Found 2 results

Article

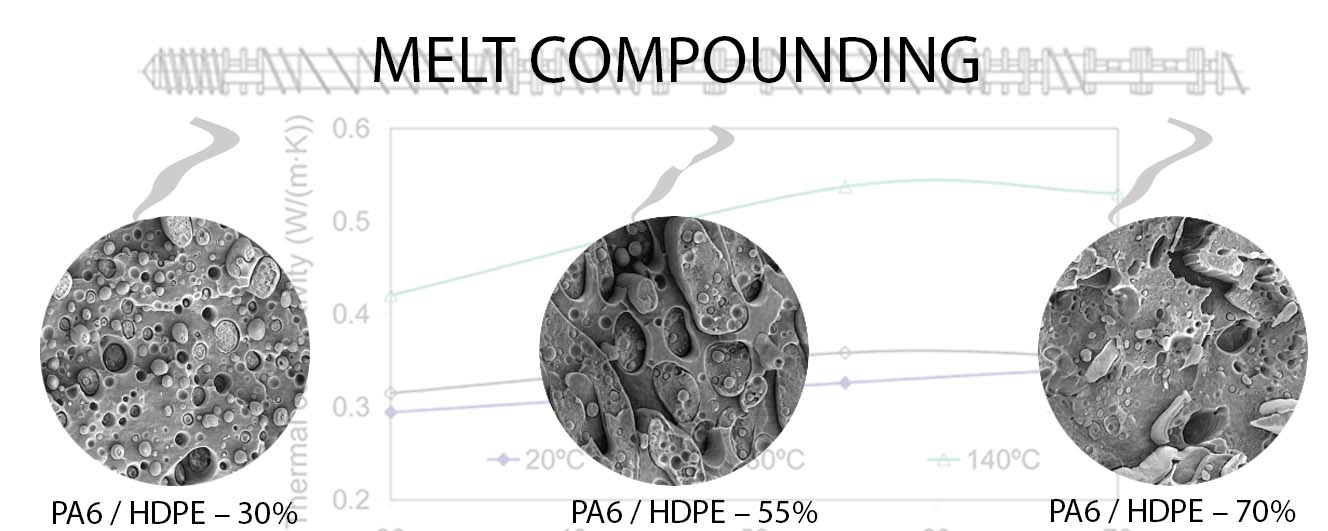

27 February 2025Thermophysical Properties of Polyamide 6 and High-Density Polyethylene Blends (Part 1. Without Compatibilization)

The structure and thermophysical properties of polymer blends polyamide 6/high-density polyethylene with component ratios of 70:30, 45:55 and 30:70, which not only provide phase inversion of the blended polymers, but also the formation of an interpenetrating network, have been investigated by differential scanning calorimetry, scanning electron microscopy and light flash method. The data on the influence of blends composition on their mechanical properties, density, structure, temperature, as well as melting and crystallization heats of polymer components have been obtained. The regularities of changes in thermal diffusion, heat capacities and thermal conductivity coefficients of polyamide 6 and high-density polyethylene individually and as part of the blends in dependence on their composition and temperature have been established. A nonlinear increase of the thermal conductivity coefficient from temperature was revealed when melting a more easily melting component of the blend. It was found that the maximum increase in thermal conductivity occurs in the blend forming an interpenetrating network. A possible way of creating composites with adaptive thermal conductivity by melting one of the components of the blend is proposed.

Article

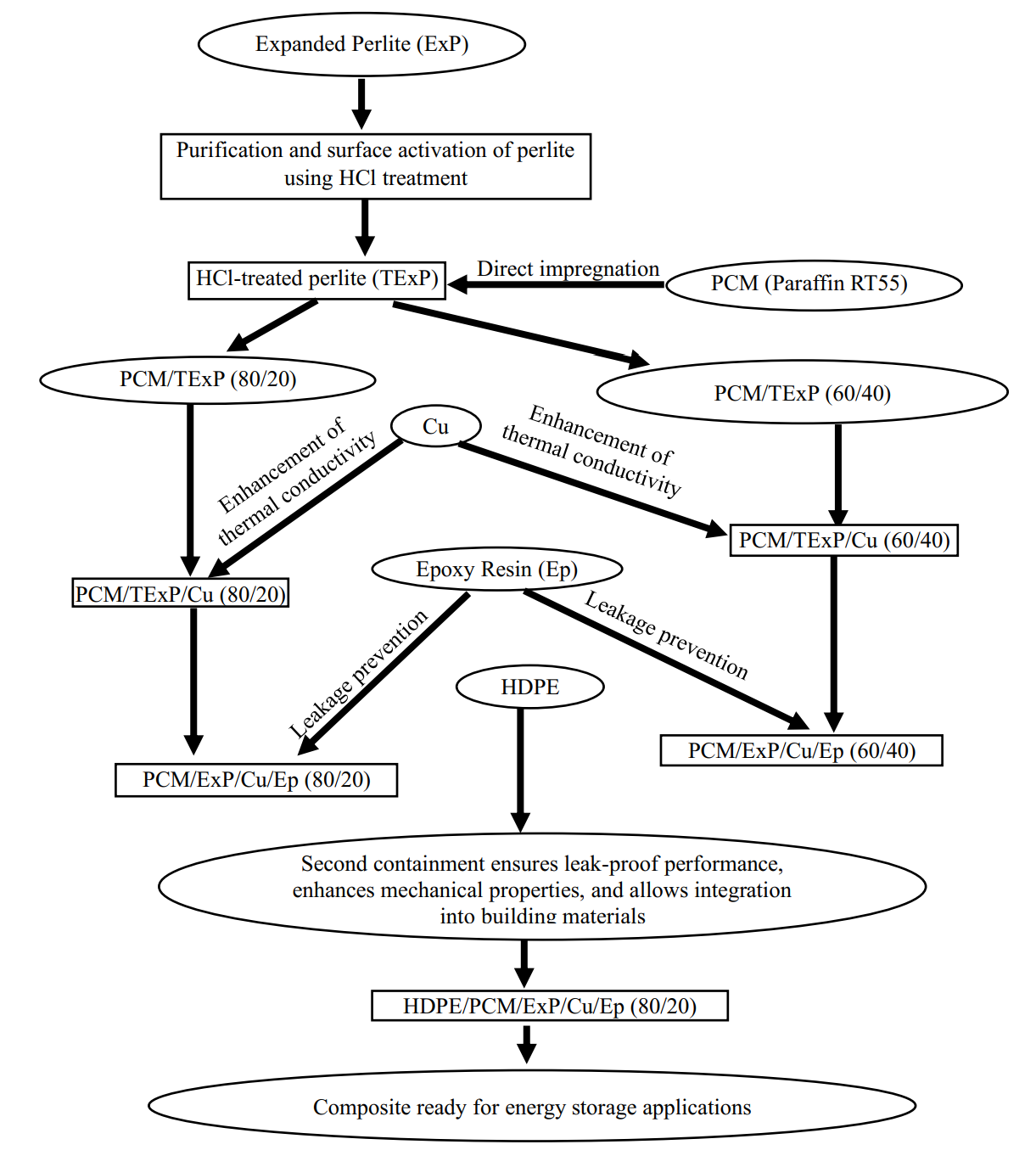

20 December 2024Preparation of a New Shape-Stable Phase-Change Material Based on Expanded Perlite, Paraffin, Epoxy, Copper and High-Density Polyethylene

Phase change materials (PCMs) face challenges such as low thermal conductivity and leakage, often addressed through attempts at encapsulation or integration into polymer matrices or porous materials. This study uses expanded perlite to prepare a PCM composite. The perlite is treated with hydrochloric acid to remove impurities and improve its absorption, then impregnated with paraffin at 65 °C, with the addition of copper to enhance thermal conductivity. After drying, the material was coated with epoxy resin to prevent leakage and mixed with high-density polyethylene (HDPE) to improve its mechanical strength and facilitate integration with other materials. Characterization techniques, including differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and scanning electron microscopy (SEM), evaluate the structure and properties of the composite. TGA results show that acid treatment increases paraffin absorption to 80% by weight, while weight loss tests confirm the effectiveness of the epoxy coating against leaks. A decrease in melting temperatures was observed in all HDPE blends, ranging from 4.72 °C to 9.58 °C, likely due to the integrated elements interfering with the reorganization of the molecular chains of HDPE. Although the preparation improved thermal conductivity, thermal tests revealed that increasing the (perlite/PCM) phase in HDPE is essential for further optimization, highlighting the potential of the composite as an effective energy storage solution for sustainable systems.