Found 52 results

Open Access

Article

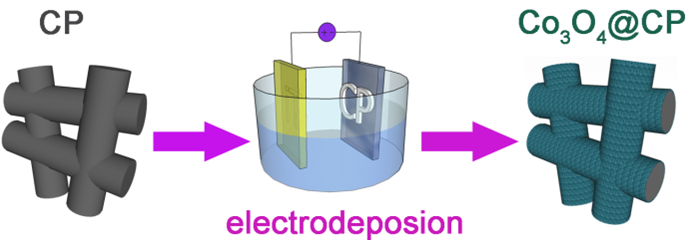

08 May 2023A High-efficiency Cathode Using Co3O4 and Carbon Paper by Electrodeposition for Rechargeable Lithium-oxygen Batteries

The conductivity, microstructure, low cost, eco-friendliness, simple and controllable preparation are key points of the preparation and application of cathode materials for lithium-oxygen batteries. Considering the above-mentioned important factors comprehensively, the Co3O4@CP electrode with a three-dimensional structure was prepared by directly growing Co3O4 on the surface of carbon paper (CP) using a simple and controllable electrodeposition method. The obtained Co3O4 depositing layer has a nanosheet microstructure and can provide abundant catalytic active sites for the oxygen evolution and reduction reactions. The network architecture of electronic transmission is constructed by CP in the cathode, promoting the efficiency of the electrode reaction. It’s worth noting that the binder-free and conductive additive-free cathode is beneficial to reduce side reactions. The lithium-oxygen battery assembled with the obtained Co3O4@CP electrode showed satisfactory electrochemical performance. The cell assembled with the obtained Co3O4@CP electrode provided a discharge specific capacity of 10954.7 mA·h·g−1 at a current density of 200 mA·g−1, and the voltage profiles of the cell were good under 100 mA·g−1 at a limited capacity of 500 mA·h g−1 based on the mass of Co3O4. Therefore, the Co3O4@CP composite material is a promising candidate with good application prospects as a cathode material for lithium-oxygen batteries.

Open Access

Article

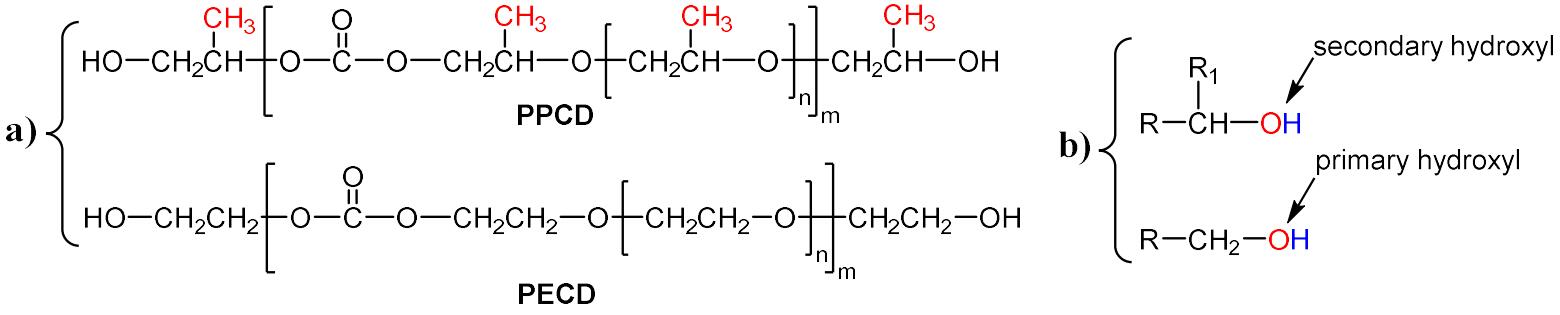

21 March 2023Waterborne Polyurethane Dispersion Synthesized from CO2 Based Poly (Ethylene Carbonate) Diol with High Performance

CO2-based aliphatic polycarbonates (APCs) are not widely commercialized due to the poor performance and high cost, compared to the traditional synthetic materials. In this paper, poly(ethylene carbonate) diol (PECD) was synthesized from CO2 and ethylene oxide (EO), and the comprehensive properties were characterized. Furthermore, the preparation and properties of waterborne polyurethane dispersion (WPU) derived from PECD were studied. The result showed that PECD had high reactivity, narrow molecular weight distribution index and excellent thermal stability. The obtained WPU exhibited superior tensile performance, adhesion properties and surface hardness. Due to the low cost of EO and CO2, PECD is expected to be widely used in the preparation of polyurethanes.