Found 1 results

Article

11 February 2025Functionalization of 3D-Printed Plastics for the Photocatalytic Removal of Organic Pollutants in Air

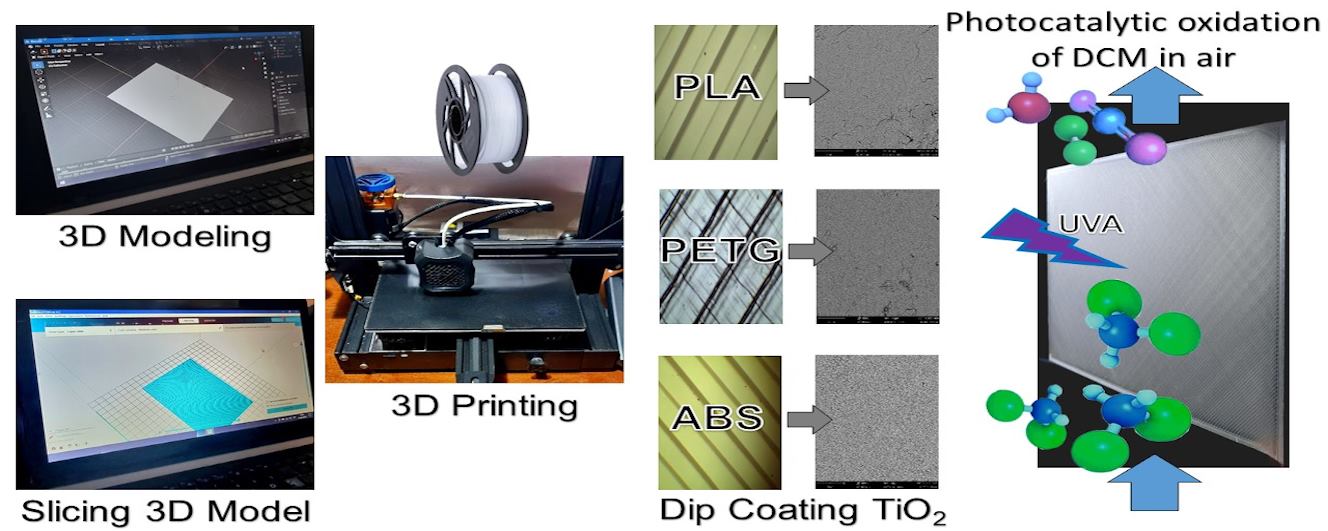

The study explored the use of 3D-printed plastics as catalyst supports for gas-phase photocatalytic applications. Specifically, it compared three commonly used plastic materials: PLA, ABS, and PETG. The process involved 3D modeling, additive manufacturing through 3D printing, and functionalization via dip-coating with titanium dioxide (TiO2). The study evaluated the loading capacity of the materials, the adhesion of the films, and the optical properties of the photocatalytic plates. Finally, the three plastic samples were tested as support materials in a laboratory-scale flat-plate reactor for the photocatalytic oxidation of dichloromethane in air. Loading capacities of around 3 mg/cm2 for TiO2 were achieved, along with radiation absorption capacities close to 65%. A correlation between loading and absorption fraction was identified, leading to the proposal of a simple saturation model; in turn, it allowed the predictive model of pollutant conversion as a function of the absorbed fraction of radiation. By analyzing both qualitative and quantitative properties and results, in order to determine the most suitable plastic material to be used in a photocatalytic wall reactor, PLA emerged as the best choice among the materials tested. These results show promise for the effective utilization of these plastics in the design of air decontamination devices.