Found 4 results

Review

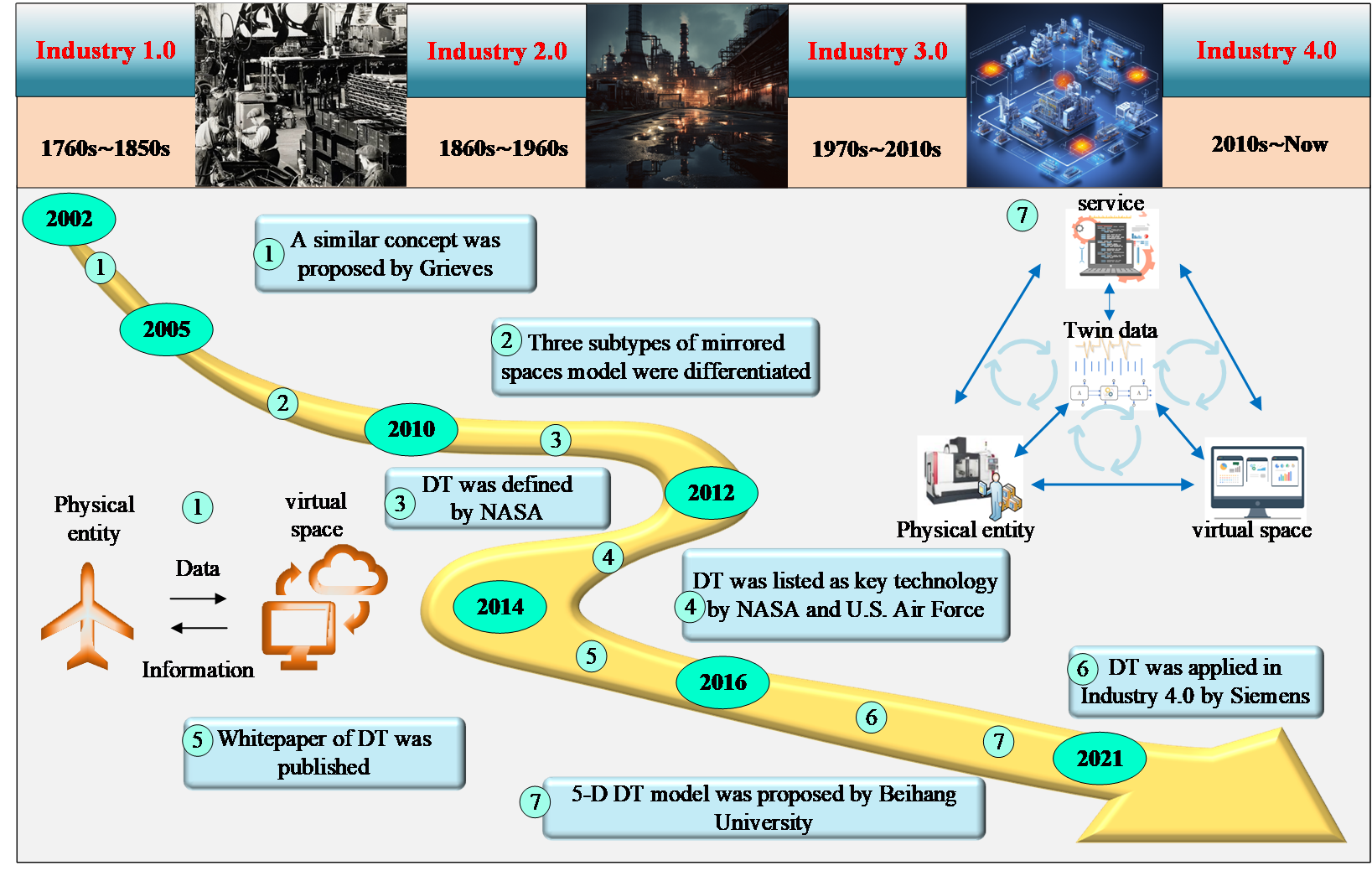

28 March 2024Digital Twins Enabling Intelligent Manufacturing: From Methodology to Application

Digital twin technology develops virtual models of objects digitally, simulating their real-world behavior based on data. It aims to reduce product development cycles and costs through feedback between the virtual and real worlds, data fusion analysis, and iterative decision-making optimization. Traditional manufacturing processes often face challenges such as poor real-time monitoring and interaction during machining, difficulties in diagnosing equipment failures, and significant errors in machining. Digital twin technology offers a powerful solution to these issues. Initially, a comprehensive review of the research literature was conducted to assess the current research scope and trends. This was followed by an explanation of the basic concepts of digital twins and the technical pathway for integrating digital twins into intelligent manufacturing including outlining the essential technologies for creating a system of interaction between the virtual and real worlds, enabling multimodel fusion, data sensing, algorithm-based prediction, and intelligent decision-making. Moreover, the application of digital twins in intelligent manufacturing throughout the product life cycle was detailed, covering product design, manufacturing, and service stages. Specifically, in the manufacturing phase, a model based on heat conduction theory and visualization was used to construct a time-varying error model for the motion axis, leading to experiments predicting the time-varying error in the hole spacing of a workpiece. These experiments achieved a minimum prediction error of only 0.2 μm compared to the actual error. By compensating for time-varying errors in real time, the variability in the hole spacing error decreased by 69.19%. This paper concludes by summarizing the current state of digital twins in intelligent manufacturing and projecting future trends in key technologies, application areas, and data use, providing a basis for further research.

Article

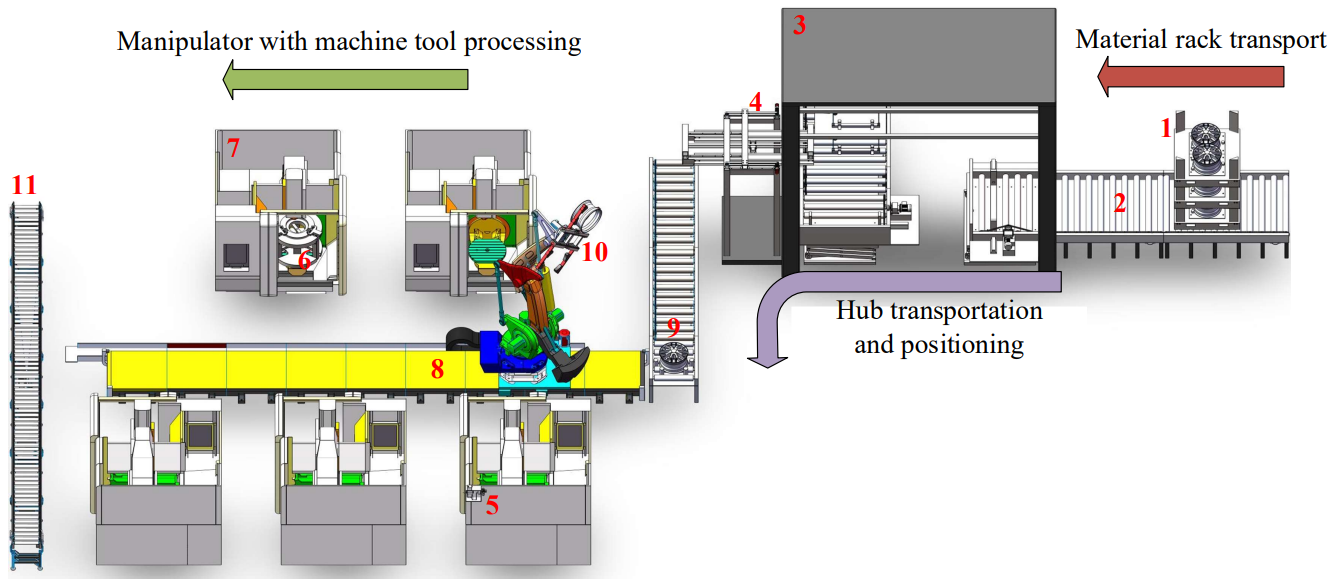

31 January 2024Design of Intelligent and Sustainable Manufacturing Production Line for Automobile Wheel Hub

The wheel hub is an important part of the automobile, and machining affects its service life and driving safety. With the increasing demand for wheel productivity and machining accuracy in the automotive transport sector, automotive wheel production lines are gradually replacing human production. However, the technical difficulties of conventional automotive wheel production lines include insufficient intelligence, low machining precision, and large use of cutting fluid. This paper aims to address these research constraints. The intelligent, sustainable manufacturing production line for automobile wheel hub is designed. First, the machining of automotive wheel hubs is analyzed, and the overall layout of the production line is designed. Next, the process equipment system including the fixture and the minimum quantity lubrication (MQL) system are designed. The fixture achieves self-positioning and clamping functions through a linkage mechanism and a crank–slider mechanism, respectively, and the reliability of the mechanism is analyzed. Finally, the trajectory planning of the robot with dual clamping stations is performed by RobotStodio. Results show the machining parameters for a machining a wheel hub with a diameter of 580 mm are rotational speed of 2500 rpm, cutting depth of 4 mm, feed rate of 0.5 mm/r, and minimum clamping force of 10881.75 N. The average time to move the wheel hub between the roller table and each machine tool is 27 s, a reduction of 6 s compared with the manual handling time. The MQL system effectively reduces the use of cutting fluid. This production line can provide a basis and reference for actual production by reasonably planning the wheel hub production line.

Editorial

30 November 2023

Editorial

08 November 2023