Found 3 results

Review

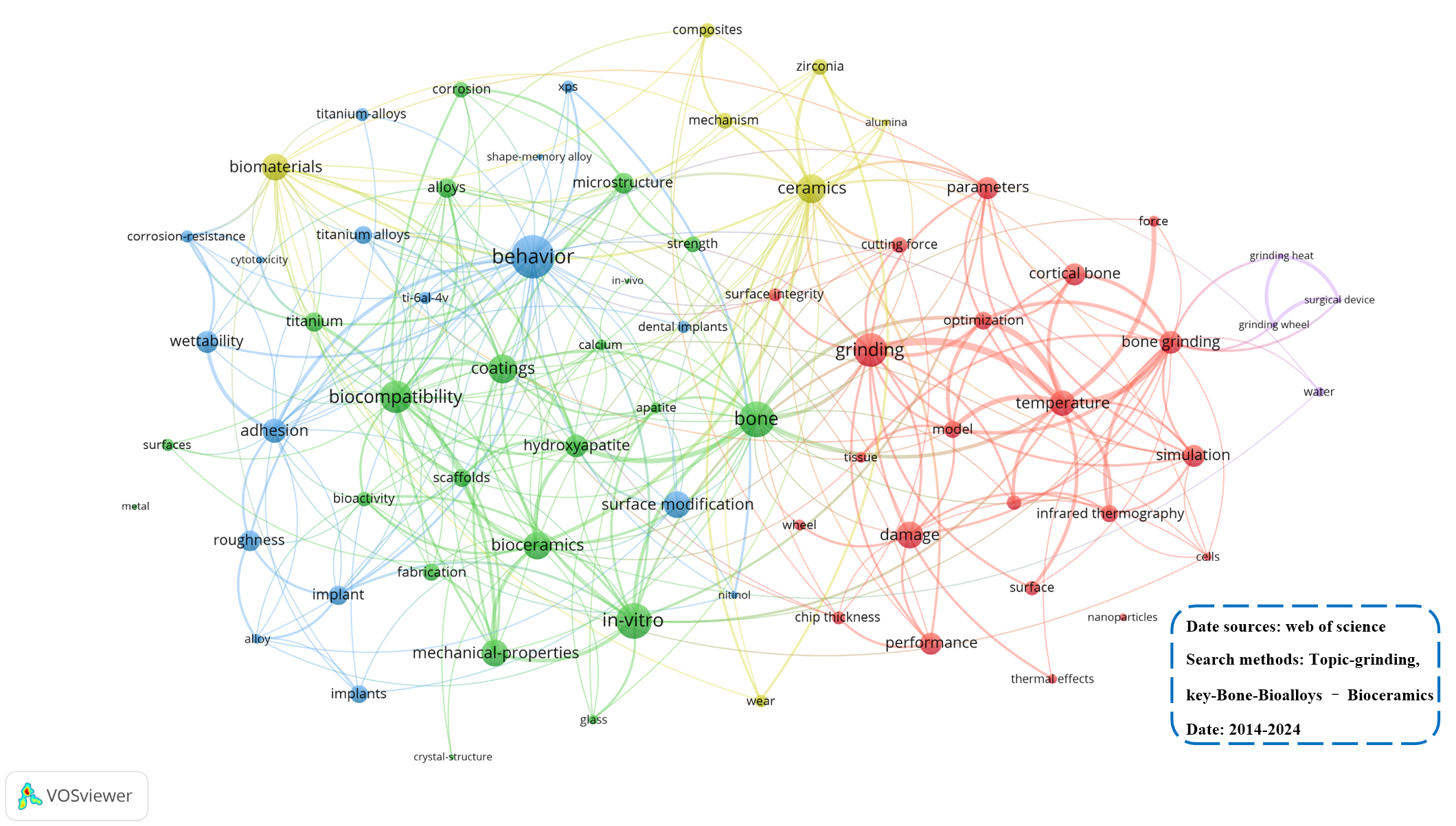

16 January 2025Biological Bone and Replacement Materials in Grinding: Force Model and Processing Capability

Grinding is widely used in orthopedic surgery to remove bone tissue material, but due to the complex and brittle structure of bone, it is prone to mechanical stresses that cause cracks and damage to the bone tissue. Furthermore, bone replacement materials typically have high hardness, strength, and brittleness, which lead to increased tool wear and damage, such as cracks and deformation during grinding. Therefore, ensuring the surface quality of bone and replacement materials during the grinding process has become a critical issue. This necessitates the development of grinding force models that consider various processing parameters, such as feed rate and cutting depth, to guide industrial production. However, currently, research on the grinding force prediction models for bone tissue and its replacement materials is relatively scarce, and there is a lack of corresponding grinding force model reviews for unified guidance. Based on this, this article focuses on bone grinding technology and, conducts a critical comparative analysis of the grinding force models for bone tissue and its replacement materials, and then summarizes the grinding force prediction models in the grinding process of bone tissue and bone replacement materials. First, according to the material types and material removal mechanisms, the materials are categorized into bone tissue, bio-inert ceramics, and bio-alloys, and the material removal process during grinding is analyzed. Subsequently, the grinding force prediction models for each material and the accuracy errors of each model are summarized. The paper also reviews the application of these grinding force prediction models, explaining how processing parameters such as feed rate and cutting depth influence grinding forces and their interrelationship. Finally, in light of the current issues in the grinding of bone tissue and replacement materials, potential future research directions are proposed, aiming to provide theoretical guidance and technical support for improving the grinding quality of bone tissue and its replacement materials.

Article

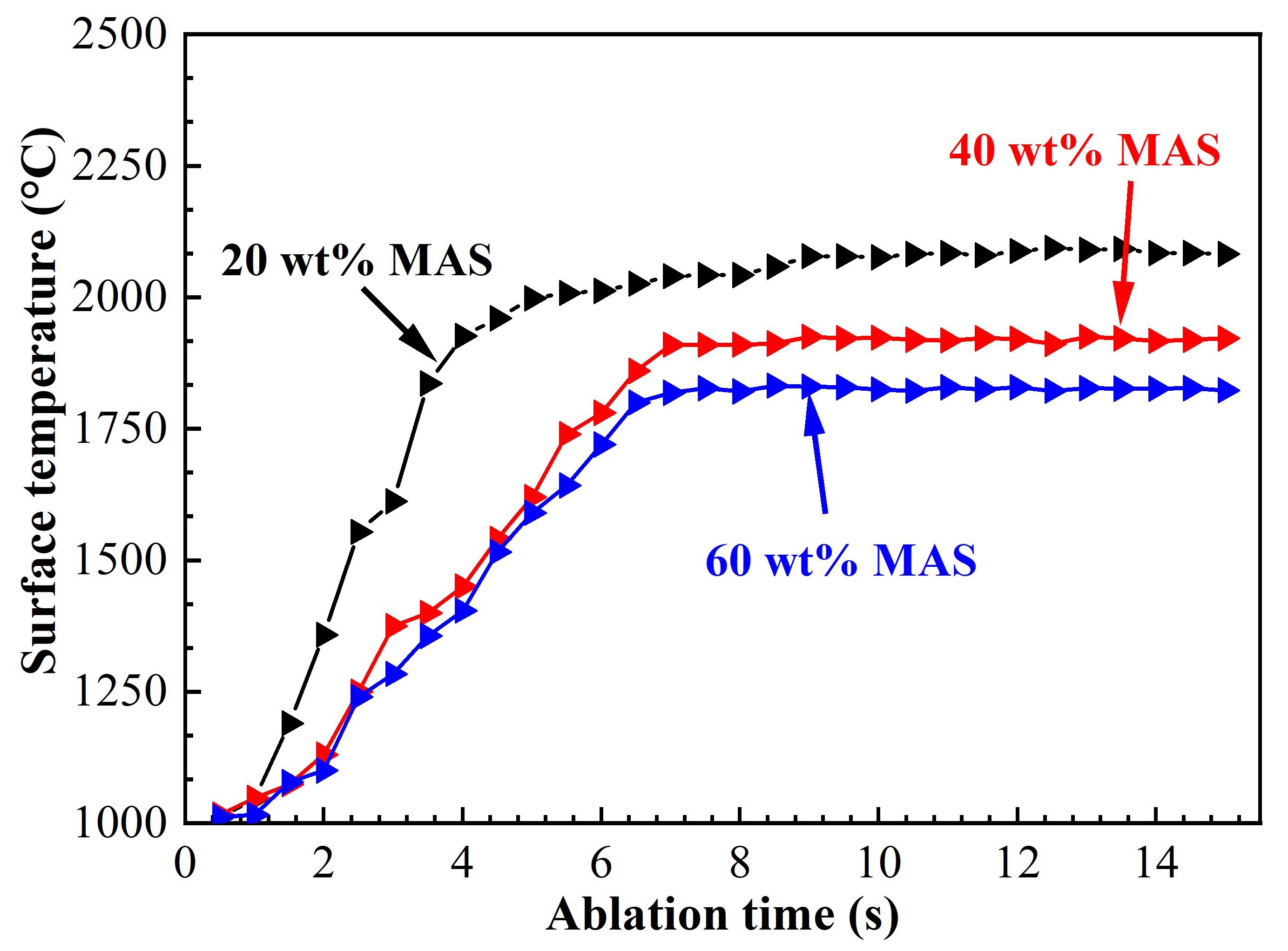

27 December 2024Effect of Magnesium Aluminum Silicate Addition on the Ablation Resistance of BN Matrix Ceramics

Ablation resistance is a critical factor in evaluating the performance of BN-based ceramic composites under extreme service conditions. This study investigates the ablation behavior and underlying mechanisms of BN-MAS wave-transparent ceramic composites with varying magnesium aluminum silicate (MAS) content through oxyacetylene torch tests. The results reveal that increasing the MAS content reduces the mass ablation rate from 0.0298 g/s to 0.0176 g/s and the linear ablation rate from 0.149 mm/s to 0.112 mm/s. The incorporation of MAS into h-BN ceramics significantly lowers the surface ablation temperature, primarily due to the evaporation of B2O3 (g) and MAS ceramics. Cross-sectional analysis of the ablated composites indicates the presence of micro- and macro-spallation in the ablation center. The primary ablation products are magnesium-aluminum borosilicate glass and mullite. Key ablation mechanisms include the oxidation of h-BN under flame exposure, the erosion of viscous oxidation products, and the physical degradation of the matrix caused by the high-velocity gas flow.

Article

11 October 2023Fibrous SiC-based Mesoporous Solids for the Photocatalytic Degradation of Organic Pollutants under Artificial Light

SiC-based mesoporous solids with fibrous nanostructure were prepared by impregnation of a polycarbosilane precursor on annealed polyacrylonitrile (PAN) fibers and subsequent pyrolysis. The obtained material exhibits a mesoporous structure and has a specific surface area of ~20 m2/g. It has a semiconducting electronic character with a bandgap of 2.65 eV, i.e., in the visible range. Adsorption tests of methylene blue were performed on the material under dark conditions, which showed an adsorption amount of 78 wt%. The photocatalytic activity of the material was then evaluated for the degradation of the dye under artificial daylight irradiation over a period of 7 h. A degradation of 94 wt% was achieved. Regeneration and reuse of the material was also tested and resulted in 97 wt% degradation after reuse, indicating potential interest of the material as a contactor in environmental remediation devices.