Found 1 results

Open Access

Article

20 December 2024Preparation of a New Shape-Stable Phase-Change Material Based on Expanded Perlite, Paraffin, Epoxy, Copper and High-Density Polyethylene

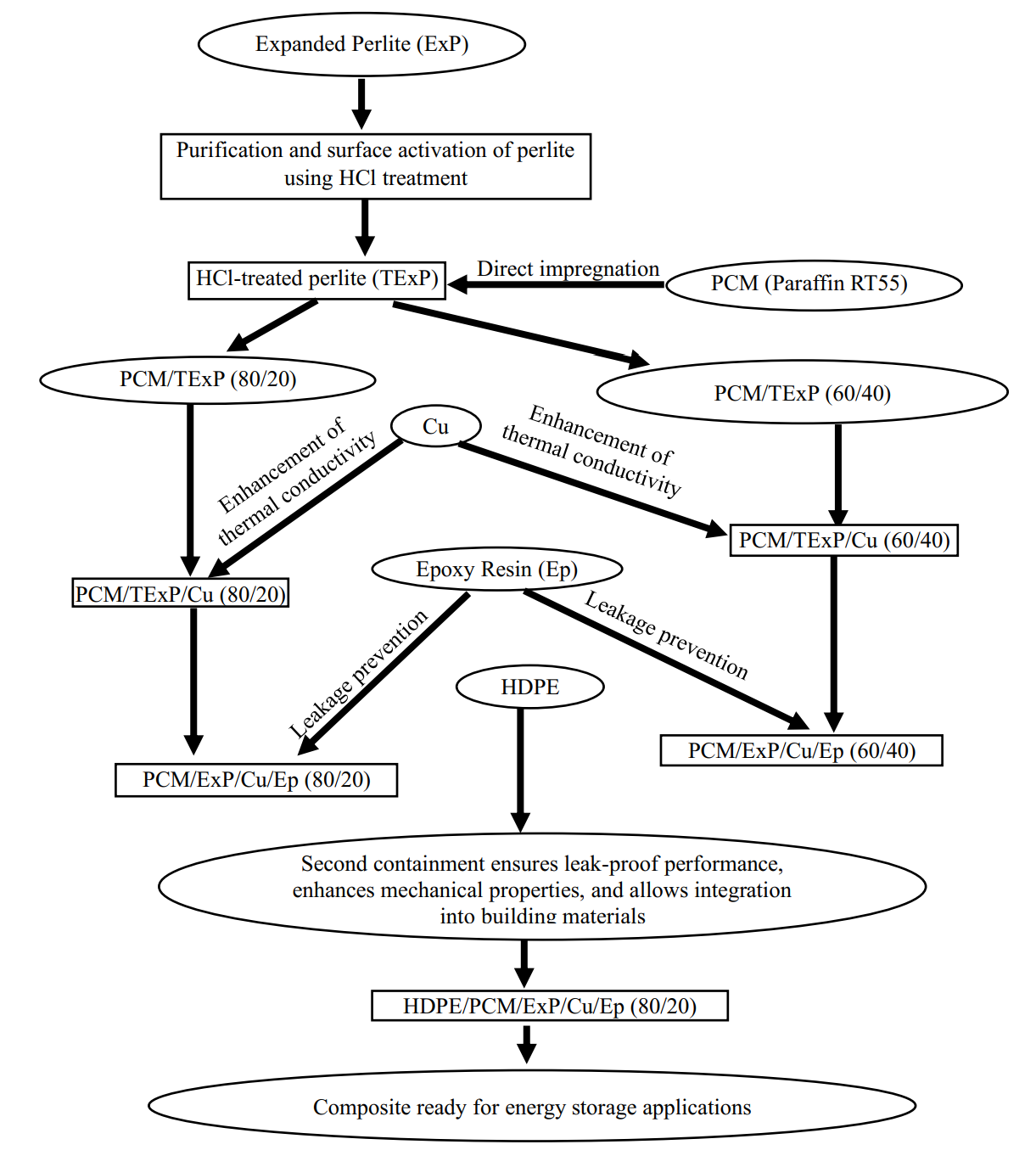

Phase change materials (PCMs) face challenges such as low thermal conductivity and leakage, often addressed through attempts at encapsulation or integration into polymer matrices or porous materials. This study uses expanded perlite to prepare a PCM composite. The perlite is treated with hydrochloric acid to remove impurities and improve its absorption, then impregnated with paraffin at 65 °C, with the addition of copper to enhance thermal conductivity. After drying, the material was coated with epoxy resin to prevent leakage and mixed with high-density polyethylene (HDPE) to improve its mechanical strength and facilitate integration with other materials. Characterization techniques, including differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and scanning electron microscopy (SEM), evaluate the structure and properties of the composite. TGA results show that acid treatment increases paraffin absorption to 80% by weight, while weight loss tests confirm the effectiveness of the epoxy coating against leaks. A decrease in melting temperatures was observed in all HDPE blends, ranging from 4.72 °C to 9.58 °C, likely due to the integrated elements interfering with the reorganization of the molecular chains of HDPE. Although the preparation improved thermal conductivity, thermal tests revealed that increasing the (perlite/PCM) phase in HDPE is essential for further optimization, highlighting the potential of the composite as an effective energy storage solution for sustainable systems.