Multivariant Time-Series Forecasting Methodology for Product Demand Using Deep Learning and Large Language Models

Received: 06 September 2025 Revised: 12 September 2025 Accepted: 19 September 2025 Published: 29 September 2025

© 2025 The authors. This is an open access article under the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).

1. Introduction

In today’s data-centric world, accurate product demand forecasting is crucial for inventory planning, supply chain resilience, and operational effectiveness. Some of the most prevalent approaches to demand forecasting use univariate models, which rely on a single variable, typically historical demand; hence, demand forecasting generally ineffectively takes into account the interactions of other complex real-world factors, such as seasonality, marketing promotions, daily weather, or economic indicators.

To overcome the limitations of using a univariate modelling, this project investigates a methodology called Multivariate Time-Series Forecasting. To improve contextual prediction, it uses a number of time-correlated variables (ALL time series variables are time correlated by definition). With the aid of numerous input features, these models can specifically learn complex temporal structures and long-term dependencies by utilizing sophisticated Deep Learning architectures such as Temporal Convolutional Networks (TCNs), Gated Recurrent Units (GRU), Transformer networks, and Long Short-Term Memory (LSTM).

Interpretability and human report-out insights are equally important to decision makers as forecast accuracy. Therefore, we integrated Large Language Models (LLMs), like Open AI’s GPT, for Intelligent Reporting, to improve our forecasting system. By generating a natural language summary and insights from the forecasting results, these LLMs assist business users in understanding significant trends, identifying anomalies, and identifying strategic opportunities without necessitating a higher level of technical expertise.

This project aims to create and implement a robust system that can predict demand for products over several relevant variables (product category, location of the warehouse, time, seasonal factors, etc.) and report those predictions in an easily comprehensible narrative report. Leveraging the power of sophisticated deep learning models such as LSTM, GRU, and transformer models, this project can make an accurate demand prediction for the products by employing a multivariate time series analysis. Our ability to build accurate models that can perform well in a fast-paced business environment occurred by analyzing high level relationships between historical sales data, price, and other external market environments to find complex yet predictable patterns.

In addition to improving the accuracy of the forecast, the system also generates well-explained and easy to understand reports with the help of large language models (LLM). Natural language generation enables stakeholders to consume analytics and make them more meaningful and usable as operational insights by extracting trends, anomalies, and recommendations, without technical expertise.

In short, this will result in improved inventory management practices, supply chain optimization that results in increased efficiencies, and data driven decision making, enabling businesses to be able to play more sustainably and proactively adapt to change as it affects at the pace of the market.

2. Problem Statement

This project aims to develop a complete-featured, smart forecasting system to forecast product demand with deep learning and LLM-corrected reporting, which consumes multivariate time-series data, has interactive visualizations, does error analysis, and offers real-time decision support to its stakeholders.

The objective of this project is to pre-process product demand data, and use deep learning models: LSTM, GRU, Transformer, TCN for multivariate time-series forecasting. Furthermore, a hybrid ensemble model will be built and evaluated using RMSE, MAE, MAPE, SMAPE, and R2. Interactive dashboards with anomaly detection and summaries will be created using Plotly or Streamlit. Additionally, GPT-like LLMs will provide automated reports. The proposed system will optionally support real-time forecasting. The system will be provided as a modular and user-friendly Python-based program, creating a living workbench for all modellers and data scientists.

3. Literature Review

While supply chain management remains critical, classical approaches will not scale to current issues and challenges. Emerging technologies offer breakthroughs to traditional supply chain methods (e.g., artificial intelligence, blockchain, and IoT) and can mitigate some of the supply chains’ ongoing issues related to transparency, security, and traceability. In general, many of the existing studies are mostly favorable for the use of AI to improve demand forecasting, and the advantages of Blockchain are obvious due to transparent and immutable data records. Despite the evidence for using Emerging Technologies to address the challenges of supply chain management, there remain operational challenges, including data security and safety of sensitive information, complete IT integration, the need for leadership, and the lack of a skilled workforce, which must all be solved before companies can fully realize the benefits of these technologies. At a high level, operational issues can often be solved with proper strategic planning, strong cybersecurity practices, and knowledge of their supply chain requirements.

According to Vijaykumar et al. [1], IoT, AI, and blockchain technologies provide better transparency and tracking capabilities in decision-making activities of the supply chains. Veena et al. [1] developed frameworks for optimizing the integration of these technologies with logistics and inventory systems. Their work focused on the systems’ responsiveness and high demand-efficiency. Roozkhosh et al. [2] utilized system dynamics in combination with AI-driven predictive models to analyze blockchain adoption. They focused on the benefits of enhanced resilience as the primary outcome. Fu [3] proposed a framework for a 6G-enabled cyber-physical supply chain for e-commerce, emphasizing the need for real-time communication and improved supply chain network coordination. These investigations reveal the increasing importance of sophisticated digital technologies in the supply chain of today. Nevertheless, most studies focus on adopting and integrating digital technologies, neglecting demand forecasting and predictive accuracy, and explainability in forecasting.

With regard to explainable AI (XAI) use within AI on perishables supply chains, Jauhar et al. [4] showed that some customer behavior analytics can help minimize losses. More recently, Kosasih et al. [5] have studied the domain of neurosymbolic AI and its explainability in SCM decision models. Supply chain operations have recently also attracted attention, with Jackson et al. [6] devising a capability-based model for Generative AI in such operations. The same stream of research concerning Generative AI, albeit with a mixed-methods approach, was studied by Sharma and Rathore [7], who focused on the technical and organizational facilitators for its use. The above works depict that the trust and utility of the systems hinge on the explainability of the models and the processes required to generate the responses. However, the case studies within the framework of explainability to real-time forecasting systems are extremely niche.

Iftikhar [8] created machine learning models for forecasting the supply chain in healthcare and enhancing the responsiveness to demand. Kaul and Khurana [9] carried out AI-led optimization for e-commerce operations and improved demand forecasting, inventory control, and delivery. Pasupuleti et al. [10] analyzed how machine learning works in automated logistics systems and showed how agility and sustainability grew. Shavaki and Ghahnavieh [11] developed a systematic review analyzing the application of deep learning to SCM and its prospects for future conceptual frameworks. According to Ma et al. [12], AI-based inventory management has also been used in retail supply chains to increase revenue growth and customer retention.Alshurideh et al. [13] reinforced supply chain intelligence and security with machine learning and blockchain.

Naeem et al. [14] explored extensively the application of AI and expert systems in vaccine supply chains. They were particularly interested in how smart distribution planning changes the delivery of vaccine logistics. In a similar vein, Kudrenko [15] delved into the impact of AI on the medical supply chain and revealed that implementing such innovations facilitates not only the supply chain’s robustness and adaptability but also the smooth flow of hospital logistics that is convenient for patients.

The research paper ‘Multivariate Time-Series Forecasting for Product Using Deep Learning and LSTMs with Intelligent Reporting” sounds very promising and highlights the tremendous benefits that such new-age technologies can bring for demand forecasting for a business. Businesses can use proven Deep Learning techniques, especially LSTM, associated with intelligent reporting to substantially enhance their forecasting abilities, thereby improving their decision-making with respect to inventory, production, and supply chain planning. Furthermore, advanced reporting techniques fused with the forecasting methods and models offer stakeholders understandable and clear presents of the analysis that make predictive forecasting research actionable. These deep learning models.

The application of deep neural language models for accurate forecasting and the generation of complex, human-like language is still not as well documented. Also, like others, most of the studies have been done on static datasets and there is limited research on real-time, scalable systems built for enterprise forecasting. Unlike XAI, which is gaining popularity, XAI in multivariate, time-series, demand forecasting still needs attention. All of these shortcomings point to the importance of artificial intelligence systems that integrate hybrid frameworks with real- time data streams to optimize actionable insights, which forms the foundation of this research.

Multivariate time-series forecasting has been investigated in a number of recent studies [16,17,18,19,20,21,22] utilizing deep learning and hybrid models like LSTM, GRU, Transformer, and attention-based mechanisms. The foundation of our suggested methodology is directly supported by these studies, which demonstrate the efficacy of sophisticated deep learning and LLM-driven techniques for enhancing forecast accuracy and intelligent reporting.

4. Methodology

The methodology was broken down into several stages, from problem definition to intelligent reporting, in order to methodically accomplish the research goals. Table 1 lists each phase along with a description of the activity involved.

Table 1. lists the stages of the forecasting system development methodology.

|

Phase |

Activity Description |

|---|---|

|

1. Problem Definition & Data Understanding |

-Define our objectives with forecasting and our KPIs. Collect our dataset and understand its attributes e.g., Product ID, Store, Price, Promotion, etc. |

|

2. Data Preprocessing & EDA |

-Address missing data and anomalies. Feature extraction (lags, rolling means). Visualizing seasonality, trend, and outliers. |

|

3. Feature Engineering & Data Preparation |

-Create time based features and categorical features. Normalize/scale the data. Train-validation-test splitting. |

|

4. Model Building—Deep learning forecasting |

-LSTM/GRU/Transformer/TCN. Compare to one classical model, xgboost, for benchmarking. |

|

5. Model Evaluation & Robustness testing |

-Keep in mind RMSE, MAE, MAPE, R2 in evaluating the models’ performance. Consider forecasting stability in the event of anomalies. Visual comparison of the predictions vs actual (possibly as part of a report). |

|

6. Dashboard & Visualization Interface |

-Build an interactive dashboard (with Plotly/Streamlit, etc.). Enable product selection, zoomable plots, and error visualization. |

|

7. LLM-based Intelligent Reporting |

-Integrate GPT or similar LLMs to automatically generate commentary. Summarise trends, anomalies, spikes in demand, etc. |

|

8. Finalisation & Deployment |

-Prepare their full technical report. Prepare their project presentation slides. Optional would be the deployment of the dashboard for demonstration. Testing and backups of the project. |

4.1. Project Requirements

The project requirements were divided into two main categories:

4.1.1. Software Requirements

-

-

OS (Windows/Ubuntu): Stable framework for development and deployment.

-

-

Python (3.9+): Most commonly used language for AI/ML.

-

-

TensorFlow/PyTorch: Frameworks for building and training deep learning models. Scikit-learn: Data-preprocessing, evaluation metrics.

-

-

Pandas & NumPy: Efficient data handling and computation.

-

-

Matplotlib/Seaborn: Visualisation of results and trends.

-

-

Hugging Face Transformers: Large language model integration for intelligent reporting.

-

-

VS Code: Easy-to-use coding and experimentation environments.

4.1.2. Hardware Requirements

-

-

CPU (Intel i5/i7): performs all the computations to train/test.

-

-

RAM (8–16 GB): ensures data is processed smoothly.

-

-

GPU (NVIDIA CUDA): speeds up deep learning training.

-

-

Storage (256 GB SSD): quicker read/write speeds for datasets and its models.

-

-

Internet: access the various datasets, pre-trained models, cloud-based tools, etc.

4.2. System Architecture & Analysis

Significant difficulties in multivariate time-series forecasting include learning interference (cross-channel correlations), distribution shifts, establishing causality, modeling spatio-temporal correlations and dependencies, feature extraction from noisy and nonlinear data, and combining models without being overly computationally expensive.

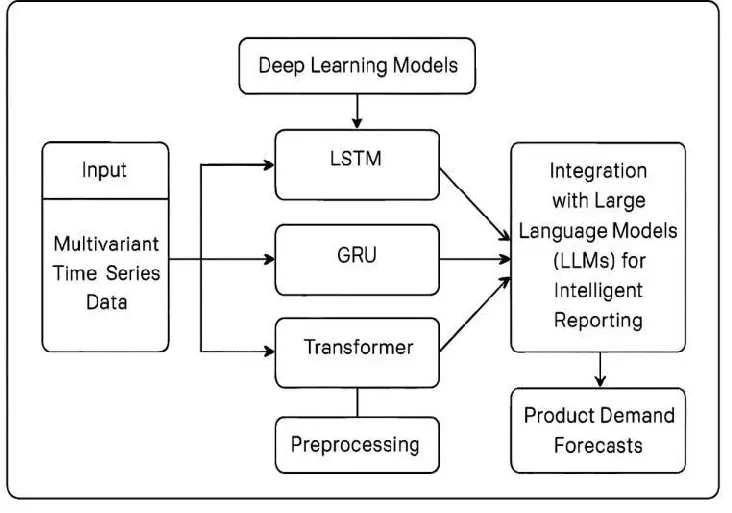

This framework addresses the issue of multivariate time-series data for product demand forecasting in supply chain contexts. With the availability of several methods inspired by deep learning in wide applications, the framework deals with the time-dependence, sequential nature, and long-range dependencies utilizing three options of deep learning models (LSTM, GRU, and Transformers).

A data preprocessing module was included to improve the feature extraction and categorizing by diminishing the noise and uncertainty in the features to make the model more robust. The output from deep learning methods will be input to the Large Language Models (LLM) to provide intelligent reporting and interpretability of the electronic models.

The goal is to provide advanced forecasting and evaluation for application of the forecast instead of uncooked analysis or reporting.

To that end, the final output is the product demand time-series forecast, which will facilitate inventory planning to facilitate efficient optimization of the supply chain. The approach integrates the data and predictive power of deep learning methods with the contextual reasoning and reporting capacity of LLM, to connect the demand signal characterizations with decision-oriented reporting.

The integrated architecture of the proposed forecasting system is illustrated in Figure 1.

Figure 1. Deep Learning–LLM Integrated Architecture for Multivariate Time-Series Demand Forecasting.

4.3. Data Flow Diagrams

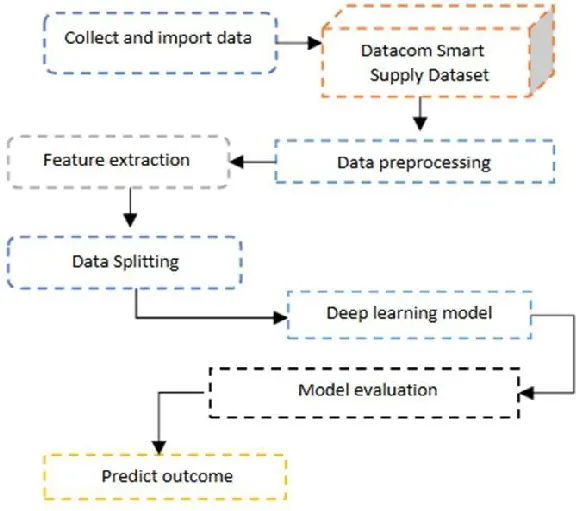

The data flow diagram illustrates the individual steps involved and the methodology behind constructing the forecasting model. The pipeline opens with the data and importation of the Datacom Smart Supply Dataset. The raw data would then require preprocessing to remove missing data, discrepancies, and normalisation. The data would also undergo feature extraction to create relevant attributes needed for the forecast. The cleaned dataset is then split into training and testing sets.

The model will then be trained with the training data to learn the temporal and multivariate patterns from the data using a deep learning model. The model evaluation phase will continuously validate the model through model performance to ensure accuracy and dependability. After successful validation, the trained model would be used to produce predictions to create demand forecasts to steer supply chain decisions.

The steps in the forecasting pipeline are summarized in the data flow diagram shown in Figure 2.

4.4. UML Diagrams

The smart contract capabilities for supply network collaboration depicts the interactions that take place between suppliers, OEMs, and the blockchain system. The lifelines are the message flows, showing the operations-enabling Supplier A, Supplier B, OEM A, and OEM B, and smart contracts SC AA, SC AB, and SC PDU on their respective channels.

For an example of (X + Y) amount of product ordered, it is possible to see the likely interaction and messages sent to allocate orders to suppliers, and from the quality information provided on the final product, how these orders would be sent to suppliers. Scenario 1, describes the SC PDU smart contract action when the final product shows no quality defect, and scenario 2, when a quality defect exists on the final product.

The full dataset is available as supplementary material at https://github.com/Pranav4555/csv (accessed on 18 September 2025).

5. Result

5.1. Performance Evaluation Dashboard

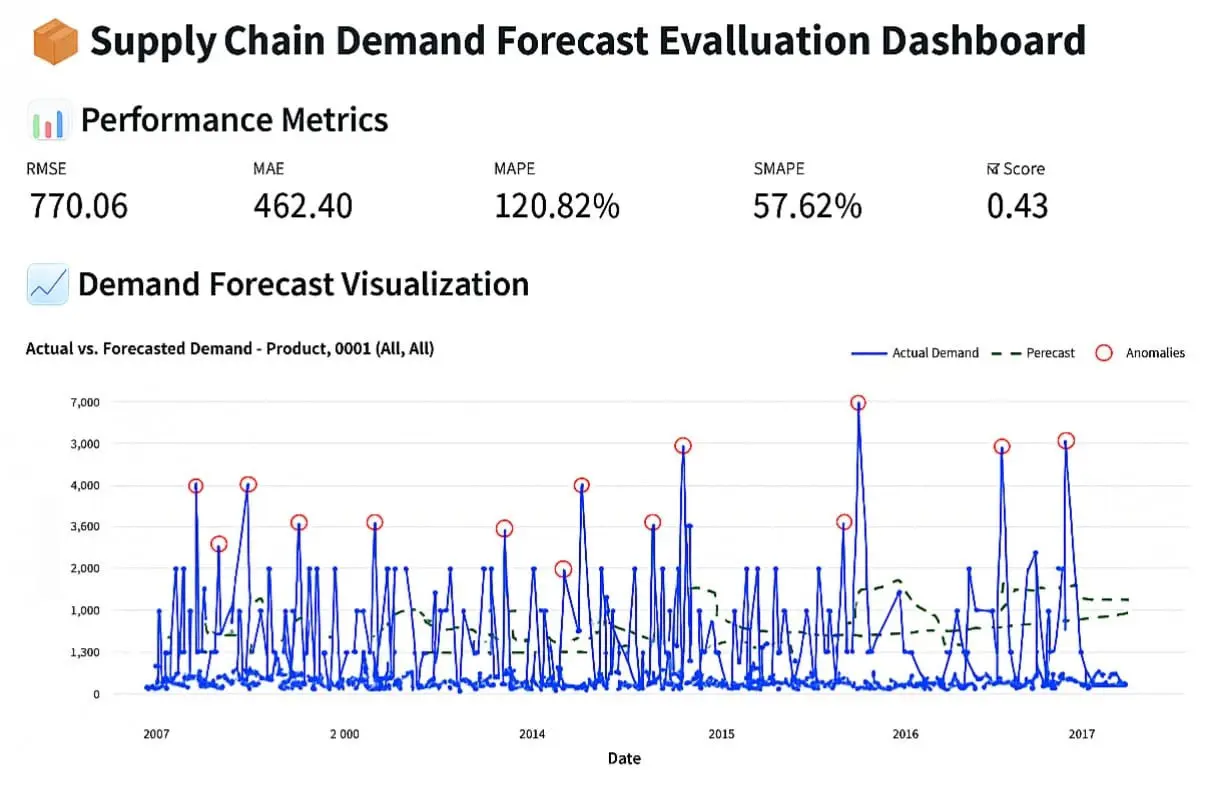

RMSE, MAE, MAPE, SMAPE, and R2 are among the important error metrics taken into account when assessing model performance, as shown in the Performance Evaluation Dashboard (Figure 3). When combined, they offer a thorough understanding of model forecast accuracy. While MAPE and SMAPE provide percentage errors for scale-free comparison, RMSE and MAE show the average absolute error magnitude. R2 quantifies how much of the dataset's variability the model can account for. The most dependable models for demand forecasting can be found with the help of this dashboard, which helps visualize comparisons between models.

5.2. Model Comparison

The LSTM, the GRU, and the Transformer all produced virtually identical forecasts with an expected 7-day demand of a similar 4480.69 units. This similarity indicates the stability of deep learning models for trend forecasting, but also hints at the model performance being influenced by their dampening of the sudden shifts in demand.

5.3. Warehouse-Level Demand Analysis

While the volumes placed through Warehouse J were substantially greater than those taken through Warehouses A and C throughout this study, the order volume across the locations was a little unpredictable. The results indicate that demand is unevenly distributed across the locations and that allocation strategies may require to be more targeted.

5.4. Monthly and Seasonal Trends

The monthly demand analysis also demonstrated significant seasonal variations, with peaks in certain months and stability in others. The presence of seasonality is a significant consideration and deserves to be included in the forecasting models to develop better plans and improved resource allocations.

6. Discussion

6.1. Interpretation of Forecast Accuracy

The models were good at capturing the overall trends in demand; however, they appeared to struggle with non-regular fluctuations. The high MAPE/SMAPE and moderate R2 indicated significantly good accuracy from a planning perspective, although poor reliability in volatile demand.

6.2. Insights into Model Comparison

The consistency across LSTM, GRU, and Transformer indicates the robustness of deep learning. The smoothing however, limits their ability to capture sharp fluctuations in demand.

6.3. Implications for the Supply Chain

These results reinforce the need to prioritize stock at high demand halls (e.g., J) and optimize allocation at low demand warehouse halls (i.e., A, C). While we observed some seasonal trends and yearly trends, it indicates we should be aligning forecasts with expected cyclical demand.

6.4. Value of Anomaly Detection

There were instances when the system flagged unusual demand spikes, allowing for proactive disruption management and contingency planning.

6.5. Shortcomings of the Current Approach

Forecast uncertainty continues to persist, given the broad confidence intervals and lack of ability to account for other external factors (e.g., promotions, holidays, changes in the economy).

7. Conclusions

The research paper ‘Multivariant Time-Series Forecasting Methodology for Product Demand Using Deep Learning and Large Language Models” sounds very promising and highlights the tremendous benefits that such new-age technologies can bring for demand forecasting for a business. Businesses can use proven Deep Learning techniques, especially LSTM, associated with intelligent reporting to substantially enhance their forecasting abilities, thereby improving their decision-making regarding inventory, production, and supply chain planning.

Illustratively, through advanced reporting, the study shows that the intelligent reporting capabilities of deep learning models analysis on the multivariate time series data offer a latent and novel approach that can easily capture the complex interrelations and patterns that exist within the data, and thereby, through advanced reporting, improve the accuracy and timeliness of predictive demand forecasting models. It has been shown that Direct Deep Learning forecasting models and architectures outstrip traditional forecasting methods and techniques in capturing complex and nonlinear relationships and adapting to business environment changes to improve forecasting accuracy.

Furthermore, advanced reporting techniques that are fused with the forecasting methods and models offer stakeholders an understandable and clear presents of the analysis that make predictive forecasting research actionable. These deep learning models.

Supplementary Materials

The following supporting information can be found at: https://www.sciepublish.com/article/pii/704, The full dataset is available as supplementary material at https://github.com/Pranav4555/csv.

Statement of the Use of Generative AI and AI-Assisted Technologies in the Writing Process

The authors employed OpenAI's ChatGPT to help with language polishing, grammar correction, and sentence restructuring for improved readability while preparing this manuscript. To make sure the output was accurate, unique, and in line with the intended meaning, the authors thoroughly examined and revised it. The authors alone bear ultimate responsibility for the content of this manuscript.

Acknowledgment

As the authors of this project, we would like to sincerely acknowledge Seema Vanjire for her unwavering support and guidance throughout our research. We would also like to thank Vishwakarma University, Department of Computer Engineering for the resources provided to us.

Author Contributions

Conceptualization, P.B. and D.P.; Methodology, P.D. and A.K.G.; Software, A.K.; Validation, P.B., D.P. and P.D.; Formal Analysis, P.B.; Investigation, A.K.G. and A.K.; Data Curation, P.D. and A.K.G.; Writing—Original Draft Preparation, D.P. and A.K.; Writing—Review & Editing, S.V.; Visualization, P.B.; Resources, S.V.; Supervision, S.V.; Project Administration, S.V.

Ethics Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Upon reasonable request, the corresponding author will provide the data that support the study’s conclusions.

Funding

This research received no external funding.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

-

Vijaykumar V, Mercy P, Beena LA, Leena HM, Savarimuthu C. Convergence of IoT, artificial intelligence and blockchain approaches for supply chain management. In Blockchain, IoT, and AI Technologies for Supply Chain Management: Apply Emerging Technologies to Address and Improve Supply Chain Management; Apress: Berkeley, CA, USA, 2024; pp. 45–89. [Google Scholar]

-

Roozkhosh P, Pooya A, Agarwal R. Blockchain acceptance rate prediction in the resilient supply chain with hybrid system dynamics and machine learning approach. Oper. Manag. Res. 2023, 16, 705–725. [Google Scholar]

-

Fu X. 6G-driven cyber physical supply chain model for supporting e-commerce industries. Wirel. Pers. Commun. 2024, 1–16. doi:10.1007/s11277-024-11017-2. [Google Scholar]

-

Jauhar SK, Harinath S, Krishnaswamy V, Paul SK. Explainable artificial intelligence to improve the resilience of perishable product supply chains by leveraging customer characteristics. Ann. Oper. Res. 2024, 354, 103–142. doi:10.1007/s10479-024-06348-z. [Google Scholar]

-

Kosasih EE, Papadakis E, Baryannis G, Brintrup A. A review of explainable artificial intelligence in supply chain management using neurosymbolic approaches. Int. J. Prod. Res. 2024, 62, 1510–1540. [Google Scholar]

-

Jackson I, Ivanov D, Dolgui A, Namdar J. Generative artificial intelligence in supply chain and operations management: A capability-based framework for analysis and implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar]

-

Sharma J, Rathore B. Examine the enablers of generative artificial intelligence adoption in supply chain: A mixed method study. J. Decis. Syst. 2024, 1–33. doi:10.1080/12460125.2024.2410030. [Google Scholar]

-

Papastefanopoulos V, Linardatos P, Panagiotakopoulos T, Kotsiantis S. Multivariate time-series forecasting: A review of deep learning methods in Internet of Things applications to smart cities. Smart Cities 2023, 6, 2519–2552. doi:10.3390/smartcities6050114. [Google Scholar]

-

Kaul D, Khurana R. AI-driven optimization models for e-commerce supply chain operations: Demand prediction, inventory management, and delivery time reduction with cost efficiency considerations. Int. J. Soc. Anal. 2022, 7, 59–77. [Google Scholar]

-

Pasupuleti V, Thuraka B, Kodete CS, Malisetty S. Enhancing supply chain agility and sustainability through machine learning: Optimization techniques for logistics and inventory management. Logistics 2024, 8, 73. [Google Scholar]

-

Shavaki FH, Ghahnavieh AE. Applications of deep learning into supply chain management: A systematic literature review and a framework for future research. Artif. Intell. Rev. 2023, 56, 4447–4489. [Google Scholar]

-

Ma X, Wang Z, Ni X, Ping G. Artificial intelligence-based inventory management for retail supply chain optimization: A case study of customer retention and revenue growth. J. Knowl. Learn. Sci. Technol. 2024, 3, 260–273. [Google Scholar]

-

Alshurideh MT, Hamadneh S, Alzoubi HM, Al Kurdi B, Nuseir MT, Al Hamad A. Empowering supply chain management system with machine learning and blockchain technology. In Cyber Security Impact on Digitalization and Business Intelligence: Big Cyber Security for Information Management: Opportunities and Challenges; Springer International Publishing: Cham, Switzerland, 2024; pp. 335–349. [Google Scholar]

-

Subramanian B, Mishra A, Bharathi VR, Mandala G, Kathamuthu ND, Srithar S. Big data and fuzzy logic for demand forecasting in supply chain management: A data-driven approach. J. Fuzzy Ext. Appl. 2025, 6, 260–283. [Google Scholar]

-

Kudrenko I. Navigating the future: AI-driven healthcare supply chains. In Hospital Supply Chain: Challenges and Opportunities for Improving Healthcare; Springer: Cham, Switzerland, 2024; pp. 553–570. [Google Scholar]

-

Ju J, Liu F-A. Multivariate time series data prediction based on ATT-LSTM network. Appl. Sci. 2021, 11, 9373. doi:10.3390/app11209373. [Google Scholar]

-

Fu E, Zhang Y, Yang F, Wang S. Temporal self-attention-based Conv-LSTM network for multivariate time series prediction. Neurocomputing 2022, 501, 162–173. doi:10.1016/j.neucom.2022.06.014. [Google Scholar]

-

Han S, Dong H. A temporal window attention-based window-dependent long short-term memory network for multivariate time series prediction. Entropy 2023, 25, 10. doi:10.3390/e25010010. [Google Scholar]

-

Douaioui K, Oucheikh R, Benmoussa O, Mabrouki C. Machine learning and deep learning models for demand forecasting in supply chain management: A critical review. Appl. Syst. Innov. 2024, 7, 93. doi:10.3390/asi7050093. [Google Scholar]

-

Wen X, Liao J, Niu Q, Shen N, Bao Y. Deep learning-driven hybrid model for short-term load forecasting and smart grid information management. Sci. Rep. 2024, 14, 13720. doi:10.1038/s41598-024-63262-x. [Google Scholar]

-

Lim B, Zohren S. Time-series forecasting with deep learning: A survey. Philos. Trans. R. Soc. A 2021, 379, 20200209. doi:10.1098/rsta.2020.0209. [Google Scholar]

-

Huang L, Mao F, Zhang K, Li Z. Spatial-Temporal Convolutional Transformer Network for Multivariate Time Series Forecasting. Sensors 2022, 22, 841. doi:10.3390/s22030841. [Google Scholar]