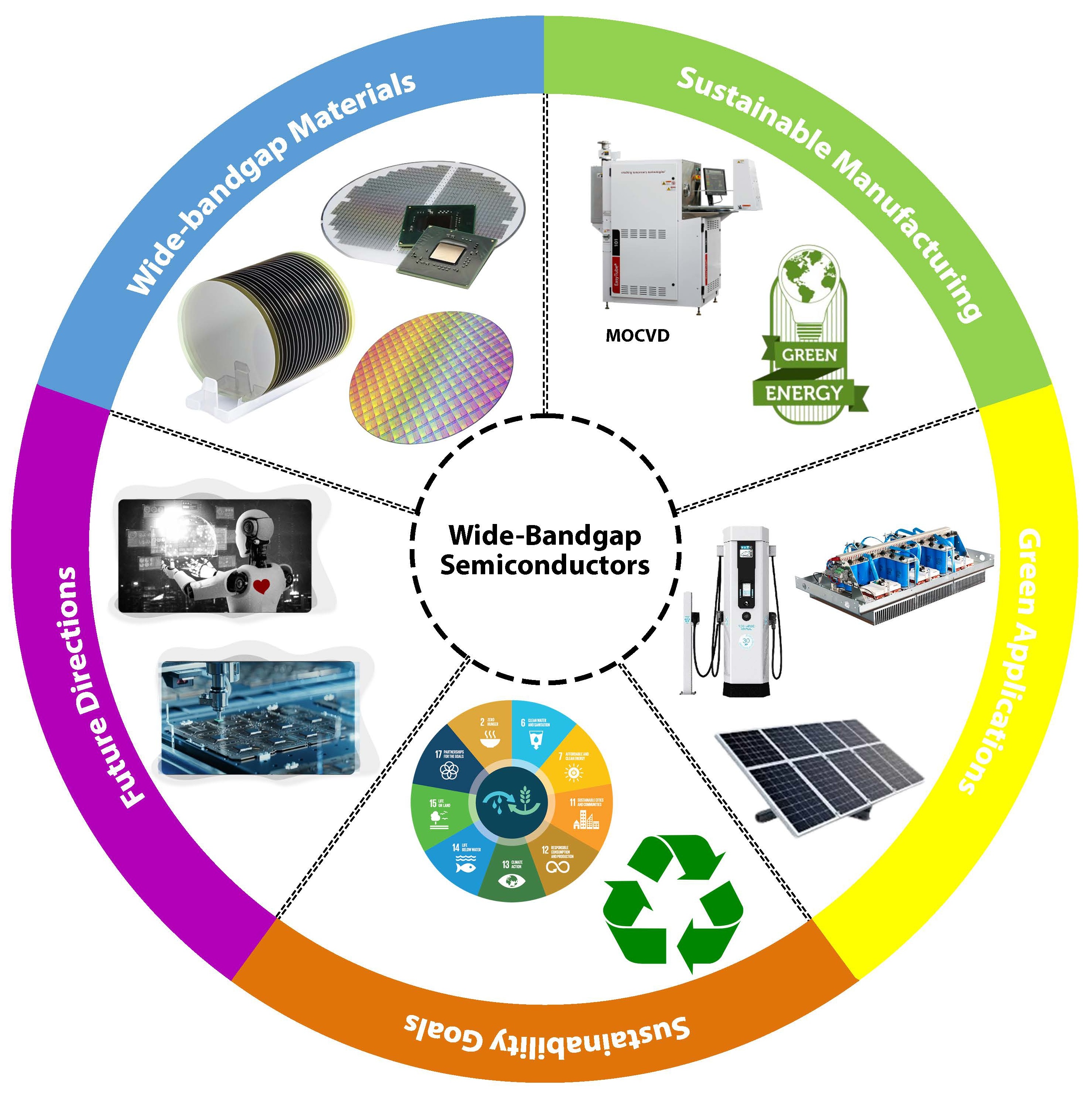

01 April 2025Sustainable Manufacturing and Applications of Wide-Bandgap Semiconductors—A Review

Wide-bandgap (WBG) semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) are revolutionizing high-power electronics due to their superior thermal conductivity, breakdown voltage, and energy efficiency. These materials are critical in electric vehicles, renewable energy systems, and high-frequency applications like 5G infrastructure. However, their production processes are resource-intensive and present significant environmental challenges. This review evaluates recent advancements in sustainable WBG semiconductor manufacturing, focusing on low-energy epitaxial growth, closed-loop recycling, and the mitigation of toxic by-products. Additionally, it highlights the role of Industry 4.0 innovations, such as AI-driven process optimization and IoT-based resource management, in enhancing sustainability. The review identifies research gaps in cost reduction, alternative WBG materials like Gallium Oxide (Ga2O3) and Diamond, and scalable green manufacturing solutions. It underscores the necessity for industry-wide collaboration and regulatory frameworks to drive the adoption of eco-friendly semiconductor fabrication. The findings of this study provide a roadmap for advancing sustainability in WBG semiconductor production, ensuring their long-term viability in the transition toward energy-efficient technologies.

Open Access

Article

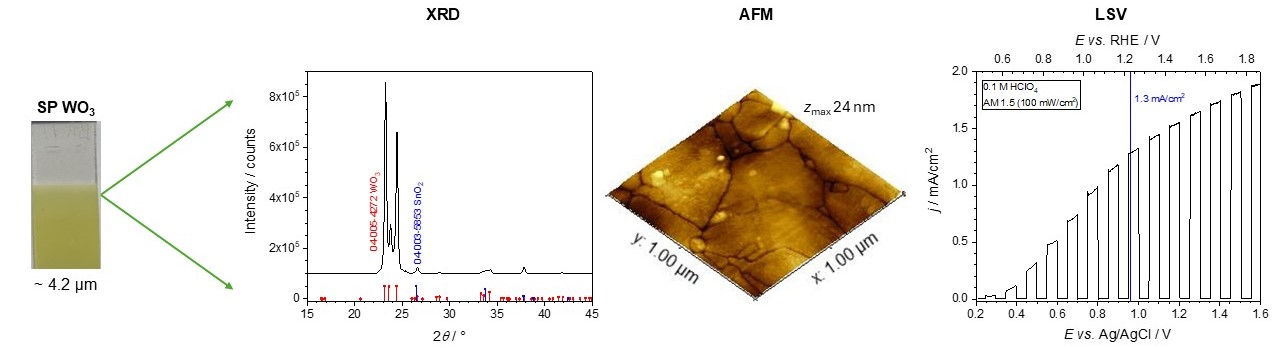

07 March 2025WO3 Photoanodes for Photoelectrochemical Applications

WO3 layers were prepared by spray pyrolysis of a peroxotungstic acid solution on FTO/glass substrates. Investigated parameters were layer thickness and influence of post-annealing in air. Films deposited at 250 °C were amorphous. Post-annealing at 550 °C for 2 h resulted in the formation of monoclinic crystalline structure. A comprehensive account of electrochemical efficiency in terms of IPCE for WO3 films as a function of the three parameters (wavelength, thickness and direction of light incidence) fully characterizing the photoelectrodes is presented here for the first time. The highest improvement in crystallinity and also the highest photocurrent response was found for WO3 layers deposited at 250 °C and post-annealed at 550 °C, namely 1.9 mA/cm2 (in 0.1 M HClO4 at 1.6 V vs. Ag/AgCl) under irradiation with a solar simulator (AM 1.5, 100 mW/cm2) and IPCE = 0.5 at 369 nm (front side irradiation), which is comparable with values obtained by other deposition techniques (e.g., hydrothermal or sol gel). Spray pyrolysis as a method of fabricating WO3 electrodes has the advantage of being able to produce large electrodes for use in practical applications.

Open Access

Article

21 February 2025Porous Cu(Mn)-Doped ZnO-MgO Nanocomposites for Photocatalytic and Antibacterial Applications

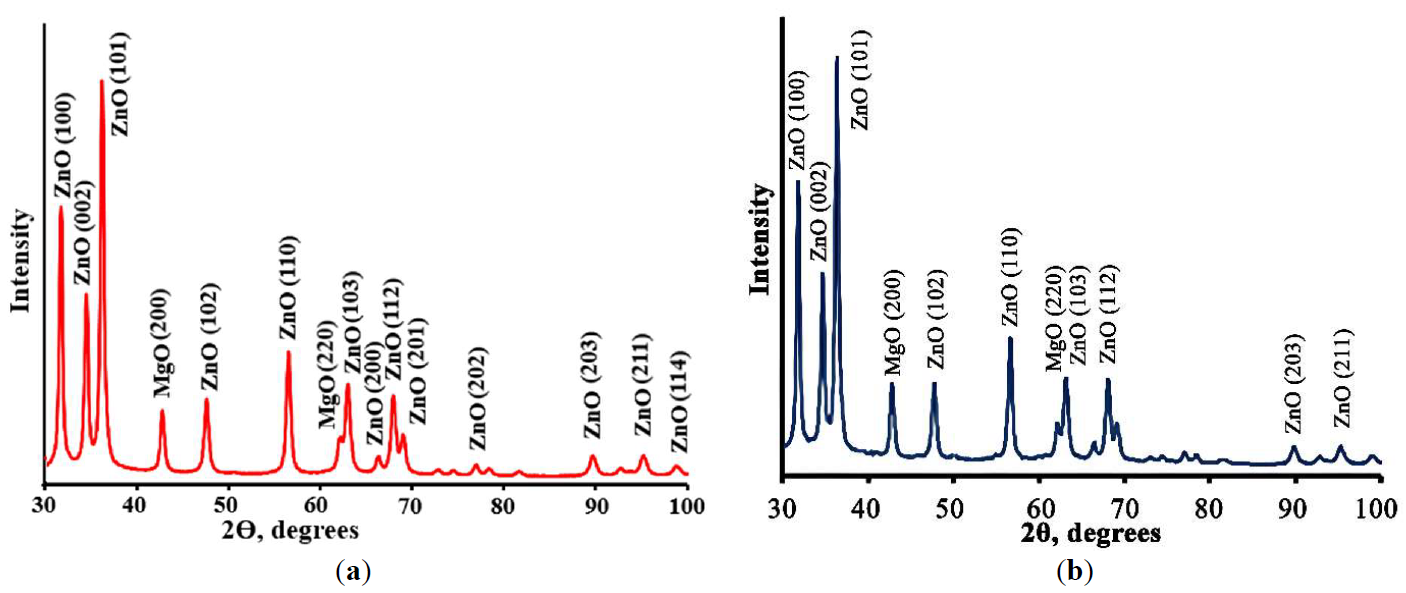

Porous Cu(Mn):ZnO-MgO composites synthesized by polymeric sol-gel method were characterized. The crystal structure, morphology, spectral properties, the ability of the photogeneration of chemically active singlet oxygen under external visible irradiation, photocatalytic and antibacterial properties of porous composites were studied. Obtained composites consist of small ZnO and MgO crystals having size less than 20 nm. It was found that Cu2+ and Mn2+ ions are embedded into the lattices of ZnO and MgO crystals, altering their crystal cell parameters. The band gap values of obtained composites are 3.41 ÷ 3.42 eV which are slightly higher than the band gap of pure ZnO. Prepared materials demonstrate a high ability of photogeneration of chemically active singlet oxygen under blue light (λ = 405 nm) irradiation. It was found that dependencies of the intensity of singlet oxygen photogeneration from the power density of visible irradiation are linear. Photocatalytic decomposition of the diazo dye Chicago Sky Blue in solutions under UV and blue light irradiation proceeds rapidly in the presence of the prepared composites (constants rate of photocatalytic dye decomposition under UV irradiation are 0.024 min−1 and 0.025 min−1 for ZnO-MgO composites doped with Cu and Mn, correspondingly). Porous composites demonstrate superior antibacterial activity against gram-positive bacteria. These materials are promising for practical application in medicine and photocatalytic technologies of air and water cleaning.

Open Access

Review

09 January 2025Recent Advancements in Alumina-Based High-Temperature Insulating Materials: Properties, Applications, and Future Perspectives

As a high-temperature thermal insulation material with excellent mechanical properties, alumina (Al2O3)-based materials hold significant potential for applications in aerospace, advanced manufacturing, automobiles, industrial furnaces, and other fields. However, the inherent brittleness of alumina poses a limitation to its wider application. Therefore, there is a pressing need to develop alumina-based materials that offer high toughness while retaining superior mechanical properties. This paper begins by exploring the structure of alumina, highlighting its thermal conductivity, insulation, and mechanical properties in high-temperature environments. It then reviews the classification and synthesis methods of alumina-based materials, along with the latest advances in design strategies. Notably, the rational design of alumina composition, structure, and morphology is emphasized as crucial for optimizing material performance, thereby supporting the industrial development and application of these materials in high-tech sectors. Finally, the paper discusses the challenges and evolution of alumina-based materials in real-world industrial applications and suggests potential directions for future development.

Open Access

Article

27 December 2024Effect of Magnesium Aluminum Silicate Addition on the Ablation Resistance of BN Matrix Ceramics

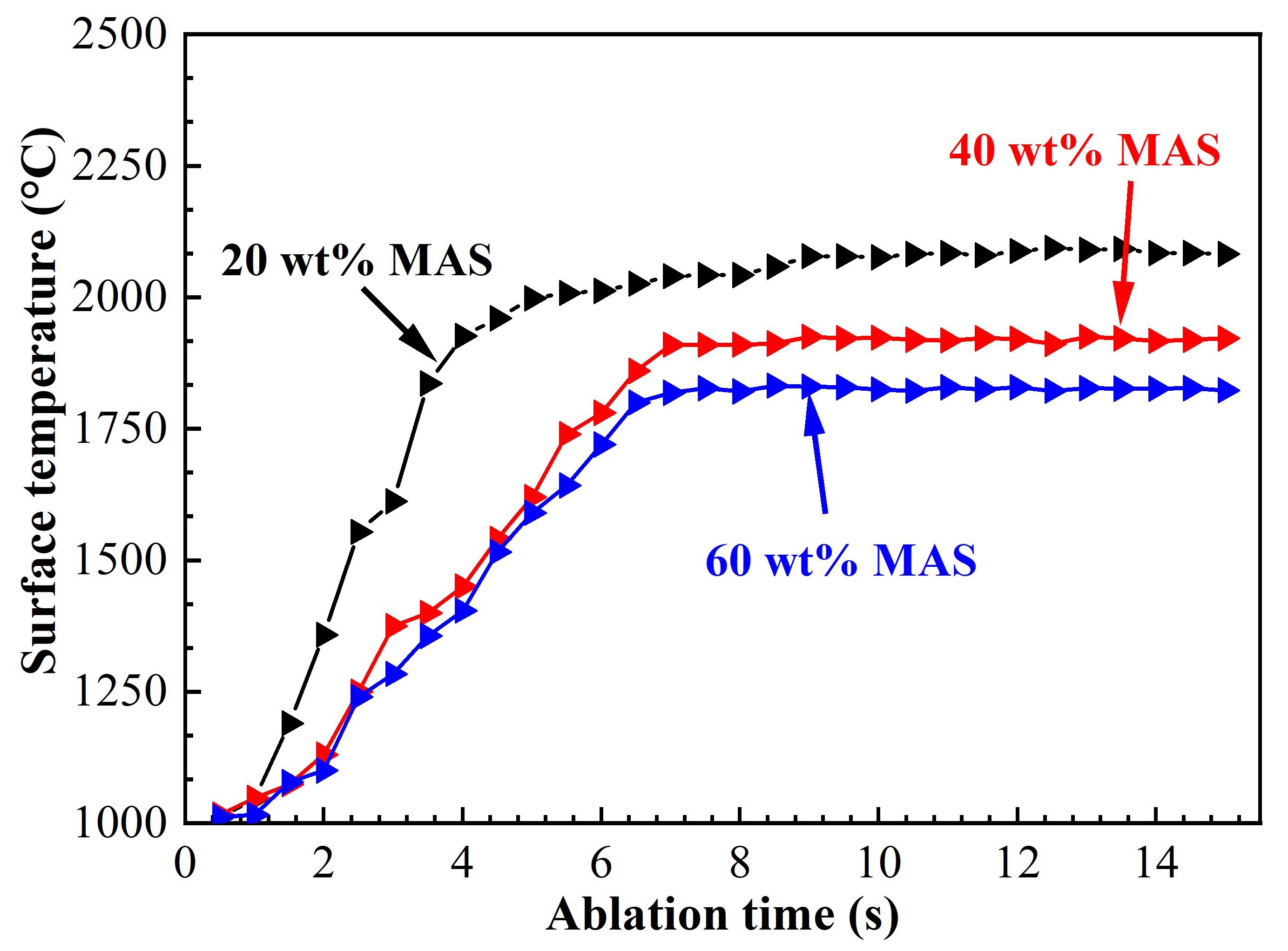

Ablation resistance is a critical factor in evaluating the performance of BN-based ceramic composites under extreme service conditions. This study investigates the ablation behavior and underlying mechanisms of BN-MAS wave-transparent ceramic composites with varying magnesium aluminum silicate (MAS) content through oxyacetylene torch tests. The results reveal that increasing the MAS content reduces the mass ablation rate from 0.0298 g/s to 0.0176 g/s and the linear ablation rate from 0.149 mm/s to 0.112 mm/s. The incorporation of MAS into h-BN ceramics significantly lowers the surface ablation temperature, primarily due to the evaporation of B2O3 (g) and MAS ceramics. Cross-sectional analysis of the ablated composites indicates the presence of micro- and macro-spallation in the ablation center. The primary ablation products are magnesium-aluminum borosilicate glass and mullite. Key ablation mechanisms include the oxidation of h-BN under flame exposure, the erosion of viscous oxidation products, and the physical degradation of the matrix caused by the high-velocity gas flow.