Found 1 results

Open Access

Article

19 June 2025Advancing Total Productive Maintenance in Smart Manufacturing: From Methodology to Implementation

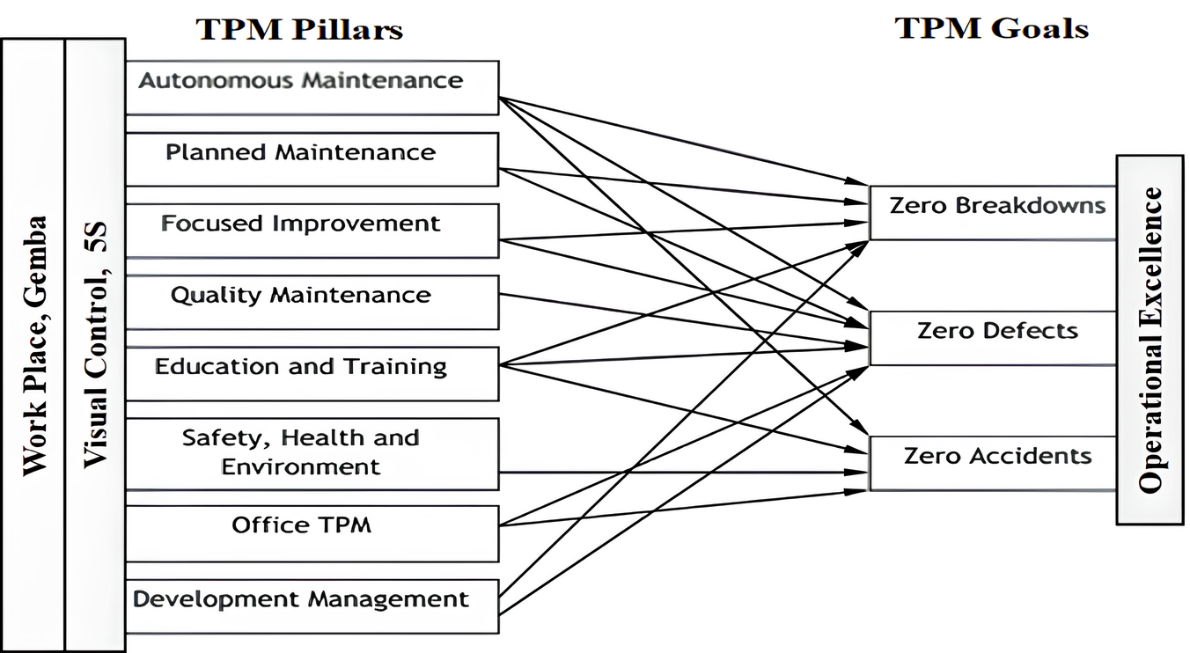

The rapid advancement of Industry 4.0 technologies has catalyzed the development of intelligent tools and methodologies to enhance operational efficiency, reliability, and productivity across modern industrial enterprises. Total Productive Maintenance (TPM), a foundational approach in manufacturing, traditionally improves equipment reliability, reduces downtime, and drives continuous improvement through proactive employee involvement. However, in the context of Smart Manufacturing, traditional TPM reveals significant limitations—chiefly its reliance on manual data collection, reactive maintenance, and limited real-time insight. This paper explores TPM’s evolution, key innovations, and cross-industry applications while highlighting challenges in adopting Industry 4.0 technologies. It proposes a comprehensive TPM 4.0 framework integrating Lean Six Sigma’s DMAIC methodology with advanced digital tools for systematic failure mode classification, risk-based maintenance prioritization, and real-time performance optimization. Leveraging IIoT-enabled condition monitoring, Digital Twin simulations, and machine learning-driven predictive analytics, the framework supports real-time anomaly detection, cognitive diagnostics, and adaptive maintenance planning—substantially improving Overall Equipment Effectiveness (OEE), cost efficiency, and system resilience. Additionally, federated learning promotes scalable, privacy-preserving AI collaboration, while blockchain enhances data security and transparency, mitigating cybersecurity risks. By merging traditional TPM with AI-driven automation and digital sustainability, TPM 4.0 establishes a foundation for self-optimizing, cyber-resilient maintenance ecosystems, accelerating the transition to autonomous manufacturing. Although conceptual, this framework offers a practical roadmap for smart manufacturing transformation, with future validation planned through case studies and pilot projects.