Found 1 results

Open Access

Article

18 April 2025Prediction of an Additive Manufacturing Defect Based on Deep Learning

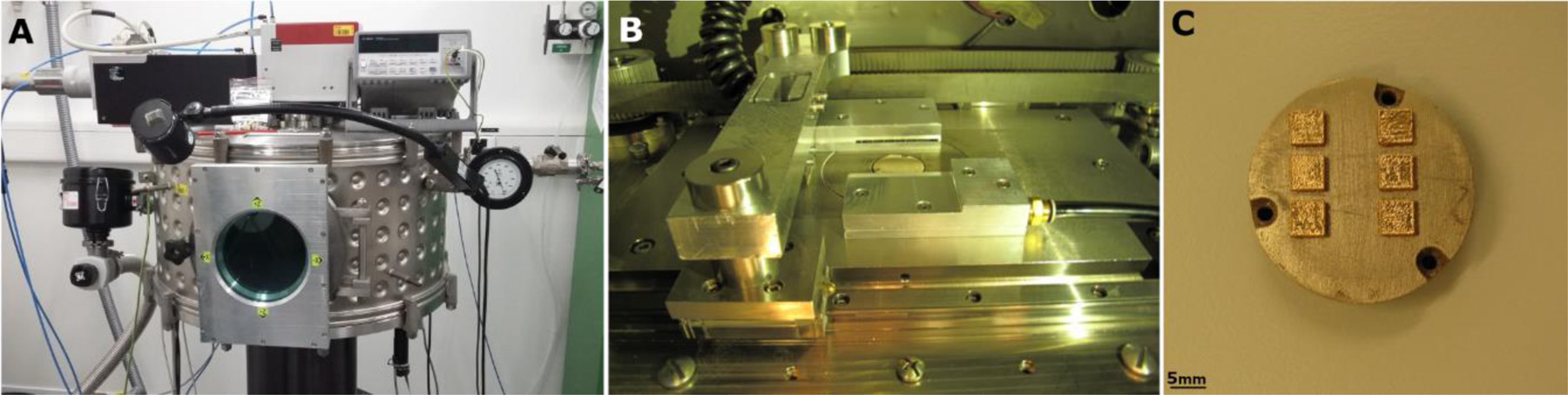

Selective laser melting (SLM) is one of the additive manufacturing (AM) methods and the most studied laser-based AM process for metals and alloys. The optimization of the laser process parameters of SLM and the prediction of defects such as cracks, keyholes, and lack of fusion (LOF) are significant for improving the product quality of SLM. Deep learning (DL) has the potential to analyze complex processes and predict anomalies; however, much data is generally needed for training a DL model. Experimental studies on AM, such as SLM, often use the design of experiments (DOE) to reduce the number of experiments and save costs and time. Therefore, much experimental data is not prepared to create the DL model. This paper deals with creating a DL model on a small experimental data set with unbalanced data and predicting the defect LOF of SLM using the created DL model. Data analytics is performed based on four DL methods, including the Elman neural network, the Jordan neural network, the deep neural network (DNN) with weights initialized by the deep belief network (DBN), and the regular DNN based on the algorithms ‘rprop+’ and ‘sag’. It is shown that the regular DNN based on the ‘sag’ algorithm, after the z-score standardization of the small data set, helps create an accurate DL model and achieve good analytics and prediction results. The three other DL methods in this paper do not work well on the small data set (with unbalanced data) in the defect prediction.