Found 2 results

Open Access

Article

12 September 2025Polymer Composites Based on Natural Minerals with Different Compositions and Their Strength Indicators

The presented scientific research work is dedicated to solving the problem of obtaining polymer composite materials with various superior operational properties based on polyolefins and a number of natural mineral rocks characterized by their corresponding characteristics, and investigating the application possibilities of the created materials. In this regard, local natural mineral resources are prepared for research in laboratory conditions through technological processes and mixed with a polymer matrix using a physical-mechanical method. The resulting mixture is brought to a ready state for research and is introduced into the process. Composite samples created on the basis of polyolefin and mineral rock are sent for research in accordance with different ratios of the components that make up the composite. The goal is to find the optimal ratio and determine the material that reflects higher quality criteria. Research conducted in this direction has yielded positive results. Research work that meets the requirements of modern chemical science can be considered satisfactory from an ecological and economic perspective.

Open Access

Article

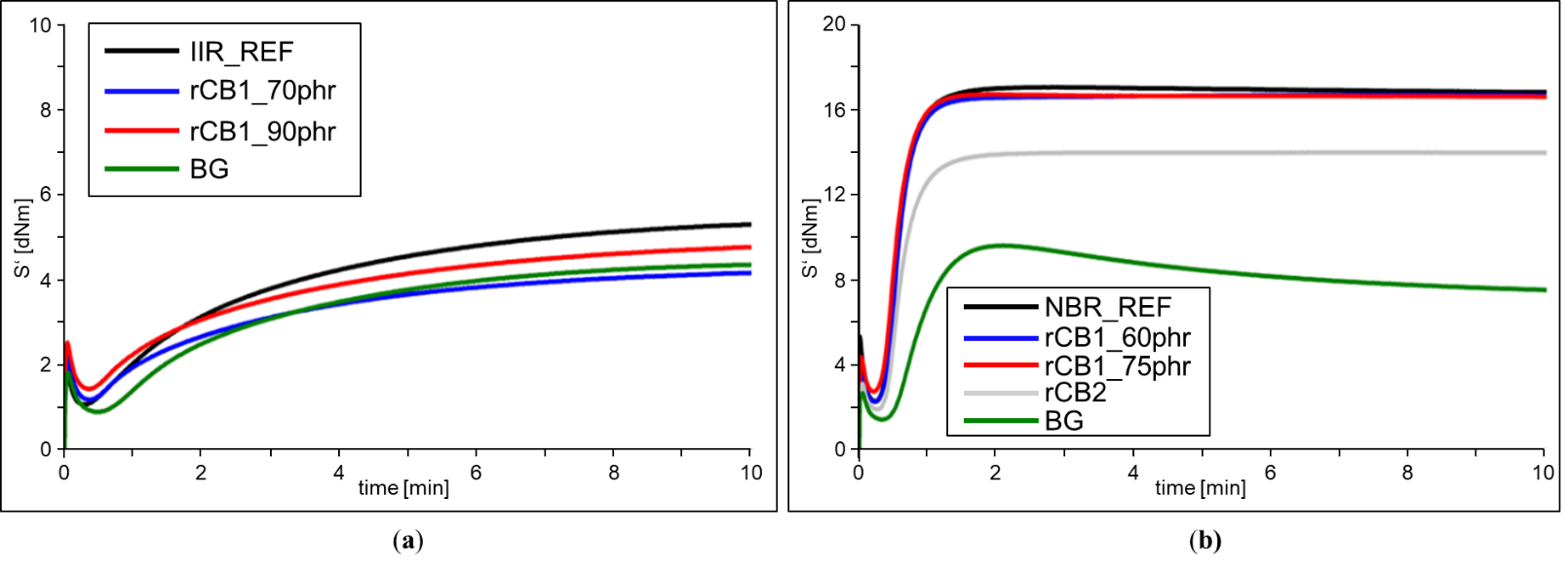

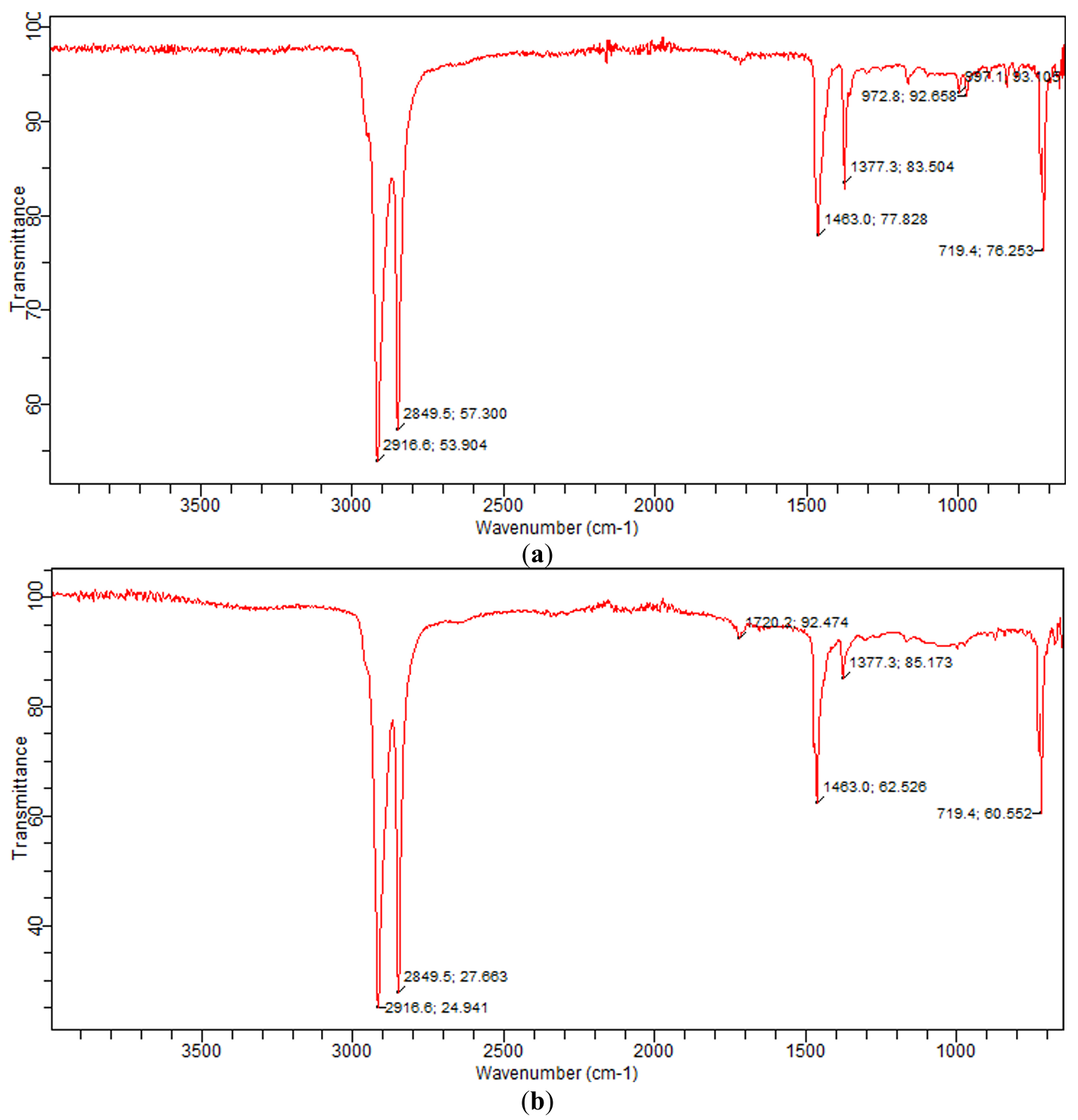

29 April 2025Application of recovered Carbon Black (rCB) by Waste Tire Pyrolysis as an Alternative Filler in Elastomer Products

The increasing global accumulation of End-of-Life (EoL) tires and the growing demand for fossil industrial Carbon Black (CB) call for sustainable alternative solutions. In this context, tire pyrolysis and the resulting recycled raw material recovered Carbon Black (rCB), are considered potential alternatives. In the study, various rCBs were incorporated into new elastomer compounds using a laboratory internal mixer and their properties were investigated. The compounds were selected based on examples of applications such as bicycle inner tubes and hydraulic membranes. By comparing the in-rubber properties of rCB-based compounds with CB reference compounds, an initial assessment of the potential use of rCB for the chosen products was derived. Compared to industrial carbon black, the use of rCB leads to a reduction in performance. Although increasing the filler content partially compensated for the mineral content in rCB and led to a slight improvement, it could not fully offset the performance loss.