Found 1 results

Open Access

Article

28 April 2025Production and Characterization of Recovered Carbon Black (rCB) by Waste Tire Pyrolysis as a Potential Carbon Black (CB) Substitute

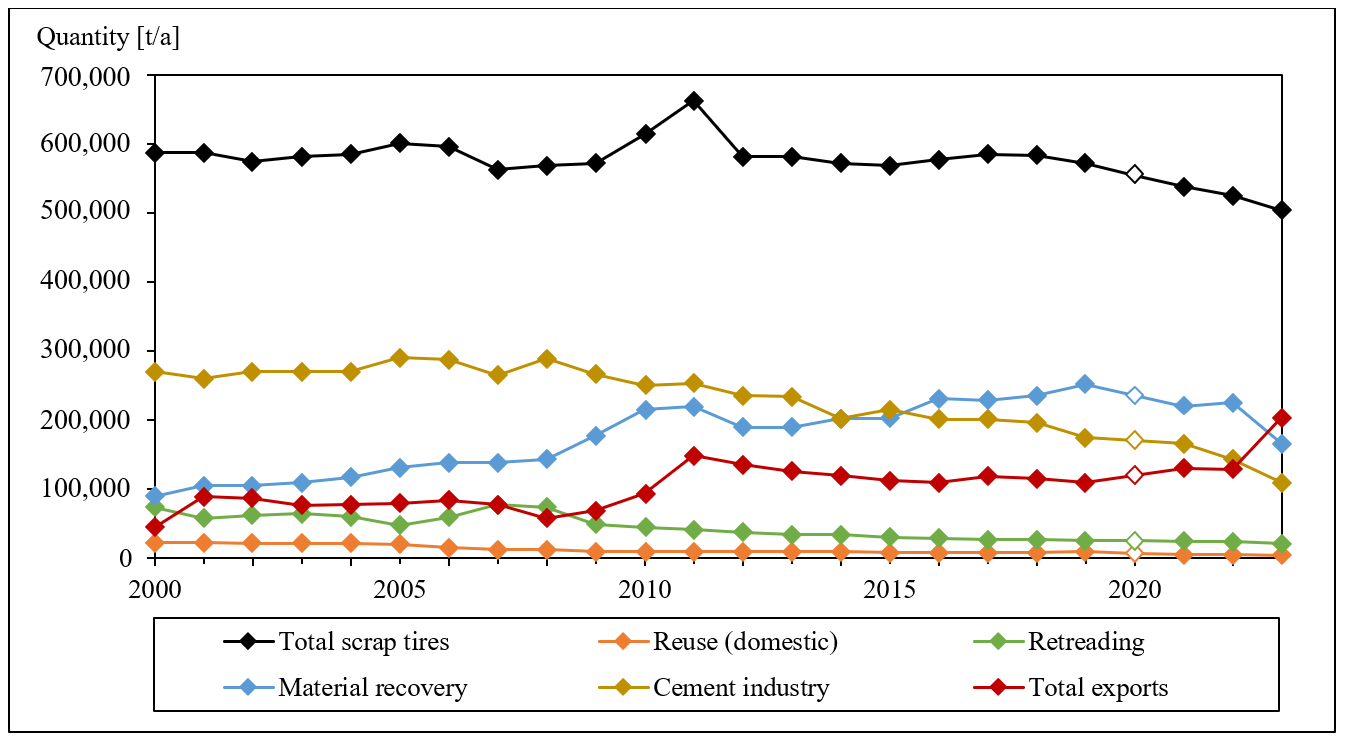

Recovered Carbon Black (rCB) from scrap tire pyrolysis offers a potential alternative to fossil-based virgin Carbon Black (CB) in the context of a circular economy. This study investigated the influence of pyrolysis process parameters on rCB yield and quality at laboratory and semi-industrial scales. The resulting rCBs were characterized and found to have surface and structural properties comparable to N500 and N600 series CBs, but with higher mineral and volatile contents. The quality of rCB is influenced by the feedstock composition, particularly the ratio of organic to inorganic components as well as key process parameters such as heating rate, pyrolysis temperature and residence time. Higher heating rates accelerate degradation and shift product distribution toward increased oil yield and reduced rCB formation, while higher pyrolysis temperatures lead to lower volatile content in rCB. Additionally, reactor and process design affect heat distribution, transfer efficiency, and mixing behavior, further shaping rCB properties. However, further testing is required to evaluate the actual in-rubber properties of rCBs. Therefore, additional tests are planned, incorporating rCB into butyl and nitrile rubber-based elastomer compounds, which will be addressed in a follow-up study. In addition, data from the current experiments will support a comprehensive Life Cycle Assessment (LCA) to evaluate the environmental impacts of tire pyrolysis and rCB production compared to other recycling methods, with details to follow in a future publication.