1. Introduction

In the process of oil exploitation and processing, a large amount of waste oily sludge is produced. These sludges are discharged directly into the environment without treatment, which will seriously endanger the safety of the environment and human health [

1,

2,

3]. In order to reduce the harm of oily sludge, the commonly used treatment technologies are: incineration, chemical extraction and thermal desorption [

4]. Because these treatment technologies have their own advantages and disadvantages in terms of treatment effect and operation difficulty, how to scientifically and reasonably evaluate these technologies and select the most suitable oily sludge treatment technology for the oil industry has become an urgent problem to be solved [

5].

At present, the commonly used technical evaluation methods for oily sludge at home and abroad mainly include: analytic hierarchy process [

6,

7,

8,

9,

10], fuzzy comprehensive evaluation method [

11,

12], grey correlation analysis method [

13,

14], Delphi method [

15] and data envelopment analysis method [

16]. In the process of system evaluation, the comments used are usually ambiguous, and the fuzzy comprehensive evaluation method (FCE) is most suitable. However, the weight of fuzzy evaluation is given by experts based on experience, which is inevitably subjective [

17]. The analytic hierarchy process (AHP) is a quantitative evaluation of the qualitative indicators in the evaluation system, which can minimize the drawbacks caused by personal subjective assumptions and make the evaluation results more realistic [

18,

19]. By combining AHP and FCE [

20], a comprehensive quantitative evaluation of multiple factors in the evaluation system can be carried out. The AHP-FCE method has been applied in many fields, including the evaluation of water pollution control technology in zinc smelting industry [

18], the evaluation of cleaner production technology in pharmaceutical industry [

21], the selection of sewage sludge heat treatment process [

22], the impact of oil projects on the environment [

23], the evaluation of the best technology of cold rolled coil manufacturing process [

24] and the evaluation of heavy metal pollution prevention and control technology [

21]. The above cases have achieved good results by using this method.

With the continuous promotion of the national practice of green low-carbon action, the research on carbon emissions of various production technologies has gradually become a trend. At present, there are few studies on the application of carbon emission evaluation to oily sludge treatment technology. Moreover, the evaluation of oily sludge treatment technology is a complex multi-objective decision-making problem [

14], which involves many factors, so it needs to be considered from multiple levels.

This paper will evaluate the oily sludge treatment technology from four aspects of environment, economy, society and technology. Since China is the world’s largest carbon emitter, and the production of industrial technology is closely related to carbon emissions, this paper first considers the impact of processing technology on the environment, and uses the emission factor method to calculate the carbon emissions of processing technology. Secondly, considering the impact of these four aspects, the appropriate processing technology is selected through the comprehensive score of AHP-FCE. The research content provides theoretical support for oilfield enterprises to choose oily sludge treatment technology according to local conditions.

2. Research Methods

2.1. Carbon Emissions Accounting Method

In order to reduce the impact of industrial technology on the environment, the carbon emissions of various technologies have strict requirements. Carbon emissions accounting is the premise of effective carbon reduction work. It can directly quantify the data of carbon emissions. At present, the accounting methods of carbon emissions mainly include emission factor method, mass balance method and measurement method. Because the emission factor method has the advantages of wide application range and can calculate the carbon emissions of specific regions, this paper chooses the emission factor method, and the calculation formula is as follows [

25].

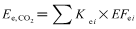

The power consumption is as formula (1).

In the formula above,

Ee,CO2 is the CO

2 emissions from electricity consumption, kg;

Kei is the power consumption, KW·h;

EFei is the carbon emission factor for electricity, kg CO

2/KW·h.

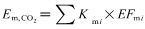

The natural gas consumption is as formula (2).

In the formula above,

Eh,CO2 is the CO

2 emissions from natural gas consumption, kg;

Khi is the natural gas consumption, m

3;

EFhi is the carbon emission factor for natural gas, kg CO

2/m

3.

The chemical consumption is as formula (3)

In the formula above,

Em,CO2 is the CO

2 emissions from the use of chemical, kg;

Kmi is the consumption of chemical, kg;

EFmi is the carbon emission factors for chemical, kg CO

2/kg.

In the above calculation formulas, the carbon emission coefficient of electricity is determined according to the document issued by the Ministry of Ecology and Environment “Notice on Doing a Good Job in the Management of Greenhouse Gas Emission Reports of Power Generation Industry Enterprises in 2023–2025”. The average emission factor of the national power grid in 2022 is 0.5703 t CO

2/MW·h [

26]; the carbon emissions of energy and materials are determined according to various CO

2 emission factors included in the 2006 IPCC Guidelines for National Greenhouse Gas Inventories [

27]. It can be seen that the carbon emission factor of natural gas is 2.66 kg CO

2/m

3, the carbon emission factor of fuel coal is 2.53 kg CO

2/kg, the production emission factor of diesel oil is 2.73 kg CO

2/L, and the carbon emission factor of extractant is 1.60 kg CO

2/L.

2.2. AHP-FCE Analysis Method

The AHP-FCE method is a more comprehensive evaluation system at present. The evaluation model consists of two parts, which echo each other. The evaluation process of sustainable treatment technology for oily sludge is shown in .

2.2.1. Establishment of Oily Sludge Technology Evaluation System

Based on the characteristics of oily sludge, such as great harm, high treatment difficulty and strong treatment timeliness [

28], the AHP-FCE model for the evaluation of oily sludge treatment technology is established. The model includes 4 primary indicators and 19 secondary indicators, as shown in .

. Evaluation system of the best applicable technology for oily sludge treatment in Chinese Shengli Oilfield.

2.2.2. Calculation of weights using AHP

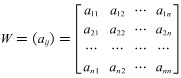

To determine the importance of each element to the previous level, this study cites a scaling method of 1–9 and its reciprocal. The meaning of the judgment scale is shown in , and the indicators are assessed by the use of expert survey. The judgment matrix

W of the importance relationship between each evaluation indicator is shown in formula (4) [

29].

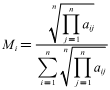

Based on the obtained judgment matrix

W, the square root method is used to determine the weights of the evaluation indicators at all levels, as shown in formula (5)

Therefore,

Ni = (

M1,

M2,···,

Mn)

T is the eigenvector of matrix

W.

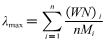

The maximum eigenvalue can be calculated by equation (6).

In the formula above, (

WN)

i is the

ith component of matrix

WN.

We calculate the consistency ratio of judgment matrix

CR using formula (7). If

CR < 0.1, then the judgment matrix is considered to pass the consistency test.

In the formula above,

CI is the matrix consistency indicator, and

RI is the average random consistency indicator.

Through the investigation of solid waste managers, on-site drilling engineers and experts engaged in the research of oily solid waste in scientific research units of Shell, Chinese National Petroleum Corp and Sino Petroleum Corp, a total of 10 questionnaires was obtained. Through the evaluation of the relative importance of the evaluation indexes of the processing technology by various relevant workers, the judgment matrix of the criterion layer and each index layer was obtained, and the weight was calculated by the square root method (helped by Yaahp V10.5 software).

After calculation, the judgment matrix CR value of the criterion layer and each indicator layer was less than 0.1, and hence each weight value can be applied. After obtaining the weights of each criterion layer and indicator layer, based on the total ranking principle of AHP, the comprehensive weight value of each indicator to the total target “best technology” was obtained.

. Judgment matrix scale and its meaning.

2.2.3. Construction of the Fuzzy Comprehensive Evaluation

(1) Construction of the value set and index membership

By constructing a value set

V = (

V1,

V2,

V3,

V4,

V5,

V6,

V7) = (Excellent, Great, Good, Medium, Ordinary, Bad, Poor). After we considered the evaluation index system of oily sludge treatment technology comprehensively, we determined the evaluation grade standard through on-site research and sampling, experiments on the physical and chemical properties of oily sludge, and expert discussion (). Then, through expert judgment and statistical analysis of the results, the membership degree matrix Ri was obtained.

(2) Multi-level fuzzy comprehensive evaluation

According to the hierarchical structure model, a two-level fuzzy comprehensive evaluation was adopted. First, according to formula (8), we constructed a fuzzy membership matrix

Ri and weight matrix

Wi of the indicator layer

B contained in the criterion layer

Ai, and obtained the membership degrees of different evaluation levels corresponding to each index in criterion layer

A through first-level fuzzy synthesis operation. According to formula (9), we obtained the second-level fuzzy comprehensive value set [

30].

(3) Comprehensive evaluation score

The performance description of the index value set “excellent, very good, better, medium, general, poor and poor” is given 7 points, 6 points, 5 points, 4 points, 3 points, 2 points and 1 point respectively. shows three oily sludge treatment technologies.

The final fuzzy comprehensive evaluation value set of the oily sludge treatment technology was multiplied by the corresponding weights of the indicators to obtain the final comprehensive evaluation score.

. The score membership normalized date of the three technical evaluation indexes.

3. Results and Discussion

3.1. Carbon Emissions Accounting of Oily Sludge Treatment Technology

In order to promote the sustainable development of the world, carbon emission is an important environmental indicator to be considered when selecting oily sludge treatment technology. The process flow of incineration technology, chemical extraction technology and thermal desorption technology is shown in . The specific energy consumption and material consumption are shown in .

The carbon emissions of incineration technology, chemical extraction technology and thermal desorption technology were 42.70 t CO

2-eq/t, 4.80 t CO

2-eq/t and 0.10 t CO

2-eq/t, respectively. It can be seen that the carbon emission of incineration technology is the highest, which is 483.6 times that of the thermal desorption technology. Therefore, incineration technology will produce a large amount of greenhouse gases and accelerate global warming. In contrast, chemical extraction technology and thermal desorption technology have less carbon emissions and have a relatively small impact on the climate. When considering the carbon emission indicators, chemical extraction technology and thermal desorption technology that generate less greenhouse gases can be considered first.

. Oily sludge treatment process: (a) incineration technology; (b) chemical extraction technology; (c) thermal desorption technology.

. Carbon emissions accounting of three technologies.

According to the characteristics of oily sludge, such as great harm, high treatment difficulty and strong treatment timeliness, 4 primary indicators of environment, economy, society and technology and 19 secondary indicators of solid-phase oily environment compliance rate and secondary pollutant removal efficiency are determined. Through the statistically summarized the scores of each evaluation indicator, and normalize the score results to obtain the membership degree of each evaluation indicator.

On this basis, three mainstream oily sludge treatment technologies are selected for evaluation: incineration technology, chemical extraction technology, and thermal desorption technology. According to the fuzzy evaluation relationship matrix of each layer and the weight set of evaluation factors, the fuzzy comprehensive evaluation mathematical model is used in the calculation, and the evaluation scores and comprehensive evaluation scores of each index in the oily sludge treatment technology are obtained as shown in .

shows that the environmental indicators account for 0.6173, the economic indicators account for 0.0565, the social indicators account for 0.2433, and the technical indicators account for 0.0829. Environmental and social impacts are a major concern due to the enormous pressure on environmental protection policies in countries around the world. Among the 19 weighted indicators, the weight of the compliance rate of the solid-phase oily environment is 0.4317, ranking first, which is consistent with the fact that oil content is the key emission indicator of many countries’ environmental protection policy, where requirements for oily sludge treatment and discharge around the world are becoming more and more strict [

32].

From the perspective of environmental benefit A1, the high-temperature incineration technology and thermal desorption technology scored higher on the B1 index, indicating that these two technologies can effectively reduce the oil content in oily sludge to 0.3%. However, the effect on the B3 index is not ideal, because the fly ash, flue gas generated during the combustion process and the exhaust gas generated during the thermal desorption process will cause secondary pollution [

33]. Compared with the other two technologies, the extraction process of chemical extraction technology is a physical process, which does not produce new chemical pollutants, eliminates the risk of secondary pollution to the environment, and therefore scores higher on the B3 indicator.

. Weight of each factor in the indicator layer to the target layer.

From the perspective of economic benefit A2 and social benefit A3, the high-temperature incineration technology has a serious waste of resources due to the large energy consumption, and the difficulty in recycling heat and crude oil [

22]. Therefore, the specific indicators of B4–B9 and B10–B13 scored the lowest. Due to the high operating temperature of thermal desorption technology, the quality of recovered oil is poor, and the score of B8 index is low. Because the chemical extraction technology maintains the original performance of crude oil and has a high recovery rate, it scores high on the indicators of B8 and B9, and maximizes the value of resource utilization [

23]. In terms of social benefits, both technologies belong to the mainstream technology of oily sludge reduction [

21,

24,

34].

From the technical aspect of A4, the incineration technology has high scores in B15, B16 and B19 indicators, suggesting that the technology is mature and has good adaptability to sludge, but there are also problems such as the large area of the whole set of equipment and the difficulty of reconstruction and expansion. Thermal desorption technology is relatively mature and has good adaptability to sludge, so it scores higher on B15 and B19 indicators. However, there are also problems such as complex installation and harsh control conditions, and the score is low in the B16 indicator. Comparatively speaking, the chemical extraction technology has higher scores in B14, B15 and B16 indicators, indicating that the technology occupies a small area, the technology is relatively mature, and it is easy to implement [

35].

Based on the above analysis, the three oily sludge treatment technologies have their own advantages and disadvantages in these 19 indicators. According to the quantitative comprehensive evaluation scores obtained by the AHP-FCE method, the incineration technology scored 4.59, the chemical extraction technology scored 5.16, and the thermal desorption technology scored 4.95. Therefore, it is more advantageous to choose the chemical extraction technology with the highest comprehensive score. However, due to the different actual situation of each oil and gas field enterprise, the emphasis of each index factor in the index layer is also different, so the corresponding oily sludge treatment technology can be selected according to its score.

4. Conclusions

Taking the current three mainstream oily sludge treatment technology as an example, this paper considers the impact of carbon emissions on the environment, and then tests the physical and chemical properties of oily sludge through experiments to determine the evaluation index of oily sludge treatment technology. The AHP-FCE method is used to calculate the comprehensive score, and the following conclusions are obtained:

(1) By analyzing the impact of oily sludge treatment technology on the environment, the carbon emissions of the three technologies were calculated using the emission factor method. Among them, the highest carbon emissions of incineration technology were 42.70 t CO2-eq/t, the lowest carbon emissions of thermal desorption technology were 0.10 t CO2-eq/t and the carbon emissions of chemical extraction technology was 4.80 t CO2-eq/t. thermal desorption technology and chemical extraction technology with lower carbon emissions are preferred. Because the greenhouse effect is closely related to gases such as carbon dioxide, thermal desorption technology and chemical extraction technology with low carbon emissions are favored.

(2) When AHP-FCE method was used for comprehensive evaluation, the highest score of chemical extraction technology was 5.16, the lowest score of high temperature incineration technology was 4.59, and the score of thermal desorption technology was 4.95. Due to the continuous improvement of people’s awareness of environmental protection, high temperature incineration technology will be gradually eliminated; thermal desorption technology is suitable for oily solid wastes which are difficult to be treated, such as impurities and complex components. Chemical extraction technology is the best choice, which is suitable for the treatment of high oil content solid waste, and the value of resource recovery is very high.

(3) The comprehensive application of carbon emission evaluation and AHP-FCE evaluation is a scientific and reasonable research method. The chemical extraction technology with relatively low carbon emission and the highest comprehensive technical score is the best oily sludge treatment method, which can provide theoretical reference for technicians to choose oily sludge treatment technology.

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 52100135), Sichuan University Postdoctoral Interdisciplinary Innovation Fund (Grant No. JCXK2207), and the Young Elite Scientists Sponsorship Program by CAST (Grant No. 2022QNRC001).

Author Contributions

Conceptualization, Jiwei Wu and Liang Ma; Methodology, Jiwei Wu; Software, Shifan Zhang and Jian Li; Validation, Haocheng Sun, Zixian Jia and Ye Xia; Formal Analysis, Jianqiang Sun; Investigation, Jiankun Liu; Resources, Jie Liu and Dongliang Pan; Data Curation, Xianzhong Yi; Writing – Original Draft Preparation, Jian Li and Shifan Zhang; Writing – Review & Editing, Jiwei Wu and Liang Ma; Visualization, Shifan Zhang and Jian Li; Supervision, Jiwei Wu; Project Administration, Jiwei Wu; Funding Acquisition, Jiwei Wu.

Funding

This research was funded by [National Natural Science Foundation of China] grant number [52100135], [Sichuan University Postdoctoral Interdisciplinary Innovation Fund] grant number [JCXK2207] and [Young Elite Scientists Sponsorship Program by CAST] grant number [2022QNRC001].

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

1.

Wang Y. Research and application of oil sludge resource utilization technology in oil field.

IOP Conf. Ser. Earth Environ. Sci. 2018,

170, 032026.

[Google Scholar]

2.

Teng Q, Zhang D, Yang C. A review of the application of different treatment processes for oily sludge.

Environ. Sci. Pollut. Res. 2021,

28, 121–132.

[Google Scholar]

3.

Hu G, Feng H, He P, Li J, Hewage K, Sadig R. Comparative life-cycle assessment of traditional and emerging oily sludge treatment approaches.

J. Clean. Prod. 2020,

251, 119594.

[Google Scholar]

4.

Cai H, Yao X, Hua S, Xu C, Gong H, Li X, Wu B. Solidification treatment technology of oil-based drilling cuttings in shale gas well.

Chin. J. Environ. Eng. 2017,

11, 3120–3127.

[Google Scholar]

5.

Zhu M. Experimental Study and Numerical Simulation of Supercritical Carbon Dioxide Extraction of Petroleum from Solid Phase; Southwest Petroleum University: Chengdu, China, 2017

6.

Guo J, Zhang Z, Sun Q. Research and Application of Analytic Hierarchy Process.

China Safety Sci. J. 2008,

18, 148–153.

[Google Scholar]

7.

Sun W, Wang JL, Feng CM, Cao P, Han W. Weighting of performance index by analytic hierarchy process for water supply enterprises.

Appl. Mech. Mater. 2013,

409, 1004–1007.

[Google Scholar]

8.

Xu X, Tan Q, Liu L, Li J. Evaluation of medical waste disposal technology based on Analytic Hierarchy process.

Environ. Sci. 2018,

39, 5717–5722.

[Google Scholar]

9.

Wang Q, Wang B, Yu H. Evaluation of electrolytic manganese wastewater treatment technology based on Analytic Hierarchy process.

J. Environ. Eng. 2013,

7, 4714–4718.

[Google Scholar]

10.

Li Y, Zhu C, Li H. Evaluation of agricultural non-point source pollution control technology based on Analytic Hierarchy process.

J. Environ. Eng. Technol. 2019,

9, 355–361.

[Google Scholar]

11.

Xiong D, Xian X. Improvement of fuzzy comprehensive evaluation method.

J. Chongqing Univ. Nat. Sci. 2003,

26, 93–95.

[Google Scholar]

12.

Liu H, Li L, Jiang B, Ni L, Yang J. Application of fuzzy comprehensive evaluation method in technical evaluation of end water treatment in industrial park.

Environ. Pollut. Control 2017,

39, 644–648.

[Google Scholar]

13.

Wang J, Guo J, Lian X. A comparative study of two improved gray Myron analysis methods.

J. North China Electr. Power Univ. 2005,

32, 72–76.

[Google Scholar]

14.

Yu H, Zhang K. The application of grey relational analysis model in the performance evaluation of agricultural product logistics companies.

Appl. Mech. Mater. 2014,

687, 5165–5168.

[Google Scholar]

15.

Brady SR. Utilizing and adapting the Delphi method for use in qualitative research.

Int. J. Qual. Methods 2015,

14, 1609406915621381.

[Google Scholar]

16.

Lim DJ. Technology forecasting using DEA in the presence of infeasibility.

Int. Trans. Oper. Res. 2018,

25, 1695–1706.

[Google Scholar]

17.

Han L, Mei Q, Lu Y, Ji M. Analysis and Research of AHP-Fuzzy Comprehensive Evaluation Method.

China Safety Sci. J. 2004,

14, 89–92.

[Google Scholar]

18.

Ruan J, Wang Y, Guo Y. Evaluation of water pollution control technology in zinc smelting industry based on AHP and fuzzy comprehensive evaluation.

J. Environ. Eng. Technol. 2021,

11, 976–982.

[Google Scholar]

19.

Shi F, Wang W, Dan Z, Yao Y, Yuan W, Yin S, et al. Evaluation of whole process control technology for electrolytic manganese wastewater based on AHP-FCE.

Nonferrous Metals (Smelting) 2022,

7, 109–116.

[Google Scholar]

20.

Li J, Shen L, Wang L, Huang J, Qian F, Zeng P, et al. Evaluation of cleaner production technology in pharmaceutical industry based on AHP-FCE model.

J. Environ. Eng. Technol. 2022,

12, 1541–1547.

[Google Scholar]

21.

Shao L, Chen G. Evaluation of heavy metal pollution prevention technology based on AHP-FCE. In Proceedings of the International Conference on Biological Engineering and Pharmacy 2016 (BEP 2016), Shanghai, China, 9–11 December 2016; pp. 223–226.

22.

Đurđević D, Trstenjak M, Hulenić I. Sewage sludge thermal treatment technology selection by utilizing the analytical hierarchy process.

Water 2020,

12, 1255.

[Google Scholar]

23.

Gao CJ, Li DP. Fuzzy comprehensive assessment on environmental impact of petroleum project.

Appl. Mech. Mater. 2013,

295, 734–737.

[Google Scholar]

24.

Huyen DTT, Tram LTB, Truong HN, Thanh TT. Application of fuzzy analytic hierarchy process and linear goal programing for selection of best available techniques of the cold rolled coil manufacturing processes: A case study in Binh Duong, Vietnam.

Environ. Qual. Manag. 2022,

31, 325–346.

[Google Scholar]

25.

You Y, Peng Z, Dai D, Sang Z, Luo H, Jia Y, et al. Calculation and analysis of carbon emissions in the whole life cycle of 40.5 KVC-GIS.

High Voltage Electr. Appl. 2022,

58, 13–19.

[Google Scholar]

27.

IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventory; IPCC: Geneva, Switzerland, 2006.

28.

Kang D, Lin H, Niu D, Tian G, Xu R, Zhang Z, et al. Research progress and prospect of oily sludge characteristics and treatment technology.

China Environ. Sci. 2023,

43, 4106–4120.

[Google Scholar]

29.

Pu H, Luo K, Zhang S. Risk assessment model for different foodstuff drying methods via AHP-FCE method: A case study of “coal-burning” fluorosis area of Yunan and Guizhou Province, China.

Food Chem. 2018,

263, 74–80.

[Google Scholar]

30.

Shi F, Wang W, Dan Z, Yao Y, Yuan W, Yin S, et al. Evaluation of Whole-process Control Technology of Wastewater in Electrolytic Manganese Industry Based on AHP-FCE Model.

Nonferrous Metals (Extractive Metallurgy) 2022,

7, 109–116.

[Google Scholar]

31.

Control Standards of Pollutants in Sludge for Agricultural Use. GB 4284-2018; Standardization Administration of the People's Republic of China: Beijing, China, 2018.

32.

Emission Standard of Pollutants for Petroleum Refining Industry. GB 31570-2015; State Environmental Protection Administration of China; State Bureau of Technical Supervision: Beijing, China, 2015.

33.

Varjani SJ, Gnansounou E, Pandey A. Comprehensive review on toxicity of persistent organic pollutants from petroleum refinery waste and their degradation by microorganisms.

Chemosphere 2017,

188, 280–291.

[Google Scholar]

34.

Roudneshin M, Azadeh A. A novel multi-objective fuzzy model for optimization of oil sludge management by considering Health, Safety and Environment (HSE) and resiliency indicators in a gas refinery.

J. Clean. Prod. 2019,

206, 559–571.

[Google Scholar]

35.

Xiong D, Wang C. Physical characteristics and environmental risks assessment of oil-based drilling cuttings residues used for subgrade materials.

J. Clean. Prod. 2021,

323, 129152.

[Google Scholar]