Found 3 results

Open Access

Review

21 February 2025Cement-Free Binders in Alumina-Magnesia Refractory Castables—A Review

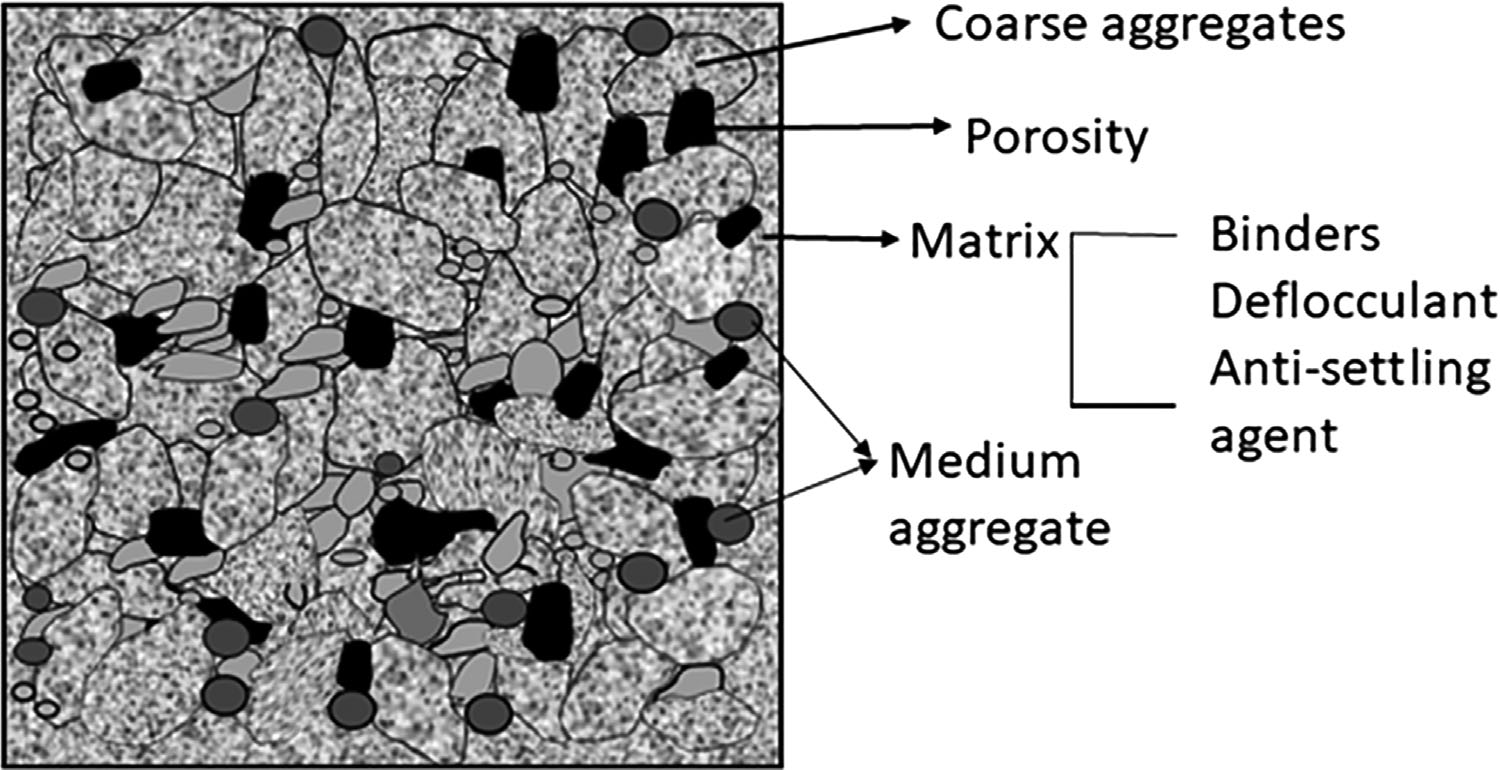

To solve the problem of the accelerated deterioration of calcium aluminate (CAC)-bonded alumina-magnesia refractory castables during the secondary refining process, the development of cement-free binders has emerged as one significant research field of castables. The hydration behavior, curing mechanism, and properties of the most recent research on cement-free binders are compared in this paper. The problems and the modification of each binder of recent research are summarized. High-temperature performance of the castables bonded by traditional hydraulic cement-free binders (ρ-Al2O3 and activated MgO) is outstanding, explosive spalling resistance of the castables bonded by sol binders (silica sol, alumina sol) is good, and the properties of the castables bonded by novel organic hydratable binder (hydratable magnesium citrate) combine the advantages of these two binders above, but the mid-temperature mechanical strength is low. Furthermore, alumina-magnesia castables bonded by organic-composited inorganic cement-free binders are expected to be a future domain.

Open Access

Review

09 January 2025Recent Advancements in Alumina-Based High-Temperature Insulating Materials: Properties, Applications, and Future Perspectives

As a high-temperature thermal insulation material with excellent mechanical properties, alumina (Al2O3)-based materials hold significant potential for applications in aerospace, advanced manufacturing, automobiles, industrial furnaces, and other fields. However, the inherent brittleness of alumina poses a limitation to its wider application. Therefore, there is a pressing need to develop alumina-based materials that offer high toughness while retaining superior mechanical properties. This paper begins by exploring the structure of alumina, highlighting its thermal conductivity, insulation, and mechanical properties in high-temperature environments. It then reviews the classification and synthesis methods of alumina-based materials, along with the latest advances in design strategies. Notably, the rational design of alumina composition, structure, and morphology is emphasized as crucial for optimizing material performance, thereby supporting the industrial development and application of these materials in high-tech sectors. Finally, the paper discusses the challenges and evolution of alumina-based materials in real-world industrial applications and suggests potential directions for future development.

Open Access

Article

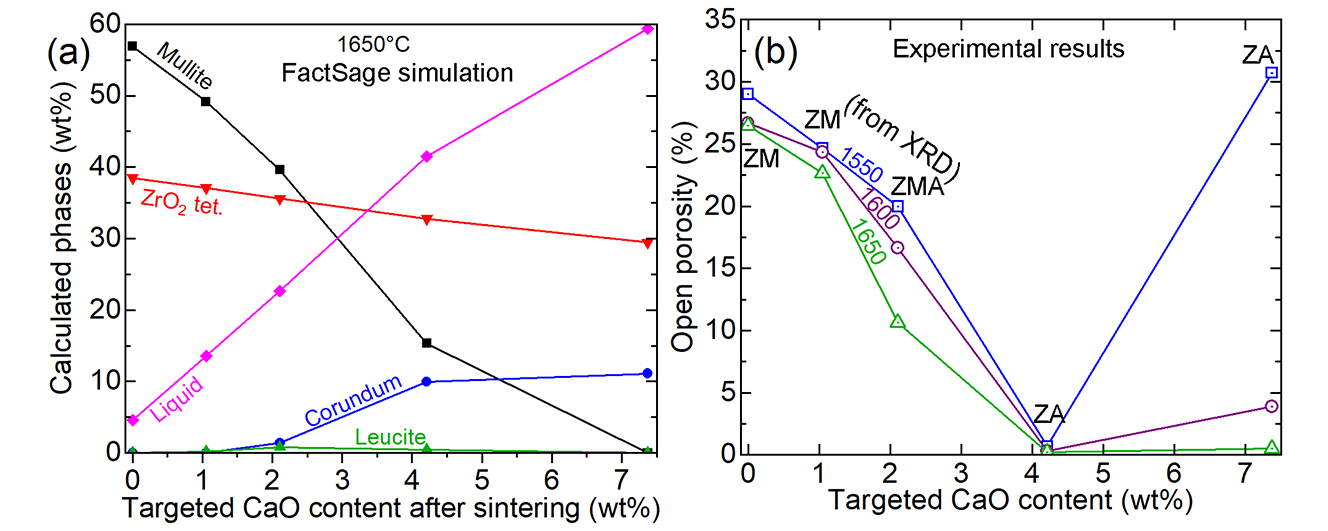

19 November 2024Calcite as a Mineralizer and Stabilizer for Low-Cost Zirconia-Mullite-Alumina Composites Synthesized from Siliceous Clay, Alumina and Zirconia

Fused zirconia-mullite (ZM) and zirconia-alumina (ZA) are expensive aggregates used in refractory formulations to enhance thermal shock tolerance and corrosion resistance, respectively. A cost-effective alternative approach was explored in this work to produce 37.4 wt% ZrO2 containing ZM utilizing conventional reaction sintering of siliceous clay, calcined alumina and monoclinic ZrO2. A series of chemical reactions ensued from 1200 °C, forming low quartz and cristobalite from the clay, in situ ZrSiO4, monoclinic ZrO2, α-Al2O3 and traces of leucite. 1600 °C was required to fully form mullite and monoclinic ZrO2 but it had 26.5% porosity even after firing at 1650 °C for 2 h. It consisted of small equiaxed primary mullite grains secondary mullite rods, and scattered and clustered, round ZrO2 grains. With 1.05% CaO addition, tetragonal ZrO2 formed, but 22.7% porosity remained despite the presence of 13.5% liquid phase having a low viscosity (0.6 Pa.s, from FactSage). With 2.11% CaO, porosity reduced to 10.7% but mullite partly dissolved, forming α-Al2O3 (ZMA aggregate). The added CaO mostly remained in the intergranular glassy phase rather than inside the ZrO2 grains but increased the thickness of the secondary mullite and the ZrO2 grains. Mullite was completely lost with 4.21% CaO doping but favorably formed cubic ZrO2 containing up to 0.26 at% Ca, interlinked α-Al2O3 rods and attained a low porosity of 0.2%. This ZA aggregate is limited to 1550 °C application temperature as excess liquid phase drained out beyond that. 7.37% CaO addition was detrimental as it formed an excessive anorthite-like liquid phase that percolated out at 1550 °C with 5.6% weight loss. Thus, in ZM-based calcium aluminate cement bonded refractory castables, the final CaO content should be restricted to below 2.1% to avoid partial dissolution of mullite.